For every owner of a private home and suburban area, a chainsaw is a necessary tool, but choosing one can be a truly difficult task, since there are a wide variety of models of gasoline saws on sale today. Using this tool, you can prepare firewood, trim trees, and also carry out work on the construction of verandas and gazebos.

Not so long ago, craftsmen used hacksaws and hand saws, but progress made it possible to develop chainsaws that became available to the average consumer. If you also decide to acquire such equipment, then it is important to pay attention to the most important characteristics, as well as determine which manufacturer is the best in its field.

Carver chainsaws can be called very popular; they are presented in different classes, as well as with a different set of functionality. To perform household tasks, you may prefer an amateur-level chainsaw, but for construction specialists, semi-professional and professional saws are suitable.

What class of chainsaw should I choose?

Carver chainsaws can be used by amateurs; they are intended for periodic use, and their power does not exceed 2 kW. Such equipment is equipped with low-profile chains that can significantly reduce vibration levels. However, in these cases you cannot count on high performance, but you can say with confidence that amateur-grade tools are light in weight, do not put a lot of stress on your hands, and are also easy to use. With their help, you can carry out minor construction work, trim trees and prepare firewood.

Carver chainsaws, which belong to the semi-professional class, will be able to withstand construction. They are quite powerful and can be used when felling trees. Their only disadvantage is that they are not designed for long-term use. If you need to saw for 10 hours straight every day, then it is best to choose a professional model. Semi-professional options can have a power ranging from 2 to 3 kW, but this parameter is mainly kept within 2.5 kW. The diameter of the barrel does not exceed 40 cm, and the weight of such instruments is approximately 6 kg.

Basic criteria for choosing a saw

Depending on the nature of the work, choose a tool based on power. There is a difference in the technical parameters of the saws:

- professional;

- semi-professional;

- amateur

You need to choose a device for specific work. The weight and dimensions of the tool depend on the power. And he won’t be able to straighten a hedge by hand, lifting a monster weighing 13 kg to shoulder level.

Each manufacturer develops safety systems when using the tool. But he cannot provide for all cases of rebound and waste of sawing products. It is the sawyer's responsibility to provide protective measures for himself. Glasses, boots, mittens and closed clothing must be the basis for access to high-risk tools.

For economic use, it is optimal to choose a low-power tool with a tire size of up to 40 cm. For professionals, the length of the cutting blade can reach 70 cm. The cost of chainsaws depends not only on the brand, but also on the purpose. For work in the country, choose lightweight and inexpensive products. The review includes Russian stamps collected, including in China, South Korean and American samples.

Choice for professionals

Carver chainsaws can be represented by professional models. They have high power, which reaches 6 kW, and such tools are intended for daily long-term loads. Chainsaws of this type are not justified for personal needs, unless you are planning to build a log house and a bathhouse. Professional models are most often purchased by organizations that engage in felling. Such equipment is designed for 2000 operating hours when working with thick trees.

Description of model RSG-38-16K

This version of the chainsaw costs 5,690 rubles. and is a household tool that can be used for small construction work and in the garden. The tool is easy to use and ergonomic, equipped with a two-stroke engine and its power is 2 horsepower. The manufacturer has equipped the equipment with an easy start system, which can be used to reduce the effort required when starting the engine. Comfort during operation is also ensured by an anti-vibration system. The air filter is protected by a housing and can be easily opened using a rotary wheel.

Chainsaw Sturm and its characteristics

The equipment was developed in Germany. The officially assembled screwdriver assembly of the model in China from supplied components allows you to obtain good quality saws at an affordable price. For all chain saws, the manufacturer provides a 25-month guarantee for professional tools and 14 months for household tools. In the manufacture of Sturm chainsaws, chrome-plated cylinders are used, which increase the service life of the engine. The engine is equipped with a heated starting system and can be operated at -300 C. There is a button to block accidental activation of the device. Other safety systems and lubrication are provided as in high-class models. The model has a power of 1.8 kW, a tire length of 46 cm and weighs only 4.2 kg. The cost of models for summer residents is about 6 thousand rubles.

User manual

The chain must be kept sharp during operation of the equipment, otherwise the operating time will be increased and the vibration level will increase. If the chainsaw's components are loose, vibration will interfere with operation. You should pay attention to the kickback, which is the jerk of the tire in an upward direction. It occurs at the moment when the chain touches another object. As a result, the operator may lose control and be seriously injured.

The Carver chainsaw, the instructions for use of which you should study before using the tool, should not be used at the first stage in the area of the end of the bar, this may cause kickback. The end of the tire must be constantly monitored; if objects accidentally touch this part, there may be a kickback, as well as a risk of injury. The manufacturer recommends that caution be exercised when continuing started cuts; cutting should only be started with the chain moving. The latter must be sharpened correctly. You should not cut several branches at the same time; when cutting branches, you must ensure that the saw does not touch other branches.

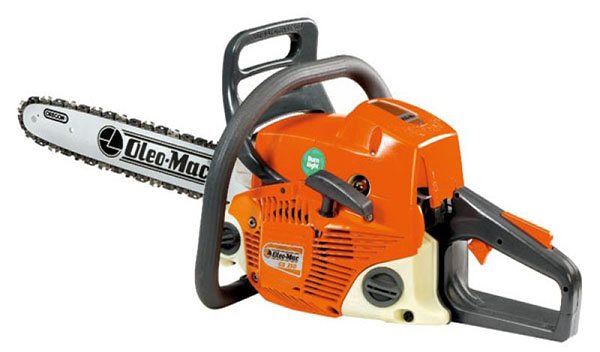

Chainsaw Oleo Mac

We represent the leading brand of global manufacturers. The Italian company Emak Group is a well-known manufacturer of manual equipment for rural work. This expensive instrument is impeccable in operation. According to the results of the rating, the Oleo Mak 937 35 cm chainsaw took second place in the first half of 2015, second only to the Shtil brand. The main difference between the products was two rings on the piston, which is rare for saw engines. And as a consequence:

- the quality of compression has improved;

- power increased;

- reliability has increased.

The main condition for trouble-free operation is the use of high-quality fuel, additives and chain lubricant.

On this topic:

Choosing a non-professional chainsaw model for gardening

Chainsaw from a Chinese manufacturer for work in the countryside

Cordless chainsaw - characteristics, models

Why and how to adjust a chainsaw carburetor

BACK FORWARD 1 of 4

All models are characterized by low vibration and a reliable system for blocking rebound or chain breakage. High-quality equipment costs from 14.5 to 40 thousand rubles, depending on the power. Models made in China can be purchased at prices above 6 thousand rubles.

Reviews of the semi-professional saw brand CARVER 262 01.004.00004

This model costs 8590 rubles. and is a semi-pro model with a chain pitch of 0.325 inches. According to users, a power of 4 horsepower is quite enough for minor construction work. Moreover, such equipment will withstand more severe loads compared to the model described above.

The device can be used for felling trees, because the equipment is equipped with a high-performance chain, cover and saw bar. According to buyers, the model is characterized by low vibration levels, easy starting and a high degree of safety. Thanks to the presence of a fuel pump, it is possible to use the equipment at low temperatures. According to professionals, porous chrome plating technology guarantees high wear resistance of the engine cylinder. The air filter is easily accessible; to do this, you just need to turn out the wheel on the housing.

The Carver chainsaw, whose owners have only the most positive reviews, has a metal crankcase, which significantly increases resistance to external influences and increases the service life of the tool itself.

Chainsaw carburetor design

Repair work is not complete without knowledge of the basics of the mechanism. By understanding the components and operating principle, it is easier to determine the cause of the failure.

Any malfunction in the carburetor threatens to stop the engine

The carburetor is one of the main functional parts of the engine, which is used to prepare and supply a fuel mixture consisting of certain proportions of fuel and air. As soon as the proportions are violated. The engine begins to act up or even stops working completely.

You can ensure proper operation of the carburetor by studying its “priming”:

- Tube with cross valve to regulate air flow.

- Diffuser. This is a constriction to increase air flow, located at the fuel inlet.

- The nozzle from which fuel is supplied (fuel arrow in the diagram).

- A float chamber that regulates the fuel level at the entrance to the channel.

Here's what it looks like in a diagram:

Diagram showing the interaction of fuel and air flow

READ How to Properly Sawing a Tenon and Groove

Operating principle: the air flow in the diffuser atomizes the fuel, creating a mixture that enters the cylinder. The greater the amount of fuel supplied, the higher the engine speed. Carburetors of different models work according to the same scheme.

Carrying out disassembly

You can repair the Carver chainsaw yourself after disassembling the tool. If we are talking about the cylinder-piston group, then first you need to unscrew the 4 bolts that secure the cylinder head. Then the latter is removed from the block, and the piston is checked by appearance. Spare parts for Carver chainsaws must be original, this also applies if you notice scoring, and the piston needs to be replaced. Sometimes the cylinder changes along with the piston.

Chainsaw Carver 25 12 Replacing Fuel Hoses

Content

Carburetor adjustment

To self-adjust the carburetor, you need to become familiar with its structure and remember the order of work that is performed to configure the parts responsible for the proper functioning of the components of the device and the parts located next to it.

It is necessary to carefully handle objects to configure the system, and also determine whether open parameters correspond to the maximum allowable values.

About the carburetor device

The carburetor is used to mix the combustible mixture with air, observing predetermined proportions. If precise doses are not followed, engine performance is compromised. When a large amount of air is supplied when mixing components, but not enough fuel, the mixture is considered “lean”.

Oversaturation cannot be tolerated, since with a large amount of fuel compared to air, engine failure or wear is also possible. Carburetor adjustment is necessary not only before initial use, but also when identifying any deviations in its operation. Before you start using your chainsaw, be sure to check it.

Carburetor components

The carburetor design contains a standard set of elements, but may vary slightly depending on the manufacturer. Components:

- The basis . This is a special tube that visually resembles an aerodynamic design. Air passes through it. In the transverse direction there is a damper in the middle of the pipe. Its position can be changed. The more it is pushed into the passage, the less air is supplied to the engine.

- diffuser _ This is an extended part of the tube. With its help, the air supply speed is increased exactly in the segment from which the fuel exits.

- fuel supply channels The fuel mixture is contained in a float chamber, then passes into a stream from which it flows into the atomizer.

- Float chamber . This is a separate structural element that resembles the shape of a tank. It is designed to constantly maintain an optimal level of fuel fluid before entering the channel from which air enters.

Don't know which chainsaw to choose? Read our article.

Are you looking for a cheaper model, but reliable and time-tested? Pay attention to Russian chainsaws.

Or research foreign chainsaw manufacturers such as Calm.

What do you need to configure

Every carburetor owner should have the necessary tools to set up this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L. Low speed correction screw.

- H. screw for high speed adjustment.

- T. regulates idle speed, in most cases it is used for experiments.

READ Chainsaw Echo Cs 3700 Video

Air filter

Before setting up the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs and turns off when you start working (see How to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T as far as it will go (see Chain oil).

To ensure a safe repair, you must prepare a flat surface where you can carefully position the device and turn the chain in the opposite direction. Need a tachometer. It determines whether there is a problem in the carburetor. When turning the screws, the sound should be perfect and absolutely equal. If you notice a squealing sound, the mixture is oversaturated.

Installation Instructions

Carburetor adjustment is divided into two main stages. The first one is called basic. It is created when the engine is turned on. The second is done when the engine warms up.

To successfully complete the carburetor adjustment procedure, you must first read the model-specific operating instructions to identify additional unit configuration features.

the initial stage

The highest and lowest speed adjustment screws should be turned clockwise until the highest resistance is encountered. When the screws stop, you need to move them in the opposite direction and leave 1.5 turns as they pass.

Main stage

The engine switches to medium speed and warms up for about 10 minutes. The screw that is responsible for adjusting the idle speed should move clockwise. It is displayed only when the engine enters stable operating mode. It is necessary to check that the chain does not move during this process.

Replacing the fuel hose on a 3816 chainsaw

how to replace fuel hose

on a chainsaw, and what if the oil leaks

from the chainsaw

? In this video we are eliminated.

Chainsaw Carver RSG-238! How to identify and eliminate a malfunction (not a carburetor)!!! ??

Oddly enough, sometimes it is like a factory defect for parts! Although not often something around 1 to 100!!! Basically.

Carburetor adjustment

In standby mode, the engine may stop (reason here). In this case, you must immediately adjust the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

Acceleration check

You need to do a little research. Device acceleration is initiated. It is necessary to evaluate the performance of the engine at maximum speed. When the engine is running properly, then when you press the accelerator, the speed quickly increases to 15,000 rpm.

READ Chainsaw Centaur BP 4520n Video

If this does not happen or the increase in speed is too slow, you must put on the screw marked L. It turns counterclockwise. Moderate movements must be observed as the rotation cannot exceed 1/8 of a full circle.

Maximum number of revolutions

To limit this pattern, you need to use a screw marked H. To increase the number of turns, turn it clockwise and decrease them in the opposite direction. The maximum frequency should not exceed 15,000 rpm.

If you increase this number, the device's engine will wear out, which will lead to problems in the ignition system. When turning this screw, you need to take into account the ignition processes of the device. If there is the slightest glitch, the maximum speed should be reduced.

Final check at idle

Before this procedure, it is necessary to perform a complete adjustment of the carburetor components when operating at maximum speed. Then check the operation of the device in cold cold mode. When the correct parameters are achieved during adjustment, you can see that the carburetor design closely matches the following criteria:

- When the standby mode is connected, the chain does not move.

Chainsaw accelerator

- When the accelerator is reduced even slightly, the engine accelerates at an accelerated rate. With a gradual increase in pressure, it is clear that the engine speed increases commensurately, reaching the maximum permissible values.

- When the engine is running, you can compare its sound to a four-stroke unit.

If the above parameters are noted to be abnormal or the device setup has not been completed completely, you need to perform the basic configuration step several times. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you need to contact a specialist.

Disassembling the carburetor if components need to be inspected or repaired

The layout of different carburetor models is almost identical, so when working with them you can use the standard layout. All items must be carefully removed and then distributed according to the order below , so that after the completion of the repair work, you can successfully get back into place.

Removing the Top Cover

- The top cover has been removed. To do this, unscrew the 3 bolts holding it in a circle.

- The foam is also removed as it is the top part of the filter that conducts the air.

- The fuel hose is removed.

- It immediately displays the drive thrust.

- The end of the cable is disconnected.

- The gas hose can be completely removed if he intentionally pulls it back.

To finally prepare the carburetor for overhaul or replacement of the smallest parts, it is necessary to carefully separate it from the main system . Sometimes additional disassembly is required. It is necessary to carefully unscrew the components and roll the fasteners into groups, as these small parts are easily lost.

READ How to Assemble a Partner Chainsaw

Instructions for the Chinese

To correctly configure the carburetor of a Chinese chainsaw, you must first remember the factory settings of the device, and then turn on the engine. As a result, it is necessary to leave it running for several hours in order to accurately determine its own parameters. Sometimes the job is done once after running the engine for ten minutes, but many Chinese-made models require special treatment.

Chinese chainsaw model

Setting procedure:

- Activities begin at idle . Using the adjusting screws, it is necessary to ensure that the engine speed is systematically increased, so you should first start it at low speed. Deviation from the norm. movement of the chain along the bus. In this case, it is necessary to adjust the outermost screws to the optimal position so that the chain remains stationary.

- Change to medium speed speed . Sometimes the engine smokes out. This defect can be corrected by tightening the screw to supply a more compact fuel mixture.

In this case, the smoke will disappear, but the engine speed will increase. It is necessary to adjust the settings to a level where when you press the throttle the engine grows constantly, no sudden jerks or interruptions are heard.

- The device's engine is checked . The chainsaw is converted to minimum speed and then the lever is pressed quickly. When pressed maximally, it is held for 3 seconds. If there is a problem with the motor, you need to gradually loosen the screw until the optimum position is reached.

- The chainsaw should work for several hours in real conditions . You need to cut the wood and then inspect all the elements involved in the event. If there are deviations, they must be corrected using adjusting devices. When all defects are eliminated and the optimal settings are established to supply the correct concentrated fuel, the installation process of the device can be considered complete.

Before purchasing, we recommend that you read the chainsaw rating to ensure reliability and quality. Look clearly at the video:

Conclusion

In order for the chainsaw to work correctly, you need to carefully do the job of adjusting the carburetor in the exact order. If there is any malfunction of the device, you must completely disassemble it yourself. In most cases, any parts that have become unusable will need to be replaced.

If the carburetor settings are constantly checked and timely measures are taken to improve its performance, there are no problems with the chainsaw.

Carrying out repairs

Before you carry out repairs, the Carver chainsaw must be disassembled. If you are faced with such a problem when the engine begins to stall at impressive speeds, then the main reason may be clogging of the spark arrester with combustion products. To do this, the muffler is removed, the surface is cleaned of carbon deposits using detergents, the base is dried with a hairdryer, and then the spark arrester is installed in place. Cleaning using dry technology is unacceptable, as carbon deposits contain carcinogens, and their inhalation can be hazardous to health. Once the muffler has been removed, the exhaust hole must be covered with a clean rag.

Video: Setting up the Carburetor of a Carver Chainsaw

- It is also better to adjust the winding of the Carver chainsaw motor by turning on 1/4 turn and trying to refuel.

- If the fuel delivery is too high, the engine will idle when the lever is set to "gas for all". This means screw L is too tight and must be backed out 1/4 turn to try to apply gas.

If, after adjusting the L screw, the Carver engine does not produce the power needed to run, you can carefully try to increase the top speed by adjusting the N screw.

They also adjust it with the engine running, but in the "gas for everything" position. Extremely carefully, the screw is screwed in 1/5, 1/6 of a turn, and they listen to the engine.

Increasing the ceiling speed can slightly extend the life of an old chainsaw with a worn piston. Weak compression is compensated by a greater supply of mixture at maximum speed.

Professional adjustment of screw H is carried out using a tachometer to determine the speed ceiling and an oscilloscope to monitor the frequency of flashes on the spark plug. Pre-compression.

READ Stihl 180 Chainsaw Doesn't Speed Up and Stalls

After adjusting screw H, the operation may change in other modes. Therefore, you need to check the operation in all modes and, if necessary, slightly adjust the adjustment again using screws L and T.

This is not always worth doing for the following reasons:

- When turned too hard, the sharp end of the auger can destroy the loose powder bronze bit found in cheap chainsaws, causing failure.

- 1.45-1.5 turns from “to the end” may not correspond to the old position of the screws, in which the chainsaw was still working until the last, and the actual factory settings.

Therefore, adjust based on the “as it was” position by no more than 1/4 turn per stroke. It is important to remember how much and in what direction the position of the screw has changed.

If you still need to tighten the screw "all the way", consider the number of turns from the "as was" position, this will return the settings to the previous position. Tighten “all the way” without effort.

The general principles of self-tuning of a chainsaw carburetor are presented in the following video: