Device, diagrams, repair

Front drive axle of the T-40 tractor - design and repair

Front axle design

The front drive axle of the T-40 AM and T-40 ANM tractors is used to increase traction forces and increase cross-country ability on moist soils and in off-road conditions. The front axle consists of a transfer case, differential, main and final gears and suspension.

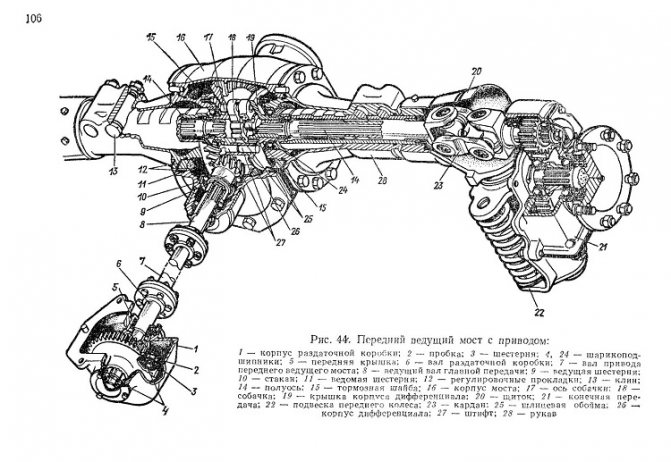

Diagram of the T-40 front axle: 1 - transfer case housing; 2 - plug; 3 - gear; 4, 24 — ball bearings: 5 — front cover; 6 — transfer case shaft; 7 — drive shaft of the front drive axle; 8 — main gear drive shaft; 9 - drive gear; 10 - glass; 11 — driven gear; 12 — adjusting shims; 13 - wedge; 14 — axle shaft; 15 — brake washer; 16 — bridge body; 17 — pawl axis; 18 - dog; 19 — differential housing cover; 20 — shield; 21 — final drive; 22 — front wheel suspension; 23 — cardan; 25 — splined holder; 26 — differential housing; 27 - pin; 28 — sleeve.

Front axle final drive

The main gear consists of a pair of bevel gears with a circular tooth. The drive gear is mounted in a cup on two ball bearings. The driven gear is part of the differential and is attached to the differential housing with bolts and pins.

During operation of the front axle, it is necessary to monitor the lateral clearance in the engagement of the teeth of the main gear. If noise or other malfunctions occur, it is necessary to check the mesh clearance or axial play of the drive gear. Due to tooth wear, an increase in the lateral clearance in the meshing is permissible up to 2 millimeters. If the gap increases due to wear of the bearing tracks, they must be replaced with new ones. The factory adjustment of the lateral clearance in the gear mesh is in the range of 0.17-0.65 mm.

Both gears are replaced simultaneously during operation and further development of their service life. When installing the sleeves, the total number of shims on both sides should be such that the differential rotates freely in the bearings by hand without any jamming or displacement.

Front axle differential

The differential allows the drive wheels to rotate at the same angular speed, which is required when driving the tractor over uneven terrain and when performing maneuvers.

The front drive axle differential design is a double-acting ratchet-type overrunning clutch. The differential consists of a housing, a splined race, a driven gear and a cover, connected to each other using four bolts. In the driven gear, cover and differential housing there are two axes each, on which a pawl is installed on a key. As the driven gear rotates, the pawls engage with the inner races by the frictional force that appears between the special patterns on the ends of the pawl axles and the surfaces of the brake washers.

Using springs, the axles are constantly pressed against the brake washers to create friction. Depending on the direction of rotation, the pawl engages with one of its ends. If the rear wheels rotate with less than 4% slip, the splined races overtake the driven gear, forcing the pawls to click along the teeth of the races. When the slipping of the rear wheels exceeds 4%, the forward movement of the tractor will decrease, while the driven gears and angular speeds of the cage will be leveled. With a subsequent increase in slipping of the rear wheels, the pawls will engage with the splined race, as a result of which torque will be transmitted from the driven gear through the splined races and axle shafts to the front wheels.

The differential is mounted in sleeves on two ball bearings: on one side on the neck of the differential cover, on the other - on the neck of the driven gear.

The T-40 front axle housing is equipped with a breather, which serves to maintain stable pressure in the cavities of the differential, main gear and hoses. To prevent oil from leaking out of these cavities, special sealing rings and cuffs are installed.

Torque is transmitted to the final drives through dual cardan shafts. Needle bearings and universal joints are unified with similar components of GAZ vehicles. All universal joints used consist of a spider and two forks. The fork holes contain needle bearings, into which the crosspiece axles are inserted.

Rework and modernization of the T-40 front axle

As a visual aid for remaking the front axle of a tractor, watch this video.

Reducer of the front axle of the T-40 tractor

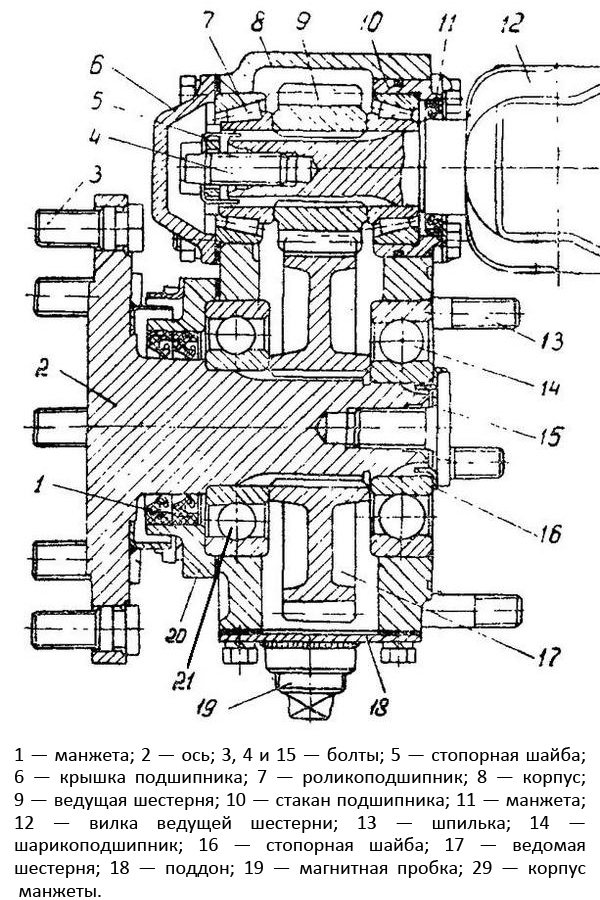

To transfer the drive from the gearbox to the front drive axle, a gearbox (transfer box) is used. The gearbox consists of a housing and a gear, which is mounted on the shaft splines. The shaft and gear are mounted in a housing on two ball bearings. Using the drive shaft, rotation is transmitted from the shaft to the drive shaft of the main gear.

To prevent winding of plants, a special protective casing is installed on the drive shaft.

Oil from the tractor transmission is used to lubricate the bearings and gears. Cuffs are installed in the front cover of the gearbox housing of the T-40 tractor to prevent oil leakage.

Diagram of the front axle gearbox: 1, 8 - cuffs; 2, 13, 19 — bolts; 3, 12 — lock washers; 4 - cover; 5 — roller bearings; 6 — body; 7 — bearing cup; 9 — drive gear fork; 10 - drive gear; 11 — ball bearing; 14 — driven gear; 15 — hairpin; 16 - plug; 17 - pallet; 18 — cuff body; 20 - axle shaft.

Front axle final drives

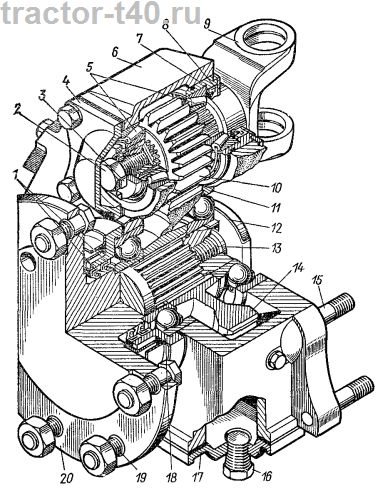

Final drives are used to increase torque and reduce rotation speed transmitted to the front drive wheels of the T-40 ANM and T-40 AM tractors. All final drives are single-stage gearboxes with spur gears. The drive gear is mounted on the splined end of the fork and is mounted in the housing on two tapered roller bearings. The driven gear is placed on the splines of the axle shaft and is installed in the gearbox housing on two ball bearings. The wheel disc is attached to the axle flange using bolts. The steering arms and brackets for the front wheel protective fenders are attached to the gearbox housing. The steering linkage rods, in turn, are riveted to the swing arms.

A little about the T-40 tractor

The T-40 tractor (“magpie”) is a wheeled tractor produced at the Lipetsk Tractor Plant from 1961 to 1995.

Production of this model is currently discontinued. During production, over 1.196 million similar tractors were assembled. The T-40, also known as the “magpie,” belongs to the 0.9 class of wheeled tractors. In the period from 1961 to 1995, it was produced at the tractor plant in Lipetsk. During this period, more than a million copies were released. The main activities are agricultural, transportation and repair and construction work with the aggregation of auxiliary mechanisms and structures. If necessary, you can attach a mower, snowblower, bale packer, plowing equipment and a compact loader. The versatility of application and a wide selection of additional functions allows you to cover a significant amount of work. Popular in farming.

The presence of a reversible mechanical transmission allows you to cover the full range of speeds when moving backwards or forwards. Supports aggregation with spare parts and devices from both light equipment (for example, T-25) and heavy equipment (MTZ-80). This makes it more versatile and popular not only in the CIS, but also beyond its borders.

During the existence of the model, a significant number of versions and modifications were released, the main differences of which were the power units used.

Among the most popular:

- Modification with all-wheel drive T-40A.

- Its lowered version of the T-40AN with a small distance between the bottom and the road surface - for performing tasks on inclined planes;

- Industrial version of the T-50A, equipped with a loader;

- Equipped with rear wheel drive T-40M.

- With all-wheel drive T-40AM.

Repair of the T-40 tractor: Main technical parameters

- Two types of engines are used: D-37 and D-144. Engine power, depending on the choice, reaches from 35 to 50 horsepower.

- The maximum speed is 26 km/h, and the minimum is 2.2 km/h. When using a special slow transmission, the speed is halved to 1.1 km/h.

- Dimensions: length - 366 cm, width - 162 cm, height 210 cm.

- The clearance between the road and the bottom is 50 cm.

- Weight 2.5 tons.

- Average fuel consumption is 120 g/minute. Proper and timely maintenance of the engine significantly extends its service life.

Front drive axle of the T-40 tractor

Before studying in more detail the main parts that make up the T 40 front drive axle, it is advisable to familiarize yourself with its features. It represents one of the most significant components of this vehicle, which is responsible for its movement across the terrain.

Thanks to the high level of reliability and simple design, the unit has a long service life. At the same time, for uninterrupted operation, it is necessary to perform timely maintenance in accordance with the manufacturer’s recommendations.

Bridge structure

The design diagram of the front axle of the T 40 tractor allows you to form an objective idea of the design of such an element. It consists of many large and small parts, among which it is advisable to highlight a number of the most important:

- transfer case and related mechanisms;

- differential;

- suspension;

- transmissions - main and final.

Since each of them has an impressive number of features, it is advisable to study them in more detail. You should consider the final drive of the bridge, which consists of two bevel-type gears, as well as the main gear. For successful fastening of the latter, a bearing and other elements are used. The driven gear is mounted using special bolts directly to the differential. It should be noted that the appearance of extraneous noise during the operation of this unit, as well as other problems, requires immediate elimination, since even with severe wear, the gap in the engagement between the gear teeth should be no more than 0.2 cm. If this indicator is exceeded, it is strongly recommended to carry out repairs by replacing damaged items.

Another important component is the differential, which is responsible for the same rotation speed of the front pair of wheels. This allows the tractor to move effectively off-road, as well as perform complex maneuvers. The main element of this part is the body, splined race, gears and cover.

When studying the drive of this unit, it is advisable to note the final drive, which is used to increase torque and reduce speed. An important element is a single-stage gearbox equipped with gears with straight teeth.

To maintain optimal tractor performance, it is recommended to monitor the play of the fork axles at the end of the agricultural work season. If it exceeds 0.4 mm, this is a good reason for carrying out repair work.

It is also necessary to mention the front axle suspension, which allows the tractor to move without strong shaking and vibrations caused by uneven road surfaces. The suspension bracket is bushed and mounted on the final drive housing, allowing it to rotate freely. Components subject to friction are lubricated to prevent excessive wear and subsequent breakdown.

The drive from the transmission to the axle is carried out using a gearbox consisting of a housing, as well as gear mechanisms mounted on a spline. The drive shaft transforms the movement to the main gear and is equipped with a protective casing. The presence of the latter allows you to avoid plants and other foreign objects getting into this important unit.

T-40 front axle diagram

In the process of servicing or repairing such a unit, the technician will be helped by a diagram of the T 40 front axle, which contains detailed information about the key structural elements, their location and other useful information. Guided by such a scheme, you can easily troubleshoot problems yourself, saving on the services of specialists.

Front final drive T-40

This mechanism consists of a single-stage mechanical gearbox with straight teeth. Its main task is to reduce the rotation speed and increase the torque of the tractor wheel apron.

The final drive gears of the T-40 and T-40 AM tractors have different gear ratios and cannot be interchangeable.

Scheme of the front side T-40

As we said above, the final drive of the T-40 tractor consists of a wheel gearbox, based on this, we need to consider its diagram