Features of making a gearbox for a walk-behind tractor with your own hands

It may seem that a gearbox for a walk-behind tractor is a complex technical device and can only be manufactured in a factory setting. However, many of our farmers have homemade gearboxes for walk-behind tractors. The most important part of the unit is the drive. When there is a need to buy a gearbox, you need to know that its further operation and even functionality depends on the quality of this particular unit. The gearbox transmits and appropriately converts torque, the conductors of which are mechanical transmissions. You can literally make a device from junk items, you just need to understand the principle of how the design works.

Motoblocks "Salut-HondaGC-190" and "Salut-HondaGX-200"

As the name suggests, the cars are equipped with Honda power units from Japan with a capacity of 5 and 6.5 hp. respectively. Honda GC-190 and GX-200 are updated modifications from the Honda product line. “Salut-Honda GX-200” has an expanded factory configuration, which includes 6 cutters that allow you to both plow and cultivate the soil along with the hundredth models. The factory equipment of other machines usually includes 4 cutters. The Honda GC-190, due to its weaker engine, is more economical and lighter than its analogues. The main distinctive advantages of this series include the walk-behind tractor engine. With its Japanese character, it is reliable, economical and smooth in operation. Noise and vibration from the power unit is minimal. The Japanese series has a cultivation strip extended to 900 mm, the cost varies from 40,000 rubles.

The listed modifications do not exhaust the entire variety of the model range. Various power units can be installed on cars of different series; the fifth and hundredth series are equipped with Japanese engines; there are options with seven-horsepower Chinese Hwasdan engines. Such an abundance of models will satisfy the most demanding taste and allow you to choose a walk-behind tractor that fully meets any needs.

Types of gearboxes

There are worm and chain devices.

The differences between them are small, but quite important. The difference lies in the characteristics inherent in the two different types: efficiency; angular velocity; number of gears; number of shafts and ratio between gears. Relatively cheap walk-behind tractors are often equipped with non-separable gearboxes for simplified assembly . In this case, the service life is significantly reduced and additional possibilities are eliminated:

This indicates the low quality of the material used to manufacture the gearbox, and that most of the parts will not be sleeved. The diagram will give an idea of the principle of its operation and service life.

Expensive walk-behind tractors are equipped with gearboxes that are more complex in design and allow further assembly and disassembly. Maintenance can be carried out by correcting all the shortcomings in the operation of the device.

Repairs are carried out in order to extend the service life. It is recommended to replace faulty parts with more expensive ones. Timely lubrication will also extend the service life.

In most cases , the gearbox converts speeds , that is, the angular speed is quickly and efficiently transformed into a low one. There will be a high angular velocity on the input shaft, and a low one on the output shaft.

To prevent unexpected breakdowns, regular high-quality maintenance . When changing speed in steps, the gearbox is called a gearbox. When a step system is not used, the device is called a variator.

Homemade bevel gear for walk-behind tractor

The design of the gearbox is not particularly complicated, and it is quite possible to assemble it yourself.

First, the rated power is calculated: (Pn); Pn = Pe (hp) x FS, which will allow you to correctly determine the angle of the bevel gear. Using the same principle, the number of possible revolutions per minute and the calculation of torque are calculated. A self-made device needs to determine operating conditions, including the radial or axial load of the shafts at their ends. Operation is optimal with the correct selection of temperature and lubricant.

The assembly is performed after these above steps. You can take the factory building . Its diameter will tell you what the bearing housing for the shaft should be like. A good quality drill and caliper will help here. Next, take two bearings under the shaft.

The steel flange is installed on the front part . A flange bearing and washer are located inside. The flange is attached to the generator with screws. The steel key with the drive gear and the driven gear shaft are selected in advance.

Units connected to the transmission mechanism to the rotary generator It has a pulley that provides V-belt transmission. It is secured to the driven shaft with a nut and spring washer.

Main elements of the gearbox

In the automotive industry, angular gearboxes are often used, because these units provide efficient operation. The angular gearbox ensures the coupling of the transmission to the engine. You can modify an already finished product. Among the main elements of the gearbox are:

- Flange.

- Generator housing.

- Pulley with V-belt drive.

- Pulley fastening.

- Steel washer.

- Rotor shaft.

- Steel key.

- Flange bearing.

- Flange mounting.

It’s quite easy to understand the gear device by looking at its transmission, which is the transmitter between the wheels and the motor. The direction changes in the walk-behind tractor. A transmission is a gearbox with a clutch . It is often used in heavy walk-behind tractors.

Main elements of the walk-behind tractor design

- Bed or frame. A motor, a transmission system to the wheels, a traction device for attachments and a suspension are mounted on it.

- Power unit. Power - 5−10 l. With. Engines from motorcycles, mopeds, compressors and chainsaws are used.

- Suspension. Usually primitive: from homemade wheels or ready-made wheels from agricultural machinery. Sometimes motorcycle and car wheels are used. It can be portal or axial.

- Gearbox for walk-behind tractor. Serves to reduce drive shaft speed with a simultaneous linear increase in torque. A gearbox from a scooter or car is often used as a gearbox.

A homemade device does not require pairing with an engine , because the calculation is made for specific tasks, and there are no restrictions due to a ready-made technical solution.

Making and assembling a potato digger

On the Internet you can find ready-made or create your own drawings for assembling the device. The main parts are as follows: a base (frame) for fastening parts, a plow for digging up soil, a linkage system, adjustable traction, soil hooks or other suitable wheels. By the way, lugs can also be made by hand. The process of assembling a potato digger begins with the manufacture of parts, and it takes place in several stages:

- Frame welding. It is made from channel No. 8 and a metal corner, the total length of the base should be approximately 1 m 20 cm.

- Then two more channels are welded: the first - one third from the beginning of the frame, the second - at a distance of about one sixth from the edge, which will be located in front. The adjustment rod of the mechanism will be installed on them.

- Metal posts are welded on the sides, on both sides, the distance between them should be about 10 cm - they will serve as fasteners for the future grille.

- The remaining channel should be attached to the outer posts; you should get two triangles, onto which the plow will subsequently be attached.

- Next, a strip of the required length, about 3 cm wide, is cut out of the metal sheet, and it is first welded to one of the triangles. After complete cooling, the strip is bent with a sledgehammer and welded to the second triangle.

- The plowshare can be made from a metal plate, a piece of pipe, or an old plow. It is attached to the elevator casing using 4 bolts, the nuts are firmly tightened.

- The reinforcement is divided into rods of the required length. One side of them is welded to a metal plate, the distance between them should be about 5 cm. Additional rods or plates can be attached to the sides so that the tubers do not fall in different directions. The second part of the rods is attached to a plate or pipe, which should be attached with hinges for free movement.

- Then the reduction unit is installed. It will allow you to change the angle of inclination of the elevator and plow as needed.

- The wheels are attached to the connecting bridge of the equipment.

- Attaching the potato digger to the walk-behind tractor is similar to the fastenings of other attachments.

Whatever model the gardener chooses, one thing is certain – modern technology can significantly facilitate the farmer’s work and save a lot of time.

Gearbox manufacturing process

First, the parameters of the power plant are calculated.

The crankshaft speed can be found in the technical specifications. This is the first quantity required to perform the calculation. The value is not constant, with the addition of “gas” the number of revolutions increases. Basic value: idle speed +10% .

Next, the suspension axle revolutions are calculated . Knowing the size of the wheels, it will be possible to calculate the amount of run-out per revolution. The number of axis revolutions is calculated to ensure a comfortable speed - 3-5 km/h, which is the second value for design.

For example, idle speed +10% is 600 rpm. The required wheel axle speed for 3 km/h is 200 rpm. So, the gear ratio should be 3:1 . The rotation speed of the axis is reduced by three times in relation to the speed of the motor shaft, and the torque increases accordingly by three times. Gearbox types:

- Gear - use the ratio of the number of teeth of the driven and driving gears. The device operates on the principle of steam in the gearbox. It doesn’t matter what shape the gears have - the teeth can be straight or oblique. A bevel gear is used when a walk-behind tractor requires an angular gearbox. It all depends on the location of the motor. If alignment is ensured between the motor shaft and the wheels, an angle is not required.

- A worm drive is needed to create a large gear ratio when there is a large difference between the revolutions of the drive axle and the engine. This design is more difficult to manufacture and maintain. The solution is optimal if the motor shaft is perpendicular to the wheel axis.

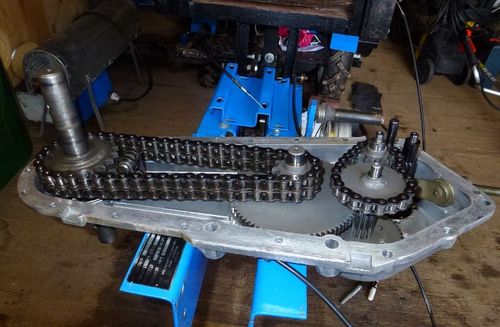

- Chain gearboxes work like a bicycle, but in reverse. The leading one is a smaller star. The reliability of the design is determined by the quality of the gear metal and the strength of the chain. A simple set from a bicycle may not withstand the load, so more durable ones are used - motorcycle ones.

- Belt devices are the simplest to manufacture. They are also the most unreliable and weak. Large torque is not transmitted, as the belts will slip. But the shock load on the engine is reduced - the design is more gentle on the drive shaft, jerks are smoothed out. Slippage is eliminated by installing a timing belt. In this case, you need to find a pair of toothed pulleys, for example, from an automobile timing system.

- Combined system. A device with a chain and gear drive can be manufactured in one housing, although the calculations in this case are more complex. But it is possible to transmit enormous torque with low engine power.

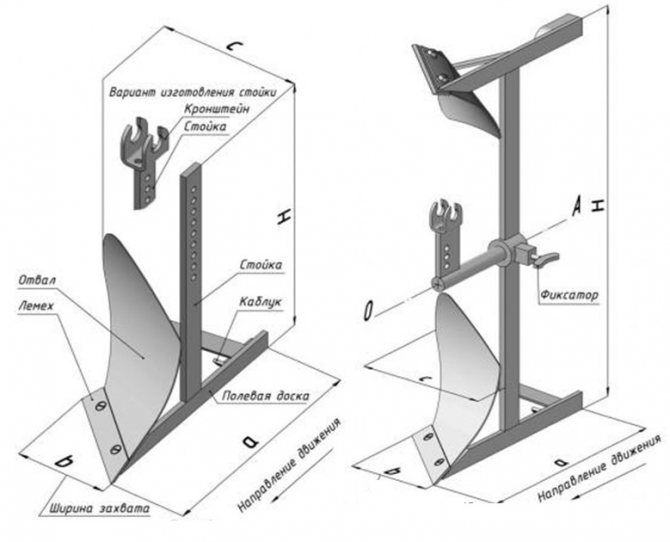

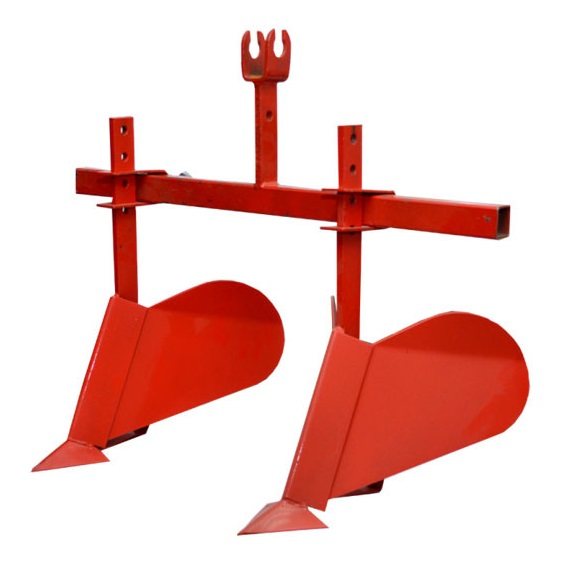

Plows for the Salyut walk-behind tractor

The plow is a working device for loosening, painting and turning over layers of soil 15-25 cm thick. The Salute walk-behind tractor, when combined with various attachments, perfectly performs many of the intended jobs - transporting goods, loosening, plowing the soil.

The set of attachments includes various units, including plows for basic types of soil cultivation.

To ensure strength, reliability and the ability to withstand sufficient loads, plows are made of durable steel. Their common design feature is a special metal comb used for plowing. Thanks to the specific shape, expanding upward, the earth does not pour back into the ditch, but is thrown to the sides.

Depending on the type of work performed, there are separate types of plows.

Types of plows:

- Single-body - equipped with one share, designed for plowing light soil. Indispensable in combination with a light walk-behind tractor when processing a small area.

- Reversible – designed for plowing heavy hard soil with medium or heavy walk-behind tractors. The ploughshare is made in the form of a feather bent upward, which, when working, lifts and turns up the lower layer of soil. Therefore, such plows have another name - reverse. After plowing, the soil becomes crumbly, making further processing much easier.

- Rotary - equipped with several blades, works on medium and heavy walk-behind tractors. Thanks to its unique design, it provides the highest productivity and allows you to plow hard soils no worse than soil tillers.

- Disc – cuts layers of excessively wet heavy soil. Disking is performed for pre-sowing soil preparation and surface loosening of stubble after harvesting.

Models

Attachments can be branded from the direct manufacturer or universal, which is suitable for walk-behind tractors of various modifications. In this case, manufacturers indicate which brands specific models are compatible with.

Plows adapted to the Salyut walk-behind tractor

There are a number of rules that will help you avoid mistakes when choosing a quality device. Compliance with them will help reduce costs, prevent damage, and make better use of the machine’s capabilities.

Plow selection criteria

- the stand should not be narrow and thin;

- Shortening the blade is strictly prohibited;

- the housing must be made of high-quality steel of sufficient thickness;

- Instructions for use are required.

Consider the size of the plow itself. For light walk-behind tractors, equipment with a small working width of up to 15 cm is used, for medium and heavy models, respectively, large sizes.

Vibrating potato diggers

The design of the KKM-1 vibrating potato digger for the Neva walk-behind tractor has an active ploughshare and a screen driven by a belt. With the help of a ploughshare, a layer of earth is cut to the required depth, then it goes onto a grate, where, due to vibration, the earth is sifted and the potatoes themselves and large pieces of earth remain, after which all this is dumped as the walk-behind tractor moves. Potato diggers of this type operate with a row spacing of 60-70 cm. Onions, garlic, beets, etc. are also harvested using this design.

Specifications

- Overall dimensions: 70*70*60 cm.

- Weight: 45 kg.

- Grip width: 39 cm.

- Productivity: up to 0.2 ha/hour.

- Digging depth: 20 cm.

- Drive from a walk-behind tractor: pulley, V-belt.

- Compatible with walk-behind tractors: Neva, Cascade, Oka, Favorit.

- Price: 12,000 rub.

Models KKM-2 and KKM-3 are not particularly different in characteristics, the only thing is that the drive from the walk-behind tractor comes through the PTO, and not through a belt, and they are installed on MTZ, Agro walk-behind tractors and the MTZ 132N minitractor, respectively.

pros

- Can work on heavy soils,

- Good working width and digging depth,

- It cleans potatoes well from soil,

- Convenient to use

- Efficiency on large areas of land,

- The walk-behind tractor has low fuel consumption.

Minuses

- Price,

- There is no point in using it on small summer cottages.

Another vibrating, rattling potato digger. A universal hitch that is suitable for walk-behind tractors with both right and left pulleys. Digs potatoes even on heavy soils. To do this, an additional knife is attached to it. Minimum required power – 6 hp. Compatible with all types of walk-behind tractors, both Chinese and Russian, and Japanese.

Specifications

- Overall dimensions: 90*67*56 cm.

- Weight: 34 kg.

- Grip width: 39 cm.

- Productivity: up to 0.2 ha/hour.

- Digging depth: 20 cm.

- Drive from a walk-behind tractor: pulley, V-belt.

- Compatible with walk-behind tractors: Neva, MTZ, Agat, Salyut.

- Price: 9000 rub.

pros

- Suitable for almost any walk-behind tractor

- Works on heavy soil

- Price.

Minuses

The efficiency is slightly lower than that of KKM-1.

Poltava resident

Potato digger for a vibrating (screening) type walk-behind tractor. It can operate both from a drive belt (with left and right orientation) and from the rear power take-off shaft. Depth can be adjusted using pneumatic wheels. Excellent versatility and high productivity make this potato digger one of the best for efficiently harvesting potatoes and other root vegetables.

Specifications

- Overall dimensions: 95*79*80 cm.

- Weight: 34 kg.

- Grip width: 40 cm.

- Productivity: up to 0.25 ha/hour.

- Digging depth: 25 cm.

- Drive from a walk-behind tractor: pulley, V-belt, PTO.

- Compatible with walk-behind tractors: Neva, MTZ, Veima, Salyut, Bulat, Motor Sich, Forte, Zubra, Favorit, Centaur, Cascade.

- Price: 9600 rub.

pros

- Aggregated with any walk-behind tractor with a belt drive or PTO,

- Excellent performance,

- High quality workmanship,

- Works also on heavy soils.

Minuses

KM-1 for MTZ walk-behind tractor

The KM-1 vibrating potato digger is aggregated with the MTZ-09N walk-behind tractor through its rear power take-off shaft. Standard wheels are metal. All articulated joints are made through silent blocks (rubber bushings).

Specifications

- Overall dimensions: 85*68*58 cm.

- Weight: 35 kg.

- Grip width: 38 cm.

- Productivity: up to 0.2 ha/hour.

- Digging depth: 18 cm.

- Drive from walk-behind tractor: PTO.

- Compatible with walk-behind tractors: MTZ.

- Price: 14,500 rub.

Hitches

Plows and hillers are connected to the Salyut walk-behind tractor through the S-13 beam and the S-20 bracket using a universal hitch. It is better to make adjustments through the hitch.

Important! The obligatory coincidence of the longitudinal axis of the regulator and the walk-behind tractor, plus the vertical position of the beam, will help to configure the equipment in the best way.

To optimally set up a plow without a hitch, it is first advisable to align the minimum parameters for plowing depth and width.

Adjusting the plow without a hitch:

- Align the minimum parameters for plowing depth and width;

- The support triangle must be in a horizontal position;

- Adjust the field board parallel to the movement.

In the future, the plowing depth, depending on the soil, can be adjusted correctly using special holes on the plow stand or by changing the angle of inclination of the body.

What kind of attachments are there for the Salyut 5L-6.5 walk-behind tractor?

The first requirement for walk-behind tractors is plowing the soil. Plowing is done with a plow. The plow is installed on a walk-behind tractor thanks to a universal hitch via the S-20 bracket and the S-13 beam.

Reversible plow

For easier and better plowing, you can purchase a reversible plow. Its locking device allows the canopy to quickly and easily change plowing direction.

For working with a conventional and reversible plow there is a support wheel, which can also work with a weeder. Also for the Salyut 5L-6.5 there is a hiller - a canopy that hills up and prepares a furrow for planting potatoes. Its shape resembles a plow, although its functions are somewhat limited. By the way, it is connected to the walk-behind tractor in the same way - through the S-20 bracket and the S-13 beam in a universal hitch.

Disc hiller

You can also attach a disc hiller to the walk-behind tractor. He hills up the potatoes and cultivates the soil between the rows. It also makes the necessary ridges, as it can adjust the width of the ground coverage, height and adjust the angle of operation of the disks. This canopy has two discs, each 400 mm in diameter.

The disk hiller has a more advanced version - the reinforced disk hiller. The functions are the same as in the previous version, the diameter is the same, however, the disks of this version are made of more durable steel.

Potato planter attachments

To plant potatoes you will need a potato planter. The hopper of such a unit can hold from 40 to 50 kg of tubers. Plants tubers from 40 to 60 mm in diameter.

The approximate weight of the potato planter for Salyut 5L-6.5 is 41 kg. The distance between planted tubers may vary from one canopy to another. In some it is 190-280 mm, in others it is from 250 to 355 mm. If you have a small area, you can buy a small-sized single-row canopy KS-1.

Flat cutter with cultivator

Let's say you need to sow a plot of wheat. A flat cutter with a cultivator is perfect for this. It is needed for weeding the soil, leveling it and preparing it for sowing.

Previously, we used a hiller and planted our garden with potatoes. Now we need to somehow get rid of the weeds. Before this we talked about a flat cutter with a cultivator. And now we can get by with a regular flat cutter. Both flat cutters are attached to the walk-behind tractor via a universal hitch.

Potato digger for walk-behind tractor

The planted potatoes will eventually help the digger to dig up the potatoes. The canopy is attached to the walk-behind tractor via a universal hitch, which we will look at later.

So, a universal hitch. It acts as an intermediary in connecting a number of equipment with the Salyut 5L-6.5 walk-behind tractor. Attaches a plow, support wheel, hiller, potato digger and flat cutter. Uses the S-13 beam and the S-20 bracket. If you need to effectively hill up the soil or weed, you can use two hillers or undercuts. To secure them, use a frame with two locks.

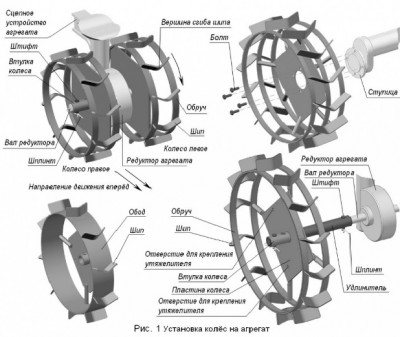

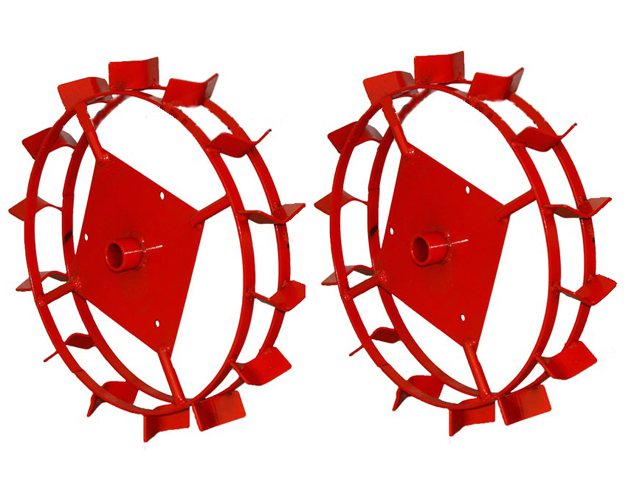

Wheels and lugs for walk-behind tractor

You can buy PSDU axle shafts for your Salyut 5. There are lugs for attaching to the walk-behind tractor and help to create row spacing of the required width. There is another version of this part - a semi-differential axle shaft. Its advantage is that it not only digs between rows as we need, but also regulates the turn of the walk-behind tractor.

Let's look at different wheels with lugs. You can buy wheels 500x100 mm. They can be an alternative to hiller, flat cutter and potato digger because they perform their functions. All walk-behind tractors of the Salyut family are approximately the same, and this canopy, in addition to the Salyut 5L-6.5, is also attached to the Salyut 5BS-6.5, Salyut 5R-6, and Salyut 5BS-1.

Wheels with lugs 500x200 mm are used when working with a plow. There is also an advanced version of these wheels with sand-filled weights - then the plow goes deeper into the ground. And wheels 700x130 mm are used in the work of the hiller, disk hiller, flat cutter and potato digger.

You can also buy weights for them. In addition, the wheel size is 800x110. All sizes of lug wheels fit all specified Salyut models.

Optional equipment

The Salyut has a specific design feature - its engine is shifted forward, which perfectly balances the plow mounted at the rear. Compared to the Neva and Oka, the center of gravity of the Salyut walk-behind tractor is shifted much closer to the surface of the earth, which makes it easier to control the walk-behind tractor, as a result, there is no need for additional balancing, and the load on the hands when moving is greatly reduced.

According to reviews from owners and repairmen of walk-behind tractors, it is most comfortable and efficient to work with Japanese engines. Pay attention to the video footage - the walk-behind tractor confidently walks along the furrow, without much effort from its owner. In the video you can see that when the operator releases the steering wheel, the walk-behind tractor with the plow continues to walk exactly along the track and plow at the same pace.

Depending on various tasks, axle extensions and metal wheels with weights are used. The wheels are installed with lugs that have a large supporting area so as not to fall through on loose soil.

Attachments

The capabilities of agricultural machinery are determined by the ability of the attachment to easily adapt to the Salyut walk-behind tractor and effectively carry out essential agricultural work for summer residents and gardeners. It’s clear that the more diverse the list of auxiliary devices, the greater the number of them that can be mechanized, thereby using the equipment as efficiently as possible.

“Salyut-100” and the earlier modification “Salyut-5” are rationally aggregated with more than 50 types of modern attachments, adapted to perform many useful jobs.

The kit with the Salute walk-behind tractor includes a minimum list of accessories.

To perform specialized work, appropriate attachments have been created, which are purchased separately. Let's take a closer look at the different types of these devices.

Adapter

The adapter is a specific towed device for a walk-behind tractor. The operator can perform various tasks while sitting on a comfortable seat and easily controlling the walk-behind tractor. Having an adapter, many functions can be performed much more efficiently and safely, especially when cultivating the soil with cutters.

Depending on the purpose, there are various designs of adapters for the Salute walk-behind tractor:

- simple - intended purely for cultivating the land;

- universal - designed for transportation of goods, various types of soil treatment.

Adapters with a long drawbar are installed on heavy, powerful machines; for light modifications, adapters with a short drawbar are installed. Modifications of adapters with additional functionality have been developed - lifting the overall linkage, widening the track.

Mower

One of the most difficult types of rural work is mowing. With a mounted mower on a Salyut walk-behind tractor, today this is quite an ordinary job.

Mowers for the Salute walk-behind tractor are:

- segmental - for mowing evenly growing thin grass on flat surfaces;

- disc (rotary) - better suited for mowing grasses of different qualities. Taking into account the density, hardness, lodging of the grass layer, and the quality of dead wood, you can optimally configure the rotary mower in accordance with the speed of the machine and engine rotation.

The Zarya disc mower works well with the Salyut walk-behind tractor, the capabilities of which allow you to mow bushes and tangled, lying grass. The video shows the effective operation of the Zarya mower, which works on the principle of a regular scythe - it mows and lays the grass into even swaths.

Video review of the operation of the Zarya mower on the Salyut walk-behind tractor

Potato digger

Labor-intensive, extremely tedious work - digging potatoes - can be significantly simplified with the help of a mounted potato screener. No damaged tubers, no shovels - a minimum of time, effort and excellent results.

As an attachment for the Salyut walk-behind tractor, a KV-3 potato digger weighing 5 kg is the most popular device.

Potato planter

The potato planter is a not so popular attachment for the Salute walk-behind tractor.

As is usually the case, in small country gardens, potatoes are planted using the extensive method - a friendly raid of all relatives and friends. On large leased plots, the effectiveness of using a potato planter as an attachment is undeniable. You can see the operation of a potato planter on a walk-behind tractor in the video.

Video review of the operation of a potato planter on a Salyut-100 walk-behind tractor

Hillers

Planting and sowing is one thing to worry about, but weeding, hilling and tireless weed control - these chores on the site sometimes take quite a lot of time. Hilling up using a Salyut walk-behind tractor with a universal harrow is easier than plowing the land; you just need to correctly adjust the angle of attack of the equipment.

Depending on the quality of the soil and the work performed, hillers are divided into:

On average, in an eight-hour working day, it is possible to hill up row crops on an area of at least 10-12 hectares.

Using a disc harrow, setting the required distance between the discs, you can conveniently hill up potatoes.

Video review of hilling potatoes on a Salyut-100 walk-behind tractor

Blade shovel

The blade, when combined with the Salyut walk-behind tractor, performs the functions of a wide shovel.

This device is convenient for removing snow, clearing the area of construction or other debris, and, if necessary, leveling sand, soil, and small crushed stone.

Video review of the operation of a shovel blade on a Salyut-100 walk-behind tractor

Trailers

The Salute walk-behind tractor with a mounted trailer is an indispensable thing in the household, a necessary equipment in the garden. Currently, you can buy trailers of various configurations, different load capacities, regular and dump, which are conveniently adapted to different models of walk-behind tractors.

Features of work

Attachments make it possible to expand the scope of application of the Salyut walk-behind tractor. You can effectively carry out absolutely all the work typical of rural areas. Undoubtedly, before starting work you will have to thoroughly understand the instructions, because the effectiveness of the equipment is, first of all, the correct settings and adjustments.

Rotary plow

Using a rotary plow, which has left and right multi-directional plows in its design, you can plow in forward and reverse directions. For the most effective work, it is better to choose a model with a plow adjustment, that is, the ability to adjust the cutting depth and tilt angle.

Plow installation:

- depress the pedal;

- fix the stand;

- after that the entire structure is rotated 90°.

Zykov's plow

Zykov's plow is significantly different in appearance from other models. The video review clearly shows that its main differences are carefully selected angles and a completely different profile of the plow-mold surface, which makes it possible to better paint the soil and turn over the layer. Such plowing almost completely eliminates weeds.

Here is a review of plowing with a Zykov reverse plow on a Salyut walk-behind tractor

Double sided plow

A double-sided plow (hiller) is used for hilling agricultural crops and destroying weeds. This device is used to cultivate the soil and cut a furrow for planting plants. Subsequent backfilling is done by turning on the walk-behind tractor in reverse. The units are distinguished with variable and constant working width.

A device with a non-adjustable width works in conjunction with a lightweight walk-behind tractor; 12 mm racks reliably protect it from overload. The most widespread are hillers with variable widths that can be adjusted. Such plows work perfectly in combination with Salyut 5DK walk-behind tractors. However, they have one drawback - the soil crumbles after passing.

Dutch hiller

Less known is the Dutch hiller, which forms narrow wedge-shaped furrows due to the movement of its wings not only to the sides, but also upwards. The formed bed ensures better contact of the planting material with the soil. Structurally simple, easy to manufacture, cheaper in cost.

Disc dipper

The disc hiller is much more productive, but its price is 3-4 times higher than usual. However, according to reviews, owners do not return to their previous devices after working with a disk hiller.

Important! All hillers work better in first lower gear. Since the forward speed decreases, which is comfortable for the operator, the traction of the walk-behind tractor increases.

The Salyut walk-behind tractor with a Japanese engine is the most successful choice of agricultural equipment in terms of a combination of proven quality and reasonable price.

By purchasing all kinds of attachments and attachments, you can further significantly expand the capabilities of the walk-behind tractor, successfully cultivating more than one hundred square meters of land.

How to connect a potato digger to a Salut walk-behind tractor

Increasingly, owners of garden plots are acquiring modern equipment as assistants. Walk-behind tractors have become especially popular recently. A distinctive feature of this technology is its versatility. Today, with their help, you can not only quickly dig up a plot, but also perform other work: planting, hilling and digging up potatoes, getting rid of weeds and much more. Moreover, if previously these works took several days, today most of them can be completed in a couple of hours.

Motoblocks are in good demand among gardeners. Mainly due to the ability to combine this device with a large number of attachments. In particular, with a potato digger. Planting potatoes is a voluminous process, but using modern technology, it can be significantly simplified, for example, using a potato digger for a Salyut walk-behind tractor. To make optimal use of all the possibilities, you need to understand the nuances and find out all the pros and cons.

You can connect this unit yourself

Owner reviews

Nesterenko Andrey, Kyiv region:

“I talked a lot with the owners of walk-behind tractors, and I was convinced that with the Russian engine Salyut 5 DK 6 hp. inferior to the Chinese Lifang 6.5 hp. at times - it constantly overheats, the walk-behind tractor jumps. This is especially noticeable when working with a rotary plow.”

Kovalchuk Sergey, Zaporozhye:

“Over 5 years of working with Salyut, I became convinced that a walk-behind tractor with a professional Honda-CX 200 engine, although it costs a decent amount, is much more durable. With good seasonal load - plowing, loosening, digging up potatoes, etc., a cheap engine will not withstand a couple of years and will require repairs. I actually had to change to a new one after two years of work.”

Protasov Ivan, Sumy region, village. Apple:

“Engines are divided into professional, semi-professional and amateur; they differ significantly in price. If they are installed on the walk-behind tractor for its intended purpose, that is, to match the loads, then they will work reliably and for a long time. I am pleased with my Salyut 100-BS-V with the American Briggs&Stratton Vanguard engine. Please note that the Vanguard marking means a professional engine; I don’t recommend buying another one – it’s a waste of money.”

Ponomarenko Ilya, Saratov:

“I recommend a reversible plow that can be disassembled - the best choice, since it is possible to sharpen the knife or, if necessary, replace it.”

Is it possible to light the second fuse of the fireworks?

In accordance with the Technical Regulations CU 006/2011, each pyrotechnic product must have instructions. And on this instruction the manufacturer is obliged to write about the prohibition of lighting the second wick. However, the fireworks are designed in such a way that if you light the second fuse, the fireworks will simply go in the opposite direction.

Here's an example of how to launch the Nighthawk fireworks:

At one of the New Year's corporate parties in 2020, such fireworks were mistakenly set on fire from the wrong side. This happens quite often in the dark. And this is what happened:

Unfortunately, the camera did not immediately rise up. Because of this, the first salvos remained behind the scenes. But you can hear from the sounds that the last 4 volleys went off at the very beginning. Thus, we can conclude that from a constructive point of view it is permissible to ignite both wicks. The effects will just go in reverse order.

Oil for the Salute walk-behind tractor

Proper maintenance and operation of the Salyut walk-behind tractor helps to extend the service life and improve the performance of the equipment. The gearbox and engine of a walk-behind tractor are one of the most important structural elements. What kind of oil should be poured into the gearbox and engine of a walk-behind tractor, as well as the frequency of its replacement, the volume is data that every owner of such equipment needs to know.

The most reliable recommendations will be those offered by motorcycle manufacturers. Let's turn to the user manuals for the Salyut-5 and Salyut -100 walk-behind tractors.

Official website of the manufacturer of walk-behind tractors Salut - www.salut.ru

User manual for walk-behind tractor Salyut - 100 download

Oil for the gearbox of the Salute walk-behind tractor

Fill the walk-behind tractor gearbox with oil through the oil filler hole of the gearbox.

The gearbox should be filled with 1.1 liters of TM-5-18 (TAD-17I) oil; check the level with a dipstick. To prevent oil from spilling out of the gearbox, engine crankcase and fuel from the engine fuel tank, the walk-behind tractor should be installed on the vehicle in its normal operating position during transportation.

ATTENTION! Before each start of work, check the oil level in the engine, as indicated in the “Engine Operation Manual”. Pay special attention to the safety precautions when starting the engine as specified in the Engine Operator's Manual. Work on a walk-behind tractor with a closed or half-open air damper is not allowed.

Excerpts from the user manual:

Maintenance performed after the first 25 hours of operation:

— Check the tightness of the threaded connections of the gearbox and walk-behind tractor components;

— Check the oil level in the walk-behind tractor gearbox

Work to be performed after every 100 hours of operation:

— Change the oil in the walk-behind tractor gearbox;

Checking and filling oil into the gearbox of the Salute walk-behind tractor

ATTENTION! Work on replacing and measuring the oil level in the walk-behind tractor gearbox should only be carried out with the engine not running!

Fill oil into the gearbox of the walk-behind tractor through the oil filler hole of the gearbox. Check the oil level in the walk-behind tractor gearbox as follows:

— to measure the oil level in the gearbox, the walk-behind tractor must be installed in a horizontal position;

— move the gear shift lever to the “Reverse” (R) position, then unscrew the plug on the oil filler hole of the gearbox and insert the dipstick into the oil filler hole until the horizontal part of the dipstick handle rests against the edge of the hole;

— remove the dipstick from the oil filler hole and assess the oil level. The oil level in the gearbox must be between two marks: if the oil level is below the lower mark, then the oil must be added;

How to make a gearbox for a walk-behind tractor with your own hands?

The design of modern walk-behind cultivators involves the presence of only a few main parts, allowing the walk-behind tractor to be as easy to use as possible.

And if there are no questions about such details as cutters or a plow, then the gearbox for a motor-cultivator is a topic of interest for discussion among users of motor-cultivators.

Owners often ask questions about what kind of oil to pour into a walk-behind tractor gearbox or even how to make a gearbox themselves. The attention paid to aspects of using the walk-behind tractor gearbox does not cease for a second.

What is a gearbox (regulator, converter)?

A gearbox is a mechanism that is used to convert torque and then transmit it to the machine shafts. The means of controlling this process are mechanical transmissions. In fact, the gearbox is that part of the walk-behind tractor, the quality of which determines how long the walk-behind tractor will serve you.

Homemade gearbox for walk-behind tractor

Types of converters for walk-behind tractors

After gardening machinery became widespread, it became necessary to optimize different types of machinery for different purposes. This trend could not but affect the regulator.

In the assembly of walk-behind tractors in the budget segment, as a rule, non-separable gearboxes are installed.

Naturally, such units are cheap for the manufacturer, because the materials from which they are made are of low quality.

The service life of such devices tends to be approximately one season, after which the regulator can be sent for scrap.

This is not surprising, because they are not collapsible, because they have a closed structure that cannot be repaired, and each breakdown leads to a complete replacement of the mechanism. In turn, collapsible converters are installed on mid- and premium-class cultivators.

Homemade gearbox for walk-behind tractor

Of course, the materials from which their mechanisms are made are much more resistant to various types of deformation; they are also able to withstand aggressive environments without reacting with them, and as a result, are not subject to corrosion.

But the main advantage of collapsible converters is their constant readiness for repair in the event of failure of one or more parts of the walk-behind tractor gearbox.

Is it worth mentioning that gear oil is used in accordance with its type and quality of its performance.

In summary, we highlight the following types of converters:

Gearbox of the Neva MB-2 walk-behind tractor

The angle converter is used in mechanical engineering; it can be found in some cars or even industrial equipment, for example, in factories. Its presence in the walk-behind tractor design makes it possible to use the device under heavy loads.

This converter is suitable for those types of cultivators where the transmission and engine are connected with the expectation of a chain.

A buck converter is sometimes called a speed reducer (colloquial form). Its main purpose is to add power when, for example, the wheels begin to slip while plowing potatoes. It is used in buildings with gasoline and diesel walk-behind tractors, the engines of which are cooled by air flows.

Gear converters are used in the systems of heavy walk-behind tractors or even cars. Since the transmission consists of a gearbox, differentials and the regulator itself, and its components are presented in the form of gears, belts, etc., the gear transmission uses this converter based precisely on the features of its structure.

Walk-behind tractor gear chains

Reverse got its name thanks to the reversing scheme, with the help of which converters of this type received their main trump card over other types, namely, the ability to use reverse gear in a walk-behind tractor. By the way, reverse is not highly productive and will not be able to provide your cultivator with high operating speeds.

Operating principle and main types of potato diggers

All types of potato diggers operate according to the same method: sharp teeth cut into the soil at a certain angle and push the tubers to the surface, after which the root crops are easily collected by hand. There are two types of such attachments – active and passive.

Passive potato diggers are simple and low in price. They are attached to the walk-behind tractor using hitches; they can be purchased at almost any gardening store. Another name for them is a universal lancet potato digger. It looks like a shovel with teeth at the top. The pointed end is dug into the ground, and together with the potatoes it falls onto the teeth.

Excess soil falls off, leaving the potatoes on the surface of the shovel. When purchasing, pay attention to what kind of soil the equipment is suitable for - hard or soft. The advantages include low cost, reliability, ease of use. The disadvantages are the use of manual labor and low productivity (at best, no more than 90% of the crop can be raised to the surface).

Potato diggers of active models are divided into vibrating (screening) and conveyor. The connection to the walk-behind tractor occurs through a belt (if the equipment is not suitable for installing belts, you need to purchase an additional belt adapter), a power take-off shaft or a special gearbox. Vibrating models, also known as rumble models, work according to the following scheme: a layer of earth is pryed up with a knife and transferred to a vibrating platform, where the soil falls off the root crops. Such models have proven themselves to be quite reliable and effective.

On conveyor potato diggers, instead of a vibration platform, a special belt is installed. Moving along it, the potato tubers are well cleaned of adhering clods of earth. Such equipment is intended for models of heavy and medium class walk-behind tractors. Based on the principle of operation - digging and peeling - the types of potato diggers are quite similar to each other.

Do-it-yourself gearbox for a walk-behind tractor

Enthusiastic farmers are wondering: how to make a geared walk-behind tractor with your own hands? The question is relevant, since making such a miracle from materials and parts available on the farm is sometimes easier and cheaper than purchasing a regulator assembled by the manufacturer at the factory.

Indeed, in the “invention” of the converter there are no super complex manipulations, and a tool made on a walk-behind tractor with your own hands always serves correctly, however, first of all, you should acquire some tools :

- screwdrivers (straight and oblique type);

- hacksaw (for metal);

- pliers or pliers;

- vice;

- some other tools and consumables, the presence of which one way or another may be needed during the assembly process.

Assembly, or rather, preparation of the converter begins with welding the housing. It can be made of metal plates. Sometimes they use a housing from the Ural shaft with its subsequent modification.

DIY walk-behind tractor gearbox

For gears, you can turn to the Friendship chainsaw (4). In this case, the end of one of the shafts is cut off and a hole of the required diameter is drilled, while a second shaft is installed on the opposite side of the future gearbox, and with it bearings and a cage. The output shaft must be secured to the pulley.

Oil in the walk-behind tractor gearbox

Just like any mechanism, the lubricant to be filled is individually suitable for the geared walk-behind tractor. Its quality directly affects the performance of the cultivator. Depending on the conditions of use, you should choose the oil individually, but fortunately, universal brands like Motul come to the rescue, and the user can’t go wrong with the purchase.

Of course, not all people are enthusiastic about assembling a converter at home. Therefore, for those who find purchasing a gearbox more profitable than designing it themselves, there are online stores that sell these mechanisms.

The average price for them ranges from 12 to 15 thousand rubles.

However, there are also much more expensive models. What matters is how pricing is structured. And, above all, the price depends on the number of functions that the converter is equipped with. You can't ignore the quality of its build - it also greatly affects the cost. Power and the ability to use reverse are also important.

These are the general characteristics of the gearbox, but there are many more. From which it follows that the gearbox on a walk-behind tractor is a complex mechanism, the choice of which should not be mistaken.

How to make a homemade potato digger for a walk-behind tractor

It is better to purchase purchased agricultural equipment for large sown areas. For owners of small garden plots, home-made potato digger models are quite suitable. The main points that should be taken into account are the possibility of easy installation on a walk-behind tractor, efficiency and adequacy to the type of soil being treated.

It is also worth familiarizing yourself with the main types of attachments for digging potatoes and deciding which option is more suitable. For example, a passive lancet universal potato digger will do an excellent job with light, loose soil. It is easy to make from an old used shovel, and reinforcement rods are suitable for rods. This will not require complex measurements, drawings, or technical calculations.

More complex vibrating or conveyor belt applications will require more extensive preparation.