Motor cultivator Neva MK-200 – model description

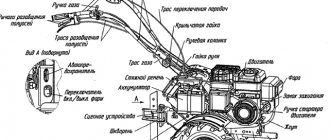

This Neva cultivator differs from its analogues in its modified gearbox, which allows operation at any of two forward and one rear speeds. This was achieved thanks to a gear transmission with an oil-filled gearbox. The video will tell you in detail about the design of the cultivator.

The weight of the cultivator is reduced due to the use of aluminum alloy. If necessary, the operator can adjust the position of the handles for more convenient use of the equipment. At the buyer's request, the package may additionally include a PTO, which allows turning the model into an analogue of a walk-behind tractor.

The Neva MK-200 cultivator can be equipped with different engines. Some modifications are equipped with gasoline engines, others are equipped with diesel internal combustion engines. Both variants have modest fuel consumption and low exhaust emissions.

Cultivator features include:

- power – 5 l. With.;

- fuel tank capacity – 3.8 l;

- plowing width – 96 cm;

- soil tillage depth – 16 cm;

- weight – 70 kg.

Reviews from owners indicate the stability of this model on loose soil and the high quality of processing hard clay soils. Due to the availability of easy access to the main consumable parts, it is very easy to maintain and repair.

User manual

Operating instructions included with Caiman brand cultivators. contains recommendations for assembling and adjusting mechanisms. To control the engine speed, a lever or rotary control is used, which has a stop position for the power unit. To select the speed and direction of movement, a separate lever is used, which moves linearly or along a sector. Before starting operation, the engine is filled with engine oil having the viscosity recommended by the manufacturer.

The design of the units includes a safety fuel valve, which opens before starting the engine. After starting the engine of the Neo cultivator or similar equipment, it is recommended to start moving immediately; idle time leads to overheating and the formation of carbon deposits in the combustion chamber. Gear shifting is performed only when the clutch lever is depressed. To ensure trouble-free operation, the cables and control rods must be inspected and lubricated annually (according to the attached map).

Motor cultivator Neva MK-80 – equipment and parameters

The Neva motor-cultivator in this configuration has small dimensions, which simplifies its transportation and use in confined spaces. The main functions of the model are high-quality plowing of the soil, removal of weeds, assistance in caring for flower beds. When performing any task, the equipment shows modest fuel consumption and high efficiency in any weather.

The Neva cultivator consists of reliable metal parts that are resistant to wear and corrosion. Its design includes small pneumatic wheels for easy movement on hard surfaces. The main element of the model is the Robin-Subaru engine, operating under the control of an air cooling system. If necessary, it can be replaced with a more efficient liquid cooling system. To start the engine, the device is equipped with a manual starter. The gearbox, gear-chain transmission and oil-filled gearbox are responsible for transmitting engine torque.

This cultivator with a Subaru engine has the following parameters:

- power – 3.5 l. With.;

- fuel tank capacity – 2.5 l;

- plowing width – 60 cm;

- soil tillage depth – 16 cm;

- weight – 55 kg.

Due to the lack of a power take-off shaft, the range of attachments for the model is significantly limited. In the basic configuration, the Neva cultivator is equipped with two cutters. To increase the width of the area to be gripped during work, you can install an additional pair of cutters on it.

Advantages and disadvantages of the manufacturer

The advantages of the equipment, according to reviews from owners, include the use of power units with increased power and torque. Installing additional wheels on the cultivator allows you to tow a trailer; weights are needed to improve traction with the ground, but the plant does not produce them. Some modifications have wheels of reduced diameter, which reduce the weight of the unit. But due to their small size, the rollers sink into loose soil, making it difficult for the cultivator to move.

The advantage of Neva cultivators is their overall dimensions, allowing the equipment to be placed in the luggage compartment of a passenger car. The kit includes additional tools (the list depends on the modification and release date of the equipment). The disadvantage of the installations is the increased cost (compared to Chinese manufacturers).

Analogs

The competitors of the equipment are walk-behind tractors assembled by. The products are equipped with identical engines and gearboxes of similar design. Similar models of cultivators are assembled under the Viking, Stihl or Husqvarna brands. The products are equipped with 4-stroke motors (cheap modifications are equipped with 2-stroke units) with chain or worm gearboxes; the production program includes installations with electric motors powered from a household AC network.

Since the appearance on the market, Neva cultivators have shown themselves to be reliable assistants on small plots of land. The equipment of the Russian company is characterized by endurance, maneuverability and low fuel consumption. In addition, Neva cultivators are easy to use and self-maintenance. This allows any novice farmer to start using them.

Motor cultivator Neva MK-70 – model features

This Neva cultivator is designed for cultivating all types of soil. It is well suited for dachas where assistance is required with plowing the soil in the garden, caring for beds and flower beds. Its advantages include maneuverability, ease of operation and self-maintenance.

The design is based on a reliable, economical Kasei 168F engine, controlled by an air cooling system. Torque is transmitted to the working parts using an oil-filled gear-chain transmission and a 2-speed gearbox. Each transmission element is made of a reliable alloy that is resistant to corrosion.

During operation, the model can move at one forward speed. Reverse is not provided in the design. When plowing the soil, the cutters rotate at speeds from 80 to 115 rpm. Despite its low weight, the equipment shows high stability on loose soil.

Characteristics of the Neva cultivator include:

- power – 5 l. With.;

- fuel tank capacity – 3.6 l;

- plowing width – 97 cm;

- soil tillage depth – 16 cm;

- weight – 44 kg.

The delivery set includes detailed operating instructions. The ease of use of the cultivator makes it possible for any novice farmer to start using it.

Positive and negative sides

Subaru engines have many advantages, of which the most notable are:

- durability;

- minimum noise level;

- reliability.

Based on consumer reviews, the power units of this manufacturer do not require replacement for a long time if the user complies with all operating requirements specified in the instructions. This became possible due to the fact that the company uses cast iron liners and rings in the design of the motors. The installed crankshaft is forged, and the cooling system has a double cyclone element.

The EX series of engines deserves special attention. These units make little noise during operation, which makes the user very happy. This is all thanks to the fact that the design has a rigid crankshaft, and an innovative development is used as a filter.

If you believe the consumer, then you rarely have to deal with Subaru engine repairs, since it has a high degree of reliability thanks to a special cooling system and a reinforced crankshaft design.

Read also: Fairing for Ural motorcycle

The only disadvantage is the need to use gasoline of at least 92 , since the engine is very sensitive to the quality of fuel. It is very difficult to start the unit in winter, but this is not important, since the walk-behind tractor is rarely used at this time of year, only as a snow blower.

Write a review

Your feedback:

Attention: HTML is not supported! Use plain text.

Grade:

Bad Good

Enter the code shown in the picture:

Hiller

AVANTGARDE walk-behind tractor with 6.5 hp engine. Kadvi 168-2

Motoblock OKA MB-1D2M7 with engine. B&S I/C 6.5 HP

Motoblock OKA MB-1D1M11 7.5 with B&S Vanguard 7.5 hp engine

OKA MB-1D1M6 walk-behind tractor with MITSUBISHI 6.0 hp engine.

Motoblock CAIMAN VARIO 60S TWK

Selecting a starter and carburetor

The starter for the carburetor can be:

The spring mechanism is easy to install and starts easily, requiring only the user to move the lever. Its operation is carried out semi-automatically, the main thing is that the engine starts and revs up.

The electric starter is installed together with the battery, since it will be powered from it.

A walk-behind tractor with an engine and an existing manual starter can be adapted to an electric starter.

For stable operation of the engine, it is necessary to monitor the operation of the carburetor, and for this it is necessary to adjust the mechanism responsible for adjusting the speed. Instability of speed is already the first indicator that it is time to make adjustments. As a rule, this is done before starting work on the walk-behind tractor, that is, in early spring, since the failure appears after the equipment is idle in the garage.

You can adjust the speed yourself if you follow the diagram below.

- At the very beginning, warm up the engine.

- Unscrew the screw that is responsible for adjusting the throttle valve. It is necessary to create some play between it and the stop.

- The cold running screw is unscrewed completely.

- The stop screw should touch the stop when it is removed. After this, it is returned half a turn to its previous state.

- You can activate the engine and let it idle for a few minutes.

- At this time, the carburetor should operate at minimum speed, while the engine should be running.

- Now, using the idle screw, adjust the number of revolutions, setting the maximum number.

- They are adjusted so that from 1100 to 1350 rotations are performed per minute.

- The last three points are repeated until the motor operates stably.

Any unit can be configured in a similar way, including the Mikuni carburetor. After 20 hours of operation, the oil will need to be changed. In some cases, you will have to adjust the belt size, check the valves and insulator.

In the video below you will see how to repair a Subaru EX21 engine for a walk-behind tractor.

All rights reserved, 14+

The use of any materials without our prior written consent is prohibited.