Short description

Modern fertilizer spreaders are a universal design that consists of important components and multifunctional mechanisms. The main role is played by the diffuser, which has the form of two disks equipped with special blades. Their coordinated rotation in one direction contributes to the uniform application of fertilizers to the soil. In some cases, these blades have additional elements - extensions. Every specialist knows that it is the adjustment of the overall length that allows fertilizer to be applied to the discs as evenly as possible.

Particular attention is paid to attached types of equipment that can be used in combination with tractors of different power. In this case, agricultural technicians give preference to a 100-horsepower or 80-horsepower engine. The final design of the mounted spreader consists of a linkage mechanism and a frame. A bunker is always attached to the top, which is equipped with two funnels. The presence of two loading grids helps prevent a situation where large granules penetrate into the unit. The lower part of the device is equipped with two funnels, which ensure uniform distribution of nutrients.

Experts note that a mounted unit is characterized by the presence of universal distribution discs. If any emergency arises, they can be easily dismantled and replaced. During active operation, the agitator shaft ensures a uniform supply of fertilizers that exit the hopper onto the distribution discs.

Advantages and disadvantages

Each type of agricultural machinery is designed to facilitate agricultural work, mine spreader. fertilizers are no exception. Before you start using it, you need to familiarize yourself with all the advantages and disadvantages.

The best electric shovels and snow blowers for snow removal

The positive characteristics of the unit include:

- Possibility of applying nutritional compositions over large areas.

- Regardless of the spreader model used, fertilizer is supplied only while the vehicle is moving.

- Rapid movement of complementary feed substances to the main destination.

- There are universal units on sale that provide a function for controlling the amount of fertilizer. The user can always increase the concentration of nutrients where needed. This function is in demand among large landowners, as it saves money.

- The unit ensures quick and uniform distribution of nutritional components over the entire treated area.

Many farmers have discovered another possibility for using this technique - seed dispersal. The only drawback is that it is not cheap. If the farm is just developing, purchasing such a unit will be problematic. Because of this, the owner has to do everything manually.

Types of spreaders

Experts are accustomed to classifying modern fertilizer spreaders according to several criteria. First of all, by the type of components added to the soil. The technique can be used for organic or mineral formulations. Even if a farmer decides to make a fertilizer spreader with his own hands, such a unit must be able to work with the following forms of materials:

- Granules.

- Dust-like fertilizers.

- Liquid solutions.

- Manure compositions.

All units differ in functionality. With their help you can grind, mix, and transport. Depending on the final method of fastening, such units are :

- Trailed. Attached to the tractor.

- Self-propelled. Fully automated, do not require connection to other installations.

- Manual. Suitable for small areas.

- Semi-trailer. They are universal, can work either independently or in combination with other machines.

- Mounted. Installed on powerful agricultural implements.

Garden shredder for grass and branches

Recently, more and more farmers have decided to make a mounted mineral fertilizer spreader with their own hands. Thanks to this, you can get a high-quality and durable unit, spending much less money.

Don’t forget about homemade manual spreaders, which are based on wheelbarrows or carts. Such a unit operates on a pneumatic, pendulum or centrifugal principle.

Pendulum units

The production of such systems occurs exclusively in foreign companies. Because of this, their popularity is at a rather low level. The main working unit is not represented by disks, but by a special swinging tube. To ensure that this part is of high quality and durable, it is made of the best quality plastic. The swinging of the tube is provided by reciprocating movements that come from the shaft.

Pendulum spreaders are inferior to disk models in terms of productivity. They produce a lot of noise and distribute fertilizer unevenly across the land.

Trailed systems

This category of units distributes fertilizers and seeds well even with minimal pressure. The equipment consists of a conveyor, a body, a drive mechanism and a dispenser. To control seeding, the user must change the speed of the conveyor and the width of the gap. Statistics show that trailed mineral fertilizer spreaders are considered the most common. Their appearance resembles a trailer. However, the accuracy of the distribution of introduced materials leaves much to be desired.

Mounted installations

Manufacturers claim that the power of such units is in no way inferior to a conventional tractor. The design is a special attachment with a frame and a spacious hopper. The spreaders are equipped with discharge grates that prevent large particles from entering the internal compartment of the unit. The lower part consists of special funnels that ensure uniform application of fertilizers.

Many landowners choose this model because it contains spreading discs. When they fail, they can be easily replaced. When the unit is actively used, previously loaded fertilizers fall onto the discs moving in the opposite direction. Thanks to this, the applied materials are distributed as evenly as possible.

DIY greenhouse from old window frames

Disc mechanisms

Such units have universal stainless steel blades, disks, and a driveshaft. The advantage is that the user can independently control the intensity of work from the tractor cabin using special dampers. Changing their position regulates the concentration of mineral or organic components. The presence of special mixers and safety nets eliminates the possibility of large particles getting into the inside of the installation.

FERTILIZER APPLICATION MACHINES

- SPARE PARTS

Spare parts for tractors Spare parts for MTZ-80/82/800/900/1221/1523/2022 10 Diesel mechanisms

- 11 Power system

- 12 Exhaust system

- 13 Cooling system

- 14 Lubrication system

- 16 Clutch

- 17 Gearbox

- 18 Transfer case

- 22 Cardan shaft with intermediate support

- 23 Front drive axle

- 24 Rear axle

- 28 Frame

- 30 Front axle

- 31 Wheels and hubs

- 34 Steering

- 35 Brakes

- 37 Electrics

- 38 Devices

- 42 Power take-off

- 46 Separate-aggregate system

- 67 Tractor cabin

- 84 Facing

- Diesel mechanisms

- Diesel mechanisms

- Joysticks

- MTZ-80,82,1221

| Cabins for tractors |

| Engines and spare parts |

- Engine gasket repair kit

- Injectors

- KAMAZ piston kit

| Amkodor loaders |

- Interchangeable Spare Parts

- Hydraulic distributors for Amkodor loaders

- ODM 8-bolt bridge

- Glass

| Spare parts for motor graders |

- Spare parts for motor graders DZ-122 (DZ-122A, DZ-122-B6, DZ-122B7)

| Consumables for road maintenance and repair |

- Spare parts for brush equipment

| Batteries, Hood insulation, Block heaters |

- Hood insulation

| Hydraulics |

- Hydraulic steering wheels

- AGRICULTURAL EQUIPMENT

Plows Harrows Tillage cutters Cultivators Mineral fertilizer spreaders Sprayers for chemical treatment of plants Hillers-weeders Rossado planting machines Potato planters Potato diggers and spare parts for them Potato diggers

- Spare parts for potato diggers Spare parts for potato digger KTN-2V

- Spare parts for potato digger Z609

| Potato sorters |

| Rotary mowers and spare parts for them |

- Rotary mowers

| Rakes |

| Balers |

| Cardan shafts for mounted agricultural equipment |

- ATTACHMENTS

Snow removal equipment for MTZ tractors Forestry equipment Road repair and construction Loading equipment for tractors Brush attachments for tractors

SPECIAL OFFERS

PRICE LISTS

NEWSLETTER FROM SONAR

Subscribe to the newsletter, special offers and price lists from SONAR

Mineral fertilizer spreaders 500 liters (funnel-shaped)

Mineral fertilizer spreaders 300 liters (funnel-shaped)

Functionality

Most often, the spreader is filled with those mineral fertilizers that belong to the salts of chemical elements - sodium, potassium, phosphorus. They penetrate the soil as deeply as possible over the entire treated surface. Before starting work, you need to pay attention to the external condition of the equipment. If necessary, you need to replace faulty parts, tighten fasteners, and treat all rubbing mechanisms with special oil.

The operating principle of the spreader is as follows:

- The necessary nutrient materials with a high level of humidity, with the size of individual fractions not exceeding 7 mm, are poured into the bunker. If the agronomist decides to use larger fractions, this is fraught with arching. Important mechanisms of the unit may stick, which will disrupt the entire work process. Loading is done using a tractor or truck loader.

- Sieve. This is a durable mesh that is installed in the bunker itself. Its main task is to prevent the entry of large particles of fertilizer and foreign objects.

- Fertilizers. All mineral and organic components reach the diffuser thanks to the shutters. It is he who is responsible for ensuring that nutrients enter the soil in a fan-shaped manner.

- Multifunctional drive of working parts. The operation of this system depends on the power take-off shaft. The frame houses the fasteners for all assembly elements of the spreader. The frame itself is represented by a powerful tubular structure. A special attachment, which is fixed with bolts, helps to increase the volume of the bunker.

Features of the Stihl FS 55 petrol trimmer

The drive of the unit is presented in the form of a single-stage bevel gearbox and a telescopic cardan shaft. The presence of universal dampers helps the farmer control the intensity of work. The main control mechanism for the mounted spreader is located under the bottom of the hopper. The main emphasis is on the movable damper, the rod and the lever attached to it. Using this technique, you can fertilize not only fields, but also gardens and pastures. Thanks to this, farmers have an excellent opportunity to feed row crops and winter crops.

When the inspection of the equipment is completed, you can set the fertilizer supply rate. To do this, fill the hopper with the necessary mineral or organic components in the required dosage. It all depends on the established standards of concentration and path length.

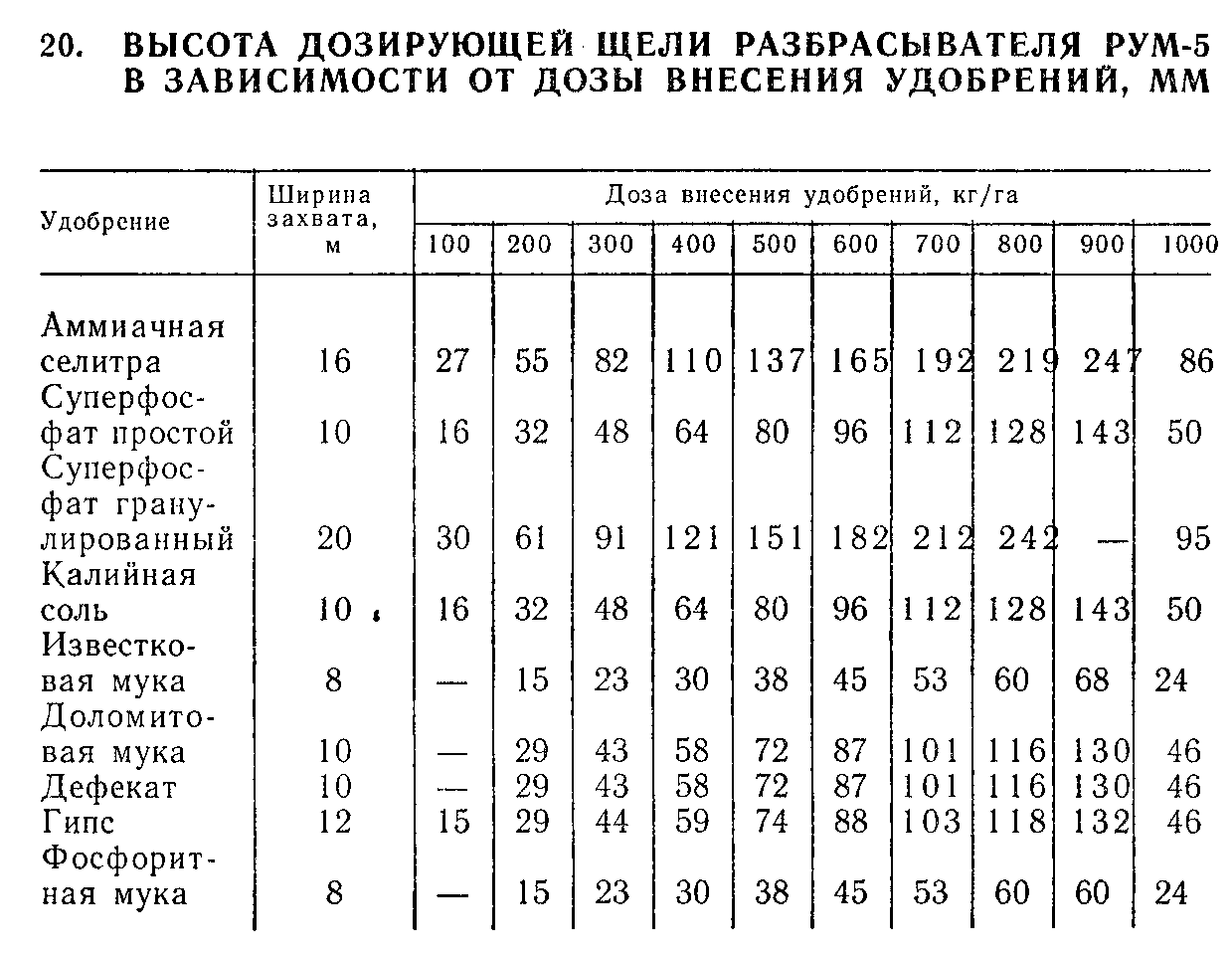

The RUM-5 mineral fertilizer spreader is similar to the 1-RMG-4 spreader.

The RUM-5 mineral fertilizer spreader is similar in purpose and design to the 1-RMG-4 spreader. Its distinctive feature is the presence of a tandem-type running system and the drive of all working parts from the tractor PTO. In this regard, for a dose of fertilizer up to 1000 kg/ha, the drive sprocket of the conveyor drive must have Z- = 12 teeth, the driven sprocket - Z2 = 15 teeth. With a dose of more than 1000 kg1ha - Z, = 28, Z2 = 33 teeth. The height of the metering slot is selected according to Table 20. The drive belts of the spreading discs are tensioned by moving the driven shaft. The belt deflection should be 6 mm with a force of 23.5 N. To uniformly apply solid mineral fertilizers when fertilizing along a tramline, use the RUM-5-0.3 spreader. This machine has a boom mounted instead of spreading discs. Fertilizers are supplied to the boom through pipelines using air forced by a fan. The working width of the machine is 10.8 m. The application dose is regulated by the amount of fertilizer supplied to the pipeline using a gate device.

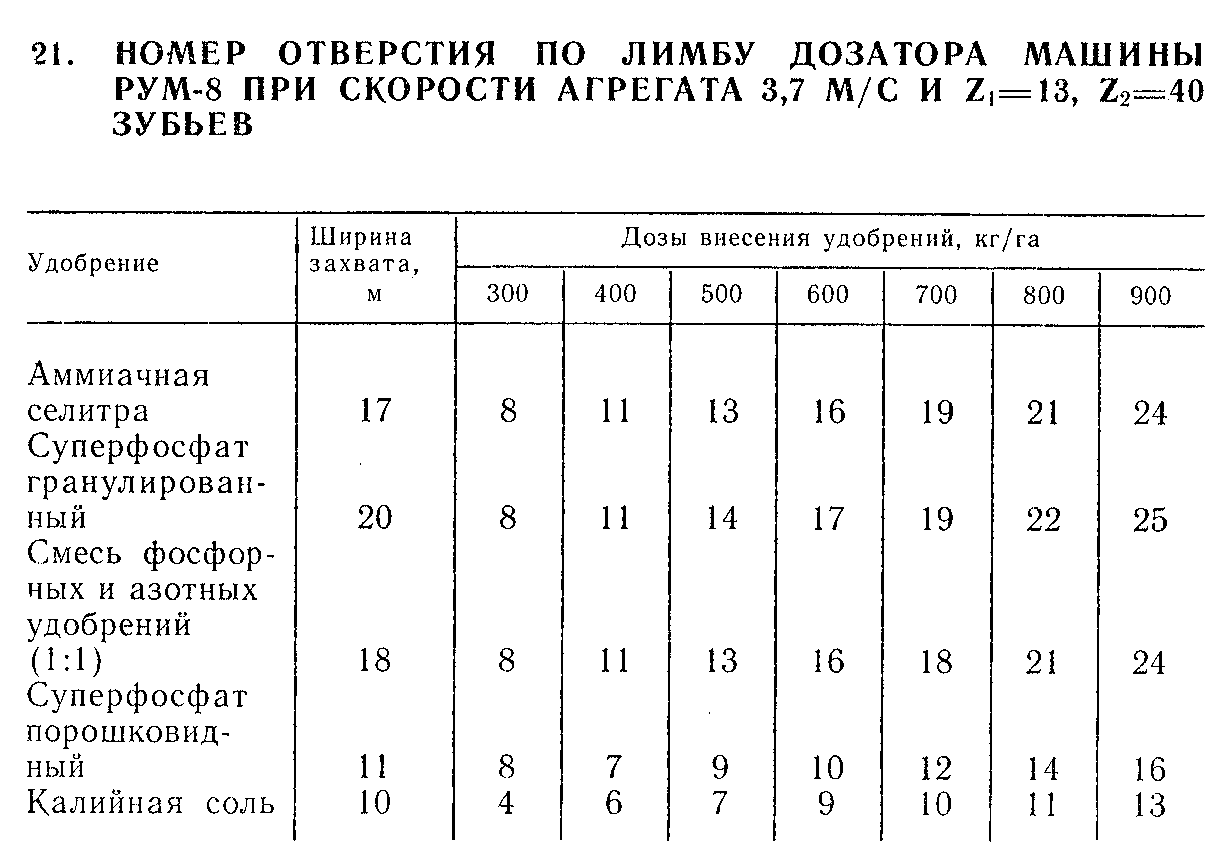

20. THE HEIGHT OF THE DOSING SLOT OF THE RU-5 SPREADER DEPENDING ON THE DOSE OF FERTILIZER APPLICATION. MM Mineral fertilizer and lime spreader RUM-8 is designed for continuous surface application of mineral fertilizers and lime. Such a machine is not used on tramlines. RUM-8 consists of a semi-trailer with a tandem chassis system, a body and spreading discs. A rod conveyor is mounted at the bottom of the body, and a metering valve is mounted on the rear wall. The drive of the working parts is from the tractor PTO. The tension of the rod conveyor is adjusted during operation of the machine by moving the driven shaft. The conveyor is considered to be correctly adjusted if its lower branch bends by no more than 10 mm. The tension of the spreading disc drive belts is adjusted by moving the driven pulley with the bearing housing. The belts are correctly tensioned if, with a force of 17.6 N, the deflection is 6 mm. The uniformity of fertilizer distribution is regulated by moving the fertilizer guide “forward” and “backward”, as well as by moving the movable walls of the fertilizer guide “towards”. The dose of fertilizer application is controlled by a metering valve and replaceable sprockets (Table 21). For a dose of up to 1000 kg1ha, sprockets are installed with Zi = 13 and Z2 = 40 teeth, for a dose of more than 1000 kg1ha - Zi = 23, Z2 = 32 teeth (Table 21). The RUM-16 spreader is designed for surface application of mineral fertilizers, lime materials and gypsum. This machine cannot be used to carry out work on tramlines. The spreader is a semi-trailer with a tandem-type running system. It has a body with two feed conveyors mounted on the bottom, and metering flaps on the rear wall. There are two discs for fertilizer distribution. During operation of the machine, the tension of the conveyor, the drive belts of the spreading discs and the dose of fertilizer applied are adjusted. The conveyor is tensioned by moving the driven shaft so that its lower branch sag by no more than 10...15 mm, and the spreading disc drive belts are tightened by the driven shaft. The deflection of the belts should be 4 mm with a force of 49 N.

21. HOLE NUMBER ON THE DISPENSER DIAL OF THE RU-8 MACHINE AT A UNIT SPEED OF 3.7 M1C AND Z = 13, Z2 = 40 TEETH The dose of fertilizer applied is regulated by the position of the dosing valve, the movement of which is performed by the steering wheel. For the required dose, the position of the steering wheel is fixed at a certain hole in the dial, which is determined according to Table 22.

Self-production

Many farmers are interested in how to make a mineral fertilizer spreader with their own hands so that it has the necessary performance properties. First you need to prepare all the mechanisms and tools. It is best to take a simple box and make 11 holes in it. Subsequently, they will be covered with rotating plates. There should be 2 holes above each plate. To control the supply of fertilizers during operation, you need to install special valves. Two wheels will be used as support.

During operation of a homemade diffuser, the rotational moment will be transmitted from the wheels to the plates, and only then to the agitator and ejector shaft. Thanks to this, fertilizers will be distributed evenly into the cultivated soil. The effectiveness of this procedure depends on how often the user stirs up the nutrients.

The demand for such equipment is due to the fact that the speed of crop development depends on the high-quality and timely application of fertilizers. A universal spreader helps to significantly save time and effort when performing agricultural work.

Types of special equipment

First of all, this technique is classified according to the type of fertilizer applied. It can be used to work with mineral or organic substances. Based on the type of construction, spreaders are divided into mounted and trailed.

A mounted fertilizer spreader is a plastic or metal hopper, which is attached to the tractor using a special frame and brackets. Since this technique has low productivity, it is recommended for use in areas with a small area.

For large fields, a trailed type mineral fertilizer spreader is better suited. It is implemented in the form of a wheeled trailer with a bunker and a distribution mechanism. A trailed fertilizer spreader has more capabilities than a mounted one. It has greater capacity and an increased working width.