| K-700 "Kirovets" | |

| Project, g | 1961 |

| Issued, gg. | July 13, 1962 - February 1, 2002 |

| Instances | 401,300 (as of 1995[1]) |

| Purpose | universal |

| Propulsion type | wheeled, all-terrain |

| Traction class, tf | 5/(5) |

| Gross weight, t | 12 |

| Location | |

| Cabin: | average |

| Engine: | front |

| Main Dimensions | |

| Length, mm | 7235 |

| Width, mm | 2530 |

| Height, mm | 3225 |

| Road (agrotechnical) clearance, mm | 440 |

| Engine | |

| Designation according to GOST | 8ChN13/14 |

| Engine make | YaMZ-238NB |

| Transmission | |

| Transmission type | mechanical/hydromechanical |

| Suspension and handling | |

| Suspension type | spring of the front axle, balancer of the rear axle. Some tractors (designed to work with bulldozers and loaders) have a rigid suspension. |

| Rotation control method | turning the semi-frames |

| Brakes | pneumatic wheeled (on early models - pneumohydraulic) |

| Equipment | |

| Hydraulic equipment | a separate separate-module system for controlling mounted and trailed machines; separate system for steering control; separate system for gearbox control |

| Pneumatic equipment | for driving brakes: compressor, buffer tank, pneumatic distributor, wheel brake cylinders |

| Electrical equipment | on-board network with voltage 12V; to start the engine and oil pump switches to 24V |

| K-700 "Kirovets" on Wikimedia Commons | |

K-700 "Kirovets"

is a Soviet general purpose wheeled tractor with all-terrain capability, traction class 5. Designed to be used in conjunction with mounted, semi-mounted and trailed wide-grab agricultural machines (plowing and deep loosening of the soil, cultivation, discing, harrowing, stubble peeling, sowing , snow retention), transport, road construction, reclamation, earthmoving and other works. Chief designer - Joseph Kotin.

Story

In 1961, for the technical re-equipment of agriculture, Soviet designers, on instructions from the government, developed a project for the first Soviet wheeled tractor of traction class 5. With an engine power of 220 hp. with., making it possible to use wide-cut implements, the K-700 increased the productivity of agricultural work by 2.5-3 times compared to other tractors.

Like many other types of equipment in the USSR during the Cold War, the K-700 was developed as a dual-use product: in wartime it was supposed to be used as an artillery tractor[2].

The production of the new machine, named “Kirovets”, was organized at the Kirov plant in Leningrad, the oldest tractor manufacturing enterprise in the USSR.

The first tractor left the assembly shop and entered the fields of the country on July 13, 1962. Mass production of the K-700 began in 1969.

Tractor K-700 on a field in the GDR, 1986

In 1975, the Kirov Plant began serial production of the Kirovets K-700A tractors with an 8-cylinder YaMZ-238ND3 engine (235 hp) and the Kirovets K-701 tractors with a 12-cylinder YaMZ-240B engine (300 hp). With.). The K-700A and K-701 tractors were unified and differed only in the engine, but both were very different from the first K-700, it was already a different tractor. Fundamental differences (not to mention the design) - there are no springs on the K-700A (K-701) (there are on the K-700). Instead of the rear fuel tank (on the K-700), the K-700A (K-701) tractor received two side fuel tanks (left, right) that merge into a single unit with the front wings of the tractor. The K-700A (K-701) has different wheels (not unified with the wheels of the K-700 tractor). This tractor was in demand not only in agriculture, it began to be used in other sectors of the national economy of the USSR. The Kirovets K-703 tractor with a reversible control post was developed. On its basis, the LT-163 timber stacker (after the LT-195 modernization), the ML-56 timber skidding machine, the LB-30 gradedozer, the PF-1 front loader, the DM-15 universal road machine and other machines were created. Various equipment was also developed for installation on the rear semi-frame of the Kirovets K-700A and K-701 tractors: loading P-4, P-4/85, hundred-throwing and others. To perform reclamation and other work, a trencher was developed on the basis of the Kirovets tractor. Seeing the great demand for the Kirovets tractor in other sectors of the national economy, the Kirov Plant began producing various equipment based on the Kirovets tractor in 1990. It was road construction and special equipment. For the needs of road workers and workers in other industries, the Kirov Plant began to produce the K-702MA-PK6 front loader, the K-702MBA-BKU universal bulldozer, the K-702MVA-UDM universal road machine, the VK vibratory roller, the SFR snow blower, mobile welding units for 4 and 8 welding posts and other equipment.

Monument to a tractor in one of the Ukrainian cities

On February 1, 2002, the St. Petersburg Tractor Plant stopped producing the Kirovets K-700A and K-701 tractors.[3] Instead, the Kirovets K-744 tractors began to be produced, which were much more expensive than the Kirovets K-700A and K-701 tractors. Plant managers explained the removal of the Kirovets K-700A and K-701 tractors by saying that these tractors were obsolete and their cabins did not meet safety standards. In this regard, there was a shortage of inexpensive tractors of the Kirovets type.

Many years of experience in operating the machine in various conditions and climatic zones have shown high reliability, simplicity and ease of maintenance, maintainability and long service life.[4]

Unfortunately, there were also disadvantages. In conditions of extremely significant unevenness of the road surface, it was possible for the car to overturn. The protruding engine worsened cross-country ability in extreme conditions. Agronomists demanded machines with less pressure on the ground. These shortcomings were never eliminated in the K-744.

Due to the demand, tractors of the K-700 series (both original models of the Kirov plant and various modifications), as well as tractors, bulldozers, loaders and special machines based on them continue to be produced by various engineering enterprises in Russia.

CJSC Petersburg Tractor Plant currently produces only special-purpose equipment based on the K-700. Agricultural tractors of the K-700 series under the Kirovets brand are no longer officially produced, and those on the market are usually restored from old ones and have very dubious origins.

As of 2020, Petersburg Tractor Plant JSC produces two models of agricultural tractors - K-744R and K-703M - in various configurations.[5]

Video

The Kirovets K-700 tractor was first produced in the Soviet Union in 1962 at the Kirov plant, mass production began in 1964, the last release was in 2000. The Kirovets K-700 is a general-purpose off-road wheeled tractor, traction class 5. It is used for agricultural work with mounted, semi-mounted and trailed wide-cut implements (plowing and deep loosening of the soil, cultivation, discing, harrowing, stubble peeling, sowing, snow retention), as well as for transport, road construction, reclamation, earthmoving and other works.

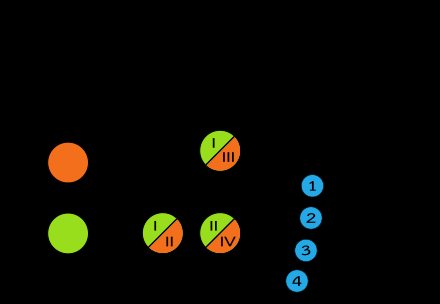

Modifications

K-703M-AS8-200

- K-700

- basic model. - K-700A

- the next model (unified with K-701, YaMZ-238ND3 engine with turbocharging). - K-701

- the next model (unified with K-700A, YaMZ-240BM2 engine).[6] - K-701M

- modification with a YaMZ 8423.10 engine with a power of 335 hp. With. In 1979, driver-inventors from Chukotka built four six-wheeled vehicles based on the K-700, which 10 years later served as prototypes for an experimental factory modification[7]. - K-702

is an industrial modification for use as a base machine for loaders, bulldozers, rollers, scrapers: the linkage system has been changed, only a hydromechanical transmission is used, and the suspension is rigid. - K-703

- industrial modification. The tractor has a reversible control post, allowing the operator to work in a normal position both when the tractor is moving forward and when the tractor is moving backward. - K-703MT

is a three-axle articulated dump truck with a lifting capacity of 18 tons.[8]

Transmission

Tractor gearbox K-700

The K-700 tractor does not have a clutch. Instead, there is a drain pedal (pressure drop in the gearbox hydraulic system). The gearbox is mechanical, with constant mesh gears, 16-speed (four-mode), with hydraulically controlled four clutches and mechanically controlled gear clutches. All gears are spur gears.[9] Number of gears (hydraulic) 4 (+2 neutral), 4 modes (mechanical), high-low switching. As a result, the number of speeds is 16 (from 1.1 to 4.4) and, accordingly, 8 rear. The box is designed to change gears without loss of power (due to friction clutches). Modes are switched by moving gears as in any manual transmission. Speeds are switched by switching the spool (by redirecting the hydraulic oil flow). The 2nd neutral turns off the hydraulic flow. The 1st neutral, in addition to turning off the hydraulic flow, mechanically slows down the drive shaft (shaft with clutches) in the gearbox like a hand brake. Therefore, you can turn on the 1st neutral only after stopping.

Specifications

- Overall dimensions: Length, mm 8400

- Width, mm 2530

- Speeds: when moving forward 2.9-44.8 kilometers per hour

- when moving backwards 5.1-24.3 kilometers per hour

- Minimum turning radius, mm 7200

- Track width, mm 2115

- Engine power YaMZ-240B 300 hp. s., at a rotation speed of 1900 min-1. Maximum torque 1240 Nm.

- Engine power YaMZ-238NB 280 hp. s., at a rotation speed of 1700 min-1. Maximum torque 950 Nm.

- Weight of K-700 A 12.8 tons.[4]

- K-701 weight 13.5 tons.[10]

Technical characteristics of K-701

Now let’s look at our “Bogatyr” in more detail, look under the hood, sit in the driver’s seat and find out what kind of equipment our hero can carry!

- Diesel - YaMZ-240B

- Rated power kW/hp — 220/300

- Basic weight/with attachment — 11450/13750

- Dimensions d/w/h — 6820/2850/3685

- Number of forward/reverse gears — 16/8

- Traction class - 5

- Hitch - three-point, hydraulic

- Lifting capacity kg. — 5500

We recommend reading: Amkodor-211: technical characteristics

Engine

The K-701 tractor is equipped with a 300-horsepower, four-stroke, twelve-cylinder water-cooled YaMZ-240BM engine.

An original solution in the steel design: a tunnel type crankcase, roller bearings on the crankshaft, and the hydraulic coupling of the fan drive is controlled using a mechanism with a spool-type thermocouple instead of the classic thermostat on the previous engine.

The intake air is cleaned by a combined two-stage system. Coarse or primary cleaning occurs using cyclone filters, secondary through four cassette filters made of porous cardboard.

The cooling system is closed-type liquid with a compensating circuit, the circulation of liquid in the system is forced. The tractor is initially equipped with pre-heating to facilitate engine starting at low temperatures.

The electric engine start system ensures that it starts without heating at temperatures down to -10 degrees. If the temperature is lower, use a preheating system.

Transmission

The K-701 gearbox is a multi-stage, mechanical, four-friction gearbox with constant gear mesh. It is installed on the front semi-frame on four AKSS-220M shock absorbers.

In fact, this is a modernized box of its predecessor K-700. This modification does not have a hydraulic pump drive for the tractor steering control systems and hitch hydraulics.

The number of sections in the oil pump has been reduced (one instead of two), the number of synchronizer brakes, on the contrary, has increased from one to two, and the gear ratio in the corresponding gears has been changed upward. To ensure seamless switching, a hydraulic accumulator was installed.

Weight and overall dimensions.

The dimensions of the K-701 inspire respect; it would be hard to call this giant compact, and it is not intended for plowing 7-acre country houses. Vast areas of hundreds of hectares are where this machine can reach its full potential.

Dimensions:

- Length without attachment/with attachment mm.- 6820/7400

- Width mm - 2850

- Height mm - 3685

- Agrotechnical clearance with a tire radius of 800mm. — 545

- Track width mm. — 2115

- Turning radius mm. — 7200

- Possibly fording mm. — 800

Controls and chassis.

The wheels on both axles of the tractor are discless, equipped with low-pressure tires and high-cross-country tread. The wheel is secured with eight nuts. The tire pressure of the K-701 tractor is selected depending on the work performed:

Plowing and other agricultural activities. work

- Pressure in front tires MPa (kgf/cm2) — 0,17 (1,7)

- Rear tire pressure MPa (kgf/cm2) — 0,16 (1,6)

Agricultural work with mounted equipment in early spring

- Pressure in front tires MPa (kgf/cm2) — 0,14 (1,4)

- Rear tire pressure MPa (kgf/cm2) — 0,11 (1,1)

Transport work

- Pressure in front and rear tires MPa (kgf/cm2) — 0,17 (1,7)

Every month it is necessary to inspect the rims and tires and monitor the pressure. Carry out regular cleaning of tires to remove objects clogged in the tread. Damaged tires with defects reaching to the cord, rims with cracks should not be allowed into service.

The frame is articulated and consists of two semi-frames: The front one is welded, closed profile, has box-section spars, in the upper plane of which there are six brackets for engine mounts. In comparison with the K-700 frame, the front hinge support, with brackets for fastening the rotary hydraulic cylinders, is made more rigid, and the height of the side members in the middle of the half-frame is increased.

The rear one is designed similarly to the front half frame. Unlike the previous model, stops for working with a loader were additionally installed, this made it possible to reduce the angle of displacement around the horizontal hinge by half, from 16 to 8 degrees.

We recommend reading: Komatsu WB93R-5EO: technical specifications

Tractor control.

The Kirovtsy uses a hydraulic, separate-unit tractor rotation control system, the hydraulic pump in it acts as an energy source, the flow of working fluid is regulated and distributed using a flow regulator and a hydraulic distributor, and hydraulic energy is converted into mechanical work using double-acting hydraulic power cylinders.

Notes

- Domestic agricultural tractors. History of development over 100 years.//A team of authors from NATI, the Moscow region branch of NATI and the Museum of Tractor Equipment together with specialists from tractor factories. - M.: 1996

- Followers of Kegress. Around the World No. 3 (2810) | March 2008

- Key milestones in the development of tractor engineering at the Kirov Plant Archived copy dated January 24, 2012 on the Wayback Machine // Official website of Petersburg Tractor Plant CJSC.

- ↑ 12

Tractor Kirovets K-700A // K-700.ru - Description of products on the website of the St. Petersburg Tractor Plant Archived copy dated May 8, 2020 on the Wayback Machine

- Mosfinance LLC.

K-701 Slavich. Agricultural wheeled tractor. www.rus-parts.ru/. — Description and technical characteristics of the model. Retrieved December 2, 2008. Archived March 15, 2012. - Pogonichev vs. Kremko 24. “Behind the Wheel” (No. 3, 1990). Retrieved February 4, 2020.

- K-703MT 6. “ZR” (No. 4, April 1994). Retrieved May 23, 2020.

- Tractors “Kirovets” L. I. Bezverkhny, A. I. Ostrovsky Moscow Agropromizdat 1986

- K-701

- Tractor K-704-4R “Stanislav”, “ProfTechKomplekt”.

- K-704-4R “STANISLAV” UNIVERSAL AGRICULTURAL TRACTOR, “AGROCENTER”.

- Agricultural tractor K-704-4R “STANISLAV” Archival copy dated July 26, 2020 on the Wayback Machine, “KaravanAgroTrade Naberezhnye Chelny”.

- FIRST tractor in the Tyumen region K-704 “STANISLAV”, “Gagarinskremtekhpred”.

Technical characteristics of the Kirovets K-701 tractor

Photo of the Kirovets K-701 tractor

The Kirovets K-701 tractor of traction class 5, complete with mounted and trailed implements, is used for basic agricultural work: plowing, cultivation, harrowing, sowing. When combined with special tools, it can be used for transport, land reclamation and road work.

Video of the tractor battle - New Holland T8030 and K-701

The K 700 is a general-purpose tractor, the first modification of which was developed and put into production in 1962. Over the forty-year history of production of the K 700 “Kirovets”, the tractor has gone through a series of modernizations, and even now you can find many copies in active use. The tractors are distinguished by their reliable design, good performance, maintainability and versatility of use. Coupled with the technical characteristics that the 700 tractor acquired thanks to the designers, this determined its long “life.”