Like any motorized equipment, a lawn mower sometimes breaks down and stops working or does not function properly.

Moreover, there is always a specific reason why the equipment works intermittently; without fixing it, repairing it will only lead to a pointless waste of money and time.

Having understood the structure of the lawn mower and the reasons for the breakdown of certain mechanisms, in most cases it is possible to eliminate them yourself.

In this article we will talk about:

- the most common malfunctions of gasoline lawn mowers;

- the reasons for these malfunctions;

- diagnostic methods;

- methods of repair and prevention.

Features of the structure of lawn mowers

Most mowers are controlled by pushing from behind, but there are also models that can be controlled using a steering wheel.

A certain type of device is designed for different jobs. The small ones handle the average average area, while the larger steering mowers are used for larger lawns.

But all devices have the same structure. Let's start with the body. Gasoline mowers have aluminum and steel bodies.

Using the lawn mower you choose for your dacha, you can also mulch the lawn.

Aluminum ones are used much more often, since such a body is durable, lightweight and resistant to corrosion.

The steel housings contain a powerful and heavy motor. Electric lawn mowers are lighter than gasoline ones and their body is made of ABS plastic. It is used to create car bumpers.

The wheels of the mower should be large in diameter, so they can easily overcome uneven surfaces. They also create less pressure on the ground and do not injure the lawn. The bearings will ensure high reliability and durability.

Many manufacturers make the two front wheels swivel. This allows for increased maneuverability. The front wheels rotate around an axis, so you don't have to lift the mower to change direction.

Let's talk about knives. All of them, as a rule, are rotary and located on the working shaft. The diameter of the blades determines the cutting width of the lawn mower.

The rotor performs the following functions :

- supporting knives at a certain distance from the ground;

- rotates quickly and cuts grass;

- has blades that serve as a fan. The air flow from the fan carries the cut grass to the grass catcher.

All knives are made of high quality steel.

A grass catcher is a large bag or plastic box with holes for air. It is easily removed and the contents are thrown away.

Many mowers not only cut grass, but can also grind it into flour. This process is called mulching. In this case, do not use a grass catcher, since the greens will serve as fertilizer after mowing.

Important! Follow safety precautions when operating the lawn mower.

DIY electric lawn mower repair

Not only factory electric lawn mowers, but also homemade electric lawn mowers fail. The main reason the electric motor stops is loss of contact and lack of power at the motor terminals.

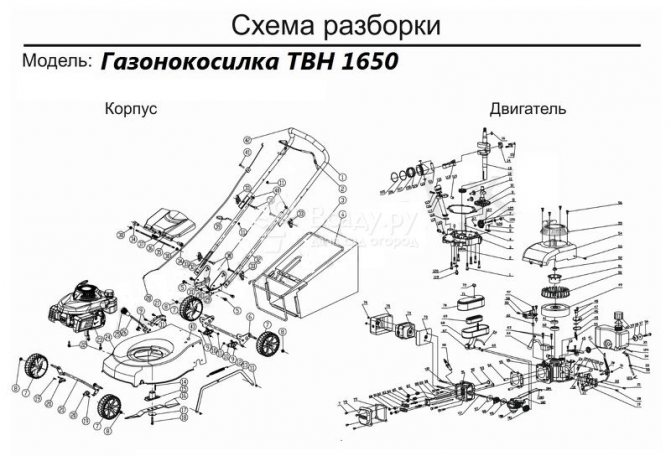

Drawing of an electric lawn mower using the example of TBH 1650

Therefore, first of all, we check the presence of voltage in the power outlet, the condition of the electrical cord and its absence. Then, if a commutator motor is used, you need to check the condition of the brushes and replace them if they are severely worn. A manual lawn mower with a brushed motor has increased durability, but requires regular brush replacement.

DIY electric mower engine repair

Manual lawn mowers with an induction motor also have problems. The phase-shifting capacitor often fails, but testing it in the field is problematic. An indirect sign of capacitor failure is:

- twitching of the motor when power is applied;

- strong engine heating even at low load;

- reduced speed;

- characteristic buzzing.

A do-it-yourself electric lawn mower is made from scrap materials that can fail. If a malfunction is detected, in any case, you need to make sure that voltage is supplied to the motor terminals, and if there is no voltage, check the operation of the switch.

DIY electric lawn mower

If there is voltage, the capacitor or brushes are in order, then the most likely cause of the breakdown is a burnt out winding. In this case, the unit will have to be taken to a repair shop. Homemade electric lawn mowers most often have to be repaired independently, since when assembling the device, all the nuances of its operation are not taken into account.

DIY electric lawn mower repair video

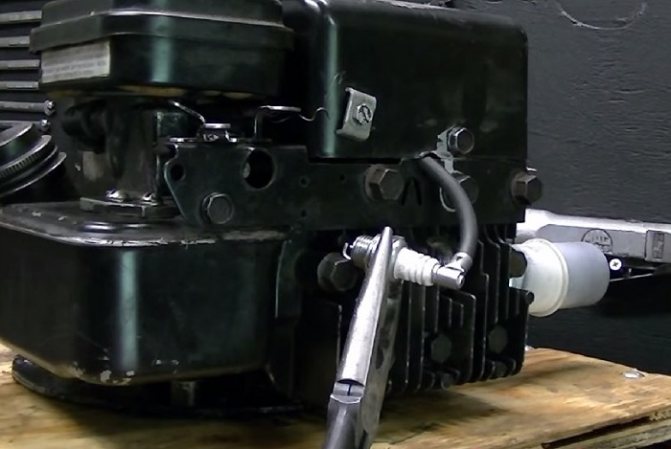

When opening the air damper

It happens that the unit stalls when the air damper is opened, idling normally. This is due to air leaks from the system caused by cracks in the fuel hose or problems with the seals. The carburetor metering system may also malfunction, and the lawn mower will stop after opening the damper.

Fuel hose in carburetor

All possible reasons why the lawn mower stalls and how to eliminate them are contained in the following video

There are many reasons why a lawn mower stops, but the most common are malfunctions associated with its carburetor . They can arise in any case. The most problematic option is when a serious breakdown occurs and you will need to purchase new parts or replace the lawn mower.

In order for the trimmer to work properly for a long time, you must strictly follow the operating instructions. It is necessary to refuel the unit with a fuel mixture suitable for its composition; the device must operate under moderate load.

What to do if the lawn mower starts and stalls{q}

Now let's look at all the problems described above in more detail.

- The lawn mower stalls when you press the gas.

- The brush cutter stalls when it gets hot.

- The brushcutter starts and stalls.

- The brush cutter stalls at idle speed.

In principle, there can be a huge number of reasons why the engine of a brush cutter stops working when you press the gas. Here we will consider only the most common ones.

Perhaps the air damper is simply clogged. And to eliminate the problem, it will be enough to simply clean the air damper. Also, the engine stalls due to a clogged air filter. To clean it, the filter should first be washed in a solvent and then blown with a stream of compressed air.

A similar procedure should be carried out with a clogged fuel filter, which prevents the flow of fuel in the required volume when the engine speed increases.

The engine may stall for other reasons. Firstly, the spacer located between the cylinder and the carburetor wore out, and secondly, the crankshaft seals began to suck in air.

We have already indicated that in this case the problem is in the carburetor. Due to increased temperatures, gasoline begins to boil in it, which is why the air-fuel mixture ceases to form or its quality critically decreases.

In addition, this problem may arise due to the fact that the carburetor is equipped with a rotary valve rather than a disc valve. If the problem has become chronic, then it should be solved radically - by purchasing a new carburetor with a disc valve.

Most likely, access to the fuel tank is difficult or completely absent, which is why a zone of low pressure is formed in it, due to which the engine stops receiving fuel in the required quantity and because of this you stop working.

The engine may stall at idle for the following reasons:

- Gearbox overheats

News oneNews oneNews oneNews oneNews onegot ready and began to prepare a not quite normal gasoline solution, which is why the speed on the drum began to drop;

- The carburetor is clogged;

- The carburetor is not adjusted correctly;

- The throttle valve is dirty;

- The choke is open, causing too much air to enter the carburetor, making the air-fuel mixture lean;

- The air filter is clogged.

To fix most problems you will need spare parts, and Well Part is ready to provide them to you at the best price.

So, why does the trimmer stall when you press the gas {q} There may be several reasons for this problem.

- The carburetor has become out of adjustment after an unsuccessful winter or after using the lawn mower too intensively. A gasoline trimmer operates on an air-fuel mixture prepared by a carburetor. If adjusted incorrectly, this mechanism prepares a lean mixture, which is not capable of providing the engine with sufficiently high speeds. You can tell about a problem with the carburetor by the characteristic vibrations of the lawn mower.

- You will know that the fuel filter is clogged by the fact that the trimmer starts and stalls. In other words, the flow of fuel is enough to start the lawn mower, but not enough to keep the engine running. It may be possible to solve the problem by loosening the valves on the filter. If not, you should wash the filter in solvents and blow it with compressed air. If after this the problem is not solved, then you should purchase a new fuel filter.

- If the engine stalls at speeds close to maximum, then there may be a problem with the breather, which regulates the flow of air into the gas tank. When fuel is consumed too quickly, which is typical when you step on the gas, a rarefied pressure forms in the gas tank, which reduces the flow of fuel to the engine.

- The engine stalls when the throttle is opened. The problem, again, is related to the carburetor, which, due to excess air, prepares a lean air-fuel mixture, which is not capable of ensuring engine operation.

We invite you to familiarize yourself with: Famous grape varieties for wine

Features of using garden equipment

It should be remembered that grass can be mowed no more than 20 cm high, 1/3 of the way at a time. Before changing the height of the bevel, be sure to turn off the machine. You need to work especially carefully on slopes and move along the terrain.

To prevent foreign objects from getting stuck in the blades, before mowing, inspect the area for stones, sticks, or anything else that might interfere with the lawn. If the device still jams, turn it off and check the knives for anything unnecessary.

We suggest you read: Why oranges should not be consumed by pregnant women

To summarize, if you encounter problems with the functioning of your lawn mower: it does not start or turns off, here is an algorithm for what to do:

- carry out an external inspection of the car for damage, see if there are any oil leaks;

- check the amount of gasoline in the tank;

- see if there are any third-party interfering objects in the knives of the device;

- pay attention to the fastening elements, whether there are any loose bolts;

- clean the mower parts if there are any contaminations;

- If the spark plugs are rusty, replace them with new ones.

Main problems with gasoline cars

Primary diagnostics is carried out from the stage of eliminating the most obvious breakdowns. When the engine does not start, it is worth checking the presence of fuel in the tank. If there are any leftovers from last season, then it is worth replacing it. After wintering, low-quality gasoline can lose its characteristics, give an unwanted sediment, or even separate into fractions based on density. In this form, it is not able to start the engine, but will only clog the system.

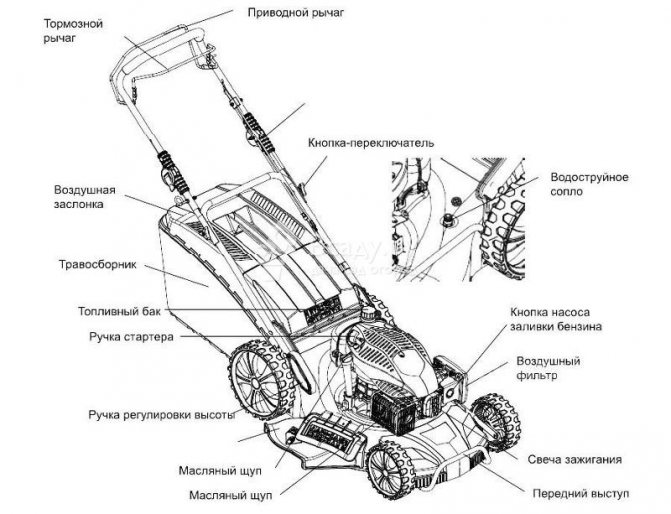

General diagram of a gasoline lawn mower

At the second stage, we find out why the spark does not appear. Its loss will prevent the fuel from igniting. We remove the cap from the spark plug and unscrew it from the seat using the special key that came with the mower. Next, we put the cap on the spark plug, bring it closer to the threaded part or metal element of the motor, and at this time the partner pulls the starter.

Checking the spark plug

With such manipulations, a powerful blue spark should appear in the working unit. It can be seen even in daylight. It is important to test this near an unpainted metal part of the motor that can conduct current.

When there is no spark, you need to go to the store for a new spark plug. Do not return it to the engine even if the spark is weak or unstable. It is better to first clean the working contacts on the head from carbon deposits.

During operation, rattling may occur in the structure. At first, it does not affect the performance of the mechanism as a whole. However, it can lead to imbalance and increased noise during operation. It is worth tightening the fastening bolts on the frame in a timely manner.

Tightening the mounting bolts on the frame

An uneven cut in the grass is an indication that your lawn mower blade needs to be sharpened. Getting to them is not so difficult, but it is important to completely disconnect the equipment from the power supply. You can do the work yourself using yews and a file or using sharpening sandpaper. It is important to ensure a uniform cutting angle along the entire line of 30 degrees. If there are chipped areas in the surface, this is evidence of contact with a hard surface. Replacing them will be quite expensive.

After switching on, a whistling sound appears. An unpleasant acoustic effect is associated with the penetration of foreign elements into the structure. They can block the roller in the aerator. You can solve the problem by turning off the blocked roller and then removing the foreign object.

The engine of gasoline-powered equipment becomes damaged almost immediately after the start of short-term operation. The culprits are a stuck crankshaft or piston. At the same time, check the presence of oil in the crankcase. With the engine turned off, manually start the rotation or add oil as necessary. However, in such a situation you often have to turn to specialists for restoration.

VIDEO: The main cause of failure and repair of the self-propelled drive of gasoline lawn mowers