Design Features

If you are the owner of a country house or a summer cottage, then you certainly have to deal with grass, weeds and unnecessary shrubs.

Lawn grass is quite easy to remove with a regular garden lawn mower , but unfortunately, such equipment will not be able to cope with large weeds, shoots and bushes.

Important! Do not use wheel trimmers to control large weeds; they are intended solely for cutting grass. Otherwise, the device will quickly fail.

In this case, you need to use special mowers designed for cutting taller and denser grass. Thanks to the features of this technique, it can easily rid you of unnecessary growth on the site.

Types of mowers for walk-behind tractors

There are several types of mowers , a detailed description of which will be given below:

- rotary;

- segmental;

- mower-cart.

Each type of equipment has its own characteristics and is designed to perform work of a certain complexity.

Rotary

A rotary lawn mower is an ideal option for a summer cottage. Its operation is based on the principle of a scythe: thanks to the rotation of the built-in legs at high speed, a fairly powerful air flow is formed, which draws the grass into the structure or throws it in the other direction.

- Electrical. The advantage of such a device is noiselessness and environmental friendliness. The mechanism is quite lightweight, low cost, and easy to operate. The downside of the tool is that it is connected to an outlet or other power source. As a rule, such mowers have little power. An electric device may be suitable for owners of small lawns.

- Gasoline. With such a unit you are not afraid of any thickets or territories. The mower has high power and is not connected to a power source. The disadvantages of the model include heavy weight, noise during operation and, of course, exhaust gases.

Did you know? The simplest mower, the trimmer, was invented in 1971 in the USA, Texas.

To make the right choice between two types of lawn mowers, you need to think carefully about the purposes for which you need the device and what areas you plan to process.

You will also need a lawn mower on the site. You can use it to mulch the lawn, and in case of a breakdown, you can repair the lawn mower yourself.

Segmental

If you need to get rid of tall grass, you should use this type of mowing machine . Thanks to the segmented knives and the features of the device, the grass is cut evenly, which allows it to be evenly laid on the surface.

The power level of this type of device ranges from 3 to 6 horsepower. This type of equipment has a working width of up to 120 cm. Some models can be equipped with special mechanisms that allow operation at 7 speeds.

The device is capable of combating weeds whose stems are up to 3 cm thick. Thanks to the presence of adjustments, you can set the mowing height parameter. There are several types of adjustments:

- stepped: you need to set a specific height from those proposed;

- smooth: it is possible to choose a height that is within the limits established by the manufacturer.

Important! Protect yourself before using the mower: check that the bolts that secure the blades and discs are securely tightened.

Mower wagon

This type is the most interesting. It can safely be called universal, since its characteristics allow the tool to be used in summer and winter.

In the winter season, the mower will easily cope with the functions of a snow blower. With this tool you can mow tough grass and remove ice crust.

Popular rotary mower models

Among the various models of mowers for walk-behind tractors, the most popular are Zarya in various configurations and modifications and KM-0.5 Terminator for Caiman Vario, Pubert Quatro Junior, MB-2 and MB-23 Neva, MB-1 Oka, “Mole”, “Ray”, “Favorite”.

Let's take a closer look at the characteristics of these models.

Mower KM-0.5 Terminator

Rotary mower KM-0.5 Terminator

The small mower KM - 0.5 is aggregated with walk-behind tractors "Vario" and "Junior" (Caiman Vario, Pubert Quatro Junior), MB-2, MB-23 Neva, MB-1 Oka, "Mole", "Favorite", "Luch" » trailed method. The rotor is covered on all sides with a protective casing made of durable metal. After mowing, the grass is crushed, so it is suitable for processing lawns.

Technical characteristics of KM - 0.5:

| TX KM 0.5 | Indicators |

| Working width | 50 cm |

| Grass cutting height | 5 cm |

| Allowable operating speed | 0.5-4 km/h |

| Equipment weight | 35 kg |

Produced at the Chuvash Machine-Building Plant, in Moscow at Agromash. The price from the manufacturer starts from 12,500 rubles.

Pros:

- Availability of spare parts;

- Manufacturer's warranty 3 years;

- Service centers are located in all major cities.

Of the minuses:

- Mulches grass, so is not suitable for making hay;

- Does not work well on uneven terrain with slopes greater than 20 degrees.

“I took the KM 0.5 rotary mower for the Neva walk-behind tractor and did not regret it. The lawn in front of the house is always smooth and neat. The only drawback is the one-piece body. It’s difficult to store a massive mower.”

“The KM 0.5 mower pleases with the quality of work with the Neva walk-behind tractor. It cuts grass well, but it doesn’t always pass between bushes and fruit trees.”

Mower "Zarya" for walk-behind tractors Neva MB-2, MB-1, MKM-3 Lander, Mole, Favorite

The mounted model of a small rotary mower has two working discs with knives on hinges. Produced in Kaluga at the Kadvi machine-building plant. Mows the grass and folds it to one side. Suitable for farmers who keep livestock. The model is lightweight and small in size. Convenient to store and transport.

Mower "Zarya"

Let's look at the technical characteristics of Zarya in the table:

| TX "Zarya" | Indicators |

| Working width | 80 cm |

| Cutting height | Up to 10 cm |

| Allowable operating speed | 2-4 km/h |

| Equipment weight | 25 kg |

Suitable not only for the Neva and Krot and Favorit walk-behind tractors, but also for small MTZ tractors with 10-12 horsepower. Spare knives are included in the package from all manufacturers, which ensure uninterrupted operation of the equipment during the season.

The advantages of the Zarya model include:

- Compactness;

- High performance;

- Light weight;

- Wide grip;

- Simplicity of design;

- Manufacturer's warranty 3 years;

- Spare knives included.

Of the minuses:

- The working parts are not completely covered with a protective casing;

- Not suitable for all walk-behind tractors.

- Knives have to be sharpened frequently.

“The Zarya mower showed itself well when preparing hay for livestock with the Neva walk-behind tractor. I prepared food for the cow for the whole winter. The job was completed 10 times faster.”

“Zarya” didn’t like it with the “Mole” walk-behind tractor, because when mowing hard, dry residues of vegetation, it often became clogged and dull. There is no protection from stones.”

The price of Zarya mowing equipment starts from RUR 13,700. In winter you can buy from dealers at a good discount. Used models cost from 6,000 rubles.

Mower Zarya-1

Rotary mower "Zarya-1"

A special model from the Kaluga Machine-Building Plant “Kadvi” is designed for the NMB-1 Ugra, “Mole” and similar walk-behind tractors with the same connection. The model has two working bodies with knives made of hardened steel. Convenient adjustment allows you to mow fields with any landscape.

The technical characteristics of the model are presented in the table:

| TX "Zarya-1" | Indicators |

| Working width | 80 cm |

| Cutting height | Up to 10 cm |

| Allowable operating speed | 2-4 km/h |

| Equipment weight | 35 kg |

It differs from Zarya in the way it is connected to a walk-behind tractor and has high performance. The design is weighted, so the grass is cut more evenly. Suitable for small agricultural complexes. It is aggregated with MTZ-80 mini tractors. Easily copes with dead bushes, sunflowers and corn.

The advantages stand out:

- Low price;

- Reliability and durability;

- Easy to maintain;

- Mobility due to low weight.

One of the disadvantages is the insufficient number of service centers in the regions.

How to make a rotary mower: step-by-step instructions

very popular lately .

If you have the desire and time, you can make a good unit yourself. We suggest that you familiarize yourself with the instructions for constructing a rotary mower.

Required material and tools

Before you start making a lawn mower, you need to prepare the following materials and parts of the future device:

- disk from a grain seeder - 2 pcs;

- chain from a chainsaw gearbox - 1 pc.;

- knives made of hardened metal - 8 pcs;

- tavern;

- opener

Among the tools you may need:

- screwdriver;

- pliers;

- nuts;

- carbide drills;

- drill.

Did you know? Because of its design, the mower-cart was popularly called “horse-mounted.”

Once the materials and tools have been prepared, you can proceed directly to assembly.

Process description

First of all, you will need to drill a hole on the disks using a carbide drill with a diameter of 6 mm. Then you need to attach the shredder to the opener, and the knives to the shredder.

Please note that the distance between the shredder and the knife should be several mm greater than the thickness of the knife. This moment is very important and necessary so that with the help of centrifugal force the knives are straightened from the disk, which would ensure the performance of the main function - mowing the grass. A prerequisite is the rotation of the knife 360°. This will protect it from damage when colliding with stones or hard objects.

To make the knife fastening axes, you will need carbon steel, the diameter of which must be at least 8 mm. It is necessary to tighten the axle until it stops using a disk.

There will be no difficulties in assembling the rotary mower if you strictly follow the recommendations.

Features of the rotary model

Rotary mowers have a simple design, which makes them easy to maintain and repair. The working bodies are disks on which knives are mounted. They are attached to the disks using movable hinges. There can be from one to several disks. The more working disks, the wider the surface area to be processed.

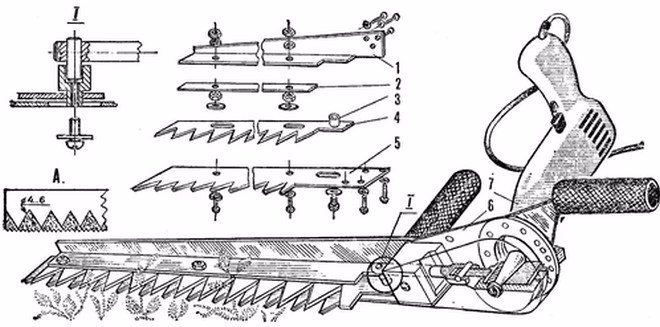

Mower blades

The price of spare parts and components is low. Spare parts for our models of rotary mowers can be purchased at any specialized store. Imported models no older than 10 years old are no worse serviced. Mowers older than 10 years old, imported, may not have spare parts, since some models are no longer produced.

The owner of a rotary mower can easily improve the lawn in front of the house and store grass for the winter for livestock. A small model is convenient for a walk-behind tractor when cleaning areas around fruit trees and beds.

Rotary mowers are produced here and also abroad. Among the largest and most popular models, mowers for walk-behind tractors “Neva”, “Zarya”, “Krot”, “Favorite” stand out. Models differ in the number of working parts and adjustment of the grass cutting height. To harvest grass for animal feed, you can use models with a height of up to 20 cm; in the local area, mowers with a cutting height of 5 cm have performed well.

The rotary mower can be combined with the Favorit, Krot, Neva walk-behind tractors in several ways:

- Front - hinged;

- The rear is trailed.

Reviews are better about mounted models for walk-behind tractors “Neva” and “Cascade”, “Mole”, “Favorit”. Their power is higher and it is easier to work with a walk-behind tractor, since the entire area being processed is visible.

Based on the method of cutting grass, rotary mowers are divided into types:

- For cutting grass and laying it in an even row. Suitable for cutting grass for hay.

- Mulching grass. Shredded grass rots quickly and is suitable for treating lawns.

Weighted model of the Zarya mower

When choosing a model for your walk-behind tractor “Neva”, “Salyut”, “Zorya”, “Favorite”, “Mole”, it is recommended to take into account the following factors:

Features of the landscape. Purpose of purchase (for cutting grass for hay for livestock or for leveling the lawn in front of the house). Weight of the mower (important when transporting, since a large model is difficult to transport). Performance (for a small lawn, the smallest mower with low power is enough). Type of grass cutting (models that mulch grass are not suitable for making hay for livestock feed).

Making a segment mower with your own hands

This type of device can also be made independently. Below we will tell you how to make a mower with your own hands .

What is needed for making

To make the device you need to prepare:

- metal beam 15x50x120mm;

- knives;

- disks;

- wheel.

In addition to the materials listed, prepare standard tools: screwdriver, drill, pliers, bolts.

Step-by-step instruction

To assemble the unit yourself, you must follow the instructions :

- holes are drilled in the metal beam that will fit the M8 bolt;

- check that each blade has a segment on the back;

- make sure that the blade has a clip for the drive lever;

- fix the knives on both sides of the beam;

- attach clamps and runners to the beams;

- install the wheel on the frame.

With the help of the walk-behind tractor shaft, the assembled mechanism will move, thereby rotating the knives. They can perform both rotational and back-and-forth movements.

It is thanks to this moment that thick stems of weeds will be easily cut off. Please note that they are not crushed.

Homemade mower-cart with your own hands

Using a riding mower, you can easily get rid of grass that has a wide stem. Let's look at the manufacturing features of the unit.

Materials and tools

To assemble the mower you will need:

- frame made of metal corners;

- 4 wheels;

- metal sheet or plywood (size 80x40cm);

- 2 cans;

- 8 metal discs;

- 4 blades;

- sleeve;

- drum;

- bolts;

- transport tape.

Did you know? The wider and larger the wheels on the mower, the less they damage the lawn and do not leave marks behind them.

Having the listed materials available, you can begin assembling the device using a standard set of tools.

Action List

We suggest that you familiarize yourself with the instructions for assembling the mower :

- Place a metal sheet on the frame.

- Install two cans without a lid or bottom onto the frame. Instead of the bottom, install metal disks, the outer diameter is 20 cm, the inner diameter is 17 cm.

- Connect the disks in pairs: fasten them with bolts.

- Attach the blades to the discs so that there is an equal distance between them, which would allow them to rotate freely.

- Insert the bushing into the drum part and secure it firmly to the frame.

- Place a sheet made of steel angles on the frame.

- Connect the drums. For this you will need a transfer tape.

- Fasten the lower drum bushing, and attach the corners to the latter.

At the final stage, you need to make sure that there is a protective element on the blade, after which you can install the assembled structure on the walk-behind tractor.

Proper installation of the mower on the walk-behind tractor

The newly purchased product must be correctly installed on the equipment in order to ensure the required performance and quality of workmanship. Let's look at the approximate order of assembly and installation using the rotary version as an example:

- We check the delivery contents (the set may differ from model to model, but, as a rule, this includes a drive belt, frame, fitting, fasteners, rotor cover, hydraulic hose, support slides, hydraulic cylinder, drive belt tension system, rotors with knives, spare parts);

2. We mount the frame to the walk-behind tractor mounts so that it is 45 degrees with the vertical plane and so that the splined parts look up;

We suggest you read How to impregnate plywood for moisture resistance

3. We install the rotors on the frame so that their knives are located at the bottom. It is important that they fit completely onto the slot;

4. Attach the rotor cover to the same slot;

5. We fix it with the attached cotter pins and nuts;

6. We install the tension system by pulling out the cotter pin and unscrewing the lock nut on the pulley. The next step is to carefully knock out the pulley so that the key does not get lost. When the system is correctly installed, its handle will be directed upward and secured with bolts from spare parts;

7. Next, we fasten the slides to the frame with bolts from spare parts so that their concave part faces inward;

8. We push the frame rings - they should be located outside the walk-behind tractor frame. After this, we finally connect the mower to the second one;

9. We throw the drive belt onto the pulley in the direction of travel. It is important that the walk-behind tractor and mower maintain alignment;

10. We install the hydraulic cylinder - hydraulic hose system (if such a connection is provided on the walk-behind tractor).

Upon completion of assembly, the product must be prepared for use:

- activate reverse on motorcycles;

- remove weights from the wheels (if any);

- put the engine at low speed;

- make a test run on a level area without interference, checking the quality of the result and, if necessary, adjusting the blades and speed.