This term has other meanings, see Mole.

| Mole | |

| Project, g | early 1980s |

| Issued, gg. | since 1983 |

| Purpose | motor cultivator |

| Propulsion type | tiller or wheel |

| Gross weight, t | 0,0485 |

| Location | |

| Engine | two-stroke carburetor with forced air cooling |

| Engine | |

| Designation according to GOST | MK-1A-02 or MK-1A |

| Engine make | Mole |

| Power, hp (kW) | 2,6 (1,9) |

| Transmission | |

| Transmission type | mechanical |

| Suspension and handling | |

| Suspension type | tough |

| Rotation control method | manually (like a motorcycle) |

| Brakes | No |

Mole

- a model of a Soviet and Russian motor-cultivator (motor-block), produced since 1983. The first motor cultivator, mass production of which was mastered in the USSR.

"Mole" is produced by machine-building plants in Moscow and Omsk.

Purpose - performing agricultural work on personal plots.

Content

- 1 Description of design 1.1 Engine

- 1.2 Transmission

- 2.1 Tilling the soil

Owner reviews of Mole cultivators

Semenov Egor, Perm

“A week ago I bought a motor cultivator MK 1A 01. Well, what can I say, this model is ideal for weeding, hilling the ground, uprooting roots in the garden, digging up potatoes, mowing grass, pumping water and transporting small loads. As you can see, this motor cultivator is well suited for medium-difficult work, but if you need to perform more difficult tasks with your assistant, then you need to take a more complex motor cultivator. As for the equipment, everything is fine there. The engine, although not very advanced, does its job perfectly, despite the fact that it has an optimal price.”

Nikonorenko Bogdan, Saratov

“More than a year ago I bought a fairly good model of a motor cultivator - MK 9 01, and first of all I want to say that although the object is not very new, it is still in excellent condition. During this time I never had any problems with the engine or any serious problems with other parts. This model has an excellent engine (four-stroke with good power of 5.5 hp) and does an excellent job of weeding, hilling beds, digging potatoes, leveling rows, etc. This motor cultivator copes well with fairly large areas of land. And the price for this unit is quite decent.

In conclusion, I want to say that if you want to buy yourself a motor cultivator, then you need to study in detail the characteristics of all the above models. Perhaps you need a unit for small jobs, then you should pay attention to simpler models. But if you need to do more difficult work, then choose a more powerful unit.”

Also follow all the rules for storing and working with a motor cultivator, because such simple actions as regular cleaning and disassembling of your assistant will extend its life for many years.

Design Description[ | ]

"Mole" with four cutters on a small bed.

Plowing in a circle. Play media file

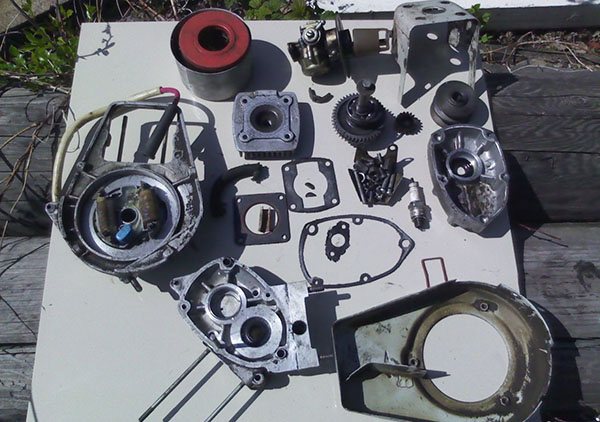

"Mole" with six cutters in operation. "Mole" with four soil cutters. Transport wheels are lowered. "Mole" with six soil cutters. Transport wheels are raised. “Mole” with two cutters for weeding and hilling potatoes. "Mole" with wheels and hiller. The V-belt drive is covered with a casing. V-belt drive, tension roller serves as a clutch.

Bolted to the gearbox is a frame (consisting of two half-frames), tubular handles for controlling the cultivator and a bracket for attaching additional accessories to the rear of the cultivator. The handles contain controls for engine speed and clutch ( on some modifications - reverse gear).

).

Soil cutters with a diameter of 320 mm are put on the output shafts of the gearbox for plowing the soil, weeding or wheels (for working with a hiller (or plow) or for operating a cultivator with a trolley).

An internal combustion engine is attached to the frame, connected by a V-belt transmission to the input shaft of the gearbox.

To roll the cultivator there are lifting wheels; during operation they must be raised or removed.

Engine[ | ]

The engine is a single-cylinder, two-stroke, air-cooled carburetor.

Working volume - 60 cm3. Power 2.6 horsepower at 5500-6500 rpm.

Engine starting is manual (rope), non-removable starter.

Carburetor K-60V[1], air cleaner - dry, with a replaceable filter element[2]. Fuel - A-76 gasoline mixed with M-8B1 motor oil (autol), ratio 20:1[3]. Fuel tank capacity is 1.8 liters.

Ignition - electronic contactless magneto MB-1[4], spark plug A-17B[5].

Transmission[ | ]

The engine is made in one block with a single-stage gear reducer (motor transmission). Lubrication of the motor gearbox is M-8B1[6] engine oil.

There is a pulley on the output shaft of the motor gearbox. Through a V-belt drive, the torque is transmitted to the pulley of the main gearbox.

The clutch is always disengaged and is engaged with a motorcycle-type handle. When the clutch is engaged, the V-belt is tensioned, its slipping along the pulley is eliminated and torque is transmitted.

The main gearbox is two-stage (chain and a pair of gears). Lubricant - transmission oil TAD-17 (SAE 85W90).

Review of popular models

The approximate dimensions of the equipment are within:

- length – from 100 to 130 cm;

- width – from 35 to 81 cm;

- height – from 71 to 106 cm.

The dimensions of the Mole motor-cultivator depend on the model, and may change with improvements in technology.

Motor cultivator MK-1A

Let's start our review of Mole motor cultivators with the MK-1A model. The unit is equipped with a two-stroke carburetor engine with a power of 2.6 hp. A crank on a rope is used as a starter. A gasoline engine with a gearbox has a simple bolted connection to the frame. The fuel tank is designed for 1.8 liters. Such a small volume is due to low fuel consumption. The unit can be refueled with cheap AI-80 or A-76 gasoline. To prepare the fuel mixture, M-12TP engine oil is used. The motor cultivator weighs only 48 kg. Such equipment can be easily transported to the dacha by car.

All control elements of the motor cultivator are located on the handles, namely:

- clutch lever;

- throttle control lever;

- carburetor throttle control lever.

The Mole MK-1A model is capable of working with attachments. The motorized cultivator is used for watering, mowing grass, cultivating the soil and caring for plantings.

Motor-cultivator Mole 2 with reverse

A special feature of the design is that the Mole motor-cultivator has reverse and a powerful engine. This allows the consumer to get a real walk-behind tractor for little money. The unit is powered by a Honda GX200 four-stroke gasoline engine with a power of 6.5 liters. With. Mole 2 has electronic ignition, a power take-off shaft, and a 3.6-liter gasoline tank. Torque from the engine to the chassis is transmitted by a belt drive.

Among other motor cultivators with similar characteristics, this Mole model ranks first in reliability. Such indicators were achieved thanks to a powerful single-cylinder engine and a trouble-free gearbox. The motor life of the engine is 3500 hours. This is quite a lot compared to the old models of the Mole motor-cultivator, whose service life reached up to 400 hours.

Important! The big advantage of a four-stroke engine is that the oil and gasoline are separate. The owner no longer needs to manually prepare the fuel mixture by mixing these components.

The power of a motor cultivator with reverse gear is enough to cover an area 1 m wide with cutters. The operating instructions from the manufacturer state that the Mole 2 motor cultivator is capable of expanding its functionality through the use of attachments. Thus, equipment can become a snow blower or mower, a vehicle for transporting cargo, or a machine for performing many agricultural jobs.

Important! The handles of the Mole 2 motor-cultivator have multi-stage adjustment. The operator can turn them in any direction, which makes it possible to optimally adjust the equipment for any type of work.

In the video we offer you to watch a review of the Mole motor cultivator:

Working with a cultivator[ | ]

Plowing the soil[ | ]

Soil cutters are mounted on the output shafts of the gearbox, transport wheels are raised, and a coulter is attached to the bracket, acting as a brake and regulating the plowing depth. Milling cutters are the working body and propeller of a motor cultivator.

The cultivator is equipped with a set of cutters (two internal and two external - “right” and “left”, respectively). When developing virgin and fallow lands, it is recommended to use only internal cutters. On relatively light garden soils, it is permissible to additionally use a third set of cutters (purchased separately)

.

With six cutters, the cultivator works even more steadily and does not “burrow” into the soil. With eight cutters, it is impossible to operate a motor cultivator. Significant overload of the engine and transmission is noted; significantly increased weight and dimensions can lead to breakage of the handles.

Weeding[ | ]

To weed weeds, instead of knives for plowing the soil, weeder blades G

-shaped.

(purchased separately)

can be installed in place of external cutters .

Weeding and preliminary hilling of potatoes[ | ]

Instead of a coulter, a potato hiller is installed (purchased separately)

.

Hilling potatoes[ | ]

Instead of soil milling machines, metal wheels with lugs are installed (purchased separately)

.

Instead of a coulter, a potato hiller is installed (purchased separately)

.

Digging up potatoes[ | ]

Instead of soil milling machines, metal wheels with lugs are installed. Instead of a coulter, a potato digger is installed (purchased separately)

.

Plowing the soil with a plow[ | ]

Metal wheels with lugs are put on the gear shafts and a plow is attached to the back of the bracket (purchased separately)

.

Haymaking[ | ]

To mow grass and make hay, a mower is attached to the front of the cultivator (purchased separately)

. Wheels are installed on the output shafts of the gearbox. The mower is connected to the engine by a V-belt drive. For this purpose, there is an additional pulley on the engine output shaft.

Pumping water[ | ]

To pump water from open reservoirs, a pumping unit is installed on the frame, connected by a V-belt drive to the engine. The V-belt drive must be removed from the traction gearbox. Pumping unit MNU-2 is purchased separately

.

Working with a small cart[ | ]

To transport cargo weighing up to 200 kg, a small-sized trolley TM-200 with a rotary coupling device is purchased. Rubber-coated wheels are put on the output shafts of the gearbox.

"Mole" with a diesel engine

These units, unlike gasoline units, can be used for cultivating virgin lands as well. The Krot 352 diesel walk-behind tractor model differs from 351 only in the presence of an electric starter. The technical characteristics of these two units are as follows:

- engine power - 6 l. With.;

- tank capacity - 3.5 l;

- engine capacity - 296 cm3;

- width/depth of tillage - 120/30 cm;

- speeds - 2 forward/1 reverse;

- weight - 138 kg;

- wheel diameter is 10 inches.

The modification of diesel "Moles" number 353 is distinguished by the following characteristics:

- engine power - 9 l. With.;

- tank capacity - 3.6 l;

- weight - 126 kg.

The remaining indicators for this model are the same as for units 351 and 352.

Modifications[ | ]

The Krot-2 cultivator is made in China with a four-stroke engine, almost an exact copy of the Russian Krot.

Initially, the MK-1 "Mole" was released as a single-purpose machine - a "milling-type cultivator." In subsequent years, additional attachments were developed for the MK-1 (weeding knife, hilling plow, mower with a segmented cutterbar), as a result of which the MK-1 became a walk-behind tractor and was mentioned in the literature along with the classic MTZ-0.5 walk-behind tractors. and Super-600.[7]

All modifications of the cultivator come down to:

- The use of a gearbox with reverse gear.

- Installation of imported engines, both two-stroke and four-stroke, on the cultivator.

Manufacturing options are possible that differ in the design of the air cleaner, carburetor, fuel valve, gas tank, etc.

In addition to official modifications, there are also modifications made by the owners. Some craftsmen install electric motors of various designs on Krot motor cultivators. Supply of electricity via cable.

Do-it-yourself motor cultivator repair

The motor cultivator has the following components:

- Fuel system (carburetor, fuel tank, air filter and fuel supply hose).

- A starter (manual or electric), it is used to spin up the main shaft using a special cable.

- The cooling system operates under the influence of the rotation of the crankshaft and supplies cold air at flywheel speeds.

- The ignition system makes and supplies a spark in the design of the cultivator.

The sooner you understand where the breakdown is in your device, the faster you will fix it and repair it.

Most breakdowns occur due to motor failure. If this is indeed the case, then you need to check:

- Is this part heated, especially in winter?

- Is the air filter clean?

- Serviceability of the ignition system.

- Are all piston elements intact? You also need to check whether this part is installed correctly (fastening and location itself).

Notes[ | ]

- From the Sh-50 or Sh-52 engine of the Riga, Verkhovyna or Karpaty mopeds. The engine design uses a large number of parts from Soviet mopeds.

- In the USSR, a collapsible oil filter was produced for Zhiguli cars, and the same filter element was installed.

- Aviation oil MS-20 40:1, special oil for two-stroke engines MGD-14M 50:1.

- The MB-1 magneto is also used on Druzhba and Ural chainsaws.

- With spark plug A-11, the engine runs stably, carbon formation on the spark plug is eliminated, and glow ignition is not observed.

- It is acceptable to use transmission oil TAD-17 (SAE 85W90).

- Walk-behind tractor - what is it and what are they ? (undefined)

.

- Wikimedia Commons has media related to Mole Cultivator

Repair of cultivator Mole.

To avoid private repair work, it is necessary to properly maintain the engine, fill with fuel and lubricant according to the instructions.

Modern models are sold under warranty; in case of the slightest malfunction, they are accepted for repairs free of charge during the warranty period.

The engine for the mole cultivator needs running-in. The fact is that the first minutes of work are the most important. During this period, the load on the engine elements is maximum. For each model, the instructions indicate the period or period for engine break-in. You need to give the parts time to grind in. Otherwise, repairs cannot be avoided.

If the time has come to “modernize” the mole, then they start by replacing the engine. The design of any model of gasoline cultivator is simple; replacement, repair or maintenance will not take much time. To do this, just follow the instructions and fulfill the conditions specified in it to replace the engine in the mole cultivator.

They are increasingly replacing the old engine with Chinese analogues, everything is clear and simple:

- Drain the oil.

- Disconnect the gas cable.

- The motor is dismantled by unscrewing the four lower nuts.

- Try on the new motor for proper mounting.

- If the mounting holes do not match, make new ones.

- Attach the engine.

- Set up the transmission belt for the mole cultivator and controls.

If there are changes in operation, it is advisable to adjust the device yourself. It is more convenient to set up and repair it yourself, because in a deserted area few people will agree to help with the repair of the cultivator during the planting or harvesting season.

Ignition of a gasoline mole cultivator from a candle. Very often this element requires preventive maintenance. So, to troubleshoot the problem you need to:

- Check the spark plugs and install new ones.

- Inspect the suppression resistance for malfunction.

- After completing steps No. 1 and 2, check the high-voltage wires.

- Next, inspect the fuel hose.

- Check the condition of the carburetor.

On this topic:

Self-maintenance of the cultivator

Assembling a homemade cultivator

Review of the Caiman NEO 505 C3 cultivator

Viking – lawn mowing equipment

BACK FORWARD 1 of 16

If the mole cultivator still does not start, but there is a spark, then the solution to the problem is in this video:

Of course, it is better to entrust more complex walk-behind tractor repairs to a professional. Modern models of cultivators are equipped with four-stroke engines to save fuel. Also, this type of motor is repaired much less often with proper care.