The Bobcat S175 loader, the technical characteristics of which allow it to maintain consumer demand for a long time, belongs to construction machines and accounts for 60% of such equipment purchased in Russia. It was this brand that became the founder of other loading equipment with a large frame. The boom of these units is raised using a three-point mechanism - unique of its kind. Bobcat S175 mini loaders are distinguished by high performance with modest dimensions. This equipment is also characterized by a long service life - every detail and build quality allow the machine to be used for work of varying complexity for a long time.

Features and Benefits of Bobcat S175

The Bobcat S175 mini loader belongs to the SSL line, which is supposed to have skid steer. If models have the designation H and HF, this means that such machines are equipped with more powerful hydraulic attachments. The latest models include the Bobcat S series loader, which features an improved cab and operator safety system.

The unit is used for more than 30 types of work in such areas as:

- municipal services - dumps, sand spreaders, scrapers, brushes are attached to the loader, which helps in cleaning city streets at different times of the year. If it is necessary to carry out landscaping work, trimmers, blades, mowers or grapples are installed on the machine. In order for a forklift to become a mini-excavator, its working part is changed. Bobcat S175 can also be used for uprooting stumps.

- agriculture - here loaders are successfully involved in operations for moving and transporting feed, hay, they are used for cultivating and cultivating land;

- construction sites - for this type of work the machine is equipped with a drill, circular saws, trencher, concrete pump, hydraulic shears.

Benefits of buying genuine Bobcat tires

The catalog of our online store contains only tires of proven quality designed for Bobket mini loaders and other brands. All popular and special sizes are available, as well as different tread patterns, so you won’t have any problems with the choice.

In addition, when purchasing such tires from us, you are guaranteed to receive a number of advantages, including:

- Durability

. High-quality tires from manufacturers such as Mitas, Solideal, Petlas, etc. will last a very long time - on average three times longer than products from other brands. This is achieved through the use of ultra-strong rubber compounds and the introduction of a number of other innovations.

- Smooth ride.

In high-quality tires, the damping force is calculated to the smallest detail, so this parameter will be at the optimal level regardless of the ambient temperature and the type of road surface under the wheels. But good shock absorption is the key to the safety of the suspension.

- Robust design

, not destroyed due to overloads. The durability of tires largely depends on how durable they are, because at certain periods any rubber experiences significant overloads. We supply only high-strength tires that can withstand any test.

- Side protection.

One of the hallmarks of high-quality tires is their high-strength side walls, protected from mechanical damage. Practice shows that these parts are the most vulnerable, and serious manufacturers have long taken care of eliminating this defect.

- Tread development

. The ability of the tire to “cling” to the surface, that is, the controllability and speed of the vehicle, largely depends on the quality of its pattern. Our rubber ensures confident movement on all types of substrates, regardless of their characteristics and humidity.

- Balanced weight.

Tires for mini loaders from TM Bobcat and other TOP manufacturers are on average heavier than other models. This was done intentionally - to increase strength and improve wheel balancing, thereby reducing the level of operating vibrations.

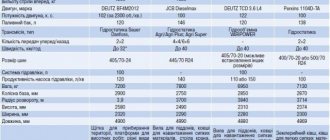

Technical characteristics and dimensions of the Bobket mini loader

The Bobcat S175, whose technical characteristics allow it to be stable on any surface, maneuverable in very limited spaces, and capable of loading onto tall vehicles, owes its thanks to these developers. The total weight of the machine is 2853 kg with a maximum load capacity of 895 kg. The tipping force of the machine is 19 tons. And the ground clearance is 19.1 cm. The forklift can move at a maximum speed of up to 18 km/h. The bucket equipment reaches a height of 3 meters.

The dimensions of the Bobcat S175 are as follows:

- height – 2 m;

- length – 3.3 m;

- width - 1.73 m.

The engine is a 4-cylinder and 4-stroke unit, the power of which is 50 l/s at 37 kW.

It is produced in Japan, which largely explains the impeccable quality with high environmental friendliness of the exhaust (within the Tier 4 standard). Engine cooling type is liquid. Diesel is used as fuel. Tank volume - 90 liters. The equipment, thanks to the coolant, is able to maintain its functionality under any conditions. Engine maintenance is simplified due to the design of one-sided access. Cooling of the unit is ensured by the lowered position of the installed fan. A muffler with a spark arrestor ensures a long service life and eliminates the need to frequently change parts.

Preheating the spark plugs is responsible for the high-quality operation of the unit at any time of the year, even at sub-zero temperatures. The dry cassette performs the function of an air filter and requires replacement at intervals specified by the technical operating conditions.

Design features of tires for mini loaders

The name Bobcat has long been a household name for mini loaders. The point is not only in the authority of the manufacturer itself, but also in the fact that its equipment appeared in our country as one of the first in this category of special equipment. And this happened back in the 70s of the last century. The modern line of models covers machines for a wide variety of industries. Therefore, it is not surprising that almost each of them requires its own type of tire, differing not only in tread pattern and seat size, but also in design.

Thus, it is customary to distinguish between the following types of tires:

- Solid cast

. They are characterized by increased strength and a high level of resistance to punctures, cuts and other mechanical damage. But these are hard rubber, intended for use indoors and on flat open areas.

- Pneumatic

. Provides optimal levels of shock absorption and handling, as well as a smooth overall ride. Designed for universal use, including on uneven surfaces and rough terrain.

- Chamber

or

tubeless

. The former are distinguished by slightly higher strength and increased maximum load capacity. The latter are easier to install, and also provide an improved level of controllability and shock absorption, which allows you to save suspension life. It should be noted that modern tubeless tires, compared to tube models, have approximately half the probability of puncture due to the special cord design.

Bobcat Loaders

American technology has always been famous for its power and versatility.

This is exactly how one can characterize almost all of Bobcat’s equipment, and especially the loaders produced by the company. The original idea of creating a universal machine for all spheres of life has undergone some changes, and the bulk of the products produced are basic machines, which, in accordance with the wishes of customers, are equipped with a wide variety of equipment. As a result, the buyer receives exactly what he needs, and the manufacturer and service centers receive the same platform, which is quite easy to maintain and for which spare parts are easy to obtain. There are several areas that the company has been actively working on over the past few decades. The most popular option are light and medium-sized loaders on wheels, crawler tracks or combined ones. At the same time, as mentioned above, it is possible to install almost any attachment available in the company’s range on new and used machines. Unification and adherence to our own standards make it possible to easily install additional equipment even in an ordinary auto repair shop, if, of course, it is close to the type already installed, for example, changing the blade to a bucket or auger installation. The same applies to the chassis - the company officially supplies devices that significantly increase the maneuverability of wheeled vehicles, for example, anti-slip chains, which are relevant in our climate, or special tracks that are put directly on the wheels using special spacers.

The use of light and medium-sized Bobcat loaders with a wide variety of attachments has had great success in Russia. There are quite a lot of current additional devices that significantly increase the efficiency of using Bobcat equipment in the everyday life of a big city.

A traditional bucket is installed where the procedure for loading, unloading, clearing sites, and so on is needed. Buckets are distinguished by maximum volume and shape, however, installing too large a bucket on unsuitable equipment will significantly complicate its operation. In the case of a telescopic boom loader, adding a larger bucket is a great way to increase the efficiency of the loader.

Installing a blade allows the loader to clear fairly large areas of debris, snow, soil, level and prepare them for the construction and covering of roads, and so on. This is a universal tool that is indispensable during heavy winter snowfalls.

To combat snow, you can also use special snow blowers. They allow you to easily remove snow from roads and paths by throwing it to the side. For this, a special installation is used, which is driven by the loader engine, so before purchasing this type of equipment, you need to make sure that your equipment provides the ability to connect such equipment.

Another easy-to-replace installation is the various cleaning brushes. There are four types of brushes, differing in the presence or absence of a hopper for collecting debris and a humidification system that allows you to give the cleaned area a fresh look.

Another type of attachment used in everyday work is special loading tools. These include forklifts that allow you to unload and move specially formed and packaged cargo on a wooden pallet around a closed and open warehouse, as well as means for loading pipes, logs and other round objects. The last type of attachment requires a hydraulic drive for its operation.

A special boom with a backhoe, also powered by a hydraulic drive, will help turn the loader into a real excavator. It allows you to use the loader as an excavator, although with very low excavation efficiency, but very mobile and passable. There are also special folding booms that take up minimal space when prepared for transportation.

The modular design of Bobcat equipment allows you to temporarily or permanently change the purpose of your existing equipment to perform a narrow range of tasks. By purchasing a Bobcat, you acquire quality, ease of operation and maintenance, and an assistant that is very unpretentious to external conditions. The equipment is available with gasoline and diesel units, equipped with or without turbines, as well as with an electric drive - for light loaders designed to work in enclosed spaces to protect workers from the suffocating effects of engine exhaust.

Post Views: 1,661

Mini loader maintenance

Operating a Bobket C175 mini loader, like operating any special equipment, requires the necessary operating skills. This model is equipped with all the necessary resources for comfortable, safe and hard work. This includes hydraulics, which allows you to work with heavy loads, a fairly comfortable and well-protected driver’s cabin. The Bob-Tach system allows you to easily and quickly change attachments to others that are needed at the moment. The last and rather weighty word in the safety of the loader is the BICS system. In case of violations of the operating standards of the mini loader, the system blocks the device controls to avoid emergency situations at work. All loader performance indicators are monitored using modern tracking sensors. Due to the fact that the special equipment is equipped with all modern control sensors, the operator’s work is greatly facilitated. In addition, all assigned tasks can be completed much faster and with better quality.

Required Resources

Buying a new mini loader makes it possible to protect yourself from various unpleasant moments associated with breakdowns. When purchasing for a certain period of time, a warranty is issued, which makes it possible to carry out repair work free of charge. After the warranty period has expired, all necessary spare parts can be purchased directly from the service center. You can also order them from suppliers. With timely maintenance, you can protect your equipment from serious breakdowns.

Application of Bobcat S175 in the modern world

The Bobket mini loader has found wide application in the modern world. These are such areas of human activity as the public utilities sector, agriculture and agro-industrial complex, construction and road construction. In agriculture, the loader is used as a feed dispenser for animals, a stacker of hay in bales and rolls, a baking powder, a cultivator, and so on. At a construction site, the loader is used for digging trenches, drilling holes, dusting asphalt, and excavation work.

In total, the Bobket C175 loader model has more than 60 functionalities that are provided by attachments. The utility sector has also found its application for this loader. This includes clearing snow, spreading salt and sand, and chipping ice. Bobcat S175 is a fairly broad-profile device. Today, the price for a Bobcat S175 loader ranges from 1 to 1.5 million rubles.