Rotary drilling ↑

The rotary method is one of the most common. The operating principle of the installation is the transmission of rotational motion to the drill string via a rotor. Drilling is accompanied by flushing or blowing (more often and simply - flushing) to remove destroyed rock from the bottom. Water or clay solution is used as a flushing agent. The method loses its effectiveness or economic feasibility in areas with a shortage of water and clay.

The lifting equipment that raises and lowers the drill string is mounted on the tower, like other elements of the rig. An internal combustion engine is used as a motor - sustainer or deck (separate or from the car). The drive transmits rotation from the engine to the rotor. The rotor converts the rotation of the shaft into rotation of the rotary table. The kelly pipe of the drill string is fixed in the table. Along the drill string, rotation is applied to the bit. The working edges of the bit destroy the rock.

The drill string receives only rotation from the rotor and retains freedom of axial movement to maintain an extended position (to avoid bending of the barrel). To ensure proper pressure on the bit, weight pipes are present in the drill string - they create a force over the bit, while simultaneously maintaining the string in an extended position.

The flushing composition flows through the hollow pipes of the column to the bit nozzles. The liquid is supplied under pressure, it erodes the soil and brings it to the surface through the annulus (the gap between the column and the shaft). The composition enters a special pit, where it is cleaned, and then the pump pumps it back into the column.

The choice of flushing composition and bit material depends on the rock being penetrated. Clay solution is used in loose rocks, and clean water is used in rocky rocks. An alternative is blowing, but it requires a tank of compressed air.

Rotary drilling is a high-speed method, it is suitable for almost all rocks. This is “almost” insidious: everything can be ruined by a banal boulder, brazenly located underground, and the walls of the trunk, actively absorbing the flushing solution. In winter there are also difficulties - the liquid freezes.

Small-sized installation for rotary drilling ↑

Regardless of the base (autonomous equipment or transport-based), size, weight, the installation consists of:

- towers,

- engine,

- drive,

- rotor,

- drill string,

- swivel,

- pressure line,

- pump,

- liquid return systems after cleaning,

- lifting equipment.

Rotor installation diagram

We offer the service of auger drilling of wells using drilling rigs

Buy Larsen sheet pile Drilling for sheet pile Rental of a KamAZ-based pit drill Leader drilling

You can order auger drilling of wells from our company. We carry out drilling work in Moscow and the Moscow region .

The variety of well drilling technologies makes it possible to accurately select the required method, which will be the optimal solution in terms of the quality of penetration, the time and materials spent, and, accordingly, the cost. Auger drilling is used if there is a need to drill a well in soft and loose rocks, where it will be ideal in all respects.

In this case, a well can only be drilled to a depth of 50 m, less often to 80 m with a diameter of 60-800 mm. Auger drilling technology is mainly used to form wells for blasting operations when the task is to carry out geological exploration or engineering surveys during exploration of certain types of minerals.

You can order auger drilling from our company

Prices for zero cycle work and equipment transfer are the lowest in the region.

For any questions call: 8 800 707-72-09

Shock-rope method ↑

The advantages of shock-rope installations are considered to be long service life, wear resistance and simplicity. If simplicity still passes for a virtue, then wear resistance and service life have no meaning for an individual citizen who wants to drill a well on his site with his own hands. He needs this installation for one time, and then let it go to dust. The simplicity of the design has its place, but not without sacrifices, and time was sacrificed - you can pick the ground with a drill glass all summer. The method and equipment are suitable for those who have a lot of strength, but no work. But a small-sized installation can be done with your own hands, without having special skills or engineering education.

The installation for drilling using the percussion-rope method consists of:

- tripods,

- block,

- drilling tool (glass/bailer),

- winches,

- cable

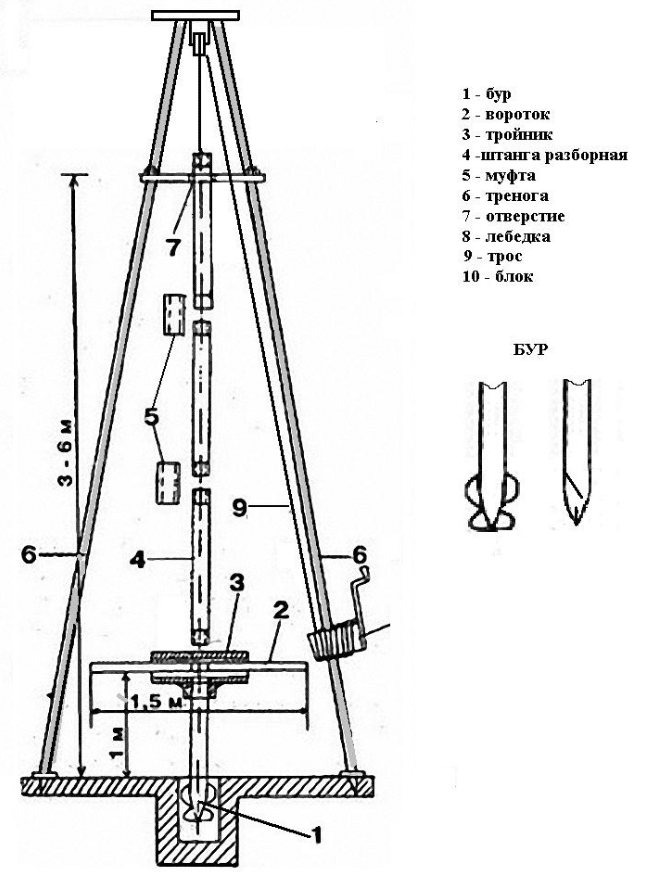

Small-sized installation for percussion-rope drilling ↑

To make a small-sized installation for percussion-rope drilling, you need to acquire a welding machine, a drilling rig, a block, a winch (optional), a cable, pipes: 3 for the frame (triangle on the ground), 3 for the legs. First, a triangle is welded, then pipes are welded to it, connected into a pyramid without a base. The block is mounted at the top (under the junction of the tripod pipes). A rope is attached to the glass/bailer and thrown over the block. Next, everyone chooses for themselves: to work exclusively with their hands or to entrust the honor of lifting the glass to the winch.

The principle of operation is amazingly simple: the drill bit is lowered into the barrel under its own weight and filled with soil (cuts the rock with sharp edges); it is removed to the surface, released and lowered back into the barrel. That's how they drill. In loose soils that do not want to linger in the glass, a bailer is used - it closes as it is filled, and the rock does not spill out. The signal to use the bailer is to raise the empty glass several times in a row.

The design can be made not triangular, but rectangular, that is, not three legs, but four. It can only be considered small-sized only conditionally - it will require a decent height.

It must be taken into account that on the way there are not only frogs and moles, but also treacherous aquifers, forcing you to interrupt the already tedious drilling process and install a casing pipe. In addition, each rock can be “taken” with a drill glass; rocky ones are destroyed with a chisel. Having stumbled upon rocks, you will have to drill in another place, and how many times this will happen is unknown in advance (they drill with their own hands when they are saving money, and they save money primarily on geological research). This is where the working resource of the installation comes in handy (we shouldn’t waste it and return it to advantage). Jokes aside, the method has existed since ancient times, and it is not abandoned - very high-quality wells are obtained. However, despite its simplicity, we do not recommend doing it yourself - the time and physical costs are too great.

Hydraulic drilling rigs - small-sized, functional equipment

Choosing a small, but truly effective and functional drilling rig is quite simple. First, you need to decide what it is needed for. If this involves drilling soft and medium-density soils, then you can save money and buy an electric or manual drilling rig. However, if you need a truly multifunctional unit, then you should pay attention to hydraulic drilling rigs.

Screw method ↑

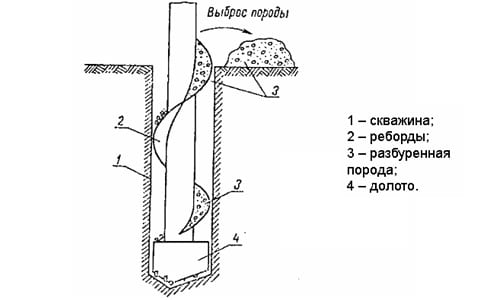

The screw method is a rotary method. They use a drill of a special design - destroying the rock, it feeds it to the surface along spiral blades.

Scheme of operation of an auger drill

Installation diagram

In the process of drilling on the simplest rigs, the drill is increased as it goes deeper.

The drilling rig is equipped with a rotation mechanism. We do not recommend performing the exercise with manual rotation of the drill - it would be better then with a glass.

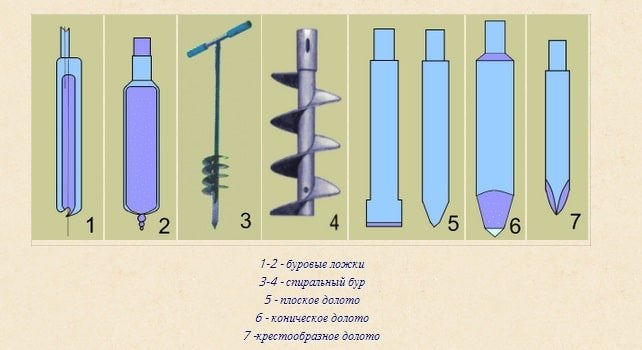

For independent citizens, there are difficulties - choosing the right drill (depending on the breed).

Auger drills

Video: drilling a well with a small-sized drilling rig ↑

Main types of homemade drilling rigs

Most of the self-made drilling rigs are manually driven, but the efficiency of such devices is quite low. They can only be used for constructing wells of insignificant depth (mainly wells for sand) in fairly soft rocks and soils.

Therefore, it is worth giving preference to units with a mechanized drive; they are capable of providing sufficient productivity and can be used for drilling wells of sufficient depth.

The most commonly used installations are those using the following drilling technologies:

- Small-sized installation for percussion-rope drilling.

- Auger drilling rig for drilling wells (works without flushing the well).

- Rotary installations, drilling of which is carried out with mandatory flushing of the well, ensuring the removal of crushed rocks to the surface.

Small-sized drilling rigs ↑

Small-sized drilling rig - “what’s in my name?” If you imagine a tripod with a small glass for independent attempts to turn the area into a colander, the association is completely wrong. Of course, there are tripods, including for percussion-rope drilling, but besides them, in the vast expanses of villages, “babies” on tracked chassis, based on a tractor and trailer, and autonomous (mobile, lightweight) are successfully working.

Autonomous block installation ↑

Stand-alone block installation

A small-sized block installation, equipped with a 15-horsepower engine (or winches) and a hydraulic drive (750 or 1500 Hm), is capable of drilling a well to a depth of 50–150 m (blowing/flushing). The unit is easy to transport/carry. It is transported in a regular car trailer.

There are different installations - for percussion-rope, rotary, auger drilling. The equipment is widely used in drilling sand wells and Abyssinian wells.

Based on a trailer ↑

Car trailer

The installation, developed on the basis of a car trailer, is powered by a 50-horsepower (or 60 hp, depending on the configuration) diesel engine. The engine can be air or liquid cooled. In addition to water intake wells, exploration wells are drilled with such installations. The equipment is used in various construction and geological works.

Car based modification

On a tracked chassis ↑

Track mounted installation

The installation on a crawler chassis is equipped with a diesel engine and hydraulic drive. In addition to drilling wells, the equipment is used in the construction of pile foundations (specifically for mechanized installation of piles) on insufficiently strong soils. The crawler track provides maneuverability to the unit and allows it to work in places where equipment on a conventional wheelbase simply cannot pass (especially heavy ones).

Based on a tractor ↑

Tractor-based installation

The tractor-based installation is highly specialized; it is suitable for rotary drilling of wells with a depth of no more than 3 m. The equipment is used in areas where soil conditions leave much to be desired. The installation is equipped with a hydraulic drive. Working tool - auger or drill.

To develop one well, purchasing a mechanized small-sized drilling rig does not make sense (it will be more expensive than a turnkey well from specialists). Equipment can be rented (it’s not difficult to find leasing, but for this form of cooperation you need to be at least an individual entrepreneur), but in any case you need to be able to handle it. What are the advantages for the average consumer of services (not counting those who will cook tripods)? The fact is that the “babies” work great in hard-to-reach places, plus the site will not be destroyed by heavy equipment. The well will be drilled where it is needed, and not where it will work out.

Application

Drilling rigs exist:

- Manual.

- Mechanical (using various types of equipment).

- Automated.

Even during the ancient Middle Ages, people tried to somehow facilitate the installation of piles and peculiar anchors. Thin pillars were “screwed” into the ground under pressure from above from various heavy loads. Several centuries later, a device was invented in the form of an auger, to which a U-shaped handle was attached. This is how the first manual hole drill was born, which is often used in our time at home.

There is also a design for manual drilling of shallow wells, consisting of pipes - usually 50 mm in diameter - with grooves for joining each other and a sleeve with a special crown - approximately 100 mm at the end. At a level of two meters above the ground, a kind of cross is attached, acting as handles on which a load is suspended, evenly distributed on the sides.

Water is gradually poured in from above for better movement of the pobedit teeth of the crown, and a circular movement is made using a cross. Under the pressure of gravity, the sleeve gradually bites into the ground. As you dive, the pipes are built up and the handle is transferred.

This is how the process of manual drilling of water wells occurs when an underground stream is shallow. But this method is now practically not used due to the large investment of time and labor. There are now many drilling rigs that can do the same job in less time and reach much greater depths.

MGBU are considered a real leap in technological progress. With the help of such installations, drilling has become possible even in places inaccessible to large drilling rigs. In the 21st century, most people open their own business in this business. To do this, you only need to have a car (it is advisable to start with a Gazelle) and an electric generator. You also need to know basic geology lessons and have a set of attachments (crowns) for various types of underground soil. And of course, an important element is the mini-drilling rig.

Such structures are erected within 15-25 minutes, take up very little space when disassembled, and only two people are needed for this work. You can purchase MGBU only in specialized stores or construction centers, but if you wish and have the necessary materials, such a unit can be easily assembled with your own hands.

For drilling water wells, a 100 mm diameter pipe and a bit with pobedit teeth are usually used to drill hard sandstone or limestone. Similar installations are also used in agriculture. The only difference is that for small holes, an auger drill is selected, designed on the frame of a large machine. In this case, the pressure is produced using the hydraulic drive of the vehicle itself (usually a T-150 tractor or a Ural truck).

The main positive and negative qualities of MGBU

Small-sized water drilling rigs are considered the most popular product among stationary and self-propelled types of machines. The advantage of a mini-installation over these types is the following:

- The possibility of simple and convenient transportation, as well as the small dimensions of the assembled product.

- The operation process does not require special attention; repair and maintenance of the machine is quite simple; this work is carried out at the drilling site.

- Possibility of using the unit in places where there is limited space.

- Quite low cost of the device when compared with stationary or self-propelled types.

- It is possible to carry out all the work with even unprofessional workers on site. The number of required personnel is 2 people.

Among the disadvantages, it is worth highlighting that the average power of the engines is quite low, and therefore drilling a well more than 100 meters deep is impossible.

Installation device

The main advantage of a small-sized drilling rig is that it can be used without hiring specialists. Installation, configuration and further operation of the unit are quite simple, and therefore almost anyone can handle it. The equipment consists of the following main elements:

- Drill barrel with fork. These two parts are the main ones for installing the fixture. Due to the fact that this is the only support for the installation, it is necessary to carry out installation only on the terrain that has been previously well compacted so that the drill does not sag.

- Next, there is a drill bit, which is the key element that carries out all drilling operations.

- An additional device is a conical lock. This element is designed to make it possible to remove and change the drill bit if the situation requires it.

- Side drains are used as guiding mechanisms, which set the direction of movement for the drill.

- The small-sized drilling rig is equipped with a very durable winch, which is responsible for lowering the drill to depth.

- The heart of the equipment is an electric motor, which converts kinetic energy into rotational and translational motion of the drill.

- The machine control panel is equipped with only two buttons - on/off. There is protection from moisture, and therefore there is no need to cover it with anything, even if it is left in the open air.

Popular models

A small-sized drilling rig, the price and quality of which are ideally correlated, allows users to resolve the issue of constructing a well. Domestic-made units are very popular among consumers.

To drill a well up to 70 m deep, users choose the RB-50/220 unit. This is piston equipment, the cost of which is from 80 thousand rubles. If you want to create wells up to 100 m deep, you should give preference to the RB100/380 model. The motor power is 4.2 kW. This is professional type equipment. The price of this unit is about 120 thousand rubles.

For small wells up to 15 m deep, you can purchase an auger drill UBK-12/25. The price of new equipment is from 200 thousand rubles.

If you want to use the installation not only for creating water wells, but also for installing piles and laying out foundations, you should purchase PM-23 equipment. The cost of the equipment is 110 thousand rubles.