Purpose

The scope of application of bulldozers depends on the traction capacity of the equipment, its weight and the installed equipment. The main task of the devices is to develop soil layer-by-layer, level it or move it over short distances.

However, special vehicles can be used in a number of auxiliary work. Sectors of the national economy where bulldozer equipment is used:

- construction;

- land reclamation;

- mining industry.

I would like to note that the traction class of bulldozers ranges from 10 to 35. The former are used in light construction work, the latter are used in difficult conditions.

To develop soils belonging to category IV, an initial level is sufficient. But for frozen ground, vehicles of class 25 and above are needed.

Among light devices, representatives of budget manufacturers are in demand, but the leaders in the heavy equipment segment are definitely premium brands. The latter fact can be explained by difficult working conditions, when the reliability of the machine comes first.

Domestic and foreign manufacturers of bulldozers

Renting a bulldozer allows you to optimize many types of work:

— digging pits for laying the foundation; — digging trenches; — quarry development; — work in areas with unstable surfaces; — clearing the territory; — marking the construction site; — leveling the ground surface; — construction of embankments and dams; — road planning.

And this is just the main list of earthworks where it would be advisable to rent a bulldozer, which is offered by the Crane-Master company. The advantages of renting a bulldozer include low prices and additional bonuses provided by the company. Thus, the cost of renting a bulldozer already includes refueling and the work of a professional, experienced operator.

Bulldozers of domestic and foreign companies

1. Bulldozers Caterpillar Inc. Caterpillar bulldozers are actively used for road construction. They are mainly designed for leveling surfaces for transport lines, residential construction sites and commercial sites. The bulldozer lineup includes the D-series (Caterpillar D4-D11) and the Caterpillar 60, one of the first bulldozers released under this brand.

Caterpillar bulldozers are reliable, multifunctional, environmentally friendly and profitable. The products of this brand are supplied to almost 200 countries around the world. To cope with such sales volume, Caterpillar maintains 109 factories and has an extensive dealer network. There are representative offices in Russia (Moscow, Leningrad region, Novosibirsk).

Addresses of distributors and car dealerships in Moscow and St. Petersburg, specializing in Caterpillar equipment, can be found on the website of the representative offices. By the way, in August 2008 the 35th anniversary of the Moscow representative office of Caterpillar was celebrated.

2. Komatsu bulldozers. Currently, Komatsu equipment is used all over the world for road construction and other works. The name of the product gives away its homeland. “Made in Japan,” we say, in one phrase immediately denoting the country of origin and the quality of the equipment it produces. The Komatsu Group company was founded in Japan in 1921. Who would have thought that the modest construction workshop of Meitaro Takeyuchi would grow into a network of about 200 large companies.

The Komatsu brand includes backhoe loaders, motor graders, mobile crushers, dump trucks and bulldozers. Komatsu bulldozers are a worthy competitor to the machines of the world leader Caterpillar. Unlike the latter, Komatsu exhibits not only crawler bulldozers (for example, models D475A-5, D155A-5), but also swamp dozers (D85PX-15, D39PX-22, D37PX-22) and wheeled bulldozers (WD900-3, WD600 -3, etc.).

3. ChTZ bulldozers . This is a multifunctional technique: bulldozers of the DET model can be used by construction companies for leveling soil of any hardness, filling holes, ditches, as well as for agricultural purposes and for cleaning city areas. The presence of replaceable devices in the DET-250, the dismantling of which does not require the participation of additional equipment, in particular lifting machines, as well as moving parts (rotary blade), the ability to use bulldozers together with other equipment (plough-brush, drilling) ensures their versatility.

The maximum transport speed of these machines reaches 25 km/h, which allows the bulldozer to be used on several sites at once, not very far from each other. The dimensions of the series equipment make it possible to carry out work even in densely built-up areas of the city. The basic configuration can be expanded at the buyer’s request (for example, a rotary blade can be installed upon request).

Related Posts

Features and advantages of construction towers

Bucket crushers, modifications, features, choice

Gearboxes for lifting equipment

Types

More often, bulldozers are assembled on a tracked chassis. Less common are wheeled analogues, which are used for auxiliary and cleaning work.

Typically, tire-mounted devices replace motor graders. This is due to greater traction capacity and stability.

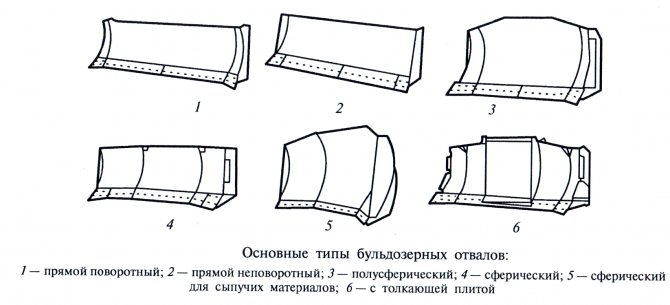

Special equipment is also classified according to the type of blade installed. It is possible to equip with several working bodies:

- Straight. This is a knife curved in a vertical plane. Individual structures can be rotated in three directions and are installed on light vehicles. Heavy ones are aggregated with fixed knives equipped with side shields. The straight blade is considered universal - it can be used in all jobs, but it has lower productivity.

- Spherical. This blade has an enlarged drawing prism, which allows it to move more bulk material in one pass. It is made of 3 sections: one central and two side, welded at an angle of up to 25 °. The design ensures minimal material loss. A spherical blade is used to move bulk materials over relatively long distances.

- Hemispherical. This is a universal blade that has the structural features of the described working tools.

To increase productivity, dumps are equipped with slopes, extensions, and other mechanisms. Modified designs are used in coal or peat deposits or when moving municipal solid waste to treatment sites.

SEM 816D

Specifications

- Operating weight, kg — 16,900

- Engine power, kW — 131

- Dump volume, m3 - 4.3

According to dealer centers in the Russian Federation, domestic consumers increasingly prefer bulldozers of the SEM brand, owned by Caterpillar. Among the popular models of this brand is SEM 816D. The weight of this machine (without ripper) is 16.9 tons. The production uses components made by Bosch-Rexroth (Germany), Parker (USA, China), Honeywell (USA, China), Weichai (China). In particular, the model is equipped with a Weichai WD10G178E25 engine.

The 816D features a continuously variable dual-circuit hydrostatic transmission that provides increased traction on each track and prevents power loss at the track when turning. Multi-disc brakes in an oil bath are installed. The basic configuration includes a hemispherical blade with a volume of 4.3 m3, shoes 510 mm wide, 2 support rollers, 6 support rollers, and a traction pin for towing.

Additionally, you can order heating, air conditioning, cold start systems, various cab options, a diagnostic display, Product Link system and other options. Optional attachments include a straight blade (3.5 m3) and a rear ripper with three teeth. In addition to the standard version, modifications have been developed for use in household waste sites, forests, swampy areas, and in hot and very dusty conditions.

The review uses materials from the portal about Excavator special equipment. RU.

Pros, cons

Compared to other special equipment, bulldozers have several advantages:

- Maneuverability. Wheeled or tracked machines can be used to prepare sites in confined spaces.

- Easy to maintain. All maintenance for equipment is kept to a minimum, and repairs are possible almost in the field.

- Performance. The high-torque properties of the devices allow them to be used in energy-intensive work.

- Patency. The crawler bulldozer has a low specific pressure on the ground, which makes it possible to operate on viscous, unstable soils.

- Use of the machine in any weather conditions. Equipping the chassis with equipment for operation in hot or cold climates expands the operational capabilities of the device.

Among the disadvantages of tracked vehicles are:

- Increased engine power and fuel consumption.

- Complex design of chassis and transmission.

- The need to store spare tracks in a certain microclimate to prevent corrosion.

- Increased noise.

- Problems with delivering equipment over long distances.

Komatsu D65EX-16

Specifications

- Operating weight, kg — 21,280

- Engine power, kW — 155

- Dump volume, m3 - 5.6

A wide range of Komatsu bulldozers (from 8 to 72 tons) are available to Russian consumers, but according to dealers, the D65EX-16 model is in greatest demand.

It is worth noting that the design of Komatsu machines uses components of its own production, including the engine and transmission. They are produced at the company's sites in Japan. The engine is one of the most powerful in its class: it is capable of delivering up to 155 kW, with a displacement of 8.3 liters.

The equipment of the D65EX-16 bulldozers sold in the Russian Federation includes a three-post ripper, a double reinforced radiator grille, a hydraulically driven radiator fan, an improved fuel filtration system, air conditioning, a color monitor, and the Komtrax remote monitoring system. The HSS hydrostatic steering system provides constant drive to both tracks without interruption of torque. The width of the track shoes included in the basic kit is 510 mm.

Along with the standard version of the dozer, Komatsu offers temperature specifications for operation at -30 and -40 degrees. In the first case, the equipment is equipped with more powerful batteries, special rollers and a final drive for low temperatures. In the second, a liquid preheater, additional sealing of hydraulic cylinders, a starter and a generator of increased power are added. The cabin is also double glazed.

One of the main features of the model is the SIGMA blade with a volume of 5.6 m3, which allows you to move soil at higher speeds and helps reduce fuel consumption. But the manufacturer has also provided other versions of dumps: hemispherical (5.6 m3), straight (3.89 m3) or PAT (4.25 m3). An auxiliary cabin heater, an electric fuel filter heater, a liquid preheater, and a Topcon automatic leveling system are available as options.

Performance characteristics

Light bulldozers include models weighing up to 10 tons. They are equipped with diesel engines with a power of up to 120 hp. With. Equipment that weighs up to 30 tons belongs to the middle class; they are equipped with engines generating up to 300 hp. With. Devices with large parameters are considered heavy.

The chassis is equipped with tracks of various widths. The wider the shoes, the less impact the weight of the machine has on the ground.

It is possible to install extra-wide tracks to increase the maneuverability of special equipment on unstable soils. Such devices are called swamp vehicles; they are used when carrying out reclamation work.

Chassis design

As a rule, a bulldozer is driven by a medium-speed engine equipped with turbocharging and cooling of the blown air.

The engines are equipped with a function for automatically regulating fuel injection depending on the current load. Diesels are selected in such a way as to ensure a torque reserve of 20-35%.

Power transmission can be of several types:

- mechanical;

- hydromechanical;

- hydrostatic;

- diesel-electric.

Hydromechanical transmissions with a three-range planetary gearbox are more common. Mechanical and diesel-electric transmissions are rarely used, and only on light vehicles.

In the latest generation of machines, hydrostatic drive has gained popularity. Thanks to modern engines, the gearbox, main gear, turning mechanisms, and brakes become unnecessary.

The drive increases maneuverability: a turn can be made on the spot by rotating the tracks in different directions.

The hydrostatic drive is technologically more complex, which necessitates the need for operating personnel with a different level of training.

CASE 2050M

Specifications

- Operating weight, kg — 22,532

- Total power, kW - 173

- Dump volume, m3 - 5.6

Three models of CASE bulldozers ranging from 13.5 to 24 tons are supplied to Russia. All machines are manufactured in Brazil. At the same time, the flagship of the line is the 2050M, one of the main advantages of which is considered to be high tractive effort (360 kN). All CASE bulldozers are equipped with FPT engines manufactured by the CNH Industrial group of companies. The diesel volume of the 2050M model is 6.7 liters, while a torque of more than 1,000 Nm is developed in a wide operating range from 1,100 to 1,740 rpm.

The machines are equipped with a Bosh Rexroth hydrostatic transmission, which provides continuously variable speed changes and constantly high torque on the track. The new V-shaped cooling system allows airflow to be directed effectively to each radiator individually, since none of them is blocked by another. As standard, CASE bulldozers are equipped with a reversible fan with an increased number of radiator fins.

The basic delivery package for CASE bulldozers includes an extended XLT chassis, which gives the equipment additional stability and, therefore, greater precision in the work performed. As an option, CASE bulldozers can be equipped with a CELT (CASE Extended Life Track) chassis type, which includes a solid sprocket, open shoes, and double bushings, resulting in uniform wear and increased service life of this component.