Each and every Makita chainsaw is a high-quality and reliable garden tool with a perfect design and many useful additional options. A good example of this is the Makita DCS4610 model, which has earned great popularity both among novice gardeners and professional forest fellers.

Chainsaw Makita DCS4610 – description and advantages of the model

The Makita chainsaw in this modification is in high demand due to a number of important advantages. Among them, first of all, the high reliability inherent in all chainsaws of this famous brand stands out. The design of the model is thought out to the smallest detail, as evidenced by a well-chosen center of gravity and the presence of a large number of useful options.

A modified starter with reduced resistance is responsible for the smooth and quick start of the Makita DCS4610 chainsaw. The model has established itself as a lightweight and easy-to-use tool, which was achieved thanks to its ergonomic design, convenient location of rubberized handles and control switches.

Other advantages of the Makita DCS4610 chainsaw include modest fuel and oil consumption, as well as a reduced level of exhaust gases. The design of the model includes several vibration-damping shock absorbers, which, coupled with its low weight, make it more convenient to operate the Makita DCS4610 chainsaw at heights.

The advantages of the model include ease of use and DIY repair. The model does not require special maintenance, so it is well suited for use by beginners.

Makita Chainsaw Carburetor Adjustment Video

Do-it-yourself chainsaw carburetor adjustment

For an independent carburetor option, you need to familiarize yourself with its structure and understand the procedure for the work that is carried out to adjust the parts responsible for the proper functioning of the components of the device and parts close to it.

It is necessary to carefully handle items for the system option, and also to determine whether the set characteristics correspond to very acceptable values.

Content

About the carburetor design

The carburetor serves to mix the flammable mixture with air while maintaining predetermined proportions. If clear doses are not followed, the proper operation of the engine is at risk. When a huge amount of air enters during mixing of the components, but there is not enough fuel, then such a mixture is considered “lean”.

Oversaturation should not be allowed, because with a larger amount of fuel compared to air, malfunctions or engine wear are also likely. Carburetor adjustment is needed not only before initial use, but also when any differences in its operation are detected. Before working with a chainsaw, do not forget to run it in.

Carburetor components

The carburetor design contains a standard set of parts, but may vary little depending on the manufacturer. Components:

- The basis . This is a special tube that is visually similar to an aerodynamic design. Air passes through it. In the transverse direction, a damper is located in the middle of the pipe. Its position can be changed. The more it is extended into the passage, the less air enters the engine.

- Diffuser . This is the constricted part of the tube. With its help, the air supply speed increases precisely in the segment from which the fuel comes out.

- Channels for fuel supply. The fuel mixture is contained in the float chamber, then passes into the nozzle, from which it flows into the atomizer.

- Float chamber . It is a separate structural element, reminiscent of the shape of a tank. Designed to constantly maintain the optimal level of fuel fluid before entering the channel from which air enters.

Don't know which chainsaw to choose? Read our article.

Are you looking for cheaper models, but reliable and time-tested? Pay attention to Russian-made chainsaws.

Or explore foreign chainsaw manufacturers such as Shtil.

What you need to have for setup

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed, in most cases used for experiments.

READ Adjusting the Energomash Chainsaw Carburetor

Chainsaw air filter

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs, and turns off when starting work (see How to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T until it stops (see Chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully place the device and turn the chain in the opposite direction. Need a tachometer. It determines whether there is a malfunction in the carburetor. When turning the screws, the sound should be perfect and absolutely smooth. If you notice squealing notes, the mixture is oversaturated.

Setup instructions

Carburetor adjustment is divided into two main stages. The first one is called basic. It is performed with the engine running. The second is performed when the engine is warm.

To carry out the carburetor setup procedure successfully, you need to read the operating instructions for a specific model in advance to identify additional features of setting up the device.

First stage

The adjusting screws for the highest and lowest speeds should be moved clockwise until the highest resistance is met. When the screws reach the stop, you need to move them in the opposite direction and leave them 1.5 turns.

Main stage

The engine is turned on at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed should move clockwise. It is released only when the engine reaches stable operation mode. It is necessary to ensure that the chain does not move during this process.

Makita(Dolmar).Interesting case

Chainsaw Makita

/Dolmar does not start. There is compression,

the carburetor

was changed. But an interesting case was discovered

Makita dcs 4610 chainsaw does not start

Makita chainsaw spare parts

Makita

dcs 4610 repair

In idling mode, the engine may stall (the reason is here). In this case, you must immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

Checking acceleration operation

Need to do a little research. Acceleration of the device is initiated. It is necessary to evaluate the proper operation of the engine during maximum speed. When the engine is functioning correctly, it means that when you press the accelerator, the speed quickly increases to 15,000 rpm.

READ Chainsaw Works But Chain Doesn't Spin

If this does not happen or the increase in speed is too slow, you must use the screw marked L. It turns counterclockwise. Moderate movements must be observed, since the turn cannot be more than 1/8 of a full circle.

Maximum number of revolutions

To limit this indicator, you need to use a screw marked H. To increase the number of revolutions, turn it clockwise, and to reduce them in the opposite direction. The maximum frequency should not exceed 15000 rpm.

If you make this figure larger, the device’s engine will wear out, which will lead to problems in the ignition system. When rotating this screw, you need to take into account the ignition processes of the device. If the slightest malfunctions appear, then the maximum speed value must be reduced.

Final check at idle

Before this procedure, it is necessary to carry out a full adjustment of the carburetor components when operating at maximum speed. Next, you should check the functioning of the device in idle cold mode. When the correct adjustment parameters are achieved, you will notice that the carburetor design closely matches the following criteria:

- When the idle cold mode is activated, the chain does not move.

Chainsaw accelerator

- When the accelerator is pressed even slightly, the engine accelerates at an accelerated pace. With gradual deepening of pressure, you can notice that the engine speed increases proportionately, reaching the maximum permissible values.

- When the engine is running, you can compare its sound to a four-stroke device.

If violations are noticed in the given parameters or the device has not been fully adjusted, you need to perform the main setup step again. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you will have to contact a specialist.

Disassembling the carburetor if necessary to check or repair components

The design of different carburetor models is almost the same, so when working with them you can use the standard scheme. All elements must be removed carefully, and then laid out in the order given below , so that you can successfully place the items in place after the completion of the repair work.

Removing the Top Cover

- The top cover is removed. To do this, you need to unscrew the 3 bolts holding it in a circle.

- The foam rubber is also removed, since it is the upper component of the filter that conducts air.

- The fuel hose is removed.

- The drive thrust is output directly to it.

- The cable end is disconnected.

- The gasoline hose can be completely removed if you systematically pull it off the fitting.

To finally prepare the carburetor for major repairs or replacement of the smallest parts, you need to carefully disconnect it from the main system . Sometimes further disassembly is required. You should unscrew the components carefully and put the fasteners in groups, as these small parts are easily lost.

READ Sharpening Chainsaw Chain for Rip Cutting

Instructions for Chinese

To correctly configure the carburetor of a Chinese chainsaw, you must first remember the factory settings of the device, then turn on the engine. Subsequently, you will have to leave it running for several hours in order to accurately set your own parameters. Sometimes work is carried out only after ten minutes of engine operation, but many Chinese-made models require special handling.

Chinese chainsaw model

Adjustment procedure:

- Activities begin in idle mode . Using the adjusting screws, you need to achieve a systematic increase in engine speed, so you should first let it run at low speeds. A deviation from the norm is the movement of the chain along the bus. In this case, you need to adjust the outer screws to the optimal position so that the chain remains motionless.

- The transition to medium speed speed is carried out . Sometimes the engine starts to smoke. This defect can be eliminated by tightening the screw to supply a leaner fuel mixture.

In this case, the smoke will disappear, but the engine speed will increase. You need to adjust the settings until you reach a level where, when you press the throttle, the engine smoothly picks up speed, and no sudden jerks or interruptions are heard.

- The device's engine is being checked . The chainsaw is switched to minimum speed, and then the lever is quickly pressed. When pressed maximally, it is held for 3 seconds. If there are problems with the engine, you need to gradually loosen the screw until the optimal position is reached.

- The chainsaw should work for several hours in real conditions . You need to cut wood, and then inspect all the elements involved in this event. If there are deviations, they must be corrected using adjusting devices. When all defects have been eliminated and the optimal settings have been established to supply correctly concentrated fuel, the device setup process can be considered complete.

Take a look at the video:

Conclusion

In order for the chainsaw to work properly, you need to carefully carry out the work of adjusting the carburetor in exact accordance with their order. If any malfunctions occur in the operation of the device, you must completely disassemble it yourself. In most cases, replacement of any parts that have become unusable is required.

By constantly checking the quality of carburetor settings and taking timely actions to improve its operation, problems with the chainsaw will not arise.

Read about which chainsaw to choose here.

Source

Technical characteristics of the Makita DCS 4610 chainsaw

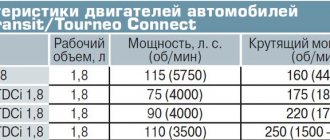

This model from the Makita brand enters the market in two versions: the DCS4610-35 modification is equipped with a 35-centimeter tire, and the Makita DCS4610-40 is sold complete with a 40-cm-long tire. There is no difference between them, except for the length of the tire , No. Both versions have the same design parameters, among which the following should be highlighted:

- Power – 2.3 l. s./1700 Watt;

- Saw chain pitch – 3/8 “;

- Fuel supply reservoir – 370 ml;

- Tank for filling lubricant – 250 ml;

- Weight including bar and chain – 4.9 kg.

The good technical performance of modifications to the Makita DCS4610 chainsaw makes the model stand out against the background of market analogues that have much smaller parameters.

Structural elements of chainsaws

All chainsaws are similar in structure, regardless of whether they are made in Europe (ECHO, Stihl, Husqvarna) or at home (Cedar, Urals). The main elements are located inside the body - the fuel tank and the engine, and outside - the starter, handle, part of the saw ( tires) with chain. A sharp tug of the cable starts the motor and it is the saw blade.

To begin with, we suggest you familiarize yourself with video clips that show how a chainsaw works and how it works:

From time to time, saws develop malfunctions that require disassembly. What can happen to such a simple mechanism as a chainsaw? At least the following:

- Stops starting;

- It starts but soon stops;

- It ceases to function in context;

- Loses strength;

Most problems are related to engine failures (fuel system, exhaust system, ignition, piston part of the cylinder) or failures of other systems and components (clutch, chain brake, tire, lubrication system). Let's look at the most common faults and how to fix them.

READ Diamond Reciprocating Saw Blade

The working chainsaw starts with one jerk and does not cut

Application areas of the Makita DCS4610 chainsaw

Reliable spare parts, well-thought-out design and excellent design parameters allow you to use the Makita DCS4610 chainsaw to solve the most complex household problems. Today the model is actively used:

- For cutting down trees with a trunk thickness of up to 40 cm;

- For pruning bushes and small branches;

- For precise sawing of logs and boards for use in repairs and construction;

- For harvesting large volumes of logs for heating private houses or cottages.

The high performance and excellent endurance of the Makita DCS4610 chainsaw allow it to be actively used by city utility workers and rescuers.

Operating instructions for the Makita DCS4610 chainsaw - rules and tips

In order to carry out repairs on a known model as rarely as possible, you should adhere to the rules specified in its operating manual. Makita recommends:

- Perform proper break-in of the Makita DCS4610 chainsaw. To do this, you need to let the tool work for about 2 minutes without load, and then proceed to sawing wood, gradually using thicker branches;

- To prepare fuel, use gasoline of a grade no less than AI-92 and branded oil for 2-stroke engines produced by well-known brands. The ratio of gasoline and oil should be 1:50. In other words, 20 ml of motor oil must be diluted in 1 liter of gasoline;

- Use only high-quality lubricant to lubricate the chain. Regularly drain any remaining oil before storing the chainsaw for long periods of time.

By following these simple instructions, you can extend the life of your Makita DCS4610 chainsaw, and you will not need to regularly change spare parts for it.

Fuel supply system repair

Fuel cannot enter the cylinder for the following reasons:

- Fuel filter is dirty. Remove the fuel hose and check for fuel leaks. If the stream is weak, you may need to clean the filter. It is removed through the filler hole of the fuel tank and cleaned; in case of severe contamination, it is replaced with a new one. As a precaution, it is recommended to replace the fuel filter every three months.

- Clogged breathing tube (holes in the fuel tank cap). Also check by disconnecting the hose to see if the needle is clogged.

- Lack or insufficient amount of fuel. There may be several reasons for the malfunction. The first reason is a clogged air filter. Air stops flowing into the carburetor in the required quantity, and therefore the engine is damaged due to the fuel mixture being too rich. The dirty filter is carefully removed, cleaned and washed with water, then dried and replaced.

READ How to Fuel a Chainsaw Oil to Gasoline Ratio

Another reason is mismanagement of carbon emissions. Adjustment is carried out with three screws.

Timely replacement of the fuel filter ensures full fuel supply

The fuel hose and blower drive must be in tight contact with the valve.

The throttle cable should be in place.

You must use instructions when working, otherwise you may only make it worse.

And the last reason is a violation of the integrity of the membrane or clogging of the carburetor channels.

To repair the carburetor yourself, you need to read all its parts

All parts must be clean, dry and undamaged.