Belarus brand tractors are successfully used with special hydromechanical equipment integrated on the machine chassis to perform all kinds of work. Popular MTZ models of traction class 1.4 kN equipped with earth-moving and loading mechanisms have become indispensable equipment in the national economy. The technical and operational characteristics of excavators based on the MTZ-82, MTZ-80 chassis are ideal for performing operations when laying and repairing underground communication lines, in construction and reclamation work. The transmission and wheelbase of the machine ensures rapid, self-propelled movement of the excavator to the work site on paved roads and off-road, has good performance, and is easy to maintain and repair. The equipment has good driving characteristics, the power of the power unit ensures the operation of the equipment.

Excavators based on the line of modern modifications of Belarus brand tractors - MTZ 82.1, 92P, 1523, 1221 are popular in the special equipment market, successfully compete with imported analogues, and captivate with their price, reliability and functionality.

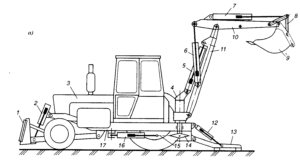

Design of excavators based on MTZ

The layout of earth-moving machines based on MTZ wheeled tractors consists of the location of hydraulically controlled equipment on the rear body of the machine frame and additional front equipment on the front linkage and beams of the tractor frame. The machine operator's workplace can be transformed by rotating the seat 180° to allow the machine to operate while moving and when operating rear excavator equipment. The overview cabin allows you to monitor and manage work processes around the perimeter of the machine. The tractor is equipped with an additional autonomous hydraulic system designed to control and drive the working parts of the excavator's earthmoving equipment. Control is carried out by levers, special distributor. equipment located on the panel of the rear wall of the cabin.

Excavator diagram based on MTZ

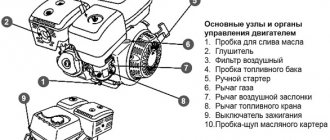

Machine components and assemblies

The machine's additional autonomous hydraulic system is designed to service the earth-moving mechanism. It includes a hydraulic pump, control distributors and a system of hydraulic power cylinders ( 16,12,5,6,7 ) connected to the moving parts of the excavator mechanism. The pump is driven from the rear PTO of the tractor.

The digging organ of the machine consists of:

- Platform 4 , which performs the function of attaching the working mechanism to the rear axle housing of the tractor and the turntable for the excavator boom. The platform allows the excavator body to rotate horizontally and change its inclination within the boundaries of the rotation angles, providing direction for digging and unloading soil.

- the boom 11 provides an articulation with the arm of the digging mechanism. Its length and slope ensures the vertical position of the working parts.

- Shoulder 10 provides force on the articulated digging bucket. In combination with the boom, its position determines the digging depth and soil unloading height relative to the position of the machine.

- Bucket 9 is an active digging part of the mechanism - its volume ensures the excavation or loading of soil.

- To ensure stability of the excavator during operation, the machine is equipped with a pair of hydraulic supports 13.

All parts of the digging mechanism are driven by corresponding hydraulic cylinders or their pairs, depending on the design of the machine.

For additional functionality, the excavator can be equipped with a bucket loader of various designs or a leveling dozer blade. The equipment is placed on the front beams of the tractor frame and the front linkage of the tractor. The working bodies are activated by hydraulic power cylinders from the standard hydraulic system of the machine.

Backhoe loader Backhoe bulldozer

FotoJoin

At the Berezovsky-1 open-pit mine in the city of Sharypovo, Krasnoyarsk Territory, brown coal is mined using a pair of the country’s largest rotary excavators. ERSHRD-5250 is a “rotary walking-rail mining excavator.” Two dozen buckets mounted on the rotor “wheel” of this gigantic self-propelled machine are capable of removing up to 5,250 cubic meters of coal per hour.

Photos and text by Slava Stepanov 1. The length of the boom of this type of excavator allows it to process layers up to 30 meters in height. That is why ERSHRD-5250 at Berezovsky operate in pairs: the thickness of the coal seam at this deposit reaches 60 meters!

2. “Wall” of coal with traces of buckets of a bucket wheel excavator. Its height is comparable to a 10-story building.

3. The principle of operation of a bucket wheel excavator is based on the continuous rotation of a large “wheel”: buckets located around its circumference scoop up rock or coal and then empty themselves under the influence of gravity or inertia.

4. ERSHRD-5250 can be compared to a 17-story building: the height of the unit is 51 meters.

5. The weight of the excavator is about 4000 tons. For example, more than 2,500 GAZ-24 Volga passenger cars, popular in Soviet times, weighed the same.

6. The crew of the ERSHRD-5250 consists of 4 people (a driver, an operator, a specialist monitoring the unloading and transportation of rock mass and a crew foreman).

7. The idea of a “digging wheel” was invented by Leonardo da Vinci in the 16th century. However, the path from the idea to its implementation took several hundred years: the operating principle of a rotary excavator was patented in the USA at the end of the 19th century, the first operating unit was created in Germany in 1916, and in our country, rotary excavators began to be used in the mid-20th century in the Donbass.

8. There are 22 buckets installed on a rotary wheel with a diameter of 11.5 meters. The unit produces 4,500 tons of coal in an hour. Fills a wagon with a carrying capacity of 84 tons in less than a minute.

9. ERSHRD-5250 digs to a depth of 2.1 meters.

10. Driver's cabin of a rotary excavator.

11. The rotor of the ERSHRD-5250 excavator is forced to rotate by two electric drives with a power of one thousand kilowatts each.

12. The capacity of the ERSHRD-5250 bucket is 600 liters.

13. Each bucket of a bucket wheel excavator has four teeth. In the Soviet years, the development of new forms of cutting surfaces was popular among inventors and innovators; they tried to increase the wear resistance of these elements.

14. The Berezovsky-1 open-pit mine is part of the Siberian Coal Energy Company (SUEK), the largest coal mining corporation in Russia. The open-pit mine is developing a brown coal deposit in the Sharypovsky district of the Krasnoyarsk Territory. Its main feature is its shallow depth.

15. Brown coal deposits were formed during the Jurassic geological period (150 million years ago). The thickness (that is, the thickness of the coal seam) at the Berezovsky deposit reaches 60 meters. Above the coal is a layer of rock.

16. The first stage of the open-pit coal mining process is stripping.

17. At different enterprises, depending on mining and geological conditions, rock is crushed either by explosions or removed using excavators.

18. “Layered cake” of rock.

19. The removed rock is transported by dump trucks to places where coal seams have already been mined in order to fill up huge pits and thus carry out reclamation of production sites.

20. At the Berezovsky-1 open-pit mine, Komatsu HD785 mining dump trucks are used to transport rock.

21. 90 tons of rock are placed in the back of a giant dump truck.

22. A layer of coal, “exposed” for the operation of a bucket wheel excavator.

23.

24. The ERSHRD-5250 excavator is driven by electric motors that consume up to 4500 kW/h of energy. It is supplied to the unit by a 10 kilovolt power line. To optimize and reduce the cost of the production process, excavators work mainly at night, when preferential energy tariffs apply.

25.

26. The rotor of the ERSHRD-5250 excavator makes more than 40 revolutions per minute.

27. The thirty-meter rotary mast of the excavator is held and controlled using a system of steel cables and winches.

28. Rotary mining excavators are one of the largest units created by man. In Russia, the largest mining mechanism of this type is ERSHRD-5250. In the world, the leadership is held by the German Bagger 293 excavator weighing 14,200 tons, built in 1995 and equipped with 20 buckets of 15 cubic meters each.

29. The ERSHRD-5250 complex at the Berezovsky-1 open-pit mine was launched in 1986. At the same time, the assembly and installation of mining equipment took two years.

30. The ERSHRD-5250 excavator was produced by the Zhdanov Heavy Engineering Plant named after Ilyich, now Azovmash OJSC (Mariupol, Ukraine). Four such excavators were produced for the Berezovsky-1 open-pit mine, two of which are currently in operation.

31. The main consumer of brown coal mined at the open-pit mine is Berezovskaya GRES-1. A unique conveyor line was created to transport fuel to the power plant.

32. Coal mined by an excavator at the face is unloaded onto a conveyor belt.

33. The length of the main conveyor from the open pit to the state district power station is 15 km.

34. Brown coal is much cheaper than hard coal, but is inferior to it in terms of heat transfer and a number of other characteristics. Brown coal is usually ground to a powder before use. Berezovskaya GRES was created taking into account all the characteristics of the fuel. The station is recognized as the most economical in Russia.

35. Consumption of brown coal should increase after the planned launch of the third power unit of the state district power plant.

36.

Did you like the article? Tell your friends:

LiveJournal

Excavator models

With the development of market relations, taking into account the needs of the market, many machine-building enterprises have mastered the production of excavators for wheeled tractors. In conditions of healthy competition, enterprises are making every effort to improve the performance of excavators, modernizing, developing and producing new designs of equipment and components, ensuring their competitive advantage in the market.

EO 2621 – single-bucket excavator

The most widely produced Soviet model of an excavator with a bulldozer blade, popularly called the “Cockerel”. The equipment is installed on the chassis of tractors of the YuMZ 6 brand. It is recognized by a remote fuel tank located in front of the radiator grille and a hydraulic tank installed on the left or right side. Models based on MTZ 82.1 evolved into modifications EO 2621DT with a straight blade and EO 2621DT.1 with a rotating blade. The unit in working condition rests on two inclined legs with hydraulic locks on hydraulic cylinders. The digging body is driven by four hydraulic power cylinders, controlling the boom tilt, arm and bucket. Two hydraulic cylinders control the boom rotation.

EO 2621 based on YuMZ 6

Excavators of the EO 2626 brand produced by the Chelyabinsk Municipal Engineering Plant are a modernized version of their predecessor described above with increased performance indicators. They are placed on the chassis of tractors of the MTZ 82.1 brand and its modifications. Machine versions differ in additional attachments - bucket loaders and dumps of various types. These models are fully equipped with domestically produced components and are distinguished by their competitive price, simplicity of design and maintainability.

EO 2626

Backhoe loaders EP 491 and EP 25

On the 4x4 wheelbase of the MTZ 92P tractor, the production of machines is carried out at the Mozyr Machine-Building Plant, which is part of the production holding of the Minsk Tractor Plant. The EP 491 model is equipped with vertically lowering rear stops. Excavator equipment has the ability to shift the digging axis in an amplitude of 590 mm in each direction, with a boom rotation angle of 180 ̊. A front loader with a capacity of 25 to 70 tons further expands the functionality of the machine. The unit is distinguished by excellent control ergonomics and improved performance.

Backhoe loader EP 25 Backhoe loader EP 491

Backhoe loaders EP 25, EP 25 02 and bulldozer excavator EP 25 01 from the Mozyr plant are produced on the basis of MTZ 82.1. The design of the earthmoving machine has a classic design with inclined paws without shifting the digging axis. Thanks to its fairly low price and high reliability, the unit occupies a place in the line of popular special machines.

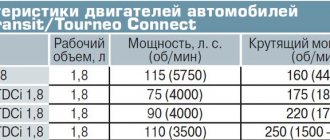

| Indicators | EO 2621DT | EO 2626 DT | EP 25 | EP-491 | EP-F-P-01 telescopic boom |

| MTZ chassis | Belarus 82.1 | Belarus 82.1 | Belarus 82.1 | Belarus 92p | Belarus 92p |

| Machine power hp | 80 | 80 | 80 | 88 | 88 |

| Productivity t/h | 28,8 | 30 | 10-35 | 10-40 | 10-40 |

| Bucket volume m.cub. | 0,2- 0,25 | 0,28 | 0,25 | 0,25 | 0,3 |

| Bucket force kN | 25 | 28 | 31 | 31 | 31 |

| Excavator load capacity max. kg | 500 | 500 | 750 | 500-950 | 750 |

| Digging depth/discharge height mm | 4100/4000 | 4150/3500 | 3900/3500 | 4350/3400 | 5000/4150 |

| Digging radius mm | 5400 | 5300 | 5200 | 5350 | 6100 |

| Angle of rotation | 170 ̊ | 170 ̊ | 170 ̊ | 180 ̊ | 170 ̊ |

Blooming excavators

EP-F-P, EP-F-P-01, EP-F-B is a series of special earthmoving and loading equipment. equipment for Belarusian wheeled tractors. The installation is located on the chassis of modern tractor models MTZ 82.2, 892, 92P, 920, 920.2, 1221.2. The designs of Blooming excavators can additionally have a shifting digging axis, a telescopic boom arm and balancing vertical stops - outriggers. Excavators can be equipped, at the customer’s request, with a loader with different types of buckets or dumps. The equipment of imported components of machines produced by Blooming provides additional reliability and ergonomics.

Mounted excavator for MTZ

Excavator equipment BL 21 of the Blooming brand is one of the few offerings on the post-Soviet market that allows the use of tractors that have not been technically converted to work with earth-moving mechanisms. The equipment is mounted on the rear linkage of the machine, the drive is carried out from the tractor hydraulic system and is controlled from a remote control station. Equipment digging depth is up to 2500 with an unloading height of 2200 mm. With small capital investments, BL 21 increases the functional use of the tractor fleet of enterprises. Used as auxiliary equipment for small volumes of earthmoving work. The lightweight version of the equipment allows for aggregation with low-power tractors of the MTZ 320 brand.

Excavator attachments BL 21 320 Excavator attachments BL 21 Excavator attachments BL 21 320

Excavator DEM 114

Produced by the Belarusian enterprise Dorelektromash, which specializes in the production of trailed and mounted machines for road repair and maintenance, as well as hydraulic units for completing equipment. The machine is placed on the chassis of tractors Belarus 80.1, 82.1-2 and Belarus 92P and is equipped with components of imported European production of the following brands: Brevini, Busak+Shamban, Filtrek, MaNULLi. Machine modifications are available with front-end loaders or bulldozer rotary blades. The hydraulic equipment is characterized by high reliability, an optimal combination of hydraulic pump performance and the throughput of a joystick-controlled distributor. Excavator unit with a shifting digging axis of 590 mm in each direction. The compact folding of the machine's boom ensures optimal load distribution on the tractor axles and safety when moving the machine. The goal of the Dorelectromash enterprise when producing the DEM 114 machine is “maximum compliance of the equipment with European standards with a competitive price.”

DEM 114 DEM 114 DEM 1144

| Indicators | DEM 114 | MEN-300 | EBP 9 | EBP 11M | EBP 23 |

| Chassis | 92P | 82.1 | 82.1 | 92P | 92P |

| Machine power hp | 107 | 80 | 80 | 107 | 107 |

| Bucket volume cubic meters | 0,3 | 0,1 | 0,25 | 0,25 | 0,25 |

| Digging radius mm. | 5350 | 3900 | 5650 | 6300 | 5650 |

| Digging depth/height mm. | 4420/3480 | 3100/2300 | 4350/3500 | 5050/4000 | 4350/3500 |

| Bucket force kN | 38 | 25 | 35 | 40 | 30 |

| Bucket load capacity kg. | 700 | 130 | 500 | 700 | 500 |

| Shift of the digging axis to the side mm. | 590 | — | — | 650 | 600 |

Excavators EPB

The Belarusian enterprise PMK 567 LLC, established in 2003, mastered the production of excavator equipment for MTZ brand tractors. The company produces four models of excavators: EPB 9 standard installation with inclined stops; EPB 11 with a shifting digging axis, reinforced hydraulic cylinders and additional support for working in the extreme positions of the carriage shifting the digging axis; EPB 23 with the performance indicators of EPB 9 equipped with a shifting digging axis, supported by outriggers; mini-excavator mounted on the rear linkage of the MEN 300 tractor with a bucket of 0.1 cubic meters. The wheelbase of the excavators is the MTZ 92P tractor. The company produces machines combining the functions of an excavator-loader and an excavator-bulldozer.

EPB 9 EPB 9 Axle displacement carriage EPB 11 EPB 11M EPB 23 EPB 23 Mini mounted excavator MEN 300 mounted excavator MEN 300 Mini mounted excavator MEN 300 Mini mounted excavator MEN 300

Wheeled excavators of the Amkador brand

Earth-moving machines are manufactured in the production holding OJSC Amkador with the holding company managing it in Moscow. Having in its structure a number of machine-building enterprises. The manufacturer completes the equipment as much as possible with units and parts of its own production, which is a competitive advantage for the manufacturer. The company has an extensive network of its own and representative trade and service enterprises throughout Russia and neighboring countries.

Backhoe loader 702EA Backhoe loader 702EM Backhoe loader 703M

To place excavator equipment on wheeled chassis, a base of MTZ 92P tractors is used. For MTZ machines, the company produces two excavator units, “Amkador 702” and “Amkador 703”. The machines are produced in combination with loading (702 EM, 702 EA) or bulldozer equipment (702EB). Excavators "Amkador 702" have a bucket volume of 0.18 cubic meters, with a digging depth of up to 4100 mm and an unloading height of 3500 mm with a digging radius of 5450 mm. The design of the Amkador 703 machine allows you to work with a displaced digging axis of 600 mm in each direction, relying on vertical balancing outriggers. The maximum digging depth is 5000 mm, the unloading height is 4160 mm with a maximum digging radius of 6230 with a digging bucket of 0.28 cubic meters.

The choice of MTZ brand tractors for equipment based on special machines indicates the sufficient technical versatility of the equipment, its reliability and high performance when operating in various conditions. Special machines on the chassis of new modifications of Belarus brand tractors successfully compete with foreign-made machines, not inferior in technical indicators and ergonomics, and having an advantage in cost.