How to make a reversible plow for a walk-behind tractor

To understand what a reversible plow is and how to make a reversible plow for a walk-behind tractor, let's look at the plowing process - the usual turning over of the earth, i.e. what was below turns out to be above, and vice versa.

After the plow passes through the ground, a furrow remains, dividing the area into plowed and not. Depending on the direction, the plow turns the earth either to the left or to the right. There are disadvantages to working on small plots of land. When you plow into a dump, when you turn the tractor, you get a small mound.

And when they plow sideways, they get a furrow in the middle. As a result, the garden turns out uneven. To avoid this, when using a walk-behind tractor or a walk-behind tractor, they try to back away and plow again. But there is idling, because when the tractor goes in one direction, it plows, but not in the other. To solve this problem, various reversible plows were invented. There are quite a few designs of such plows, but when using them, fuel and time are significantly saved and work becomes more convenient.

Kuhn Manager reversible plow

Also check out these articles

- Rotary mower for walk-behind tractor Neva

- Insecticide Coragen

- Chisel plow

- Cultivator Hyundai T 850

The ability to select the working width and protection system made the Manager model range ideal for working with medium-power tractors, such as KhTZ-17221, Case Magnum 310, MTZ-2022 and others, and under any working conditions. The maneuverability of the reversible plow allows you to work with high productivity even on small plots. You can work with the same tractor as for a mounted plow, but using a larger number of bodies and working width.

Photo of Kuhn Manager reversible plow

The tilt of the reversing mechanism allows you to smoothly rotate the plow in relation to the direction of movement. The load-bearing wheels are located close to the tractor for an optimal turning radius, which guarantees straightness when exiting the furrow and minimal unplowed space at the edge of the field.

Specially designed plow head articulations provide a rotation angle of 110°.

The support frame of the Kuhn Manager reversible plow allows you to significantly reduce the load on the tractor coupling device during reversal of the plow. This technological solution also allows for a lower center of gravity. The rotation of the plow is carried out by 2 linear hydraulic cylinders, directly connected to the moving parts, without a mechanical system. This extremely simple, wear-free technology does not require special maintenance.

The articulated joint allows the plow to follow the undulations of the working area. Due to this, a uniform plowing depth is ensured. Moreover, when leaving the furrow, when the front bodies are deepened, the rear ones still continue processing. This technology allows for better plowing of field edges and reduced unevenness. The system is automatically locked when the furrow exits (the lock is closed during maneuvering and during transportation) and is released when entering the furrow.

After processing, the soil is ready for the use of other mechanized means, for example, precision seeders, etc.

Technical features of the cabinet Kuhn Manager

- Semi-automatic hitch with variable height - the procedure for attaching and uncoupling is simplified;

- An articulated frame with mechanical adjustment of articulation stiffness ensures structural rigidity;

- Patented bolt-on burst fuses reduce damage to struts during actuation;

- The dumps are made of “Triplex” steel using the most unique hydraulic press in Europe under a pressure of 5000 tons;

- The hardness of the dumps is 9000 vickers - the highest in the industry;

- Single or double acting automatic turning cylinder does not require high oil pressure in the tractor hydraulic system to turn;

- Innovative design of the bolt fuse: it is triggered not by shearing, but by rupture - thereby eliminating the deformation of the body, thereby extending its service life;

- Simplicity, efficiency and durability;

- Only Kuhn Manager and Kuhn Challenger plows have a carriage with two support wheels;

- It is possible to add another building.

Technical characteristics of the Kuhn Manager reversible plow

| Technical specifications | Manager C - 5-case | Manager C - 6-case | Manager C - 7-case |

| Number of cases | 5 | 6 | 7 |

| Maximum tractor power (kW) | 110 | 132 | 154 |

| Maximum tractor power (hp) | 150 | 180 | 209 |

| Prevention | bolt break fuses T | bolt break fuses T | bolt break fuses T |

| Working width (cm) | 35 and 40 | 35 and 40 | 35 and 40 |

| Height under frame (cm) | 80 | 80 | 80 |

| Distance between housings (cm) | 102 | 102 | 102 |

| Frame square section (mm) | 180 | 180 | 180 |

| Type of dumps | cylindrical - screw - strip | cylindrical - screw - strip | cylindrical - screw - strip |

Installation of a reversible plow to a walk-behind tractor

Let's look at the design of a reversible plow for a walk-behind tractor using a specific example.

The plow is designed for crumbling and turning the arable layer, and is recommended for use on soils that have already been cultivated.

Main characteristics of the plow

- Plowing depth 20cm;

- Width of ploughshare (grab) 22 cm;

- To adjust the plowing depth, there are 3 holes in the stand;

- Height 76 cm;

- Width 32 cm;

- Length 48 cm;

The plow is connected to the walk-behind tractor using an appropriate hitch.

The plow must be adjusted so that the side edge of the field board during operation is parallel to the direction of movement, i.e. along the wall of the furrow. And the support triangle formed by the cutting edge of the ploughshare, the heel and the bottom edge of the field board must be in a horizontal plane.

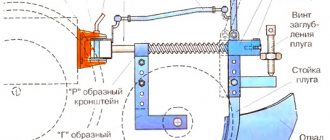

In order to adjust the plowing depth, you need to adjust the angle of inclination of the plow body in the vertical-longitudinal plane. To do this, use additional holes in the mini-coupler bracket and the plow stand, or use the hitch adjusting screw.

During operation, you can adjust the correct installation of the plow. The design of this reversible plow allows the soil layer to be dumped in one direction, both during forward and reverse strokes. To change the body of the reversible plow, it is enough to rotate it 180° around its axis and lock it in the working position. Before you start working with the plow, you need to equip it with lugs to ensure reliable adhesion of the unit drive to the cultivated soil.

Safety precautions when working with a reversible plow

Before starting work, check that all threaded connections are securely tightened. Remove all foreign objects from the treated area. When maneuvering the machine with the plow installed, as well as when reversing, be especially careful. To avoid injury from protruding sharp corners and edges, maintain a safe distance from the implement while operating.

Wear protective gloves when servicing the implement. When you have finished your work, you need to clean the plow. All parts and threaded connections that do not have a paint coating must be treated with lubricant. The plow must be stored indoors.

Reversible plow Lemken

Each unit of this company is assembled individually, at the request of the buyer and taking into account his needs. Lemken have a stepped system with a working width of 30-50 cm. The model range can be with 1-6 bodies. The distance between the bodies of the models is 90 or 100 cm. It is aggregated with tractors 45-250 hp type YuMZ-6 but more powerful. Lemken offers its customers plows in the OF version, which make it possible to plow both in the furrow and outside.

Photo of Lemken reversible plow

All Lemken machines have modern Unitron hydraulics and a double-acting switching cylinder, automatic fixation of the vertical position of the plow in the furrow. This makes it possible to quickly deploy the equipment and, when working, you need to additionally adjust the angle of inclination of the plow. The basic configuration includes a tool box, so every shear bolt is always at hand.

Technical features of Lemken plows

- semi-mounted reversible plow for highest productivity with hydraulic or stepwise adjustment of the working width of each body from 30 to 55 cm

- variants from five to nine furrows for tractors with power from 92 kW (125 hp)

- distance between bodies 100 or 120 cm, frame height 80 cm

- Comfortable, tool-free skimmer adjustment

- The support wheel moves within the plow frame (from six-furrow plows) for optimal plowing at the edge of the field and plowing near fences or other obstacles

- also available with continuous mechanical or hydraulic overload protection system

- Also available in Onland version for plowing, both in-furrow and out-of-furrow.

- The plow tower has a solid linkage shaft of category II or III made of spring steel.

- By absorbing large shock loads, the shaft protects the tractor and tower.

- The tower is attached to the frame using an axle made of high-quality heat-treated steel.

- The axle has two roller bearings that are accessible for lubrication. Particular strength and long service life are guaranteed.

A similar effect from use is given by the PPO 8-40 plow.

Lemken Specifications

| Specifications | Number of cases | ||||

| 2 | 3 | 4 | 5 | 6 | |

| frame 110x110x8 mm (Europal) | |||||

| Width of cultivated soil, cm | 60-100 | 90-150 | 120-200 | ||

| Weight, kg | 552 | 707 | 862 | ||

| Power, hp | 70 | 80 | 100 | ||

| frame 120x120x10 mm (VariOpal) | |||||

| Width of cultivated soil, cm | 90-150 | 120-200 | 150-200 | ||

| Weight, kg | 753 | 949 | 1.180 | ||

| Power, hp | 100 | 130 | 160 | ||

| frame 140x140x10 mm (Juvel) | |||||

| Width of cultivated soil, cm | 120-200 | 150-250 | 180-300 | ||

| Weight, kg | 1.210 | 1.410 | 1.610 | ||

| Power, hp | 160 | 190 | 230 | ||

| frame 160x160x10 mm (VariDiamant) | |||||

| Width of cultivated soil, cm | 120-200 | 150-250 | 180-300 | ||

| Weight, kg | 1.280 | 1.495 | 1.710 | ||

| Power, hp | 180 | 210 | 250 | ||

Video review of the Lemken plow

Do-it-yourself reversible plow for walk-behind tractor, drawings and description

If there is no experience in this type of activity, you should first consult with a specialist to understand the main complexities of the process.

Each type of plow has its own design features. The simplest design has a single-body plow, and this is the best option for beginners who do not have the appropriate skills in this matter.

At the top of the reversible plow body there is a curved feather, which allows you to process the overturned layer of earth. Therefore, this product is optimal for processing hard soil.

In the process of manufacturing such a structure, it is very important to follow all instructions and carefully follow the drawing parameters. The slightest inaccuracy will significantly affect the characteristics of the product, and during operation will negatively manifest itself in the results of work.

To make a plow you need to use steel 3-5 mm thick. The ploughshare is made first. It must be removable. The cutting part must be beaten on an anvil and sharpened.

The next thing is to do the dump.

A pipe with a diameter of half a meter and a wall thickness of 5 mm is used as a blank. Using gas welding, the blade blank is cut out according to a template and subjected to grinding with a grinder. After manufacturing these two parts, the plow body is made from steel 2-3 mm thick and the structure is assembled.

Plow design for walk-behind tractor

The plow has a suitable geometric shape of its share and a heel design for plowing hard, lying soil. The design of the unit itself for the walk-behind tractor is dismountable. It is made of durable material, since this part is subject to heavy loads when working. After the plow, the land is cultivated with a cultivator.

For each type of walk-behind tractor, for example Neva, Cascade, Favarit, Salyut, there are several types of such equipment. Also today there are universal models that are suitable for almost all types of equipment.

There are two types of plows for walk-behind tractors:

- Single-hull. This is a single share plow suitable for light soil.

- Reversible or reversible. Such models immediately turn over the soil thanks to their shape in the form of a curved feather at the top. This model makes it possible to work on harder ground. The soil after processing with this technique has a more crumbly appearance and is easier to process in the future. Weeds practically do not appear on such soil.

- Rotary. Has several blades.

You can learn more about the variety of plow in the thematic video.

Adjusting and setting up a plow for a walk-behind tractor

After the plow is made, you need to configure it. But before that, you need to configure the walk-behind tractor. After the walk-behind tractor has been taken out to the field, the wheels with rubber tires must be removed and replaced with wheels that are equipped with lugs.

Otherwise, during plowing, the walk-behind tractor with a reversible plow will begin to slip due to soil resistance.

Then the plow for the walk-behind tractor is attached to the attachment. To adjust the device, the nuts on the mount are not fully tightened. Then, using two metal pins, we fix the unit with the motoblock mounting bracket. The quality of plowing directly depends on the most correct setting.

Basic steps for adjusting the plow

To carry out balancing, the walk-behind tractor is installed with its wheels on specially prepared stands. The depth of plowing depends on the height of these stands. For winter tillage, the height of the stands is 20-25 cm, for spring tillage - approximately 15-20 cm.

Using the adjusting bolts, you need to set the angle of the plow. We make sure that the “heel” of the plow remains parallel to the ground surface.

After securing the plow, the walk-behind tractor is placed on the ground. The control handles are adjusted to the height of the plowman's lower back.

At the last stage, we evaluate the correctness of the plow settings using an experimental method.

We plow two or three furrows and determine the cutting depth, the distance between the ridges and the quality of the soil dump. If the distance between the furrows is more than 10 cm, or they overlap, then repeat the adjustment.

Review of the most popular plow models for walk-behind tractors

Selecting the model of this unit you need depends on the type of soil on your site, the power of the walk-behind tractor, as well as its model. It is worth noting that a lot depends on the correct installation and configuration of the plow before work. Let's look at the most popular models of this unit for plowing land today in the form of a table.

| Model | Type | Weight | Tillage depth | Walk-behind tractor for work | Price |

| For G85/G85D/G107D | Negotiable | 12 kg | 20cm | G85/G85D/G107D | 16 00-1700 rubles |

| Without hitch for walk-behind tractors Favorit, Salyut, Cascade, Neva, MB-1, OKA | Single-hull | 9.55 kg | 15-20 cm | Favorite, Salyut, Cascade, Neva, MB-1, OKA | 1,750-1,800 rubles |

| Reversible for walk-behind tractor GS 81, GS 101, GS 12 | Negotiable | 18 kg | 20-25 cm | Garden Scout GS 81, GS 101 and GS 12, as well as with tractors based on walk-behind tractors | 3300-3500 rubles |

| On the Salute walk-behind tractor | Single-hull | 8 kg | 15-20 cm | Firework | 1500-1600 rubles |

| For walk-behind tractor Oka, Ugra, Salyut, Neva, Mole | Negotiable | 10 kg | 20-25 cm | Oka, Ugra, Salyut, Neva, Mole | 1300-1800 rubles |

| Mole plow for walk-behind tractor | Single-hull | 8.59 kg | 15-20 cm | MKM-3 Lander (Plowman), Hitachi S169, NMB-1 Ugra, MB-2 Neva, MB-1 Oka, Cascade, Beam, Favorite, Salyut-5, Agat | 1000-1200 rubles |

| Double-turn plow for walk-behind tractor | Negotiable | 15 kg | 15-20 cm | MKM-3 Lander (Plowman), Hitachi S169, NMB-1 Ugra, Mobile K G85, MB-2 Neva, MB-1 Oka, Cascade, Beam | 4050-4150 rubles |

| Plow P1-20/3 for walk-behind tractor | Negotiable | 13 kg | 20-25 cm | Mobile K G85, Ghepard, Agros, MTZ Belarus | 1300-1500 rubles |

| Plow P1-20/2 for walk-behind tractor | Single-hull | 8.5 kg | 15-20 cm | MKM-3 Lander (Plowman), Hitachi S169, Mobile K G85, NMB-1 Ugra, MB-2 Neva, MB-1 Oka, Cascade, Beam, Favorite, Salyut-5, Agat | 1200-1300 rubles |

| Rotary plow on walk-behind tractor | Reversible, has several blades | 40 kg | 30 cm | For almost all walk-behind tractors | 70000-78000 rubles |

| Zykov's plow | Negotiable | 9kg | 20-25 cm | Neva, Salyut, Favarit, Oka | 1700-1800 rubles |

If you compare the prices in the table, you can see. That you can purchase this product for plowing land in Russia at a price of 1,000 to 5,000 thousand rubles. Of course, this does not take into account the Rotary model, but this technique is different from all the others. Having looked at the average price review for these products, I would like to dwell in more detail on some models that have distinctive features. By the way, if you don’t want to buy it, you can make a homemade plow for a walk-behind tractor.

Zykov's plow

Zykov's plow differs from other models in its specially designed shape. This allows you to work with it well, crumble and turn the soil well. Thanks to this, it is possible to achieve almost complete disappearance of weeds.

This model consists of:

— the body of the unit, which has a ploughshare;

— a rack with which the equipment is attached to the walk-behind tractor;

—

field board, thanks to which the equipment rests against the wall of the furrow and makes the model more stable;

— supporting part;

- a feather that turns the soil and allows you to obtain more uniform and even arable land.

Rotary plow

This model is completely different from all the others. It is often compared to a cultivator. The design of the rotary unit consists of several curved shares, which are fixed on one axis. During operation, such an axis rotates and turns the soil, which significantly distinguishes this model from a cultivator.

The rotary unit cultivates the soil to a depth of 25-30 cm, with little physical effort. Working with such a model is easier than with conventional equipment, since you can

move not only along a straight path. Now many farmers are arguing about the efficiency of the rotary unit, but it is more popular among summer residents when cultivating woven and overgrown soil.

We present to you a video on working on a rotary unit, where the actions themselves speak for themselves.

Of course, there is no point in buying such expensive equipment for cultivating a small plot, since it will be cheaper to hire workers with professional equipment. Which will dig everything up once, and in the future such heavy plowing will no longer be required. And to cultivate not very compacted soil, you can use a simple cultivator plow or a double-turn plow.