GAZelle is a whole family of small trucks that are produced at the GAZ plant. The first car of this series rolled off the assembly line back in 1994. The GAZelle was assembled even in some CIS countries. In 2003, the car underwent a slight restyling, receiving more modern headlights, a radiator grille and a front panel. 2005 became a landmark year for the car plant, as the millionth GAZelle truck rolled off the assembly line. This car is loved by many due to the fact that to drive it you only need a category “B” license, because the permissible maximum weight does not exceed 3500 kilograms.

Advantages of the car

Most car enthusiasts know that the GAZ-3302 (GAZelle) is one of the most unpretentious cars on the Russian market. Its maintenance requires a minimum of costs, but still do not think that this car does not require any care at all. Practice has shown that most of those who complain about problems with their car simply handled it carelessly.

In fact, the GAZ-3302 is an excellent combination of not the highest price and excellent consumer qualities, which many models from competing manufacturers cannot boast of. This car has an excellent suspension that can be easily modified. GAZelle is an incredibly versatile and maneuverable car that can drive on most types of road surfaces. Even dirt will not stop the GAZ-3302. The photo below can prove this.

GAZelle overload

The first thing any GAZelle will certainly encounter when it gets into the garage of almost every Russian businessman is the daily overload of the car. Enterprising people try to squeeze literally all the juice out of the poor GAZ-3302, forgetting that its frame was designed by engineers for only one and a half tons of carrying capacity (of course, there is a small reserve).

By the way, the carrying capacity of a GAZelle van is even less, since the all-metal body also has a considerable weight. Many entrepreneurs do not pay attention to this, starting to load their car to the maximum, after which many complaints appear about problems with the car. In addition to the frame, both the transmission and the engine suffer.

The GAZ-3302 can handle an overload of no more than five hundred kilograms without any special difficulties, and only if this happens once or twice. But if you constantly overload the car, problems will begin.

First, the GAZelle springs will begin to “give up.” Of course, you can strengthen them, but this is also a double-edged sword: the springs will undoubtedly support a much larger load, but the car will significantly lose its smoothness. In addition, even the smallest bumps on the road will lead to the strongest jumps of the car. If, on top of everything else, the GAZ-3302 is driven overloaded on bad roads, then the frame of the car may not be able to withstand it. And this can end not only in the loss of time and money on repairs.

Making changes to the body structure

Some GAZ-3302 owners install a very high booth (about four meters high) on their car. At the same time, the owner does not take into account that an even greater load will be placed on the car frame. In addition, the car’s center of gravity shifts, which means that the GAZelle will begin to roll significantly when cornering, and the aerodynamics will not change for the better. Such body modifications should only be carried out by the manufacturer. In general, every driver should know that making changes to the design is a violation of technical regulations, that is, it is unlikely that it will be possible to pass a technical inspection legally.

Design features of the gearbox of the GAZelle-3302 car

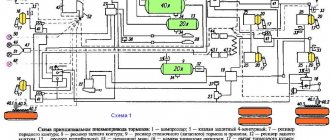

Gazelle GAZ-3302 cars are equipped with a manual, five-speed, three-shaft gearbox with a fifth overdrive gear.

The bulk of the gearbox is identical to the gearbox installed on GAZ-3110 Volga vehicles. The differences between the gearbox of Gazelle cars are significant gear ratios in all gears except fourth, as well as an oversized shift lever housing and an enlarged lower end of the lever.

Gearbox gear ratios: 1st 3.618 2nd 2.188 3rd 1.304 4th 1 5th 0.794

The box housing consists of 2 units - front and rear housings, made of aluminum alloy and connected through a gasket with ten bolts in one plane, perpendicular to the axis of the shafts. For maximum alignment of the bearing seats and grooves for the switching mechanism rods, the crankcases are connected to each other through guide bushings. In the bores of the crankcases, the primary, secondary and middle shafts with helical poles of continuous engagement are located on radial ball bearings. The secondary gears are placed on roller (needle) bearings with plastic cages. The gears of the 2nd, third, fifth gears and the intermediate shaft drive are mounted on the middle one and form a gear block. The teeth of the first gear gear (and they are also reverse gear) are machined directly on the intermediate shaft. The reverse helical idler gear receives continuous drive from the idler when driving in all gears and in the neutral position of the shift lever. It is based on a roller bearing on a static axis, fixed to both crankcases.

The box is equipped with inertial synchronizers. Their ring gears are connected to the gears using small splines.

The gearbox shift mechanism of the GAZ-3302 consists of rods with forks and heads, in the grooves of which the lower end of the shift lever is placed. The engaged gears are locked using spring-loaded balls. A locking device, consisting of 2 plungers and a locking pin, prevents the engagement of 2 gears. The shift lever has a damping device that prevents vibration at high crankshaft speeds.

It will be useful: Which charger for a car battery to choose

The rear splined end of the secondary shaft engages with the sliding fork of the cardan transmission. The fork shank is inserted into the steel babbit bushing of the rear gearbox housing extension and, moving in this bushing and along the secondary splines, it compensates for the axial movement of the cardan transmission during operation of the rear suspension.

On the secondary shaft there is a driving screw shaft for the speedometer drive. The box is lubricated with transmission oil poured into the crankcase in a volume of 1.2 liters.

To fill and drain oil, filler and drain plugs with conical threads are used. The drain plug has a magnet to catch small metal particles of shavings and sawdust. Filler plugs are located on the side walls of the crankcase on both sides. Next page""""""

- 1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20. 21.22.23.24.25.26.27.28.29.30.31.32.33.34.35.36.37.38.39. 40.41.42.43.

Driving style

The service life of the GAZ-3302 (GAZelle) car is significantly influenced by the driving style of a particular driver. If you drive your car carelessly, you can destroy it much faster than the famous “high-quality” Russian roads would. Because of this, you should be very careful when selecting drivers for your company, because their skills and careful handling of equipment are the key to the success of any business.

Take care of your car! Do not forget that if you treat a GAZelle carelessly, then it simply physically will not be able to bring as much profit as it would if driven carefully. There is no need to try to earn quick money, there is no need to overload the car every time.

If you drive a GAZelle carefully and take care of it, then the figure of five hundred thousand kilometers will not seem unrealistic. Anyone who loves their GAZelle knows that it can bring in millions of rubles in profit.

Features of Gazelle gearbox repair

- Features of Gazelle gearbox repair

- Features of Gazelle gearbox repair

- How does the gearbox work on a Gazelle?

- When is transmission repair necessary?

- Main gearbox malfunctions on GAZ 3307 vehicles

- How to repair a Gazelle gearbox

- Necessary tool for removing and disassembling the box

- Step-by-step instructions on how to remove the box

- Dismantling and assembling Gazelle gearbox

Do not think that repairing a Gazelle gearbox with your own hands is easy. The gearbox is a complex mechanism that transmits torque from the engine shaft to the drive wheels. Your safety depends on it and the slightest deviations in the operation of the gearbox signal the need for diagnostics. You should not be afraid of difficulties - after all, there may not be a service station nearby, and step-by-step instructions will help even a novice car enthusiast to successfully cope with the matter.

Features of Gazelle gearbox repair

The Gazelle gearbox is reliable and durable. But constant loads sometimes lead to its breakdown. Gazelle gearbox repair will require the driver to:

- knowledge of vehicle hardware;

- the ability to remove the gearbox, disassemble it, and then reassemble it and put it in place;

- strict adherence to safety regulations;

- attention, accuracy and patience.

How does the gearbox work on a Gazelle?

Gearbox – mechanical, five-speed. Comprises:

- two aluminum crankcases (connected with 10 bolts);

- primary and secondary shafts (connected to the crankshaft and cardan);

- an intermediate shaft with cut teeth for 1st gear and reverse gear, a pressed-on gear block and a speedometer drive gear;

- inertial synchronizers;

- spring-loaded balls for fixing gears;

- locking gears at the same time;

- lever damper device;

When is transmission repair necessary?

The signal for urgent repair of the Gazelle gearbox is:

- Inability to change gear or if it is difficult to do so.

- When trying to change gear while driving, a loud cracking sound is heard.

- Shifting gears on your own (risks an accident).

- Any extraneous noise, crunching, knocking in the gearbox.

- Routine diagnostics of the Gazelle's gearbox must be carried out every 300,000 km.

Main gearbox malfunctions on GAZ 3307 vehicles

Long-term operation of Gazelle cars has made it possible to compile a list of the main malfunctions of the Gazelle gearbox and their possible causes:

- The cause of the humming noise during operation is the destruction of worn parts or loosening of the fastening bolts;

- Crunching in the gearbox - destruction of bearings;

- Crackling sound when switching – synchronizer rings are worn out;

- Difficulty shifting gears - jamming in the gearbox drive, wear of gears, burrs, etc. (needs to be disassembled and inspected);

- Self-switching off speeds - misalignment of gear teeth, wear of rods and forks, loosening of the gearbox and driven shaft fastenings;

- Oil loss - crack in the crankcases, weakening of fasteners, wear of the gasket, oil seal, etc.

How to repair a Gazelle gearbox

The breakdown has been found, the causes have been clarified - all that remains is to begin repairs. To do this, you need to remove and disassemble the gearbox.

Necessary tool for removing and disassembling the box

For repairs you will need an inspection hole or overpass, as well as tools:

- a set of keys (for 10, 12, 13, 14, 17, 19);

- Screwdriver Set;

- beard;

- wooden blocks;

- pliers (pliers);

- mount;

- pullers;

- hammer;

- needle file, sandpaper;

- brass pad or copper hammer;

- mandrel for old oil seals.

- container for draining oil;

- rags;

- CV joint-4, transmission oil, GOI paste.

Step-by-step instructions on how to remove the box

When repairing a Gazelle gearbox with your own hands, first of all you need to drive the car onto an overpass or inspection hole. After this, proceed to remove the box:

Step 1 – empty the crankcase of oil;

Step 2 - remove the cardan:

- using a file, mark the relative positions of the universal joint and the gearbox extension, as well as the flanges of the cardan and rear axle;

- Using keys 12 and 13, remove the intermediate support fasteners;

- using keys 14 and 17, remove the cardan fasteners to the flange of the main gear drive gear;

- remove the shank from the gearbox (pull it back and pull it out);

- Plug the resulting hole with a rag.

It will be useful: The fuel pump does not pump when the ignition is turned on

Step 3 – get the lever:

- from inside the cabin, remove the cover and the upper part of the lever;

- Unclench the spacer sleeve, remove the rubber cushion and the locking sleeve;

- remove the floor seal and protective cover, unscrew the cap and remove the lever.

Step 4 – disconnect the speedometer and reverse light switch from the gearbox.

Step 5 – remove the gearbox:

- Unscrew the fasteners of the exhaust pipes and bracket to the gearbox (keys 12 and 14);

- disconnect the gearbox from the clutch housing (4 nuts);

- protect the block head with a wooden block;

- remove the cross-member of the gearbox mount and rocking it, pushing the box itself back.

Dismantling and assembling Gazelle gearbox

Troubleshooting requires rebuilding the Gazelle gearbox. Disassembling the gearbox must be done in stages:

- Remove the bearing cover, change the seal (key 12, screwdriver, mandrel).

- Remove the fasteners for the reverse axle bushing (key 13).

- Remove the retaining ring from the input shaft bearing (using a thin screwdriver).

- Remove the breather.

- Disconnect the crankcases (12mm wrench, hammer and brass mandrel).

- Engage reverse gear (turning the input shaft).

- Remove the gear fork mount (key 10).

- Remove the lever housings and the plate with the gasket (key 12).

- Remove the springs and balls (3 pieces each) of the clamps (magnetic screwdriver).

- Remove the rods in order - 1, 2, 5, reverse, 3 and 4 gears and the locking pin.

- Using wrench 13, unscrew the fastening of the reverse gear axis and remove the retaining ring of the rear bearing of the secondary shaft.

- Remove the shafts (using a copper hammer) and disassemble them. When disassembling, carefully lay out the parts in order and mark their relative positions.

Reassembling the Gazelle gearbox after repair is carried out in the reverse order. The shafts should be installed simultaneously (tied with twine). Before assembly, you should carefully inspect the crankcase (for cracks, nicks, nicks). Wash all parts (in kerosene, diesel fuel), inspect (bearings, shafts, gaskets, gear teeth, etc.). Any traces of corrosion should be sanded down. Replace all broken or suspicious parts with new ones, lubricate them with transmission oil, CV joints-4 (cuffs, splines, etc.). Treat crankcase fasteners with sealant. Do-it-yourself replacement of Gazelle gearbox bearings should be done every 100,000 km.

Installing the gearbox Install the gearbox in the reverse order. The splines must be lubricated with CV joint-4. Next, the cardan is installed (you need to make sure that the marks match). After installing the gearbox, pour in 1.2 liters. oil into the crankcase (up to the filler hole). As you have seen, the work of repairing a transmission is a big one and the preparation for it must be serious.

Subscribe to our feeds on social networks such as Facebook, Vkontakte, Instagram, Pinterest, Yandex Zen, Twitter and Telegram: all the most interesting automotive events collected in one place.