Engine, power elements

In countries with higher environmental standards, the Caterpillar D9R bulldozer is equipped with the 3408E HEUI™ engine. For other regions, it is possible to equip it with a 3408C diesel engine. The difference is the absence of the HEUI electric fuel injection system, which provides 44% more torque.

To achieve high power at low crankshaft speeds, diesel engines are equipped with turbocharging and a charge air cooler. And reliability is achieved by reducing the number of mechanical connections. The same purpose is served by electronic protection of the power unit in case of idling, cold start and other unfavorable conditions.

Photo source: cat.comPhoto Caterpillar D9R

The traditional solution for Caterpillar bulldozers is a torque divider. The torque converter is responsible for transmitting 75% of the torque developed by the engine, the remaining 25% goes through the planetary gear directly to the drive shaft. The result is an increase in the efficiency of the power transmission, as well as an increase in the amount of torque.

Another solution well known to Cat dozer owners is raised final drives. The designers ensured the isolation of these elements from the effects of soil and the elimination of the consequences of shock loads.

| Engine model | 3408E HEUI™ |

| Inner diameter of cylinders | 137 mm |

| Piston stroke | 137 mm |

| Working volume | 18 l |

| Fuel tank | 908 l |

DEVICE Caterpillar D9R

The supporting structure of the Caterpillar D9R bulldozer is based on a reinforced rectangular frame with solid-rolled side members. Solid steel parts with no joints add strength to the machine. The special design of the crankcase ensures a high location of the final drives, protecting them from dirt, abrasive wear and shock loads. An articulated balance bar and oscillating axis maintain the orientation of the roller frame.

The Caterpillar D9R undercarriage relieves up to 50% of the loads placed on the bulldozer. The rollers and idlers are equipped with symmetrical Duo-Cone seals for increased service life. The raised drive sprocket takes some of the load off the elements and transfers it to the main frame. The tubular frame design and additional reinforcement in problem areas make the chassis resistant to increased loads.

Chassis characteristics:

- type – for severe working conditions;

- track width – 2250 mm;

- shoe width – 610 mm;

- lug height – 84 mm;

- number of shoes (on one side) – 43;

- number of road wheels (on one side) – 8;

- track pitch – 240 mm;

- contact length of the caterpillar part with the ground – 3474 mm;

- The contact area of the tracked part with the ground is 4.24 sq.m.

The Caterpillar D9R transmission is based on a 6-speed planetary manual transmission with power shift. The speed and direction of movement of the equipment is controlled using a single lever. Large oil-cooled clutches absorb energy efficiently for smooth operation.

To increase the efficiency of the transmission, a torque divider is used, which distributes the incoming torque in a ratio of 3 to 1. The main part of the force passes through the hydraulic system, the rest through the drive valve. Due to the transfer case, the bulldozer has sufficient performance while moving. The divider also protects the transmission from sudden changes in loads.

Travel speeds (forward/reverse):

- 1st gear – 0-3.9/0-4.8 km/h;

- 2nd gear – 0-6.8/0-8.4 km/h;

- 3rd gear – 0-11.9/0-14.7 km/h.

Towing force:

- 1st gear – 725 kN;

- 2nd gear – 400 kN;

- 3rd gear – 218 kN.

The Caterpillar D9R hydraulic system has automatic control based on the actual load. The system uses a flywheel-driven piston pump with a capacity of 239 l/min.

The bulldozer cabin is large. In the initial version, it is equipped with FOPS and ROPS protection systems. The operator's seat with many settings is convenient to use. Control of the equipment is simplified, and the operating mode is set automatically.

Cabin, controls

The system for monitoring the current state of the Caterpillar D9R bulldozer, developed by the company’s specialists, is equipped, among other things, with warning indicators.

The cabin is placed on insulating supports, which reduces vibration and noise levels to 84 dB (A). Ergonomic controls are distinguished by the fact that they do not require significant effort from the operator. Also, for the convenience of the driver, a high-comfort seat is installed; it is fully adjustable.

Photo source: cat.comVibration and noise levels in the Caterpillar D9R cab are reduced to 84 dB

The Caterpillar D9R bulldozer has levers that are used to both disengage the side clutches and stop the tracks. Direction of movement and speed are controlled using a single control handle.

To improve visibility, in addition to the sloping hood, a fuel tank with a recess is installed. Wide door windows provide good lateral visibility.

The control system can be selected: either a standard version with onboard clutches and brakes, or a differential steering and braking control system is available. In the second case, power is continuously supplied to both tracks.

A feature of the hydraulic system of the Caterpillar D9R bulldozer is that one of the two pumps is activated when turning, and the second is responsible for the operation of the blade and other attachments. This allows all elements to be provided with the necessary power.

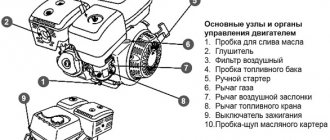

ENGINE

The Cat D9R is equipped with a modern Caterpillar 3408 series engine of its own production. The engine design includes a cooler and turbocharging. A mechanism for direct fuel supply to the combustion chamber is available as an option.

Other features of the unit include:

- minimum number of connections;

- Gray cast iron is used as the main material for the cylinder block, which increases the strength of the structure;

- the presence of electronic protection when starting in sub-zero weather;

- stability of performance characteristics regardless of working conditions;

- a solid reserve of torque.

Caterpillar 3408 engine characteristics:

- working volume – 18 l;

- rated power – 330 (443) kW (hp);

- rotation speed – 1900 rpm;

- number of cylinders – 8;

- cylinder diameter – 137 mm;

- average fuel consumption – 40 l/hour.

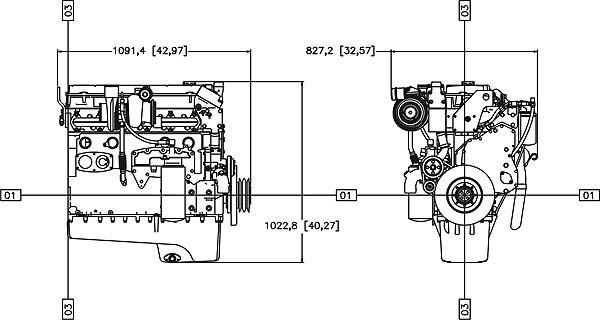

Dimensions Caterpillar D9R

| Overall width (by axles) | 3 303 mm |

| Machine height | 3,996 mm |

| Ground clearance | 507 mm |

| Shoe width | 610 mm |

| Number of shoes per side | 43 |

| Track width | 2 250 mm |

Specifications Caterpillar D9R

| Operating weight | 48,784 kg |

| Blade capacity | 13.5-16.4 cubic meters |

| Power | 354 kW/474 hp |

| Engine model | 3408E HEUI™ |

| Inner diameter of cylinders | 137 mm |

| Piston stroke | 137 mm |

| Working volume | 18 l |

| Fuel tank | 908 l |

| Overall width (by axles) | 3 303 mm |

| Machine height | 3,996 mm |

| Ground clearance | 507 mm |

| Shoe width | 610 mm |

| Number of shoes per side | 43 |

| Track width | 2 250 mm |

Caterpillar D9R video

Chassis

When developing this part of the machine, Caterpillar specialists set out to improve the balancing of the machine and extend the service life of individual elements. The optimal solution was the high location of the drive sprockets. The design is also characterized by an elastic suspension, which helps minimize the impact of shock loads.

A special feature of the rollers and idlers is the presence of 2-cone seals. And the end rings included in the track links prevent lateral play and help achieve maximum seal fit. By additional order, it is also possible to install protective guards for the guide wheels.

Photo source: cat.comPhoto Caterpillar D9R

Wheeled excavators

Specifications:

- Engine model - C4.4 and C7.1 ACERT;

- Net power – 95.0 kW-124.0 kW;

- Maximum speed - 25.0 km/h-37.0 km/h;

- Bucket capacity - 0.76 m-31.18 m3

- The maximum digging depth is 5450.0 mm-6680.0 mm.

The new line of wheeled excavators includes models: M315D2, M317D2, M320D2, M322D2. The machines are equipped with C4.4 and C7.1 engines with ACERT technology. Engines meet US Tier 3, EU Stage IIIA emission standards. Thanks to its quick response to load changes, the engine maintains power at the same level regardless of operating conditions. The ability to operate in three operating modes, including economical, will significantly reduce fuel consumption, optimize transmission performance, and provide an optimal balance between performance and fuel efficiency.

For severe operating conditions, special gearbox protection and reinforced axles are provided, which ensure rigidity and long service life of the machine. Caterpillar wheeled excavators have convenient controls and are equipped with a comfortable multifunctional cab. All necessary operator information is displayed on the high-resolution LCD monitor, and a rearview camera combined with improved forward and side visibility ensures safe machine operation. Work Tool Selector allows you to select from 10 preset hydraulic work tools and quickly change between them.

Frame

The main frame of the Caterpillar D9R bulldozer includes box-section side members (this shape ensures reliable alignment of all components). Robust steel castings also add strength to the main frame, balance bar saddle, front cross member and blade stabilizer axle. The upper and lower spars are solid rolled. The blade is located as close to the body as possible - this was achieved due to the special design of the stabilizer beam, and the result is better controllability of the working equipment.

Motor graders

Specifications:

- Engine model – C7 ACERT, C6.6 ACERT, C9 ACERT;

- Effective power (1st gear) – 93 kW-397 kW;

- Maximum speed – 46.6 km/h – 51.7 km/h;

- Operating weight (standard equipment) – 16.88 t-33.71 t;

- Blade width – 3.7 m-7.3 m.

In the company's catalog, motor graders of the K and M series, characterized by high operational efficiency, have maximum productivity and durability, guarantee power and precision when performing work, including in difficult conditions. The C7 ACERT and C6.6 ACERT Series engines provide the machine performance needed to maintain consistent grading speeds for maximum productivity.

Thanks to the high torque and the ability of the engine to operate stably at maximum load conditions, the power necessary for smooth operation during sudden short-term increases in load on the machine is achieved.

Thanks to ACERT technology, all processes in the fuel combustion chamber are optimized, which allows the fuel to be used with maximum efficiency. ACERT engines also feature lower emissions to meet international safety standards.

Caterpillar C9 ACERT diesel engine (USA)

Industrial engine C9 ACERT

manufactured by Caterpillar (USA) - 6-cylinder, in-line, 4-stroke, with direct fuel injection, turbocharging with a charge air cooling system with atmospheric air (turbocharger with wastegate), electronic control unit (ADEM™ A4), HEUI™ fuel system, high efficiency oil filters, lighter cylinder block design, split connecting rods.

Engine power is 205-280 kW at a crankshaft speed of 1800-2200 rpm. The engine meets Tier 3 (US EPA) and Stage IIIA (European Union) emissions standards thanks to the use of ACERT (Advanced Combustion Emissions Reduction Technology). It covers four systems to reduce exhaust emissions and covers the fuel system, the fuel combustion process, the clean air system into the engine and the implementation of an electronic monitoring and control system.

Benefits of the Caterpillar C9 ACERT diesel engine

:

— Thanks to wet cylinder liners with a middle mounting belt, fuel consumption and exhaust toxicity are reduced.

— Increased service life due to the use of induction hardening of internal surfaces.

— Improved control of fuel injectors.

— The design of the oil filter has been modified to reduce engine wear.

Specifications:

| Parameter name | Meaning | |||||||||||||||||||||||||||||||||||

| Number of cylinders | 6 | |||||||||||||||||||||||||||||||||||

| Cylinder arrangement | in-line | |||||||||||||||||||||||||||||||||||

| Cylinder diameter, mm | 112 | |||||||||||||||||||||||||||||||||||

| Piston stroke, mm | 149 | |||||||||||||||||||||||||||||||||||

| Working volume, l | 8,8 | |||||||||||||||||||||||||||||||||||

| Compression ratio | 16,1:1 | |||||||||||||||||||||||||||||||||||

| Engine operating mode | ||||||||||||||||||||||||||||||||||||

| Engine power, kW (hp) |

|