Place of the Vector-410 combine in the Rostselmash product line

The Vector combine can be called the “younger brother” of another modern Rostov combine, the Akros. Both families belong to the single-drum type of grain harvesting agricultural machines. "Akros" is a new fifth-class combine harvester, and "Vector" is a fourth-class one. The Vector-410 modification is a combine harvester equipped with almost the same equipment as the Acros, but much more compact and economical to use.

In general, from the standpoint of economic efficiency, Akros combines require a larger scope and larger areas per season than Vectors. The Vector has a less powerful (but also more economical) engine, a smaller hopper volume and lower productivity. Its element is small peasant farms, where its use is most appropriate and economically profitable.

The Akros-530 was the first to go into mass production at Rostselmash in May 2007. "Vector-410" followed it in 2009. This development of the Rostselmash design bureau also became a completely new project, created from scratch, taking into account all modern trends in the global combine construction.

“Vector-410” (design name RSM-101) was for the first time in the history of domestic production of agricultural machinery developed not through paper drawings, but in an electronic end-to-end design system. This approach helped in creating a truly modern, competitive agricultural machine in all respects. A clear and conscious focus on market needs played an important role in the process of launching this model into series.

In this sense, it was designed to meet the needs of small and medium-sized farms. For whom the acquisition of more powerful and productive equipment, especially imported equipment, is too expensive.

On the other hand, to continue to use the Niva, Yenisei and other Soviet-era combines that have exhausted their service life many times over means constantly investing in the repair of long-standing and fairly “tired” agricultural machinery. Moreover, the funds are not only monetary, but also temporary. But during the harvest, every day and even hour has a special meaning.

Technical characteristics of the Vector-410 combine

The overall dimensions of the Vector-410 combine are slightly smaller than those of the Akros harvester. In the transport position, without the header, they are:

- Length x Width x Height (in mm): 7938 x 3559 x 4010. Length with header - 12 meters.

Unloading a full bunker on the Vector takes only 2 minutes.

At the same time, the bunker, located immediately behind the cabin and having a volume of 4.5 cubic meters, can increase in height, expanding the volume accordingly, up to six “cubes”. The hopper is opened in height using an electric mechanism. The operator does not need to leave the cab for this.

- The volume of the bunker is from 4.5 to 6 cubic meters.

- The speed of unloading grain from the bunker into the body of the vehicle is 42 liters per second.

- The height of grain unloading from the bunker is 3475 mm.

- The weight of the Vector-410 combine (without header) is 11075 (+/-300) kg.

We recommend reading: Terex TLB 825 RM: technical specifications

An important advantage of the Vector-410 combine (and other Vectors too) is that in its class only it can produce such a variety of schemes for working with the non-grain part of the crop.

Straw can not only be chopped and scattered across the field, but also collected for cattle feed, placed in neat windrows or stacks. Since “Vector-410” can, if necessary, be equipped with a forming stacker, with pre-pressing, the capacity of which is 12 cubic meters. This device collects straw into dense piles and automatically unloads them on the go.

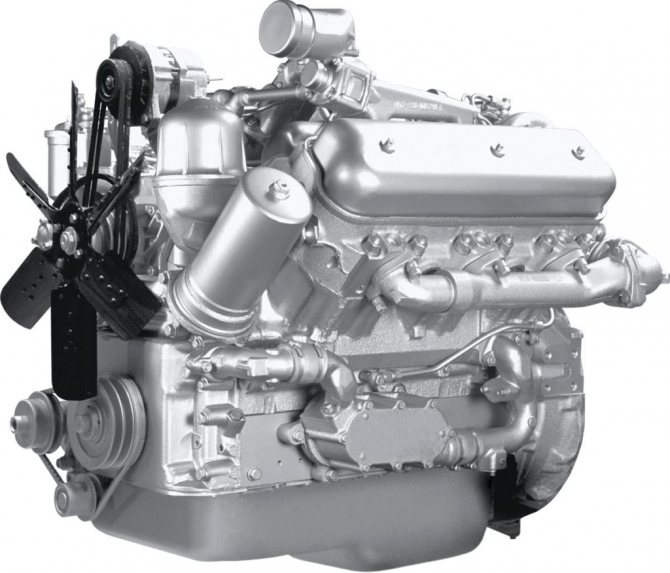

Engine of the Vector-410 combine

Vector-410 combine harvesters are equipped with a turbocharged diesel engine from Yaroslavl Motor. This is a six-cylinder, four-stroke V-shaped diesel engine with turbocharging, liquid cooling, liquid-oil heat exchanger, mechanical speed controller, with intermediate cooling of charge air in an air-to-air heat exchanger installed on the product.

It should be noted that these motors were developed and put into production specifically for installation on Rostov combines of the Vector family, as part of long-term cooperation between Rostselmash and Yaroslavl Motors.

- The power of the YaMZ 236-ND engine is 210 horsepower, or 154.5 kilowatts.

- Overall dimensions of the motor (Length x Width x Height), in mm: 1210 x 1045 x 1100.

- Engine weight – 985 kg.

- Rotation speed, min-1: 1900.

- Maximum torque, N.m (kgf.m): 882 (90).

- Frequency at maximum torque, min-1: 1200-1400

Turbocharged diesel YaMZ 236-ND.

An important feature of this modern, economical turbocharged diesel engine is the additional power reserve. It allows you to provide all the necessary technological processes under any conditions. Under intense and peak loads, this engine provides an additional increase in power from fifteen to twenty percent.

Fuel consumption, economic efficiency, ease of maintenance

As you know, the cost of fuel consumed is the main and most significant cost item for maintaining a combine. In this regard, Rostselmash positions the Vector-410 as an extremely economical combine with one of the lowest operating fuel consumption rates in its class - from 1.8 to 2.5 liters of diesel fuel for every ton of threshed grain.

Coupled with a “spacious” fuel tank of 540 liters, an excellent result is achieved, so to speak, “operational logistics” - at least 16 hours of continuous operation without the need for additional refueling of the combine. Thus, Vector-410 works two full eight-hour shifts without refueling.

Vector combines are also equipped with an air compressor with a 110-liter receiver. With its help, you can, if necessary, carry out shift maintenance of the combine directly in the field. The system ensures that the compressor runs for five minutes when the engine is off.

As in Akros, the engine in Vector-410 is located at the rear, immediately behind the bunker and is arranged in such a way as to ensure maximum accessibility of all necessary parts and assemblies during maintenance.

Transmission and chassis "Vector-410"

Vector combines are equipped with a hydrostatic transmission GST-112, which provides stepless adjustment of the speed of the agricultural machine within each of the three gears. The range of operating speeds is wide enough to optimize the loading of the MSU (threshing and separating device).

"Vector-410" at harvest.

The hydrostatic transmission changes gears extremely smoothly, which contributes to better cleaning of complex and problematic areas of grain fields. The speed of the Vector-410 combine is up to 25 kilometers per hour.

- Drive wheel tire type – 28L/R26.

- Steering wheel tire type – 18.4/R24.

As additional options, the Vector-410 combine harvester is available in an all-wheel drive version, and can also be equipped with a replaceable half-track. The all-wheel drive modification and tracked chassis are a good help and real help when working on marshy and swampy soils, as well as when harvesting rice.

We recommend reading: Made for CLAAS: Bor plant will begin serial production of glass for TUCANO combines

Hydraulic system of the Vector-410 combine

Power hydraulic pumps of three systems (main, steering, chassis) are combined on Vector-410 into a single pumping station unit. The working fluid for all systems is the same and is poured into a common 50-liter hydraulic tank.

Hydraulic distributors are distinguished by a large number of sections and are located in easily accessible areas. Unlike the Akros, which uses imported hydraulics (German-made), all elements of the Vectors’ hydraulic system are supplied by domestic enterprises, including some aviation and defense factories.

The technology for manufacturing hydraulic systems for Vector-410 provides for thorough preliminary cleaning of the internal surfaces of pipelines using special equipment. To increase the reliability of hydraulics, Vectors abandoned solder joints. Instead, pipeline connections using cutting rings were used. The routing of the pipelines was also changed. The hydraulic system of these combines uses fluorine rubber seals, which have a lower degree of shrinkage and are an order of magnitude more durable than conventional ones. And instead of cast blanks for hydraulic fittings, stamped ones are installed.

Combine harvester Vector 410

It is actively used on small and medium-sized farmlands. The cost of the Vector 410 is much lower than its foreign analogues, with high reliability and efficiency of the combine. With the help of Vector 410, agricultural crops are harvested in all ways: direct, combined, separate. With additional equipment, you can harvest corn, soybeans, sunflowers, rapeseed, seed grasses and vegetables. There is a limitation in the slope of the landscape - up to 800.

Unit design:

- Engine part with a six-cylinder four-stroke diesel engine with turbocharging;

- Power Stream is a unified type of header that is also suitable for other combines from this manufacturer

- Ergonomic cabin that minimizes harmful production factors for the driver (moisture, dust, vibration);

- Hydraulics and chassis;

- A transmission that allows the unit to reach speeds of up to 25 km/h.

Advantages of the model:

- High-speed thrust "YaMZ-236-ND", creating a power of 210 horsepower;

- Fuels and lubricants are consumed rationally - about 2.5 liters of diesel fuel per ton of grain;

- Hydrostatic transmission “GST-112”, which allows you to smoothly select the required gear for a specific task;

- The cutting height is adjustable;

- The hydraulic unit is connected to a large hydraulic receiver of 50 liters;

- “Power Stream” header with wide grip;

- “Level Glide” is a system that allows you to adapt to the complex terrain of the field.

The Vector grain harvester is available with all-wheel drive and crawler tracks, depending on the buyer’s wishes.

Technical characteristics of the unit:

- Harvester – 5/6/7/9 meters;

- Bunker capacity – 6 m3;

- Productivity – up to 12.8 tons/hour;

- Unloading speed – 50 liters/second;

- Weight – 11 tons.

You can evaluate the specifics of the unit’s operation using the video.

Cabin of the Vector-410 combine

Machine operators of the past, even in their wildest dreams, could not imagine the greater comfort and convenience of work that the modern ergonomic Comfort Cab on Akros and Vectors provides.

The combine operator's workplace is reliably protected from noise, vibration and dust. With the help of advanced air conditioning, heating and ventilation systems in the cabin, you can create an extremely healthy and comfortable microclimate that does not depend on the temperature “overboard”.

Audio equipment is included as standard in the cabin. Namely: a speaker system, an antenna, a ready-made seat for the radio (you just need to connect standard connectors). The comfortable, sprung work chair is equipped with a whole series of necessary settings. It is possible to adjust the seat according to individual characteristics and fully concentrate on cleaning. There is also a full (soft) folding seat for the helm.

Ramzan Kadyrov driving the Vector-410 combine harvester.

The steering column, adjustable both in height and in tilt level, will also help you “tailor” your workplace. The huge glass area of the cabin provides excellent visibility in all directions. Very close, at arm's length, there is a cool drink - a special cooling compartment is provided for this.

The main control element of the combine is made in the form of a multifunctional joystick-manipulator located on a handle “sharpened” for the natural grip of the palm. As standard, the Vector-410 cabin is equipped with a special voice warning system “Adviser”, which is designed to monitor threshing and the entire technical process as a whole, giving voice signals to prevent failure of parts and components of the combine.

Design of the Vector 410 combine harvester

When designing the grain harvesting transport, the team tried to achieve not only high power of the combine, but also excellent driving characteristics combined with ease of use. Therefore, the operator’s workplace (cabin) has a large overview due to large tinted windows, and a comfortable temperature inside the cabin provided by the air conditioning system. What is missing in older models like KSK-100.

Most of the core modules work great out of the box, but can be improved with the addition of optional components. For example, an air compressor and a fuel consumption monitoring system can be added to the engine. The chassis can be equipped with all-wheel drive and a removable half-track, and the thresher can be equipped with an automatic lubrication system.

The power of the combine is provided by a 6-cylinder engine of 210 hp, which is turbocharged and has a torque reserve of up to 15%. Continuous operation of the equipment for 16 hours is ensured by a large fuel tank of 540 liters. At the same time, work in the dark is not excluded, because There is a set of 6 halogen lamps that provide effective illumination of the treated space.

The silence in the cabin, ensured by the vibration damping system, is filled with the sounds of the built-in radio. Also, among other things, there is a system for adapting to the field topography based on hydromechanics and a modern information system with the function of announcing the status of systems and situational framing.

Header of the Vector-410 combine

Like the Akros, the Vector-410 combine is equipped with a Rostselmashevsk universal unified harvester for grain crops, called “Power Stream”. The working width of the headers of this series is 5,6,7 or 9 meters.

All Power Stream headers are equipped as standard with a simple and reliable hydromechanical system for copying the field surface topography “Level Glide”. A high-quality cut is ensured by the planetary drive of the Schumacher knives. This gearbox has proven itself well on Akros, where it was first installed only as an additional option; on Vectors it is included as standard.

The high-inertia threshing drum, according to Rostselmash, has the largest diameter in the world - 800 mm. It is distinguished by its careful handling of grain, almost complete (95%) separation and unsurpassed adaptability to difficult and problematic breads: curled, moistened, clogged, etc.

The time-tested residual separation system, consisting of a four-key seven-stage straw walker, and an effective two-stage cleaning system with an autonomous final threshing device ensure minimal losses of grain with straw and chaff, as well as its purity. The grain that ultimately ends up in the bunker has excellent cleanliness and cut quantity. At normal humidity, it is already ready for sale.

We recommend reading: Terex 860 SX: technical specifications

Vector 420 combine harvester

The Vector 420 combine harvester is designed for processing medium-sized areas. During one season, the Vector combine can harvest about seven hundred and fifty hectares of wheat. The equipment has a large separation area, as well as a unique threshing geometry. Despite the fact that the presented model is very similar to the Vector RSM 101 Vector 410 combine harvester, there are a number of significant differences between them:

- The unit is equipped with a CUMMINS-QSB 6.7 engine with a power of 220 l/s.

- The Vector 420 combine does not have all-wheel drive, and there is no replacement of the wheeled chassis with a half-track.

- Despite the fact that the Vector 410 and 420 combines have almost identical dimensions, the model in question is five hundred kilograms lighter. This gives a head start in the maneuverability and maneuverability of agricultural machinery in various conditions.

We can say with confidence that the presented Vector combine has become the best option for starting farms, since purchasing expensive imported machines at the initial stages of activity is not possible. It is worth noting that repairing the cooling radiator of the Vector combine will cost the owner relatively little, compared to foreign analogues.

Operating experience of the Vector-410 combine according to owner reviews

Reviews about the Vector-410 combines are overwhelmingly positive. These agricultural machines showed their best performance, fulfilling their warranty period without serious breakdowns or annoying misunderstandings. And continuing to work further, requiring only the replacement of consumables and bearings, in a word, minimal intervention and investment. At the same time, the following is of great importance: “if anything happens, dealers and the necessary spare parts, as they say, are within walking distance.”

Especially enthusiastic reviews from those who moved behind the wheel of the Vector from the Niva and other outdated Soviet combines: instead of a bunch of levers, there is a convenient manipulator that you quickly get used to! (In general, you quickly get used to all the good things: the absence of dust, comfortable air temperature in the cabin, excellent visibility in all directions, and the ability to perform all basic operations from your workplace without having to leave it, etc.)

According to the owners’ reviews, “Vector-410” showed itself remarkably well in harvesting not only grain crops, but also sunflowers. The final product - both grain and seeds - comes out of the bunker incredibly clean, ready for sale. The voice warning system is not just a toy, but a really useful thing that alerts you to the occurrence of various types of emergency situations (for example, burrs caught in a straw walker).

Among the shortcomings, there are various little things that spoil the overall good impression. For example: the hopper full sensor sometimes does not work; the air filter clogs very quickly (which is facilitated by the cooling system fan); the pump, which is located under the radiator, dumps the chaff onto the tool box (it is necessary to attach an air duct to drain the chaff down); grain in the bunker often accumulates on the right side and begins to spill over the edge, although the left side of the bunker is half empty (it is necessary to increase the right apron of the bunker); the bracket on which the pipelines for draining oil from the hydraulic system and engine are attached touches the left rear wheel and bends it; and so on.

In the cabin, the air conditioner “blows only to one point.” The antenna is not working. Which, however, is quite natural: the waves of radio stations, especially the FM range, are well “caught” only in cities, near them and on large highways. In the field, even “Radio Russia” and “Radio Mayak” can not be “caught” everywhere and not always.

The operator's workplace in the Vector-410 cabin.

Opinions are often expressed that Vector-401 is a combine harvester for fields with low and medium yields. With a yield of over forty centners per hectare, it becomes difficult for him to work, the combine can barely cope, and grain losses begin to increase.

There is also this interesting opinion: “And most importantly, Vector-410 is precisely the technology that helps the younger generation gain a foothold on the earth. You won’t be surprised by old combines with a lot of levers. Here, levers were replaced by electronics and a computer, which greatly simplified the work. So, in our household, not only I, but also my son, have already driven the Vector.” (Head of a peasant farm in the Zernograd district of the Rostov region).