General parameters of LBU-50 drilling rigs

The drilling machine is equipped with a mechanical drive. The equipment is mainly used for wells:

- used in the construction of a wide variety of objects;

- having a technical purpose;

- geological developments;

- designed for water intake.

The technique has a list of significant advantages:

- from the very beginning of work, the soil breaking tool experiences enormous pressure from a special device;

- during drilling, the rotator can be tilted away from the hole being made due to its unique configuration;

- the equipment is designed for installation of casing columns;

- The machine allows you to drill holes using the cable-percussion method, while simultaneously using a winch.

A minor disadvantage of drilling equipment is that it is driven by a motor from the transport base.

The LBU 50 drilling rig has the following serial models: 05, 07, 08, 10, 20.

The following can be used as optimal mobile bases:

- ZIL-131;

- URAL;

- KamAZ.

Photo of the LBU-50 drilling rig on a KamAZ chassis

With the drilling system you can do the following:

- make holes with augers up to 500 mm in size;

- form pits up to 850 mm;

- make wells using the rotary impact method with a diameter of 550 mm;

- drill holes using the flushing or blowing method with a diameter of up to 490 mm;

- with the dry method, the hole size reaches up to 172 mm.

Drilling rigs LBU 50: modifications, technical characteristics, photos and videos

The Russian company Geomash has earned credibility and popularity thanks to its reliable instruments for drilling wells. The head office of the plant is based in Moscow, and production lines are in the Kursk region.

The drilling machine is equipped with a mechanical drive. The equipment is mainly used for wells:

- used in the construction of a wide variety of objects;

- having a technical purpose;

- geological developments;

- designed for water intake.

The technique has a list of significant advantages:

- from the very beginning of work, the soil breaking tool experiences enormous pressure from a special device;

- during drilling, the rotator can be tilted away from the hole being made due to its unique configuration;

- the equipment is designed for installation of casing columns;

- The machine allows you to drill holes using the cable-percussion method, while simultaneously using a winch.

A minor disadvantage of drilling equipment is that it is driven by a motor from the transport base.

The LBU 50 drilling rig has the following serial models: 05, 07, 08, 10, 20.

The following can be used as optimal mobile bases:

Photo of the LBU-50 drilling rig on a KamAZ chassis

With the drilling system you can do the following:

- make holes with augers up to 500 mm in size;

- form pits up to 850 mm;

- make wells using the rotary impact method with a diameter of 550 mm;

- drill holes using the flushing or blowing method with a diameter of up to 490 mm;

- with the dry method, the hole size reaches up to 172 mm.

Design features

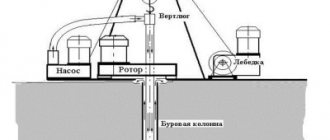

The machine is equipped with a mechanical drive device and a rotator, and the feed structure is driven by a mast, which is the guiding force.

The mast has a transport and working position. They are changed by hydraulic cylinders. The mast is also equipped with a single string rig, which is located at the top.

The drilling device has powerful headlights, thanks to which it remains operational in the dark. The entire system is controlled using reliable remote controls, which are located on the mast structure and on the frame. It is also important to create comfortable working conditions for the installation driver. For these purposes, the structure is equipped with a convenient removable platform.

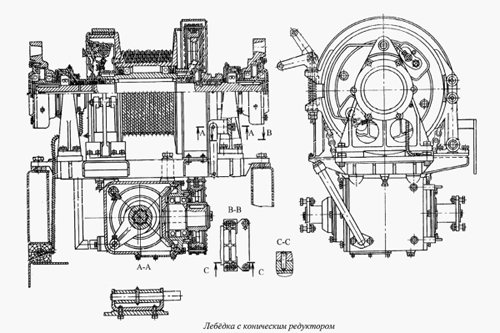

Drawing of the LBU-50 drilling rig winch

Basic equipment

In the basic version, the installation is equipped with the following equipment:

| Device | Unit measurements | Data |

| Drills with augers | mm | 135, 180, 230, 300, 330, 350, 400, 500 |

| Equal augers | mm | 200, 320, 470 |

| Augers with removable chisel | mm | 300 |

| Augers with sliding chisel | mm | 350 |

| Breaking Projectiles | mm | 121 |

| Set for shock-rope work: | ||

| — blow.-driving glass | mm | 89 |

| - impact-driving cartridge | mm | 108 |

| - casing system | mm | 127 |

| Dry working kit | ||

| Column device | model | SKS-127 |

| Blowing kit | ||

| Device for flushing work | ||

| Devices for continuous technology | ||

| Boers | mm | 650, 850 |

| Sliding augers | mm | 650, 850 |

| Pneumatic plunge hammers | mm | 550 |

Additional equipment for forming well systems

The installation is designed, if necessary, to work with the following equipment:

| Tool | Model |

| Pump | NB-50 |

| Compressors | PK-50 |

| Generators for welding | 500 |

| Two hydraulic jacks | |

| Winch | |

| Balance | |

| Desktop | |

| Casing table |

The technology for forming wells has several modifications:

| Equipment | 20 and 05 | 07 | 08 | 10 |

| Winch | + | + | + | + |

| Balance | + | — | — | — |

| Pump | — | + | — | — |

| Compressor | — | — | + | — |

| Generator | — | + | Optional | + |

| Front jacks | — | + | + | + |

| Rear jacks | + | + | + | + |

| Additional rear jacks | — | + | + | + |

| Loading platform | + | + | + | + |

| Driver's platform | — | + | + | + |

| Swivel | — | + | + | — |

| Clamping table | — | + | Optional | — |

| Desktop | — | Optional | + | + |

| The basis | ZIL, URAL, KAMAZ | KamAZ | KamAZ | KamAZ |

Photo of modification LBU-50-08

Technical characteristics of the LBU-50 drilling rig are presented in the table:

| Characteristics | Unit measurements | Indicators |

| Drive power | kW | 95-165 (depending on the chassis) |

| Innings | m | 3,25-3,9* |

| Top feed | kgf | 12000 |

| Bottom feed | kgf | 4000 |

| Frequency spindle | rpm | 14-101, 14-220* |

| Torque | kgm | 2000 |

| Load capacity of winch device | kgf | 2500 |

| Well depth | m | 16-200 (depending on drilling method) |

| Diameter of formed holes | mm | 190.5-850 (depending on drilling method) |

* - depends on the installation model

Video review of modifications of the LBU-50 drilling rig:

1 Comment

allspectech.com

Design features

The machine is equipped with a mechanical drive device and a rotator, and the feed structure is driven by a mast, which is the guiding force.

The mast has a transport and working position. They are changed by hydraulic cylinders. The mast is also equipped with a single string rig, which is located at the top.

To provide mobile drilling rigs with stability and balance, the machine is equipped with hydraulic jacks.

The drilling device has powerful headlights, thanks to which it remains operational in the dark. The entire system is controlled using reliable remote controls, which are located on the mast structure and on the frame. It is also important to create comfortable working conditions for the installation driver. For these purposes, the structure is equipped with a convenient removable platform.

Drawing of the LBU-50 drilling rig winch

Basic equipment

In the basic version, the installation is equipped with the following equipment:

| Device | Unit measurements | Data |

| Drills with augers | mm | 135, 180, 230, 300, 330, 350, 400, 500 |

| Equal augers | mm | 200, 320, 470 |

| Augers with removable chisel | mm | 300 |

| Augers with sliding chisel | mm | 350 |

| Breaking Projectiles | mm | 121 |

| Set for shock-rope work: | ||

| — blow.-driving glass | mm | 89 |

| - impact-driving cartridge | mm | 108 |

| - casing system | mm | 127 |

| Dry working kit | ||

| Column device | model | SKS-127 |

| Blowing kit | ||

| Device for flushing work | ||

| Devices for continuous technology | ||

| Boers | mm | 650, 850 |

| Sliding augers | mm | 650, 850 |

| Pneumatic plunge hammers | mm | 550 |

Additional equipment for forming well systems

The installation is designed, if necessary, to work with the following equipment:

| Tool | Model |

| Pump | NB-50 |

| Compressors | PK-50 |

| Generators for welding | 500 |

| Two hydraulic jacks | |

| Winch | |

| Balance | |

| Desktop | |

| Casing table |

Drilling rig LBU-50 is the leader of Russian drilling production

The Russian company Geomash has earned credibility and popularity thanks to its reliable instruments for drilling wells. The head office of the plant is based in Moscow, and production lines are in the Kursk region.

General parameters of LBU-50 drilling rigs

The drilling machine is equipped with a mechanical drive. The equipment is mainly used for wells:

- used in the construction of a wide variety of objects;

- having a technical purpose;

- geological developments;

- designed for water intake.

The technique has a list of significant advantages:

- from the very beginning of work, the soil breaking tool experiences enormous pressure from a special device;

- during drilling, the rotator can be tilted away from the hole being made due to its unique configuration;

- the equipment is designed for installation of casing columns;

- The machine allows you to drill holes using the cable-percussion method, while simultaneously using a winch.

A minor disadvantage of drilling equipment is that it is driven by a motor from the transport base.

The LBU 50 drilling rig has the following serial models: 05, 07, 08, 10, 20.

The following can be used as optimal mobile bases:

Photo of the LBU-50 drilling rig on a KamAZ chassis

With the drilling system you can do the following:

- make holes with augers up to 500 mm in size;

- form pits up to 850 mm;

- make wells using the rotary impact method with a diameter of 550 mm;

- drill holes using the flushing or blowing method with a diameter of up to 490 mm;

- with the dry method, the hole size reaches up to 172 mm.

Design features

The machine is equipped with a mechanical drive device and a rotator, and the feed structure is driven by a mast, which is the guiding force.

The mast has a transport and working position. They are changed by hydraulic cylinders. The mast is also equipped with a single string rig, which is located at the top.

To provide mobile drilling rigs with stability and balance, the machine is equipped with hydraulic jacks.

The drilling device has powerful headlights, thanks to which it remains operational in the dark. The entire system is controlled using reliable remote controls, which are located on the mast structure and on the frame. It is also important to create comfortable working conditions for the installation driver. For these purposes, the structure is equipped with a convenient removable platform.

Drawing of the LBU-50 drilling rig winch

Basic equipment

In the basic version, the installation is equipped with the following equipment:

| Device | Unit measurements | Data |

| Drills with augers | mm | 135, 180, 230, 300, 330, 350, 400, 500 |

| Equal augers | mm | 200, 320, 470 |

| Augers with removable chisel | mm | 300 |

| Augers with sliding chisel | mm | 350 |

| Breaking Projectiles | mm | 121 |

| Set for shock-rope work: | ||

| — blow.-driving glass | mm | 89 |

| - impact-driving cartridge | mm | 108 |

| - casing system | mm | 127 |

| Dry working kit | ||

| Column device | model | SKS-127 |

| Blowing kit | ||

| Device for flushing work | ||

| Devices for continuous technology | ||

| Boers | mm | 650, 850 |

| Sliding augers | mm | 650, 850 |

| Pneumatic plunge hammers | mm | 550 |

Additional equipment for forming well systems

The installation is designed, if necessary, to work with the following equipment:

Modifications

The technology for forming wells has several modifications:

| Equipment | 20 and 05 | 07 | 08 | 10 |

| Winch | + | + | + | + |

| Balance | + | — | — | — |

| Pump | — | + | — | — |

| Compressor | — | — | + | — |

| Generator | — | + | Optional | + |

| Front jacks | — | + | + | + |

| Rear jacks | + | + | + | + |

| Additional rear jacks | — | + | + | + |

| Loading platform | + | + | + | + |

| Driver's platform | — | + | + | + |

| Swivel | — | + | + | — |

| Clamping table | — | + | Optional | — |

| Desktop | — | Optional | + | + |

| The basis | ZIL, URAL, KAMAZ | KamAZ | KamAZ | KamAZ |

Photo of modification LBU-50-08

Technical characteristics of the LBU-50 drilling rig are presented in the table:

* - depends on the installation model

You might be interested in: The best modular parquet in Moscow

magistraltrade.ru

Modifications

The technology for forming wells has several modifications:

| Equipment | 20 and 05 | 07 | 08 | 10 |

| Winch | + | + | + | + |

| Balance | + | — | — | — |

| Pump | — | + | — | — |

| Compressor | — | — | + | — |

| Generator | — | + | Optional | + |

| Front jacks | — | + | + | + |

| Rear jacks | + | + | + | + |

| Additional rear jacks | — | + | + | + |

| Loading platform | + | + | + | + |

| Driver's platform | — | + | + | + |

| Swivel | — | + | + | — |

| Clamping table | — | + | Optional | — |

| Desktop | — | Optional | + | + |

| The basis | ZIL, URAL, KAMAZ | KamAZ | KamAZ | KamAZ |

Photo of modification LBU-50-08

Technical characteristics of the LBU-50 drilling rig are presented in the table:

| Characteristics | Unit measurements | Indicators |

| Drive power | kW | 95-165 (depending on the chassis) |

| Innings | m | 3,25-3,9* |

| Top feed | kgf | 12000 |

| Bottom feed | kgf | 4000 |

| Frequency spindle | rpm | 14-101, 14-220* |

| Torque | kgm | 2000 |

| Load capacity of winch device | kgf | 2500 |

| Well depth | m | 16-200 (depending on drilling method) |

| Diameter of formed holes | mm | 190.5-850 (depending on drilling method) |

* - depends on the installation model

Technical characteristics of LBU-50

| VENDOR CODE | LBU-50 |

| FEED STROKE, MM | 3250 – 3900* |

| FEED FORCE, KGS: | |

| – UP | 12000 |

| - DOWN | 4000 |

| SPINDLE ROTATION FREQUENCY, RPM | 14-101; 14-220* |

| TORQUE, KGSM | 2000 |

| WINCH CAPACITY, KGS | 2500 |

| CONDITIONAL DRILLING DEPTH, M: | |

| – AUGERS | 60 |

| – AUGER DRILL | 25 |

| – WITH AN AUGER DRILL SLIDING ON THE ROD | 16 |

| – WITH WASHING | 200 |

| – WITH PURGE | 100** |

| DRILLING DIAMETER, MM: | |

| – AUGERS | 500 |

| – AUGER DRILL | 850 |

| – WITH RINSE (FINAL) | 190,5 |

| – WITH PURGE (FINAL) | 190,5 |

| – DOWNHILL HAMMERS | UP TO 550 |

Read also: How to cut horizontal borders with which tool

CO 2 drilling rig

The CO 2 mobile rig is a crawler-mounted drilling rig. Its main purpose is to drill wells no more than 30 m deep, which will be used for the construction of a pile foundation. In this case, the diameter of the well does not exceed 600 mm. But the manufacturer took into account the technology of forming piles with reinforced soles. Therefore, auger drilling of wells using CO 2 type machines makes it possible to drill holes for piles with expansion at the base. So the diameter of this expansion reaches 1600 mm.

The installation is based on a crane-type vehicle on which the equipment itself is hung. The latter is a drill core consisting of two parts. The carriage, electric drive and pipe-shaped guide are also located here.

The technology of auger drilling wells using a CO 2 type machine depends on the depth of the work being carried out.

- If the depth does not exceed 12 m, then the machine operates without extending sections of the drill column.

- If it is necessary to drill wells 12-22 m deep, then one section is pulled out.

- If the penetration is within 22-30 m, then sections are pulled out immediately.

It must be taken into account that the soil from the first 6 m of excavation, which appears on the surface, is removed manually. The soil from the lower layers is removed with a special device called a cleaner.

Here is the sequence of operations:

- begin drilling up to 6 m, clearing the soil that appears on the surface with shovels;

- as soon as the entire auger sinks into the ground, drilling is stopped and, using a winch, it is raised to the surface, moving it away from the drilling site;

- install an auger cleaner, which is used to immediately clean the tool from the soil;

- remove the cleaner;

- move the auger to the well and continue drilling.