Feed dispenser KTU-10 from the popular

Since the process of automation has firmly taken hold of the agricultural process, feed dispensers have been increasingly used in work. It is very popular among farmers, which is based in the Moscow region. It produces a wide range of products, including fertilizer application equipment, trailers and feed distributors. One of the best-selling feed dispenser models is the KTU-10.

About the manufacturer of the feed dispenser "RKT-10"

The manufacturer of RKT-10 feed dispensers is OJSC MordovAgroMash, a plant founded in 1961 in Saransk on the basis of a repair and technological station. For the first two decades, this enterprise carried out major repairs of GAZ trucks, their individual parts, assemblies and assemblies; restored a variety of agricultural equipment and produced non-standardized machines.

In addition, in the 70s, the production of two-axle tractor dump trailers of the 2PTS-4-785A brand was established here. In the 1980s, trailers for passenger cars, bodies for UAZ cars, and then Gazelle cars began to be produced here; feed distributors, rotary mowers, universal seeders, trailed fire extinguishing systems “Vodoley”, grain loaders “3SHH-20” for GAZ, ZIL, KamAZ vehicles; significantly expanded the range of tractor trailers.

Due to the fact that the company has mastered the production of the widest range of trailed agricultural machines, in modern times it has been able to occupy one of the leading positions in the agricultural machinery market in Russia. In addition to the modified RKT-10 feed dispensers, MordovAgroMash today produces such promising equipment as: self-loading and self-unloading semi-trailer-rolled hay "PRT-12"; universal grain seeder “SZU-6” with simultaneous application of fertilizers; semi-trailer grain reloader “PPT-25”; tractor dump semi-trailers with cargo pushing out by a front movable wall; mounted utility equipment for tractors, and much more.

We recommend reading: Komatsu d65e-12: technical specifications

Feed dispenser KTU-10

The KTU-10 model is designed for processing and dosing feed mass, for harvesting agricultural crops in conjunction with harvesting machines, for unloading crushed feed into stationary dispensers, which are located in close proximity to animals, as well as for unloading mass into storage facilities. The KTU-10 feed dispenser has the following features:

- The design of the equipment is a towing device based on rubber wheels. The body is made of especially durable metal, and conveyors are mounted along the bottom.

- The chassis is as simple as possible, and it is equipped with hydraulic brakes. The entire braking system is controlled by the driver from the tractor with which the feed dispenser is mounted.

Reviews from owners of RKT-10 feed dispensers

In general, RKT-10 feed dispensers have proven themselves on farms on the positive side. Among its positive qualities, peasants note reliability and extreme simplicity of design, as well as very good maintainability. Almost any breakdown can be repaired quickly, literally “on the knees”, on our own, without the involvement of specialists or any special equipment and tools.

The owners have complaints about the quality of the material (metal) from which the feed dispenser itself is made. Not only is it not sufficiently resistant to corrosion, but it is also rather weak in itself. It happens that the slats, shafts, and tension mechanism of the transverse conveyor bend, or that the slats cling to the dampers (when the slats pass under the platform). Therefore, you should work with this feed dispenser very carefully, in no case overloading it.

Because when overloading a semi-trailer chassis with silo, of course, nothing bad will happen; but the longitudinal conveyor can easily tear (especially if it is already pretty worn out). Or the longitudinal conveyor slats can “gather in a bunch”; can break the key grooves on the drive shaft of the same longitudinal conveyor.

Therefore, overloading the feed dispenser should definitely be avoided, as it is detrimental to its mechanisms. “The main thing is to work with it carefully, and you won’t have to change anything except the bearings. Although I always have in stock 1 set of longitudinal conveyor, transverse conveyor, drive sprockets of the longitudinal conveyor, drive shaft of the transverse conveyor, connecting rod and crankshaft pawl. (I have 4 of these feed dispensers),” the owner of a private cattle breeding farm shares his experience.

We recommend reading: Design of the diesel engine fuel system

Device

The main elements of the feed dispenser are:

- Body. Its rear sides are hinged, and the floor is finished with wooden boards.

- The chassis, consisting of a frame, axles, springs, as well as a towing mechanism, secured with hinges and having a towing loop.

- The longitudinal conveyor is a pair of parallel chains that move along the bottom of the body. It is driven by a drive shaft and a beater shaft.

- Beaters are the basis of the dispensing device.

- The braking system is based on the rear wheels. The blocks are driven by the tractor driver from the cab.

- Electrical equipment.

Operational Features

Before use, the feed dispenser should be run in for half an hour. You should start with low speed, and then switch to normal. The KTU-10 model is aggregated with the Belarus tractor.

The equipment is loaded with feed mass evenly. To distribute feed, you must turn on a special operating mode, and the gear lever must be moved to 1st or 2nd gear.

At sub-zero temperatures, the feed dispenser must be kept in a warm room to avoid the formation of ice on conveyors and other moving mechanisms.

Tractor feed distributor KTU-10, RKT-10 (Feed dispenser)

Tractor feed dispenser KTU-10, RKT-10 (Feed dispenser) is designed for transportation and dosed distribution of crushed feed to animals, as well as for servicing corn and silage harvesting machines and transporting various agricultural goods with rear unloading.

The drive of the working parts is carried out from the tractor power take-off shaft. Provide uniform distribution of feed on one or two sides.

Technical characteristics of KTU-10 (RKT-10) Weight: 2127 kg. Load capacity: 4 tons. Conveyor chain: anchor Transport speed no more than: 30 km/h. Number of service personnel: 1 tractor driver

Operation of KTU-10

Prepared, pre-crushed feed is loaded evenly into the KTU-10 body. The feed dispenser is fed into the feed passage by a tractor. Already in it the power take-off shaft is turned on. A longitudinal conveyor with scrapers delivers feed to the beaters, which loosen it and, in turn, feed it to a transverse conveyor, and it distributes, depending on the design of the dispenser, on one or simultaneously on both sides.

If the unit operates as a self-unloading trailer, then the longitudinal conveyor unloads the feed back through the folded tailgate.

The distribution rate is adjusted by adjusting the ratchet mechanism, as well as by changing the speed of the longitudinal conveyor and tractor.

All this work can be performed by one person, providing feed to a herd of 300-400 heads.

Feed dispenser KTU-10

The KTU-10 model is designed for processing and dosing feed mass, for harvesting agricultural crops in conjunction with harvesting machines, for unloading crushed feed into stationary dispensers, which are located in close proximity to animals, as well as for unloading mass into storage facilities. The KTU-10 feed dispenser has the following features:

- The design of the equipment is a towing device based on rubber wheels. The body is made of especially durable metal, and conveyors are mounted along the bottom.

- The chassis is as simple as possible, and it is equipped with hydraulic brakes. The entire braking system is controlled by the driver from the tractor with which the feed dispenser is mounted.

Device

The main elements of the feed dispenser are:

- Body. Its rear sides are hinged, and the floor is finished with wooden boards.

- The chassis, consisting of a frame, axles, springs, as well as a towing mechanism, secured with hinges and having a towing loop.

- The longitudinal conveyor is a pair of parallel chains that move along the bottom of the body. It is driven by a drive shaft and a beater shaft.

- Beaters are the basis of the dispensing device.

- The braking system is based on the rear wheels. The blocks are driven by the tractor driver from the cab.

- Electrical equipment.

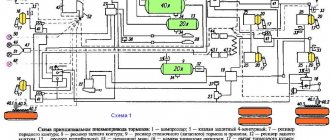

Diagram of the feed dispenser KTU-10

1 - bottom, 2 - rear board, 3 - side board, 4 - extension board, 5, 18 - enclosing panels, 6 - sidewall, 7 - beater block, 8 - reflector shield, 9 - front side, 10 - unloading conveyor , 11 – distributor drive, 12 – brake device, 13 – telescopic shaft, 14 – hydraulic mechanism for lifting an additional conveyor, 15 – chassis, 16 – additional conveyor, 17 – rear light and turn signal.

Operational Features

Before use, the feed dispenser should be run in for half an hour. You should start with low speed, and then switch to normal. The KTU-10 model is aggregated with the Belarus tractor.

The equipment is loaded with feed mass evenly. To distribute feed, you must turn on a special operating mode, and the gear lever must be moved to 1st or 2nd gear.

To use the feed dispenser as a transport device, the ratchet mechanism must be activated, and for self-unloading, a special arrangement of pawls and discs is used. This agricultural machinery allows you to regulate the supplied feed mass by changing the speed of the conveyor.

At sub-zero temperatures, the feed dispenser must be kept in a warm room to avoid the formation of ice on conveyors and other moving mechanisms.

Design Features

The RKT-10 feed dispenser is built on the chassis of a 2PTS-4.5 tractor trailer, or on the chassis of a PPTS-4.5 semi-trailer. It is aggregated with a wheeled tractor with a traction class of 1.4 t (which is preferable, but 0.9 t is also possible), equipped with a separate hydraulic system; having a towing device in accordance with GOST-2349, as well as special terminals for connecting the brake pneumatic system and electrical equipment.

In terms of design, the RKT-10 feed dispenser is a tractor semi-trailer with sides made of rolled profiles. A dispenser with one-sided unloading is produced under this name; double-sided is called “RKT-10/01”. In the RKT-10/02 modification (with a twin axle, on balancers), both axles with wheels are located in the middle of the semi-trailer, next to each other. Modification “RKT-10/03” is uniaxial.

Option "RKT-10/2".

The drive of the beaters and the unloading mechanism is carried out from the PTO - tractor power take-off shaft, 540 rpm. The electrical equipment of the unit is a single-wire DC system with a voltage of 12 Volts, powered by the tractor. The trailer is unloaded and the feed mixture is distributed using a working conveyor. The grinding mechanisms are two transversely located beaters, which are located directly in front of the unloading conveyor.

We recommend reading: Clutch: device, principle of operation