High-quality, reliable and inexpensive cultivators from MTD

For many years, equipment from Europe was considered high-quality and reliable, and at the same time expensive. However, this is not the case, at least as far as the price is concerned, since it is affordable and can compete even with Chinese goods. One such manufacturer that offers high European quality at reasonable prices is MTD. However, despite the location of the production, the company still comes from the USA.

Specifications

| Power | 5.5 hp |

| Weight | 50 kg |

| Processing width | 33/61/81cm |

| Clutch | belt |

| Gearbox | chain |

| Reverse | There is |

| Guarantee | 1 year |

| Manufacturer country | Germany |

| Overall dimensions (H*W*D) | 80x65x70 |

| Cultivator type | Heavy cultivator |

| Engine | B&S 700 Series OHV - 163 cc. |

| engine's type | gasoline 4-stroke |

| Engine Manufacturer | Briggs&Stratton |

| Number of speeds | 1 forward/1 reverse |

| Adjustable steering column | in 1st position |

| Processing depth | up to 32 cm |

| Milling cutter diameter | 30.5 cm |

| Fuel tank capacity | 2.8 l. |

| Manufacturer country | Germany |

| Guarantee | 2 years |

If you need a reliable and maneuverable cultivator for working on a large area with high-quality components, then we advise you to pay attention to the MTD T/380 B cultivator. This model has many advantages, one of which is the professional Briggs & Stratton engine (made in the USA). This garden equipment is assembled in Germany, but we all know that the Germans know how to produce high-quality and reliable units.

A reliable, economical cultivator with a long engine life will become an indispensable assistant for summer residents, gardeners and those whose work is related to agriculture.

MTD cultivators

MTD is an American company, whose products, however, for our market, are produced and assembled in European factories. For example, in online stores you can often see that a cultivator was produced in Germany and assembled in Hungary. Only high-quality components are used, as well as engines of our own production or from world leaders such as Honda and B&S. Over its 67-year history, the manufacturer has managed not only to establish itself from the best side, but also to develop certain principles and traditions of production.

Peculiarities

MTD cultivators are made from high-quality materials and components, and the level of assembly corresponds to the premium segment. Despite this, the price remains quite affordable and accessible, which makes the equipment an ideal choice for many summer residents and gardeners.

Advantages and disadvantages

MTD cultivators have the following advantages:

- Affordable prices;

- High quality components and assembly;

- Wide range of available equipment;

- A wide dealer network, which will not only make it easy to purchase a unit, but also provide high-quality and timely service.

Comparing with other well-known manufacturers, the maximum power of the units is in the middle range, which does not allow the equipment to fully cover all consumer needs. This is the only but significant drawback.

Cultivator MTD T/245

The MTD cultivator will be an excellent choice for all fans of reliability and high quality. Manufacturers have supplemented the unit with an MTD Thorx 55 motor, the power of which (5.5 hp) is enough to perform many basic tasks and cultivate even virgin soil.

Many owners of the device say that they use it to replace a shovel, since the immersion depth of the cutting element is 32 cm, which allows them to achieve excellent results without much physical effort. The engine is periodically cooled by the influence of air flow, so there is no need to worry about overheating of the mechanism elements.

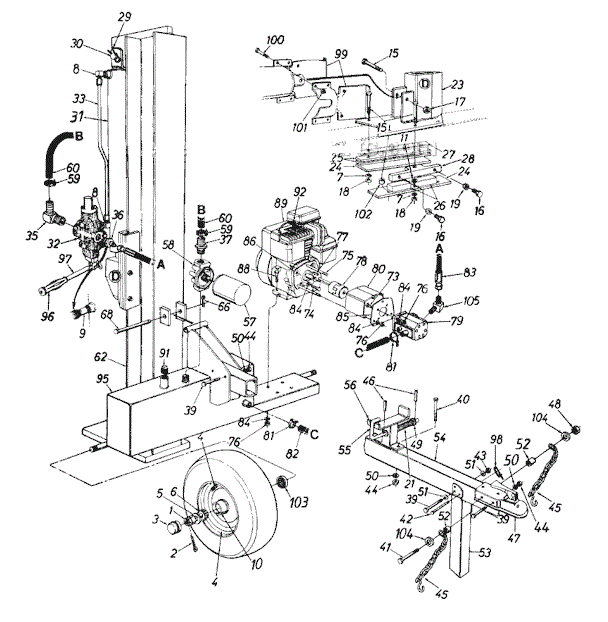

The maintainability of the model and the availability of spare parts are also a positive feature of the technical development, because you can quickly and easily replace an element using the diagram presented below.

Specifications:

- Fuel – gasoline A-95;

- Weight – 39 kg;

- The width of the cutters is 30.5 cm;

- Recommended oil – SAE 10W30;

- The capacity of the fuel tank is 1.4 liters.

The upper placement of the motor valves of the MTD T/245 cultivator helps to increase productivity, lower fuel consumption and reduce noise during operation.

Operating instructions for cultivator MTD T 245

Operating instructions for the MTD T 245 cultivator engine

Device

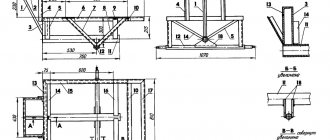

The design of motor cultivators is as simple as possible: this is the main frame to which the gearbox is attached, control handles, removable transport wheels, and a soil tillage depth regulator are welded. The launch is manual and occurs due to a special rotor cable. Control occurs on a principle similar to motorcycles: the clutch is always open, and when the handle is rotated, it closes, and the cutter receives power from the engine. Almost all models have only forward gear, and only the largest T 380 also has reverse gear. There is no point in using such a device for small areas, but when processing large areas, additional gear will be indispensable.

Review of popular models

The company offers two types of power units, the main difference of which is their purpose. Cultivators with an electric motor practically do not start in Russia and Ukraine and are represented by only 1-2 models.

Electrical

Such motor cultivators are ideal for working in greenhouses and small beds. In the first case, this is due to the absence of any exhaust gases that could accumulate in the room. And the second is convenient for economic and practical reasons: electric cultivators are cheap, weigh lighter, and also do not require gasoline.

Technical characteristics of the only electric model of the cultivator :

Advantages and disadvantages

Under the logo of the American concern MTD, powerful and high-quality equipment for various household and industrial needs has been produced for quite some time, including a line of cultivators. Such agricultural devices have earned particular popularity due to the production of components and assembly in Germany.

During the operation and improvement of existing models of cultivators of the brand, the main advantages and disadvantages of European units were noted. Among the advantages, we can highlight some characteristics of the technology.

- In the process of manufacturing parts and assembling devices, the manufacturer focuses its products primarily on domestic consumers. Taking into account the nuances and characteristics of Russian and post-Soviet farms, climatic conditions, etc.

- All models are regularly improved. This applies not only to external changes, but also to the internal structure of such important components as the engine, carburetor, and starter.

- Cultivators are equipped only with certified spare parts that fully comply with European quality standards.

- Despite the high-quality assembly and the use of first-class parts, agricultural machinery of the light, medium and heavy class of the MTD brand stands out at a very affordable price.

- The manufacturer offers consumers not only gasoline, but also electric devices for cultivating land. Electric motors also stand out for their durability and practically do not fail during operation.

However, European auxiliary equipment is not without some disadvantages.

- As the owners note, the motor cultivator cannot always be transported in the trunk of a passenger car, since some models of MTD units are too large.

- In some regions there are difficulties in purchasing original components.

- There are cases when the drive belt of a device stretches quite quickly, in light of which the equipment will need unscheduled maintenance.

Device and characteristics

MTD cultivators are equipped with four-stroke MTD ThorX engines or American Briggs&Stratton devices.

Based on power and weight, units of this brand are divided into 3 types.

- Light vehicles. Such devices in most cases are powered by an electric motor. As a rule, the mass of devices is only 2-3 tens of kilograms. Equipment in this category stands out for its maneuverability and mobility.

- Middle class cultivators. These can be gasoline or electric units, as a rule, the engine power of which varies between 3-4 liters. With. The weight of cultivators in this segment does not exceed 40 kilograms.

- Heavy vehicles. This technique is designed for processing large areas of land. The cultivators operate on American engines with a capacity of 5-10 hp. With.

Typically, such devices can be modified and perform many tasks using additional attachments.

Models of MTD cultivators operate on a worm gearbox; all internal components and mechanisms are reliably protected by the steel casing of the devices. American brand engines do not produce much noise during operation, and are also quite economical in terms of fuel consumption. All types of machines have a built-in soil tillage depth limiter, which increases the efficiency of their work.

The cutters included in the basic package can be quickly removed and installed back, since their fixation involves the use of bolts. Most machines are equipped with an ergonomic removable handle, which increases comfort during operation and transportation of the devices.

Motoblock mtd 240 instructions

Nov 15 • Uncategorized • 50 Views • No comments on the post Motoblock MTD 240 instructions no

Contents

Cultivators are agricultural assistants in cultivating the top layers of soil. They loosen soil of varying densities without turning it over. As a result, it turns out soft, loose and enriched with oxygen. The equipment both prepares the area for sowing and provides further care for it.

Table of contents:

How to choose a cultivator

A cultivator is a high-performance tool that saves the user’s effort and time. It is an alternative to a shovel, hoe and rake.

When purchasing equipment, you need to specifically understand what type and scope of work it is intended for.

Light cultivators are suitable for loosening soft soil in small areas. Their power is sufficient for work on an area of 5–10 acres. They are equipped with electric motors with a power of up to 1.5 kW or gasoline equivalents with up to 5 hp. The width of the strip of cultivated soil does not exceed 45 cm, and the depth - 25 cm. The weight of such equipment reaches 25 - 30 kg.

Average cultivators can handle the volume of work on an area of 10–15 acres. With a chain gearbox and a working width of up to 80 – 90 cm. Their main difference from light analogues is the ability to use attachments. The units operate from a two- or four-stroke engine.

Professional heavy cultivators are powered by powerful diesel engines. Their power varies from 5.5 to 9 hp. They are equipped with a chain reducer and gearbox. At a time, such a machine processes from 0.8 to 1.2 m of surface with a depth of up to 30 cm. Such models provide the largest number of attachments and functions. Heavy equipment copes with hard layers of soil and virgin soil. And for plowing they buy powerful walk-behind tractors.

Cultivator MTD T240

The MTD T240 cultivator is a good assistant for gardening and vegetable gardening. It is used for a number of jobs:

- loosening the soil,

- weeding beds,

- application of fertilizers,

- planting and digging root crops,

- hilling,

- plowing.

The machine is powered by a four-stroke, single-cylinder gasoline engine ThorX55. Its power is 5.5 hp. with a cylinder volume of 173 cm³. Cooling is carried out naturally by air flows. The cultivator is equipped with a worm-type gearbox, and the clutch is produced by a conical clutch.

The unit has one forward gear. Reverse gear, that is, reverse, is not provided.

The equipment is started by a manual starter. With a few pulls on the engine cable.

The fuel tank capacity is 1.4 liters.

The unit is equipped with 4 steel saber cutters with a diameter of 31 cm. The system develops up to 120 rpm. And its design allows you to quickly replace damaged knives with new ones. The working width of the cultivator reaches 61 cm, with a depth of 25 cm.

Equipment weight 39 kg.

The average cost for an MTD T/240 cultivator is 450 USD.

The supply consists of:

- cultivator,

- transport wheel,

- cutters,

- rules for operating the machine and its engine,

- warranty service card,

- boxes.

MTD T/240 is a lightweight cultivator, optimal for cultivating areas of up to 10 - 15 acres. It is usually used for pre-sowing work, fertilizing the soil and leveling the landscape.

Features of the MTD T240 cultivator

Users note a number of features of the MTD T/240 cultivator:

- powerful engine, as for a light cultivator,

- efficient bevel clutch and worm gear,

- oil pump for high-quality processing of parts,

- adjustable Y-shaped steering wheel,

- durable steel body,

- removable motor for convenient transportation and movement of the cultivator.

Operating instructions for the MTD T/240 cultivator

1. General safety rules:

- use the cultivator for its intended purpose,

- do not overload the equipment,

- Persons over 16 years of age are allowed to work,

- do not touch rotating parts of the equipment,

- work away from fire and sparkling elements,

- storage is carried out in a dry room away from flammable objects,

- Carry out repairs and maintenance of the cultivator from specialists.

2. Working with MTD T/240:

- Before the first start, fill the gearbox with oil,

- check its level before each use or every 5 hours of operation,

- use fuel recommended by the manufacturer,

- make sure there are no strangers, children or animals in the work area,

- use only working equipment,

- When dirty, clean the engine, muffler and cutters from grass debris,

- start work with the clutch lever fully depressed, otherwise its wear will accelerate,

- If the movement of the cutters is blocked, turn off the cultivator. Fix the problem and continue working.

The MTD motor-cultivator, declared by sellers as a German product, is produced by enterprises in Hungary (there are also Chinese-assembled copies). Factories produce several modifications of equipment, which differ in the power of the power plant and the list of auxiliary equipment. The products are intended for cultivating and loosening soil in personal plots.

Model overview

Among the available range of MTD cultivators, it is worth highlighting the most popular units.

MTD T 380 M ECO

The equipment is used for pre-treatment of soil before sowing, as well as for subsequent care of crops. The configuration of the machine involves the additional installation of a number of attachments to increase the functionality of the machine.

The unit operates using a high-performance Thorx 55 motor with a power of 5.5 liters. With. Design features and a good motor allow the unit to cope with processing even heavy types of soil.

The rotation speed of the cutters is 140 rpm, the clutch fork is a lever reminiscent of a steering column, thanks to which the worker can operate the device with either hand, which increases the productivity of the machine. Additionally, the device is equipped with reverse. The fuel tank capacity is 2.7 liters, the device is equipped with a rear transport wheel, and the cultivator weighs 45 kilograms.

MTD T 240

This motor cultivator is positioned as a powerful agricultural machinery that can perform work on a site with an area of 0.15 hectares. The unit is equipped with a Thorx 55 engine with a capacity of 5.5 liters. With.

In this model, the motor is removable, so the device can be easily transported or the motor can be used with other machines. The volume of the gasoline tank is 2 liters. The device is operated manually. The equipment is compatible with additional mounted and trailed equipment; the cultivator handle is adjustable in height and tilt angle.

Video

Cultivators are agricultural assistants in cultivating the top layers of soil. They loosen soil of varying densities without turning it over. As a result, it turns out soft, loose and enriched with oxygen. The equipment both prepares the area for sowing and provides further care for it.

Table of contents:

How to choose a cultivator

A cultivator is a high-performance tool that saves the user’s effort and time. It is an alternative to a shovel, hoe and rake.

When purchasing equipment, you need to specifically understand what type and scope of work it is intended for.

Light cultivators are suitable for loosening soft soil in small areas. Their power is sufficient for work on an area of 5–10 acres. They are equipped with electric motors with a power of up to 1.5 kW or gasoline equivalents with up to 5 hp. The width of the strip of cultivated soil does not exceed 45 cm, and the depth - 25 cm. The weight of such equipment reaches 25 - 30 kg.

Average cultivators can handle the volume of work on an area of 10–15 acres. With a chain gearbox and a working width of up to 80 – 90 cm. Their main difference from light analogues is the ability to use attachments. The units operate from a two- or four-stroke engine.

Professional heavy cultivators are powered by powerful diesel engines. Their power varies from 5.5 to 9 hp. They are equipped with a chain reducer and gearbox. At a time, such a machine processes from 0.8 to 1.2 m of surface with a depth of up to 30 cm. Such models provide the largest number of attachments and functions. Heavy equipment copes with hard layers of soil and virgin soil. And for plowing they buy powerful walk-behind tractors.

Attachments and spare parts

Attachable components are quite in demand, as they make it possible to improve the purchased equipment. Among the most current tools, such details stand out.

- Milling cutters. This equipment is present as standard on many MTD cultivators; however, some jobs may require different diameters of these tools, so the manufacturer offers additional parts with different widths and depths of soil grip.

- Plows. Thanks to powerful engines and a durable steel body, motor cultivators can be used for processing virgin soil - during such work, the plow is an indispensable tool. The list of offered components also includes reversible plows, which more thoroughly process and break up heavy soil.

- Mowers. All models of MTD equipment can be used in conjunction with mowers; most often, cultivators are equipped with rotary types of auxiliary tools.

The lineup

MTD 240

This is a representative of light motor cultivators, the sole purpose of which is to mill the soil.

- The MTD 240 is equipped with a gasoline engine with a capacity of 5.5 horsepower. The engine is started using a manual cable. It drives cutters at rotation speeds of up to 120 revolutions per minute.

- The weight of the MTD 240 is only 42 kg.

- The tank capacity is designed for 1.4 liters of gasoline.

- The delivery set includes 4 cutters with a diameter of 30.5 cm.

MTD T/240 OHV 600

This is a modification of MTD 240.

It is easy to separate the engine from the frame and gearbox. To carry out this work there is no need to use special tools. The owner will need no more than 1 minute to assemble.

The T/240 OHV 600 walk-behind tractor has low fuel consumption. It is only 0.8 liters per hour of operation.

It can carry out work with additional attachments.

The weight of the T/240 OHV 600 is only 39 kg, and the maximum cultivation width is 88 cm.

MTD 330

This walk-behind tractor has a Briggs&Stratton Power Build four-stroke petrol engine with a power of 5.5 hp.

- MTD 330 launch type: manual.

- The maximum cutting width is 61 cm.

- The diameter of the wheels on this device is 20 cm.

- The fuel tank volume has been increased to 2.8 liters.

- The standard package includes a set of cutters and pneumatic wheels.

- Weight MTD 330 - 45 kg.

- MTD 330 can only move forward.

MTD 380

This walk-behind tractor is equipped with a 5.5 horsepower ThorX 55 gasoline engine.

- The package already includes 6 cutters, which allows you to increase the working width to 81 cm.

- Also, the MTD 380 has a reverse, which allows you to move backwards.

- The fuel tank is designed for 2.2 liters of gasoline.

- The weight of the model is 57 kg.

Motor cultivator MTD T/240

This option is an excellent budget device, which, moreover, has a collapsible design and can be easily transported.

Specifications:

- Power – 5.5 l. With.;.

- The depth of tillage is 25 cm;

- Fuel tank capacity – 1.4 l;.

- Number of speeds – 1;.

- Gearbox – worm;.

- Clutch – conical clutch;.

- Weight – 40 kg..

MTD T/240 Operating Manual

The cultivator is suitable for use in small areas, since it will not load and will be able to cope 100% with the task. The handles are adjustable to suit the height of the operator, and the forged cutters will allow you to cope even with heavy soil.

By following the operating features described in the manual, you can significantly extend the life of the device and save yourself from unnecessary trouble with repairs.

Special video files will be able to clearly demonstrate the principles of operation and answer many questions.

Attachments

MTD walk-behind tractors are in demand due to their versatility. With the help of additional attachments, they are able to automate a large number of agricultural works.

Milling cutter

This is the main attachment that comes with all models of MTD walk-behind tractors.

Milling cutters allow you to mix the top layer of soil and make it homogeneous.

Each MTD model has its own maximum cutting width and depth of insertion. Therefore, it is necessary to pay attention to this when choosing a device.

Plow

MTD walk-behind tractors are durable and can even process virgin soil with milling cutters, but in rocky soil it is still recommended to use a plow.

It goes into the soil and turns it over and over again. Reversible plows have a special plowshare design that allows the soil to turn over on it several times, break up large piles of soil, and only then throw it aside.

Mower

You can connect a mower to MTD walk-behind tractors. This attachment allows you to clear areas with large thickets of weeds, or maintain the grass level in parks and lawns.

The most common type of mower is rotary, they cut the grass using rotating blades.

Hiller

When potatoes are grown, they must be periodically hilled to increase the yield. MTD walk-behind tractors can help with this work.

The manufacturer offers disk hillers, which rotate when the device moves and throw soil onto the crops.

If you don’t have a hiller at hand, you can use a regular plow. However, in this case you need to be extremely careful, since there is a possibility of digging up the crops before they ripen.

Potato digger

MTD walk-behind tractors can dig up potatoes using a potato digger. In appearance, it very much resembles an ordinary plow with welded steel rods.

While moving, he picks up a layer of earth and directs it to the rods, where they break and leave only fruits on the surface.

User manual

Before starting full use of the MTD walk-behind tractor, new owners should pay attention to the operating instructions. It contains the characteristics of the device, details, principles of assembly, running and maintenance.

First launch and run-in

The key to long-term use of MTD walk-behind tractors is the correct use of the device during the first hours of operation.

Don’t think that you can assemble an MTD walk-behind tractor yourself without an instruction manual. Be sure to refer to it during assembly.

Next, you should fill in oil and gasoline, since they are not included in the factory configuration.

After this, the MTD walk-behind tractor starts running in. This is the time during which the machine operates at minimum power. This is done to ensure that the engine parts are completely lubricated, fit into the grooves and rub against each other. If you immediately put a large load on the MTD walk-behind tractor, then due to high friction there is a possibility of immediately damaging the parts.

The break-in should last about 6 hours. After this, it is necessary to change the engine oil, since a large number of abrasive particles accumulate in it during this period.

Service

The schedule for carrying out technical work is presented in the operating instructions for the walk-behind tractor.

- The engine oil should be changed every 25 hours of operation of the device. The manufacturer recommends using all-season semi-synthetic options with the 10W-30 classification.

- The transmission oil must be changed after 100 operating hours. It is recommended to use Tap-15V or TAD-17i as a fresh lubricant.

- Before changing the oil, be sure to drain the oil.

- All MTD walk-behind tractors are petrol. They run on AI-92 or AI-95 fuel. Only clean and fresh gasoline should be poured in, since the devices are sensitive to the quality of the fuel.

Basic faults and repairs

Every owner of MTD walk-behind tractors needs to know how to eliminate the most common faults:

The engine does not turn on:

- Lack of fuel (add if necessary);

- Old gasoline (you should drain the old one and add clean new fuel);

- The throttle control lever is not in the correct position (it should be in the “Start” position)

- The choke control lever is in the wrong position (set to the “Choke” position);

- The high-voltage wire has come off the spark plug (check the connection);

- Soot has formed on the spark plug or the gap between the electrodes has changed (depending on the situation: replace the spark plug or set the correct gap);

- The carburetor “overflows” gasoline (Put the choke control handle in the “Run” position and start the engine);

- The engine control switch is in position “O” (it must be in position I to start the engine).

The engine does not run smoothly:

- The throttle control lever is in the “Choke” position (during operation it should be in the “Run” position);

- The contact on the spark plug comes off (fasten the wire securely);

- Dirt or water has entered the fuel tank (drain the old fuel and fill with clean fuel);

- The vent in the fuel tank is clogged (clean it);

- Dirt has entered the carburetor (clean the fuel system and adjust the carburetor).

Manual

To extend the life of the equipment in question and ensure its safe operation, the following rules should be observed:

- People over 16 years of age can operate the machine.

- The unit must be used strictly for its intended purpose.

- Do not get close to working cutters.

- The device should be stored away from flammable and flammable products.

- It is necessary to regularly carry out preventive and maintenance maintenance of the cultivator.

Before using the machine, you need to fill the oil pump with the recommended fluid, and then change the oil every 25 hours of operation. It will also be necessary to adjust the height of the handle for the operator and set the required plowing depth, depending on the condition and type of soil.

Further operation of the unit is carried out by selecting forward or reverse gear, as well as removing branches, stones and other obstacles from the surface being processed. After work, the cutters and side parts, as well as the cooling and exhaust system, should be cleaned.