Petrol mowers, like all petrol-powered garden tools, are not difficult to maintain equipment.

You can and should repair and configure yourself. For example, adjusting the carburetor of a lawn mower with your own hands is a matter of five minutes. The carburetor from a lawn mower is a component in the power system. In it, like any carburetors, the process of mixing air and fuel (gasoline) takes place for further supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, for which the carburetor is adjusted.

Main problems and malfunctions of the carburetor.

Mesh filter. There are usually only two problems with this element:

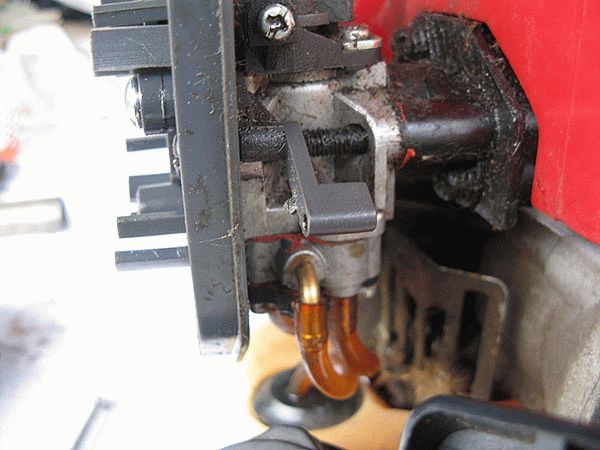

In order to find out the cause of the breakdown, unscrew the fuel filter cap to remove the strainer. If dirt has simply accumulated on it, then washing it in gasoline or blowing it out will help.

If there is visible damage to the mesh filter, be sure to install a new one. There may also be damage to the fuel supply pipe (during repairs, it is practiced to check this element).

In most cases, the carburetor starter does not function due to blockages. Acetone or the same gasoline should be used for washing.

Blowing clogged carburetor parts with compressed air is an acceptable and convenient repair practice.

The throttle body, carburetor parts, intake or exhaust pipes - all of these parts are subject to depressurization. You can definitely check it in a primitive way - spread soap foam on the problem area.

The structure of a lawn mower carburetor

The basis of the lawn mower carburetor is an aluminum body. It contains a diffuser (a hole with internal contours). Air is forced through this hole. The oxygen (air) supply rate depends on the cross-section (pass hole) of the diffuser.

The diffuser is equipped with fuel channels. Fuel is drawn from them using an air flow.

Install externally on the carburetor:

- fuel pump;

- jet system;

- system for adjusting the fuel-air mixture;

The principle of operation of a lawn mower carburetor

The throttle valve determines the amount of air supplied, and engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the fitting in the carburetor. The liquid then moves through the inlet and outlet valves of the pump. Filtered with a mesh. It moves along the needle valve into the membrane chamber.

Step-by-step operation of the device:

- Air supply into a tube with an air baffle (damper). The partition regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed with a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a narrowing. A chamber with a float regulates the temporary volume of gasoline. In the float chamber the pressure level is neutral, and in the tube with a narrowing it is already low. Due to the pressure difference, fuel penetrates through the nozzle.

- Accelerating air flow promotes the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air-fuel mixture enters the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the throttle is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a lawn mower is creating an optimal fuel mixture due to the correct air supply.

How does a trimmer consume fuel?

A lawn mower is a very simple device. There's nothing special about it. And so many people buy it for their needs because everyone can learn to work with it and quite quickly.

Anyone who has relied on a gas trimmer should know that one of its most important characteristics is fuel consumption. And there is a simple explanation for this. First of all, the device must perform its functions for a long time so that there is no need to refuel for a long time. It's always convenient.

MAIN! However, in this case, of course, the fuel tank will be large. As a result, its overall design becomes complex. And this will complicate the work. Is it possible to find a reasonable solution in this situation? You can solve the problem by reducing your fuel consumption.

Next, we will talk about how this can be, what determines the fuel consumption of a trimmer, and we will advise which gasoline is best suited for your work.

How to adjust the carburetor on a lawn mower

Before adjustment, the filters must be thoroughly cleaned according to the maintenance instructions.

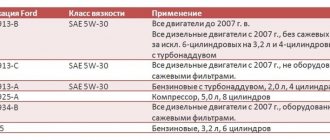

Further adjustment of the lawn mower carburetor is done with your own hands using adjusting screws. There are three in total:

Right (L) – adjusting the fuel mixture for low speeds.

You need to find the maximum idle speed. To do this, slowly turn the screw (L) to the right and left.

To adjust, turn the screw a quarter turn counterclockwise.

Lower (T) – is responsible for adjusting the engine at idle.

- clockwise – increase;

- counterclockwise – decrease.

For correct adjustment of idle speed it is typical:

- stable operation of a cold engine;

- not over-revving a hot engine;

- there is a large reserve of revolutions for the trimmer head;

- stable operation of the engine when changing position (sharp raising or lowering of the knife).

Left (H) – mixture adjustment at high speeds. (The screw is adjusted last).

The overall adjustment of maximum speed, engine power, temperature and gasoline consumption depends on the left screw (H).

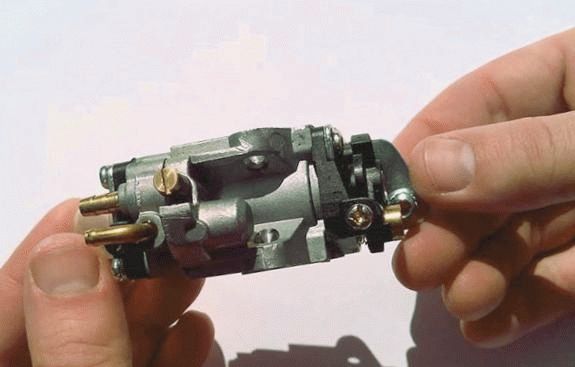

Setting up the carburetor of a lawn mower with the last screw is done as follows:

- Open the throttle to full, while releasing full throttle. Turn the screw clockwise until the speed drops (in this case, use your ear).

- Turn the screw as slowly as possible counterclockwise until the engine runs rough.

- Then turn back just a little, barely hearing stable, smooth operation.

- For a more visual application of skills, it is more convenient to consider the work of an experienced user:

It is interesting that from the point of view of the author of the video, the setting (its correctness) is determined by the color of the spark plug, and not just by the engine speed and stability.

Correctly adjusting the carburetor with your own hands in this case means combustion of the fuel mixture without residue; the color of the spark plug should be light brown.

Adjusting the carburetor of a brush cutter in practice - video

How to calculate fuel consumption on a trimmer

One of the most important problems that any owner of this equipment faces. Sometimes the manufacturer clearly indicates the fuel consumption per unit of power (horsepower or kilowatt) in grams. You can find this information in the loading specifications table. However, despite all its usefulness, it does not provide a clear picture of how much fuel is needed to operate.

How to determine the consumption rate for 1 hour?

It is calculated as follows:

Q = Nq / (1000Rk1), where:

- N. Power supply;

- Sq. Indicator of specific fuel consumption of the loader;

- R. Fuel density (diesel). Usually taken in an amount of 0.85 kg/dm3;

- K1. This is the percentage of time running at maximum engine speed.

Output power and specific fuel consumption are specified in the instructions. Data is entered into it in the form of a graph. It is created by specialist manufacturers. The basis for this is the results of tests in different modes. In practice, achieving maximum transfer speed is very simple. Fully depress the accelerator. As a result, the loader accelerates, overcomes the rise with the load, lifts it to the maximum permissible height, and all this, remember, at maximum speed. Of course, in this mode the bootloader will only work part of the changes. Therefore, it is necessary to use a coefficient denoted by k1: it characterizes operation at maximum speed. This can be called an individual indicator of the specificity of the bootloader.

Calculation example

Let's assume that a diesel forklift was hired to load and unload railcars. He works a whole shift (8 hours) without climbing slopes or using the maximum fork, because the platforms he serves are only 1500-2000 mm high. The maximum speed of the power unit is only used when the unit is accelerating to cover the distance between loading and unloading areas. This operation takes about 30% of working time.

But it may be so. The company operates around the clock. But shipment of materials (products) during this time is carried out only 2 times in 2 hours. The loading time of the forklift at minimum or medium intensity is maintained.

You can adjust the carburetor of a lawn mower yourself

with your own hands takes 5 minutes.

Carburetor

from a lawn mower - this is a node in the power system. In it, like all carburetors, the process of mixing air and fuel (gasoline) takes place for subsequent supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, which is why the carburetor

.

Main problems and malfunctions of the carburetor.

Mesh filter. There are usually only two problems with this element:

In order to find out the cause of the breakdown, unscrew the fuel filter cap to remove the strainer. If dirt has simply accumulated on it, then washing it in gasoline or blowing it out will help.

If there is visible damage to the mesh filter, be sure to install a new one. There may also be damage to the fuel supply pipe (during repairs, it is practiced to check this element).

In most cases, the carburetor starter does not function due to blockages. Acetone or the same gasoline should be used for washing.

Blowing clogged carburetor parts with compressed air is an acceptable and convenient repair practice.

The throttle body, carburetor parts, intake or exhaust pipes - all of these parts are subject to depressurization. You can definitely check it in a primitive way - spread soap foam on the problem area.

The principle of operation of a lawn mower carburetor

The throttle valve determines the amount of air supplied, and engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the fitting in the carburetor. The liquid then moves through the inlet and outlet valves of the pump. Filtered with a mesh. It moves along the needle valve into the membrane chamber.

Step-by-step operation of the device:

- Air supply into a tube with an air baffle (damper). The partition regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed with a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a narrowing. A chamber with a float regulates the temporary volume of gasoline. In the float chamber the pressure level is neutral, and in the tube with a narrowing it is already low. Due to the pressure difference, fuel penetrates through the nozzle.

- Accelerating air flow promotes the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air-fuel mixture enters the engine cylinder through the fuel pipe.

This is interesting: Top 9 myths and mistakes of drivers

The level of air density in the system depends on the area of the open air damper. The wider the throttle is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a lawn mower is creating an optimal fuel mixture due to the correct air supply.

Why do you need it and how to fill out a fuel and lubricants write-off report

Any organization, in order to carry out its business activities, bears the cost of purchasing fuel from its income. These costs are included in the list of tax expenses.

If the resource consumption complies with the standards established by the state, then VAT is not charged on it.

Why is such a document needed?

Based on write-off acts, fuel consumption is constantly monitored within the organization. These acts, which are drawn up on the basis of documents on fuel consumption when performing work, after filling out are submitted to the accounting department and stored there, since they serve as justification for one of the types of costs for conducting business activities before the tax inspectorate.

Fuels and lubricants include diesel fuel, gasoline, natural gas, other fuels, motor oil and special lubricants.

Documents on resource consumption are compiled for each unit of vehicles, tractors, loaders and other mechanisms that consume fuel and lubricant.

Their compilation is regulated by the internal documents of the organization, and they can be compiled daily, weekly or monthly, depending on the operating mode of a particular mechanism or vehicle.

List of mechanisms that consume fuel and lubricants

To correctly justify its expenses for business activities, each organization must have a list of mechanisms and vehicles that consume fuel and lubricants. It can be:

- trucks and cars (including rented ones), buses;

- cranes on automobile and tractor chassis;

- internal combustion engine loaders;

- tractors and graders;

- autonomous gas, diesel and gasoline generators;

- heating devices running on gasoline, diesel, natural gas and other types of fossil fuels;

- chainsaws, lawn mowers, etc.

Basic consumption rates

Basic standards for the consumption of resources by the equipment available in the organization are developed by the chief engineer and chief specialists in accordance with the technical characteristics of a particular unit and its wear and tear:

- For cars and trucks, the basic fuel and oil consumption rates are adjusted to the mileage.

- For machinery cultivating the land (mainly tractors), consumption depends on the work performed.

- For autonomous electric generators - from the generated electricity.

- For heating devices - from the generated thermal energy or maintaining established microclimate parameters under certain weather conditions.

To see how flammable materials are written off in the 1C program, see the following video:

Drawing up a document

Ideally, a write-off report is drawn up monthly in any form for each unit of equipment or device that consumes fuel and lubricants.

It is usually compiled by an accountant, a person working on a specific mechanism, and a specialist who has developed basic consumption standards. The act has the force of a legal and financial document only if it contains the signatures of the persons who compiled it and the head of the organization who approved it.

What should it include?

The document must indicate:

- Date of preparation.

- Last names and initials of the persons who compiled the document.

- Last name and initials of the manager who approved it.

- The name of the mechanism (for cars the state number is also indicated) for which the report is drawn up.

- Inventory number.

- Type of work.

- Basic consumption standard in appropriate units (kg/ha, l/km, kg/hour, kg/KW x hour).

- Actual production by the mechanism over the past month in the appropriate units (ha, km, hour, kW x hour).

- Clarifying coefficients that reflect the conditions under which the mechanism operated.

- The weighted average price of the resource for the past month.

- Cost of materials used.

Here you can find a free example of filling out the document.

Clarifying coefficients express climatic conditions, the severity of the soil being processed by the tractor, the load on the truck, the frequency of bus stops, the cost of unproductive heating of the mechanism, and much more.

Carburetor for trimmer: device and do-it-yourself adjustment

The carburetor is one of the most important components of a lawn mower, the function of which is to prepare the fuel mixture. If you handle the tool carelessly, the carburetor may fail, making further work with the brush cutter impossible. To repair the tool with your own hands, you should study in detail the design, operating principle and features of setting up the carburetor of a gasoline scythe with your own hands.

How does a lawn mower carburetor work?

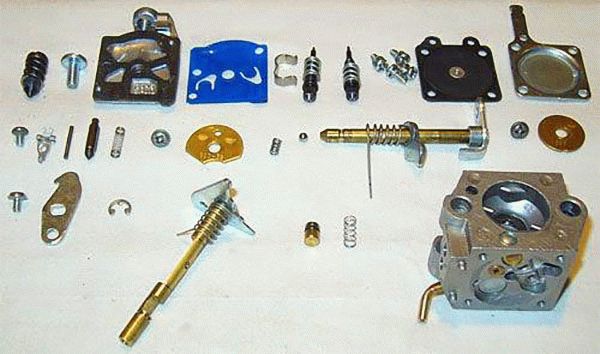

The carburetor design is almost the same, both in well-known German and Swedish brush cutters, and in Chinese-made tools. This unit consists of the following parts:

- Diaphragm fuel pump;

- Adjustment system with atmospheric membrane;

- Idle system;

- Primer for pumping, which makes it easier to start the brushcutter engine;

- Elastic plate with two valves;

- Needle valve;

- Dosing system with rotating rotor;

- Throttle valve.

The carburetors of modern lawn mowers work according to a certain principle. The diagram below shows the movement of air and fuel mixture in the carburetor design.

First, the air enters the tube through the throttle valve, after which it passes to the diffuser - the place where the tube narrows, where the air flow becomes especially intense. From the diffuser, air enters the float chamber, where it is mixed with the fuel mixture. After this, the air-enriched fuel is sucked into the pipeline and enters the engine cylinder.

Adjusting the trimmer carburetor - how to set it correctly?

Before adjusting the carburetor for a brush cutter, you will need to clean all the air and fuel filters included in the tool’s design. Further adjustment of the carburetor is carried out using three screws:

- Right marked “L”;

- The lower one is marked “T”;

- The left one is marked “H”.

The correct procedure for adjusting the carburetor is as follows:

- First you need to find a stable low speed of the lawnmower engine. To do this, slowly turn the screw “L” clockwise and counterclockwise. Once you have determined the optimal low RPM for the engine, turn screw “L” ¼ turn counterclockwise;

- Then you need to find the most stable engine idle speed. To do this, you need to engage the “T” screw. By turning it clockwise, you increase the speed, and counterclockwise, you lower it.

- The last step will be to adjust the high speed of the lawnmower engine. To do this, you will need to press and hold the gas trigger, and at this time move the throttle lever to its highest position;

- After this, turn the screw “H” clockwise until you hear the motor running as quietly as possible;

- Then turn the same screw in the opposite direction until you hear the motor running rough;

- Turn screw “H” clockwise again until you hear the motor running smoothly.

After completing the above steps, you need to check the engine of the lawn mower. In this case, special attention should be paid to its operation at idle. If you have adjusted the carburetor correctly, you will notice that the cold engine runs steadily and the trimmer head has a large power reserve. In this case, a hot engine does not show high speed and runs stably when the gas trigger is pressed.

Adjusting the lawn mower carburetor: the main points

Despite their high productivity, mobility and unpretentiousness in operation, modern lawn mowers can hardly be classified as complex devices. Over time, any mechanism is subject to wear, and therefore parts and components require special attention from the owner. One of these trimmer elements is a carburetor, designed to form a fuel mixture and supply it to the combustion chamber. Increased consumption when the proportions of gasoline and oil are correctly observed or a drop in engine power indicates the need to adjust the carburetor of the gasoline trimmer.

Lawn mower consumption

A gas powered mower is no longer uncommon and can be found in almost every household area. There is nothing special about its design and even a beginner can use it. However, there are points that require special attention. For example, do you know what the gas consumption rate for a lawn mower should be, and what numbers this figure depends on? If not, this article will provide you with a very useful source of information.

So, first, let's find out what determines the consumption of gasoline lawn mowers. Here are some important points:

- Power.

- Features of the engine design (two- or four-stroke).

- Cutting width.

- Area of the site and its relief.

Let's talk in more detail about each of the factors.

Pay attention to the engine!

Do you want to keep your lawn mower's mileage to a minimum? Take a closer look at units with a 4-stroke engine, such as the Huter GLM-5.0. This model is more expensive than a two-stroke engine, but the fuel savings will significantly cover your budget.

What relief is there on your site?

When purchasing a lawn mower, keep in mind that most are designed for smooth surfaces. So if you have buds in your yard, make sure your new garden mate has big wheels that give her a good medium-sized ride. Thus, the device should not strain too much and consume a lot of fuel.

READ How to Change the Flywheel on a Stihl 55 Trimmer

It should be noted that for areas with difficult terrain, it is better to buy a front-wheel drive mower, which has better maneuverability.

Cutting capacity and width.

Both indicators are closely related. The greater the power, the greater the cutting width. Note that in the model you are interested in, these concepts are properly balanced. Accordingly, the larger the cutting width, the less time you spend mowing the lawn, and the gas mileage on the lawn mower in this case will not exceed the norm.

In addition, all cutting parts will not be subjected to heavy loads, which will significantly increase their service life. Let us remind you that all repairs and sharpening of cutting parts should only be performed by an after-sales service specialist.

Adjusting the carburetor trimmer

The initial step in restoring proper operation of the fuel system is to clean the air filter.

Trimmer carburetor with screws

- fuel adjustment screw (“L”);

- high speed adjustment screw (“H”);

- the screw responsible for idling the engine (“T” or “AT”).

Adjusting fuel supply at minimum speed

Before you start adjusting the gas trimmer carburetor, you need to warm up the engine to operating temperature.

Fuel adjustment screws

Setting trimmer idle speed

Location of carburetor adjustment screws

The “T” (“AT”) screw serves as a limiter for the reciprocating movement of the fuel valve and when it is tightened, the engine speed increases, and when unscrewed it leads to a decrease in the crankshaft speed. Professionals advise adjusting the idle screw of the lawn mower so that the internal combustion engine operates a little faster at minimum speed, but the head with the fishing line or knife remains motionless. If after these manipulations it is difficult to start the trimmer “cold”, then just tighten the “T” screw a quarter turn and try to start the engine again.

Adjusting the maximum speed screw of the brush cutter

After restoring the fuel supply to minimum speed and adjusting the idle speed, it is necessary to check the stability of the mechanism at increased speed.

Setting at maximum speed

Adjusting the motor at high speeds is carried out to protect against overheating and reduce hand fatigue when pressing the accelerator button. If the internal combustion engine operates unstable at maximum speed, then screw “H” must be tightened slowly until smooth and precise operation is ensured.

During operation of the brush cutter, it may be necessary to adjust the fuel supply screw (“L”) for optimal speed.

Gasoline trimmer: purpose of the tool in the country

A lawn trimmer is essentially a gas-powered grass scythe. It is used for mowing ornamental grass (leveling, trimming), for mowing weeds, and for cutting grass for hay.

The trimmer does this quickly and accurately, in addition, it is lightweight and easy to maintain and does not require much storage space - the main difference between a trimmer and a lawn mower.

With a trimmer you can not only cut grass and herbaceous plants, it perfectly cuts thin (2.5-3 cm in diameter) branches of trees and shrubs - so it can replace pruning shears in the garden.

Did you know? There are special models of trimmers that, in addition to their main purpose, can also be used for removing snow and clearing paths. Their kit includes snow removal attachments.

Before choosing a gasoline trimmer, you need to at least briefly know the basic parameters of the tool. The key when choosing a gas trimmer will be how often you plan to use it and what areas it is intended to cover.

Based on this, the best gasoline trimmer for your specific area is selected based on the power and performance of each individual model.

The best gas trimmers do not necessarily have the most power. If you have a small lawn, you won't need the most powerful trimmer. A good, medium-power gasoline trimmer will do just fine. But if the area being processed is large and there is a need to work on it for 6-7 hours a day, then a more powerful trimmer is needed.

According to the type of suspension, there are strap trimmers - the best option for infrequent use, and trimmers with a backpack suspension - these are best taken for constant, almost daily load on the tool.

According to the type of drive, gasoline trimmers come with a straight shaft or a metal cable. It is better to take a tool driven by a direct shaft - they are more wear-resistant. Based on the type of engine, gas trimmers are divided into two-stroke and four-stroke.

We suggest you read: When can you take out and plant geraniums outside in the spring?

The former are filled with oil already mixed with gasoline, the latter have separate compartments for oil and gasoline. Two-stroke engines are considered noisier, and their service life is often shorter. And four-stroke engines are more durable, more expensive to maintain and repair, but at the same time they are a little quieter.

The engine can be located in the upper or lower position. Those located at the top are preferable - they are more convenient to use, cool better, are more protected from clogging with grass and debris, and they usually have more power.

The line included with the trimmer is used only for cutting grass. There are several types of fishing line based on the type of pattern:

- in the shape of a star - for a green decorative lawn or young grass;

- in the shape of a square - for tall grass with thick stems;

- in the shape of a circle - a universal type, suitable for both the lawn and woody and dry grass stems and leaves.

To cut branches and trim bushes, you will need a knife. There are models equipped only with fishing line, and there are models with both fishing line and knives.

Based on the type of bar (handle), trimmers come with a curved handle for small loads or a straight handle for larger loads. The weight of the trimmer, as a rule, does not affect the operation of the tool in any way; it matters for the person working with it - if it is a man, then you can take a heavier model, if a woman, then a lighter one.

When choosing a tool by weight, you need to take into account the size of the trimmer's gas tank - the larger it is, the heavier the fully charged trimmer will be (on average by 0.6-1.5 kg).

Before choosing a lawn trimmer, study all the features of each model - some of them are equipped with additional useful functions. This could be a snow removal attachment, an anti-vibration system - for hand comfort, quick start of a trimmer with a decompression device, which increases the service life of the tool.

We invite you to familiarize yourself with the Roundup consumption rate

It should be noted that all improvements add value to the product. The most inexpensive are household trimmers, and the most expensive are brush cutters.

Important! The larger the trimmer's cutting width, the greater its performance.

Tips for repairing a gas trimmer carburetor

- Regardless of the manufacturer, there are factory defects in trimmer carburetor parts.

Adjustment screw spring

For example, the adjustment method described above may not give positive results if the number of turns of the mixture supply screw spring is too large and, as a result, it is impossible to optimally reduce the level of gasoline supplied. To eliminate this, you can shorten the spring yourself a little or purchase a new one in accordance with the instruction manual.

This is interesting: Overtaking on a winter road: important rules

When purchasing oil, many owners of lawn mowers follow the recommendations for preparing the fuel mixture indicated there.

Gasoline trimmer oil

So, often the information on mixing gasoline and oil indicated on the can differs from the instructions in the trimmer's passport. As a result, black carbon deposits can quickly form on the spark plug, which leads to a drop in power and increased fuel consumption. Therefore, when preparing the working mixture, you should follow the recommendations specified in the instruction manual. In most cases, the proportion for a run-in internal combustion engine is 1:25. It is worth noting that many tool owners prefer to prepare fuel “by eye,” which will certainly lead to rapid wear of the piston scythe if the oil portion is reduced and the formation of soot on the spark plug with an increased amount of lubricant.

- Correctly implemented above tips for adjusting the trimmer carburetor will help to avoid not only engine overheating and increased fuel consumption, but will also significantly increase the service life of other parts and components of the tool. Pay attention to the operation of the lawn mower in all modes and carry out scheduled maintenance and repair of the tool on time.

Scope of application

Gasoline lawn mowers have a huge range of applications; large devices such as riders can be used in agriculture. To maintain cottages and houses, it is more advisable to use trimmers or devices on wheels, since they are cheaper and easier to operate. A large number of trimmers are purchased for private organizations that monitor the surrounding areas of their offices and enterprises.

Review of the best models

Among the large number of mowers on the market, the following models can be distinguished from the rating:

- Among the wheeled models, one of the best is the Garden Scout. This is a rotary lawn mower that is ideal for medium-sized areas at home or in a summer cottage;

- Champion produces both mechanical and a variety of trimmer and wheel trimmer models. Models from the LM series are suitable for home and garden use.

Important! A gasoline lawn mower does not require special care. It is enough to regularly change the oil and clean the working elements and components. The frequency and conditions of maintenance are specified in the instructions.

A gasoline lawn mower is the simplest and most common device for working in various conditions. But when purchasing, you need to weigh the pros and cons of a particular model, as well as what goals the summer resident sets before purchasing the unit. In any case, a gasoline lawn mower will become an indispensable assistant in any household, no matter how much it costs!

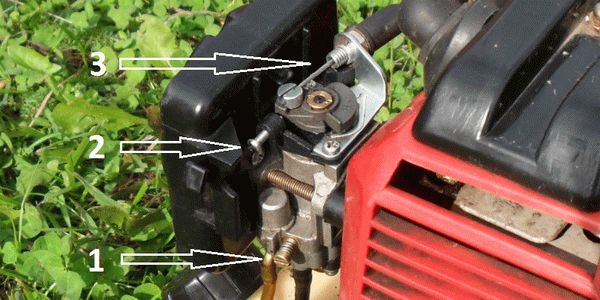

Carburetor adjustment

Before adjusting the carburetor, wash the air filter. It is recommended to wash it after every 10 hours of operation. After this you can start making adjustments. The example photo shows the carburetor of the PRORAB-8406 petrol trimmer. The numbers indicate the adjusting screws that we will use.

Carburetor adjustment screws for petrol trimmer PRORAB-8406

Purpose of adjusting screws:

- Fuel mixture supply adjustment screw.

- Idle speed adjustment screw.

- Maximum speed limit screw.

Start the lawn mower and wait until it warms up.

Fuel supply adjustment

Start slowly turning the fuel mixture adjustment screw until the engine starts to stall, or until it stalls if you don’t have time to catch the moment. After this, unscrew the screw a quarter turn if the engine does not stall, or half a turn if it does stall. Start the stalled engine. Check by opening the throttle to see how the engine picks up speed. Continue unscrewing screw No. 1 a quarter turn until the engine, when accelerating, begins to confidently gain increased speed. This will be the moment of the most economical stable operation of the engine. For the petrol trimmer PRORAB-8406, the adjusting screws are turned clockwise and unscrewed counterclockwise; for some other brands of gas trimmers it may be the other way around.

Idle speed adjustment

Let's start adjusting low speeds. Screw No. 2 limits the return movement of the throttle lever - by turning it, we increase the idle speed, and by unscrewing it, we decrease it. Adjust so that the engine runs confidently at low speeds and even a little faster (for better starting), but so that the reel with fishing line or the knife does not rotate, and there is a sufficient reserve of revolutions before they begin to rotate. If the engine has difficulty starting, increase the idle speed further.

Maximum speed limit

After adjusting the fuel mixture supply and low speed, check how the lawnmower engine will operate at maximum speed. If necessary, limit the maximum speed to the required level using the #3 hollow screw. Loosen the locking nut and screw in the screw to decrease the maximum speed, or turn it out to increase. After adjustment, tighten the nut. Setting the maximum speed is necessary to protect the trimmer motor from overheating and the ability to use the start key lock to reduce fatigue of the right hand.

In the future, it may be necessary to adjust the trimmer carburetor. For example, if the engine starts to rev poorly when running at full load, unscrew screw No. 1 another quarter turn. If starting is difficult, increase the idle speed. Both weather conditions and the quality of the fuel mixture can affect the operation of lawn mowers. Vibration can cause the adjusting screws themselves to turn.

Fuel Consumption Rate for a Husqvarna Lawn Mower

Content

Features of Husqvarna gas tank models

The mower is a reliable and indispensable assistant for every modern summer resident and home owner in cutting grass, fighting weeds and weeds. Its independence from electricity makes the gas scythe more efficient and maneuverable.

Husqvarna hand trimmers, traditionally used for this type of mower, consist of a rod on which the motor and operating element are mounted at different poles. The quality of workmanship, guaranteed by the Swedish manufacturer and appreciated by the consumer, has made gasoline scythes of this brand a leader in its segment.

1 Top model of Husqvarna household gas station

The Husqvarna 128 R is popular among home users for treating small areas. It has the following main technical characteristics:

- two-stroke two-stroke gasoline unit with a displacement of 28 cm3;

- engine power 0.8 kW or 1.1 l s;

- fuel tank with a volume of 0.4 liters with a fuel consumption of 507 liters per hour;

- straight fixed rod with a diameter of 24 mm;

- T-type bicycle handle with engine control parts, increased ergonomics;

- presence of an anti-vibration system;

- The cutting system consists of a 2.4 mm wide blade and a metal four-bladed knife;

- cutting width 25.5 cm of knife and up to 40 cm of fishing line;

- overall dimensions 286 × 244x1829 mm;

- weight 5.0 kg.

Gasoline trimmer Husqvarna

The multifunctional petrol machine Husqvarna 128 R, capable of easily and quickly changing cutting elements, is designed for convenient and productive work in garden and lawn care. Safety in operation is ensured by the presence of a protective casing. This prevents accidental contact with cutting parts.

READ Husqvarna Chainsaw Starts Poorly

Husqvarna 128 R has a manual starting system. Smart start. Starter cord reduces resistance by 40%. The Start button is the return type. Once pressed, it automatically returns to its previous position and is ready for easy starting again.

The development of the Husqvarna 128 R has been equipped with the latest E-TESN 2 technology, which reduces exhaust emissions. This does not affect engine power, but ensures environmental friendliness with low exhaust gases.

The ergonomics of the handle and the ease of holding the device are ensured by an optimal angle of inclination and an anti-vibration system. This allows you to work with the Husqvarna gasoline pump for a long time without experiencing fatigue or discomfort.

Standard equipment for gasoline pumps

The standard version of the Husqvarna 128 R model, belonging to the household class, includes:

- brushcutter directly;

- backpack fastening two shoulder type;

- semi-automatic trimmer head T 25 with fishing line;

- knife with four blades made of metal Grass.

1.1 Review of the motorcycle trimmer. trimmer HUSQVARNA 128R

1.2. Husqvarna's top car-class model

Husqvarna 323 R is a professional lawn mower with a lightweight design that has won the favor of users. Ideal for treating large areas in parks, golf courses, etc. Long and hard work with this device will not feel like hard work.

Motokosa: oil, gasoline and overtaking

The question is how much oil should be given, which is one, gasoline: 92 or 95, what if the instructions say otherwise. AND.

Preparation of the fuel mixture for two-stroke engines

The video shows how to make a fuel mixture for two-stroke engines. Filling mills, chainsaws, etc.

The technical characteristics of this model are as follows:

- two-stroke gasoline engine with a cylinder capacity of 24.5 cm3;

- power 0.9 kW or 1.2 liters;

- fuel tank with a volume of 0.5 liters with a fuel consumption of 0.495 liters per hour;

- straight rod with T-handle 1483 mm long and 24 mm thick;

- presence of an anti-vibration system;

- The cutting system consists of a 2.4 mm thick blade and a metal knife;

- Overall dimensions: 1844 × 270 × 285 × 132 mm;

- weight 4.5 kg.

READ Husqvarna 372 DIY Repair

Husqvarna 323 R Petrol

This machine also makes it easy and quick to replace the cutting element. The universal protective cover allows you to safely change the cutting part on the rod and the mowing process itself.

The model is equipped with a Smart start easy-start system; the primer pumps air into the carburetor. The fuel pump forces gasoline into the carburetor after a long period of inactivity and provides a quick start.

Ignition switch with return spring. The fuel tank is transparent, which allows you to control the amount of fuel.

The bevel gearbox has high torque up to 9000 rpm with the cutting edge parallel to the ground. This ensures the quality of the grass.

The ergonomic handle, positioned at an adjustable angle to the shaft, has control buttons.

Standard equipment on the Husqvarna 323 R includes:

- motokosa;

- semi-automatic trimmer head T 25R with line;

- grass cutting knife Graas 255-4;

- backpack fastening two shoulder type.

Using this model makes it easy to mow grass of any hardness, bushes and tree seedlings. to menu

2 Operation and repair of Husqvarna gasoline pumps

Before starting work, the vehicle must be prepared. Therefore:

Cutting element options

- lubrication of all friction parts;

- installation of the cutting element;

- filling the fuel mixture.

Gasoline for refueling must be of good quality AI class 92. Fuel with a higher octane number cannot be used. The device will overheat and the motor will quickly fail. The fuel mixture should not be stored for future use; when it is stored, it loses its quality. It is recommended to use only freshly prepared mixture with special oil for two-stroke engines. Good fuel is the main criterion for the performance of the device.

READ Husqvarna Ignition Coil Gap

Stopping gasoline operation can be caused by clogged fuel or air filters. If the engine stalls or is poorly started, and there is a fuel mixture in the tank and its quality is beyond doubt, you need to pay attention to the filters. Often they must be sufficiently cleaned or washed with gasoline or water and detergent, and then taken back. If heavily soiled, replacement is required.

Trigger repair

- Starter failure . a breakdown of the cable handle or a breakdown of the cable itself can be repaired independently. Other problems with the starter can be eliminated by replacing it completely.

- There was a spark. You need to clean the spark plug, make sure it works and return it to its place or replace it.

- The engine starts after starting and there is a lot of vibration. There is a misalignment in the carburetor setting. Individually adjustable using adjusting screws.

- The reason why the engine stops after starting may be a clogged fuel valve. By cleaning and cleaning it, we will restore fuel flow to the carburetor.

This is often a faulty tool. Their list is much wider. When purchasing gasoline pumps, you should pay attention to the presence of a technical passport with operating rules. They contain a detailed description of possible failures and step-by-step actions to resolve them. Husqvarna's instructions are very easy to understand and work on.

The manufacturer provides a warranty for all Husqvarna models. For consumer models, the warranty period is 2 years. For cool tools. professional, it's one year.

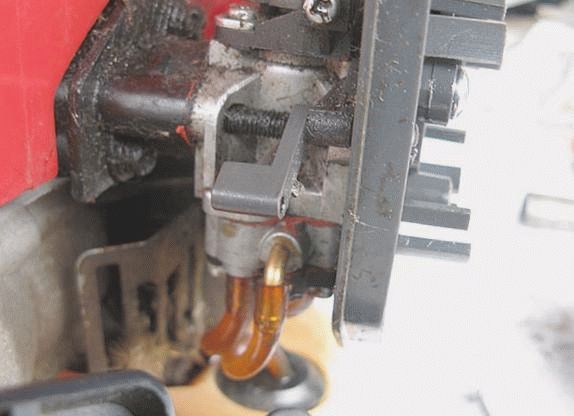

The spring may interfere

My first attempt to adjust the carburetor of the lawn mower did not yield anything, since the spring of the fuel mixture adjustment screw was in the way. The factory spring turned out to be too thick when compressed and did not make it possible to reduce the fuel supply to the required level. I had to pick up another spring and continue the adjustment after replacing it.

Fuel mixture supply adjusting screw with spring

In the photo above there is a factory spring, below there is an adjusting screw with a selected spring. I’m writing about this because I’m not sure that this is an isolated case and that someone else may encounter the same situation.

From personal experience

Petrol mower or trimmer

A trimmer is a broader concept than a lawn mower, since it can also be electric. A gasoline trimmer and a gas mower are one and the same.

Some authors claim that a trimmer is a weaker tool, in contrast to a more powerful brush cutter, which can be used for mowing bushes. Personally, I have a tool with a maximum power of 1.7 kW and, as stated in the instructions, capable of mowing small bushes up to 10 mm thick. The user manual is called “Gasoline trimmer. "

Fuel mixture proportion

I read somewhere that if the operating manual for the lawn mower and the oil canister indicate different proportions for preparing the fuel mixture, you should use the proportion indicated in the manual.

For a long time I did this - excess oil flowed from the engine onto the gas tank and carbon deposits constantly formed on the spark plug, since the manual indicated the proportion for a run-in engine was 1:25, and on the canister - 1:50. After switching to a ratio of 1:50, the appearance of oil drips stopped. The spark plug continued to burn, but with less intensity (the carburetor was not yet adjusted).

Until now, some users of gas-powered tools determine the proportion of the fuel mixture “by eye.” If the amount of oil is underestimated when preparing the mixture, after some time an extraneous sound may appear immediately after starting the engine, which gradually disappears during warm-up, and the engine stops with a sharp jerk. Continuing to operate the trimmer in this mode will result in its failure.

Gasoline consumption standards for trimmers

For example, the Husqvarna 122C, which has a 0.8-liter two-stroke engine, consumes 630 g/kW/h. The fuel consumption of the STIHL FS 50 CE gas mowers is 20 percent lower. In addition, it emits 70 percent less harmful emissions into the environment than two-stroke models.

The following are tips that experts give to users. They relate to the choice and use of the fuel mixture.

Experts advise buying mainly AI-92 gasoline for trimmers. To prepare a mixture with the correct ratio of oil and gasoline, you need to maintain a balance of 1:30. Violation of this ratio leads to engine damage.

Store the mixture in containers that are clean and safe. Since the fuel mixture sometimes settles, be sure to shake the can before refueling.

There is no point in pouring more gas than you can use. Then it is better to fill than to clean the container.

MAIN! The lawn mower will last a long time and will be economical in fuel consumption for those who strictly follow the simple rules for storing the trimmer.

The gasoline engine has a complex structure and therefore requires constant maintenance. Therefore, before starting work, you must familiarize yourself with the operating rules of the device and follow the recommendations developed by the manufacturer.

It is necessary to constantly monitor the cleanliness of the internal surface of the case. To prevent the corrosive juice of the caustic grass from corroding any part of the device, experts recommend cleaning the machine after finishing work.

READ How to Properly Sharpen a Lawn Mower Blade

Before purchasing a mower, you need to determine where it will be stored. In this case, it is necessary to take into account the dimensions of the device. It makes sense to look at a model that folds the handle. In this case, it will find a place in any storage. That is, this option is simply perfect for storing the device.