Advantages and features of feed dispensers

To simplify work on the farm, feed dispensers are now increasingly being used. The owner of an enterprise may consider it advisable to purchase such expensive equipment if his farm contains a large number of animals.

The unit has the following advantages and features:

- Grinds and prepares (if necessary) feed for livestock according to their needs.

- The mechanism has built-in dispensers that regulate the amount of food supplied to the animals. Serving size calculations can be determined by measuring the volume or weight of the food.

- Modern feed dispensers have a function that determines and regulates the temperature of the feed. Also, some types of units are connected to monitors, so you can monitor the preparation of food for livestock.

All these functions increase the cost-effectiveness of keeping the herd by controlling feed consumption. According to statistics, using such technologies it is possible to increase the percentage of annual cow milking by ten percent.

Mobile feed dispensers

To distribute coarse and succulent feed, mobile tractor feed dispensers with body hoppers mounted on the chassis are mainly used. Due to their versatility, ease of maintenance and high performance, these feed dispensers are mainly used on cattle farms. Mobile feed dispensers can increase labor productivity by approximately 5 times compared to stationary feed dispensers.

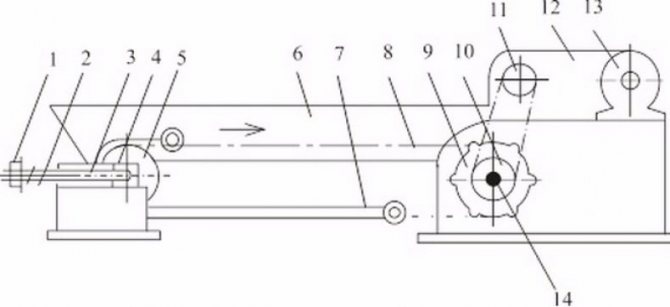

Feed dispensers KTU-10A

(Fig. 14.) are designed for transporting and unloading into feeders on one or both sides of pre-crushed coarse and succulent feed, root tubers, pulp and feed mixtures. It can also be used for transporting silage, haylage and other feed.

The main assembly units of the feed dispenser: frame with chassis 4, body 3 with bottom 2, beater unit 1, longitudinal 5 and transverse 6 conveyors, drive with cardan 7, linkage 8, kinematic transmissions, braking device and electrical equipment. Two-axle feed dispenser, aggregated with MTZ type tractors.

Chassis

The feed dispenser consists of a welded frame, front and rear axles with springs and four pneumatic wheels and a towbar. The rear wheels are equipped with hydraulically driven shoe brakes, which are controlled from the tractor driver’s cab.

Body

all-metal, with a hinged tailgate. The underbody is made in the form of a metal frame and covered with boards. Two pairs of bushing-roller chains slide along the boards, to which stamped transverse metal strips are attached, forming two longitudinal conveyors.

Drive shaft

The conveyor is located in the front part of the body and rotates in four plain bearings. It is driven into rotation from the lower beater shaft through a crank mechanism.

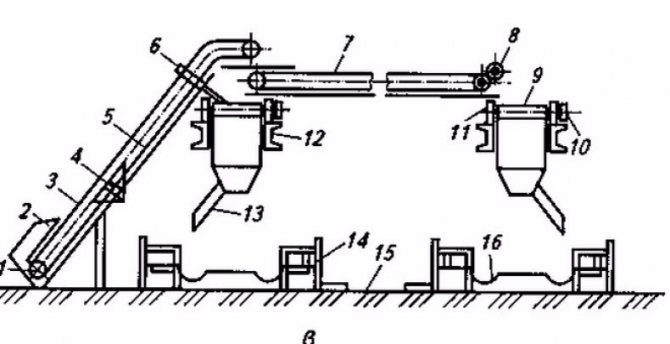

Figure 14 — Tractor universal feed dispenser KTU-10A:

- 1 — beater block; 2 — bottom (base of the body); 3 — body; 4 — chassis with air brakes and spring suspension; 5, 6 - longitudinal and transverse conveyors; 7 — distributor drive with cardan;

- 8 - spoke

Read also: Amateur selection variety Yubileiny Tarasenko

Dispenser

consists of a block of beaters and an unloading (transverse) conveyor. The beaters rotate in bearings mounted on the sides of the body.

The working parts of the dispenser are driven from the tractor power take-off shaft through the cardan shaft of the feed dispenser.

Types of feed dispensers

Since farming business is popular in our country, you can see very different feed dispensers on the market. It is not profitable to use them at home. However, in large industries they are necessary.

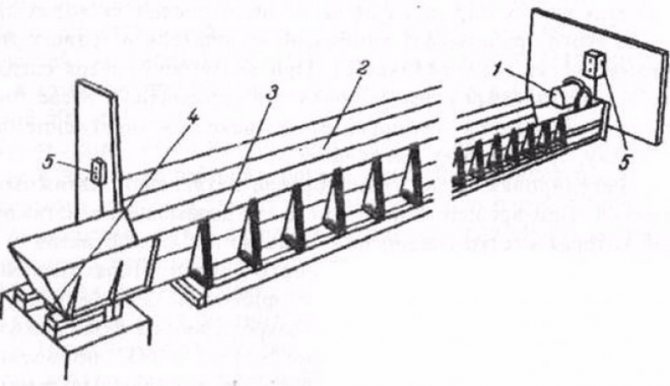

Stationary feed dispensers

Stationary unit

Stationary mechanisms for distributing feed are distinguished by the fact that they must be mounted directly in the barn, without the possibility of further transportation.

The units operate using electric motors.

Stationary mechanisms can be belt, belt-slat, belt-chain or scraper type.

The main functions of such feed dispensers are to supply portions of feed into a container provided for this purpose. With the help of a transformer, food is transported and distributed throughout all pens.

Examples of the most common feed dispensers in our country:

- KRS mechanism – 15.

- TVK dispenser – 80B.

- Single-sided tape KLO – 75.

- Tape double-sided CLC – 75.

- Dispenser used on dairy farms, RK – 50.

Mobile feed dispensers

Mobile feed distributor

Mobile distributors distribute and supply dry and green feed to livestock.

Semi-liquid nutrition is provided using special mixers (often purchased from pig farms).

The mobility of the mechanism is explained by the fact that it distributes feed from the bunker, and distributes it to the feeders of all pens of the farm using dispensers, which are equipped with the function of independent movement.

The mobility of mixers working with liquid and semi-liquid mixtures is relative. This is explained by the fact that units of this type move along special tracks pre-installed on the floor surface. They can carry out their mission exclusively in one building.

An important advantage of this type of dispenser is that they mix liquid or semi-liquid feed before serving it to livestock. Thanks to this function, all animals receive food of uniform consistency.

Among the mobile feed dispensers that have earned a good reputation in our country are:

- Unit RS – 5A.

- Mechanism KS – 1.5.

- Dispenser KSP – 0.8.

- Universal action unit KTU – 10A.

- Small RMM – 5.0.

- Mixer RSP – 10.

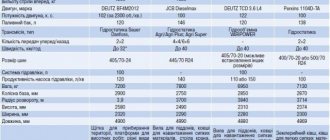

Technical characteristics and descriptions of popular models

When choosing a feed dispenser, you should take into account its characteristics. They are common for all types (productivity, feed supply speed, volume of the working hopper) and specific.

For stationary dispensers, this is the belt speed and power consumption. For mobile devices, this is the transported weight, the speed of movement during transportation and distribution, the turning radius, and overall dimensions. Both types of models are popular.

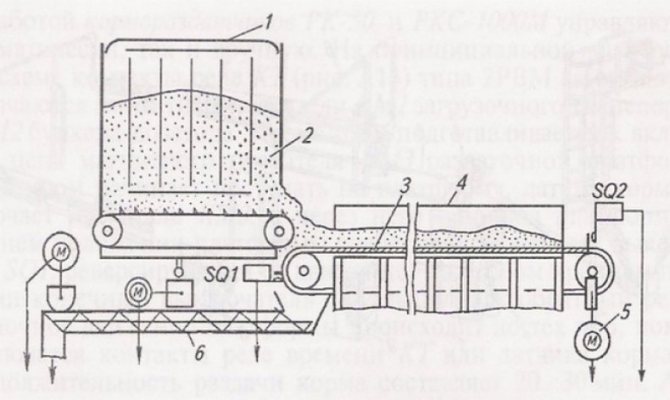

Stationary

Stationary feed dispensers are used either on large farms with feed workshops, where it is necessary to automate and optimize feed supply as much as possible, or on small farms, where it is impossible to use mobile dispensers due to the size of the premises and feeders.

The drive is supplied from an electric motor through a gearbox to a chain that drives the belt. The feed from the receiving hopper is evenly distributed with a tape along the entire feeder, after which an automatic switch installed on one of the circuit elements is activated.

Its parameters:

- feeding front length - 74 m;

- productivity - 38 t/h;

- serviced livestock - 62;

- electric motor power - 5.5 kW.

Their use is most effective in barns adjacent to the feed shop - this avoids overloading of forage, gas contamination of the premises, and ensures an optimal microclimate. KRS-15 is a stationary scraper feed dispenser for dry crushed and succulent stalked feeds, such as silage, hay, green mass, and feed mixtures.

The working part is a chain-scraper conveyor , located inside the fence, driven by an electric motor. Forage is fed from a hopper or mobile dispenser into a fence and then distributed along a chute using scrapers. The drive switches off when the first scraper has completed a full revolution.

Its parameters:

- feeding front length - 40 m;

- productivity - 15 t/h;

- livestock served - 180;

- electric motor power - 5.5 kW.

There are two versions of this model - for 100 and 200 heads with one and two conveyor-distributors, respectively.

Read also: Features of caring for ampelous pelargonium at home

Its main elements are an inclined conveyor, a transverse conveyor, one or two distributor-conveyors and a control unit. Each conveyor has its own electric drive.

The conveyor-distributor is a belt conveyor half the length of the feeder, which moves along guides, located along the feed aisle at a distance from 1600 mm to 2600 mm from the floor.

The stern passage should not be wider than 1.4 m. It is driven by a steel cable wound on drums. The speed of movement is regulated by changing gears in the transmission gearbox, changing five positions.

Food enters the receiving container of an inclined conveyor, and from it is fed to a transverse conveyor located horizontally in the center above the dispensing conveyors. It directs the feed to the first or second conveyor-dispenser. Using a rotating tray, it is directed into the feeder to the right or left of the feeding passage.

Its parameters:

- feeding front length - 75 m;

- productivity - 3–30 t/h;

- livestock served - 200;

- electric motor power - 9 kW.

Technical characteristics of RMM 5.0:

- load capacity - 1.75 t;

- Bunker volume - 5 m3;

- productivity - 3-38 t/h;

- feed rate - 0.8-16 kg/m (number of steps - 6);

- length - 5260 mm;

- width - 1870 mm;

- height -1920 mm;

- base - 1 axis;

- track - 1.6 m.

It combines a mixer equipped with a two-speed multiplier, a feed mixer and a feed dispenser. In essence, this is a mobile feed workshop that allows you to mix, prepare and distribute feed.

Thanks to its single-axle base, ground clearance and size, it is quite maneuverable and has good maneuverability. Aggregates with TC class 1.4 tractors, including MTZ-82 and MTZ-80 tractors.

Technical characteristics of AKM-9:

- bunker volume - 9 m3;

- preparation time - up to 25 minutes;

- productivity - 5 - 10 t/h;

- feed rate - 0.8–16 kg/m (number of steps - 6);

- length - 4700 mm;

- width - 2380 mm;

- height - 2550 mm;

- base - 1 axis;

- passage width - 2.7 m;

- rotation angle - 45°.

Upgraded Technologies

Distributing feed on the farm

Feed dispensers will allow you to create a competent diet for cows.

The dose can be administered by volume and weight of the portion.

The second case involves the use of scales.

Powerful, high-tech equipment is used to feed large herds with healthy food.

This technique will allow you to regulate the cooking temperature and time. In addition, you can change the intensity of mixing, as well as the degree of grinding.

Cost-effectiveness is an inherent advantage. This will prevent large losses of feed mixtures. Statistics show that it is possible to increase the productivity of one individual by 500-1000 liters if costs are reduced to 7%.

Feed dispensers for cattle are designed for all types of feed. The advantage of the stationary type is its simple design, small dimensions, and the ability to be used in small rooms where mobile equipment cannot be used.

Mobile equipment can be used within one room. The hopper is moved using built-in rails or wheels throughout the barn.

Mixer dispensers have many of the same characteristics. Mixing equipment is built into the bunker, and food dispensing devices are connected to it. The dispensers can be controlled using a control panel, and the device is powered by a flexible cable.

You can purchase such models both in online stores and in markets. The cost of each model depends directly on the capabilities and functions. Of course, models that can dose and select food are more expensive than simple analogues.

In addition, the time spent, which is so necessary in a large farm, will be reduced. Without special equipment, keeping and breeding livestock would be difficult.

The video shows a feed dispenser-chopper for cattle farms: