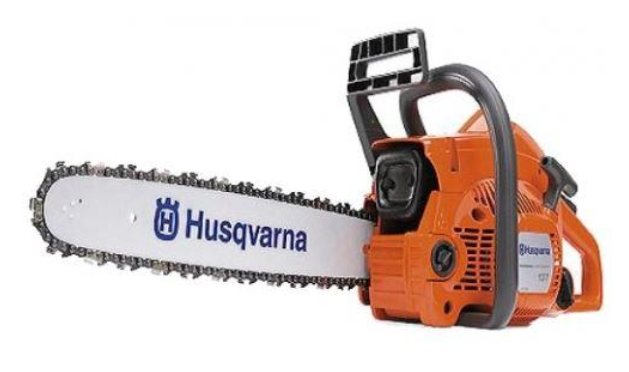

The device of the Husqvarna 137 chainsaw

Among the advantages of the Husqvarna 137 chainsaw is its simplicity of design. The model is powered by a reliable gasoline engine with a volume of 36.3 cm3. An effective forced air supply system is responsible for its cooling. To refuel Husqvarna 137, its device provides large reservoirs for fuel and oil. Recycled gases from the engine cylinder are sent to the muffler, from where they enter the environment.

A tire with a length of 33 to 38 cm is responsible for cutting wood. A chain is installed on it with a pitch of 0.325 “. To adjust the tension of the saw chain, the Husqvarna 137 device has a tension screw.

The controls of the chainsaw are represented by a button to turn the ignition on and off, a gas lever and a mechanism for adjusting the throttle position. All switches are located at the rear of the tool, close to the operator's hands. Also at the rear of the Husqvarna 137 there are 2 handles and a starter cable.

To protect the feller, the chainsaw is equipped with a guard that prevents damage to the right hand. To stop the tire in the event of a kickback, the tool is equipped with an inertial chain brake.

All internal mechanisms of the chainsaw are protected by a durable plastic case. It withstands drops and light impacts of the tool on hard objects.

The design of the Husqvarna 137 chainsaw is designed in such a way as to give the operator free access to the main consumables of the tool. This allows you to easily replace worn parts directly in the field.

Characteristics

In terms of efficiency, the Husqvarna 137 can be compared to the Stihl 180 chainsaw. Each chainsaw had its dedicated fans. Each owner presented valid facts in favor of owning their saw, and they were right. Both had their pros and cons. However, the Stihl 180 remained, and the 137 was replaced by a Husqvarna 236 chainsaw.

Basic technical conditions:

- Engine type: internal combustion engine, gasoline;

- Engine capacity: 36.3 cc Cm;

- Engine power: 1.64 hp / 2.2 kW;

- Fuel tank capacity: 419 ml;

- Oil tank capacity: 200ml;

- Tire length: from 33 to 38 cm;

- Chain pitch: 8.25 mm (0.35 in);

- Weight: 4.6 kg.

From the given characteristics of the engine and the saw set (tires, chains) it is clear that the chainsaw belongs to the class of fans. It is quite powerful and allows you to cut tree trunks with a diameter of up to 40 centimeters on hemp without much effort.

For those who are still interested in listening to a professional opinion on the comparison of chainsaws from competitors: Stihl 180 and Husqvarna 137, we recommend watching an interesting video.

Technical characteristics of the Husqvarna 137 model

Among the advantages of the Husqvarna 137 chainsaw are its solid technical characteristics.

These include:

- power – 2.18 l. With.;

- maximum torque – 13000 rpm;

- fuel tank capacity – 370 ml;

- oil tank capacity – 190 ml;

- recommended tire length – 33–38 cm;

- chain pitch – 0.325 “;

- weight with cutting element – 5 kg.

Thanks to its good characteristics, the Husqvarna 137 chainsaw can be used not only in private households, but also in forest felling. The tool is good at cutting branches, removing and clearing old bushes and cutting down trees with a pole diameter of up to 40 cm.

Business date, meeting

According to its parameters, the saw is designed to solve everyday problems. Thanks to its light weight, compact size and low price, it is ideal for small jobs: cutting firewood, boards, cutting tree branches, cleaning trees and shrubs on the site.

READ Why the Electric Saw Saws Crookedly

By the way, the chainsaw was in great demand among road workers due to its compactness and reliability. This was ideal for long periods of tree trimming on city streets.

Despite the amateur class, the chainsaw has been and remains very popular among loggers, as it is ideal for small jobs when collecting firewood.

Adjusting the carburetor of the Husqvarna 137 chainsaw with your own hands

For the efficient operation of Husqvarna 137, correct carburetor settings are very important. This tool assembly must be adjusted in cases where the saw does not start, is unstable, or consumes a significant amount of fuel.

In this case, you will need to perform the following steps:

- First, you will need to install the saw on a flat surface and lay it on its side;

- After this, you need to turn the screw all the way, which regulates the engine idle speed;

- Next, you will need to turn this screw 4.5 turns counterclockwise. After this, you need to make sure that while the motor is running in this position of the screw, the saw chain does not rotate;

- If the saw chain moves along the bar, you need to continue turning the screw slowly. Each time it is re-checked, it must not travel more than 1/16 of a turn.

After completing all of the above steps, you will need to start the chainsaw and give it about a minute to warm up. If the carburetor is adjusted correctly, the engine of the tool will operate much more stable, and the amount of fuel it consumes will be significantly reduced.

How to Adjust Idle Speed on Husqvarna 137

Content

Adjusting the carburetor on a Husqvarna chainsaw

Chainsaw Husqvarna (Husqvarna) 137. carburetor adjustment.

The best advice I can give you is to contact the specialists! Believe me, for very little money, specialists will adjust the carburetor and check the general condition of the saw. If you still need to adjust the carburetor on the Husqvarna 137 saw without the help of others, then I will try to carefully outline this common rumor process. Also, at the end of the post, I added a video on how to adjust the carburetor of a chainsaw at idle speed.

Adjusting and tuning the Husqvarna 137 carburetor

husqvarna137.carburetor adjustment

In the picture above you can see three screws for adjustment. They have their own skill and purpose:

Screw T is needed to adjust idle speed.

Screw L is used to adjust low speed.

Screw H regulates the highest speed.

Adjustment procedure:

First, using screw L (rotating it), we look for the highest idle speed. When we have found them, we need to turn this common rumor screw a quarter turn counterclockwise. If in this position the chain continues to spin, then by rotating the screw T we achieve its stop.

Then we warm up the engine at full speed for about 10-15 seconds and turn screw H a quarter counterclockwise. We wait 10 seconds and listen - the engine should sound like a 4-stroke. If a squeal is heard, then the mixture is lean (unscrew the screw), if the mixture smokes rich (tighten the screw).

After adjusting the low and high speeds, we set the idle speed with screw T. This is done like this:

1.The engine must be running

4.5. Rotate screw T clockwise until the chain begins to rotate.

3. Rotate the screw in the other direction until the chain stops.

With a properly adjusted carburetor, your chainsaw develops rapidly and sounds just like a 4-stroke engine.

Remember that to properly adjust a chainsaw carburetor you need a tachometer and experience. Therefore, it is better to contact a special service!

READ Carburetor Husqvarna 128r Carburetor Adjustment

Do-it-yourself carburetor adjustment on a chainsaw

Adjusting the chainsaw carburetor ensures efficient operation of the tool at operating power with economical fuel consumption. The adjustment must be performed with a clean fuel and air filter. For a larger number of carburetors, adjustment is carried out with 3 screws: for high and low speeds and idle speed .

Screws H and L adjust the ratio of the mixture of gasoline and air, determined by the opening of the carburetor throttle valve. When the screws are unscrewed, the mixture becomes richer, and the speed drops accordingly; when the screws are tightened, the mixture becomes leaner - the speed increases.

The designation H refers to the maximum speed screw that controls the main jet, L. to the minimum speed screw that controls the idle jet. Using screw S, the idle speed is precisely adjusted. Sometimes, to simplify setup, the number of available carburetor adjustment screws is reduced.

Setting up a chainsaw carburetor is divided into two stages - basic (factory settings), carried out with the engine turned off. and the final one, performed with the engine running and warm. The exact value of the rotation angles should be taken from the operating instructions for the specific chainsaw. Failure to follow manufacturer's instructions may result in engine damage.

Basic carburetor adjustment.

The adjusting screws for maximum H and minimum L revolutions are slowly turned clockwise until they stop, and then turned back 2 turns; other settings are also possible

Carburetor adjustment!!!Husqvarna 137-142 AntiReg!

Hare to feed the Chinese and rednecks!!! Disassemble and clean the carburetor, change dry diaphragms, twist etc.

How to properly adjust the carburetor on a Husqvarna chainsaw

How to tune the carburetor on a chainsaw Husqvarna

Adjusting the carburetor on a chainsaw using three THL screws.

Checking and adjusting idle speed.

We find the highest idle speed, to do this we slowly turn screw L in different directions. After finding the position of the highest engine speed, turn screw L 1/4 turn counterclockwise. If the chain rotates at idle speed

, screw T or (S) should be turned counterclockwise

until it stops.

READ How to Refill a Chainsaw Partner

Checking and adjusting the maximum speed.

Changing the maximum number of revolutions is carried out by screw H. When it is screwed in (clockwise rotation), the speed increases, when turned out. are decreasing. Chainsaw engines have the highest rotation speed from 11,500 rpm. up to 15000 rpm. A higher speed is not ensured by the ignition, in addition, it becomes dangerous for the engine. Limit speeds can be determined by interruptions in ignition. If they advance, screw H is turned slightly counterclockwise

arrows.

If the engine operation is not checked for acceleration and maximum speed, then the adjustment of the chainsaw cannot be considered complete.

When you smoothly press the gas trigger, the engine should confidently and quickly pick up speed from idle to maximum speed (from 2800 rev. to 11500-15000 rev. depending on the unit). If the speed is gained slowly, with a delay, screw L must be slowly turned counterclockwise, but no more than 1/8 of a turn.

After adjusting the acceleration and maximum speed, you should again check the operation of the saw at idle speed. The engine must run steadily and the chain must not move. The chainsaw adjustment must be repeated if this condition is not met, except for the basic adjustment stage.

Adjusting the chainsaw carburetor

The carburetors of most chainsaws have three screws for adjustment:

- L – jet screw for low speed adjustment

- H – jet screw for high speed adjustment

- Screw. T at Partner and Husqvarna (at Shtil LA ) - adjusting the idle speed of the chainsaw

Screws H and L adjust the ratio of the mixture of gasoline and air, determined by the opening of the carburetor throttle valve. When the screws are unscrewed, the mixture becomes richer, and the speed increases accordingly; when the screws are tightened, the mixture becomes leaner - the speed drops.

READ Husqvarna 137 Chainsaw Carburetor Maintenance And Adjustment

The T(LA) screw is designed to adjust the idle speed. The basic adjustment of the chainsaw is made at the manufacturer during the final test. The carburetor is usually adjusted to supply a richer (than optimal) fuel mixture. The factory setting must be maintained for the first hours of operation of the saw. Then (optional) more precise adjustment of the carburetor is made.

We begin the adjustment by adjusting the idle speed; to do this, rotate the T screw (LA) counterclockwise, achieving a complete stop of the chain at stable engine speeds.

For further precise adjustment, you will need a tachometer and it is better to entrust it to specialists. especially since in most cases it may not be needed.

We start setting up the tool with screw L, then use screw H and finally screw T (LA).

We find the highest idle speed, to do this we slowly turn screw L in different directions. After finding the position of the highest engine speed, you must turn screw L 1/4 turn counterclockwise . If the chain rotates at idle, screw T should be turned counterclockwise until it stops.

Screw H regulates power and speed. Adjusting the carburetor to a lean mixture leads to excessive speed, engine overheating and failure of the piston chainsaw.

Warm up the chainsaw engine at idle speed for at least 10 seconds and turn screw H 1/4 turn counterclockwise. Let the engine run for about 10 seconds. then we check the maximum engine speed with a tachometer. If the maximum speed does not correspond to the specifications, the operation should be repeated. When the mixture is supplied too rich, the muffler begins to smoke; when the mixture is too lean, the saw squeals and overheats.

We complete the adjustment by adjusting the idle speed, as already described above. The idle speed is set correctly if the engine runs smoothly at minimum speed and the chain does not rotate.

Source

Chainsaw malfunctions and their elimination

There are typical faults that owners of the Husqvarna 137 model most often encounter. In order to be able to fix them yourself, you need to study the signs of their occurrence and effective methods for repairing them.

The chainsaw stalls at full throttle - how to solve the problem?

The cause of this breakdown is most often the spark plug flooding at the moment when the engine begins to quickly gain speed. To fix the damage, you should unscrew and clean the spark plug, and then dry it completely. Next, you need to drain the remaining fuel through the spark plug hole. At the end, you need to screw the spark plug back into place and try to start the tool again.

Another common cause of failure is lack of spark. Repairs should begin by inspecting the contact between the high-voltage wire and the tip of the spark plug. If the contact is not broken, and the saw still stalls when you press the gas, then you should inspect the electronic ignition unit. This unit cannot be repaired, so it will have to be replaced entirely.

Replacing the Husqvarna 137 sprocket

It is necessary to change the Husqvarna 137 sprocket if, when the engine reaches medium speed, the engine begins to stall.

As indicated in the operating instructions, the procedure should look like this:

- First you need to remove the cylinder cover and unscrew the spark plug;

- Next, you need to take a plastic or metal stopper for the motor piston, as well as a key for dismantling the centrifugal mechanism. Using a key, you need to twist the centrifugal mechanism in the direction in which the chain rotates;

- Then you need to inspect the clutch disc. If only the sprocket is faulty, then only it needs to be replaced. If the entire clutch disc is completely broken, along with the springs and cams, then the entire disc will have to be replaced;

- After this, you need to install a new clutch disc. To clamp the centrifugal mechanism on the motor shaft, you will need to unscrew the piston stopper and pull the starter cord towards you. Then you need to screw the stopper all the way;

- Next, you will need to clamp the centrifugal mechanism with a key in the direction against the rotation of the chain.

After completing all of the above steps, you will need to start the saw and let it idle for 1-2 minutes. This is necessary to warm up the engine and grind in the new clutch disc. You can then continue working with the tool.

Chainsaw Husqvarna 137, model description

Currently, the Husqvarna 137 chainsaw has been discontinued, but it still remains a competitive tool with high performance, durability and maintainability (the owner of the equipment, who has all the necessary spare parts, can perform the necessary repair and adjustment work with it, with his own hands). This modification of the chainsaw is successfully used for sawing logs and boards (longitudinal, transverse and diagonal cuts), trimming tree crowns, trimming branches, and in construction.

READ Assembling and Disassembling the Motoblock Gearbox

Commissioning the Husqvarna 137 chainsaw

To ensure long-term operation of your Husqvarna chainsaw, you need to follow a number of simple steps:

- Assemble the device.

- Install the headset, pull the chain.

- Prepare the fuel mixture and refuel the chainsaw.

- Pour fresh oil into the oil tank.

- Start the chainsaw as described in the manual.

- Check the serviceability of the brake system.

- Check the saw at idle speed and adjust the carburetor if necessary.

- Make sure that the oil supply to the circuit is in the correct quantity.

- Husqvarna 137 chainsaw tested.

READ Tire for Electric Saw Parma M

The fuel mixture consists of high-quality AI-92 gasoline and original Husqvarna engine oil for two-stroke engines in a ratio of 50/1, where 100 ml of engine oil per 5 ml of gasoline.

Chainsaw works

The breakthrough period lasts 10 hours. During this time, it is not recommended to load the tool; the load should not exceed half the power of the power plant. During the breakthrough period, the moving parts of the power plant start up. If the tool is overloaded, the piston may become stuck, damaging the power source and therefore the chainsaw itself.

About malfunctions

If you have finally made your dream come true and purchased for your farm such an indispensable assistant as the Husqvarna 137 chainsaw, then it’s time to familiarize yourself with all possible breakdowns and methods for eliminating them.

After all, as they say, you need to be prepared for anything and a breakdown can occur at the most inopportune moment. Today, there are a huge number of workshops that repair this type of equipment, but it takes time to get your chainsaw in working order and you will also have to pay a certain amount for the service.

But, you must agree that it is much more economical and easier to repair the Husqvarna 137 chainsaw with your own hands. In fact, if the damage is not significant, then there is no point in spending money, and you can easily fix the damage. And so that in such cases you at least have an idea of what’s wrong with your instrument and how to perform “first aid,” below we will provide all the most common malfunctions and instructions for repairing Husqvarna 137.

In this video you can see disassembly instructions:

The device does not start - the ignition system is faulty

If you encounter a chainsaw malfunction, the first thing to do is check the spark plug. But this must be done very carefully, using a special hook to first disconnect the wire. The most important thing you should pay attention to is the appearance of the candle itself.