The Polesie KZS 1218 combine harvester is a machine with a very high throughput. At a little more than 12 kg/sec, this combine can process more than 18 tons of grain (wheat) in an hour. This is what allows him to work quietly with very high yields of almost all grain crops.

Combine harvester Polesie KZS 1218

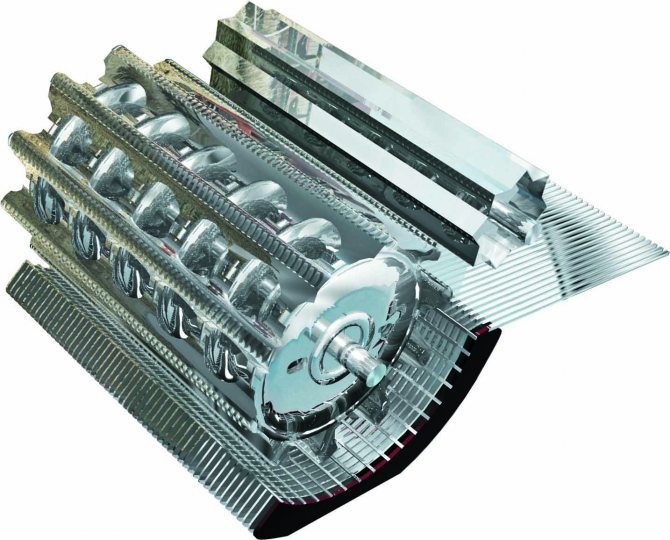

Such high performance can be achieved precisely due to the fairly high power of its engine (approximately 330 hp), a threshing scheme with two drums, as well as a pre-accelerator for feeding the entire threshed mass, increased separator areas and an excellent cleaning system. The direct competitor of this model is the ACROS 580 combine.

At the same time, the combine works perfectly at high humidity when harvesting difficult-to-thresh crops.

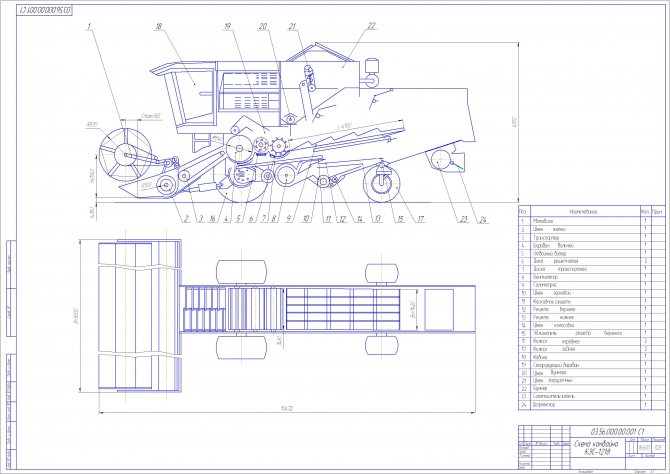

Design of the Polesie KZS 1218 grain harvester

The high-performance PALESSE GS12 combine operates effectively in a wide range of grain crop yields. Grain mass throughput of at least 12 kg/s, grain productivity (wheat) from 18 tons per hour or more - these main indicators are achieved through the use of a 330-horsepower engine, a double-drum threshing system with a preliminary accelerator for feeding grain mass, and an increased area separation and cleaning systems.

Design of the Polesie KZS 1218 grain harvester

At the same time, the combine is well suited for working in adverse conditions when harvesting difficult-to-thresh crops with high humidity, and is also combined with other types of equipment, for example, the T-150K.

The combine harvests the non-grain part of the crop according to the following technological schemes:

- chopping and spreading straw across the field;

- laying straw in a windrow.

The combine harvester is equipped as standard with a grain header with a working width of 7 m. The following can be supplied as options:

- grain headers with working widths of 6, 8 and 9 m;

- grain picker;

- device for harvesting rapeseed;

- a set of equipment with a header for harvesting corn for grain;

- modified soybean header;

- device for harvesting sunflowers.

Often a corn header can be used.

The PALESSE GS12 combine is certified for compliance with the requirements of the European Union with the right to apply markings.

Combine harvester KZS-10K "PALESSE GS10"

The KZS-10K “PALESSE GS10” grain harvester is, on the one hand, a classic single-drum threshing and separation scheme that combines stability and quality of threshing with economical operation. On the other hand, these are advanced technical solutions, such as a header with the best cutting device in the world, three-stage cleaning and a high level of automated control of harvesting parameters. The combination of these qualities, taking into account the moderate price, gives every reason to consider the PALESSE GS10 the “golden mean” in grain harvesting.

The use of PALESSE GS10, in addition to harvesting cereal grains, with adapters for harvesting various crops makes it possible to increase its seasonal load from 180 to 300 engine hours, which ensures a reduction in direct operating costs per unit of operating time by at least 1.4 times.

The Big Drum threshing apparatus with a high-inertia drum with a diameter of 800 mm gives excellent results when harvesting in conditions of normal humidity and average straw content, providing high throughput of the combine.

The presence of seven cascades with an optimal height difference on each of the five straw walker keys and a large amplitude of the counter movement of the keys improve the separation of grain from the straw heap, maintain stable productivity and reduce losses.

A three-stage fine cleaning system with electrically adjustable air flow intensity from the cabin guarantees high purity of the bunker grain.

The grain unloading system with a top-mounted unloading auger allows you to quickly load car bodies with high sides with grain, saving time on cleaning.

A large-volume cabin (2.6 m3), with panoramic glass, equipped with air conditioning, a fully adjustable operator’s seat - this is real comfort at a high level.

In the updated PALESSE GS10 combine, the hydrostat handle has become even more functional. To the functions that can be controlled with one hand and require quick decision-making, in addition to controlling the speed of movement, the position of the reel and its rotation speed, the position of the feeder chamber and instantly turning off its drive, the ability to control the grain unloading system has also been added.

When started, the on-board computer automatically checks the circuits of sensors and mechanisms for serviceability, provides viewing of an electrical diagram with circuit numbers and tips for troubleshooting. Automatic adjustment of the working elements (threshing gap, threshing drum speed, cleaning fan speed) is performed by a computer based on the crop being harvested and its condition, or from previously stored settings.

The feeder chamber is characterized by a stable and high-quality supply of grain mass. Three supports of the upper conveyor shaft, which evenly distribute the load on the chains, and sprockets with an increased number of teeth ensure the durability of the conveyor chains, and the lower shaft made of a durable pipe on reinforced bearings further increases the reliability of the feeder chamber.

The use of hydropneumatic accumulators on the hydraulic cylinders for raising/lowering the feeder chamber improves the quality of the header's copying of the field topography and prevents damage to the header and feeder chamber.

The use of a hydraulic motor in the design of the feeder chamber ensured stepless reversal of the conveyor, significantly reducing the time required to complete this operation.

The fuel tank with a capacity of 500 liters used in the design of the combine is made of high-quality polymer materials and has advantages over a metal fuel tank - durability and corrosion resistance. It is an effective solution to the problem of fuel system clogging with corrosion products.

The reliable and economical YaMZ-236BE2-28 engine has sufficient power reserve to ensure stable operation of the combine. The upper platform of the combine is equipped for safe and convenient maintenance of the motor unit.

The inclusion of a second receiver in the basic package made it possible to increase the total volume of the pneumatic system to 80 liters, creating a new reserve for saving time on shift maintenance. The installation of an additional pre-cleaner in the engine air supply system increased the efficiency of cleaning the incoming air, increasing the stability of the engine.

An effective solution to increase convenience and reduce maintenance time: fully opening hoods, securely held by pneumatic cylinders, provide unobstructed and convenient access to the components and mechanisms of the combine.

The cutting device with durable stamp-welded fingers with upper and lower cutting edges, with an up/down system of alternating segments, gives an exceptionally clean cut and ensures self-cleaning. The planetary gearbox used to drive the cutting apparatus of the header provides a high cutting frequency (1108 strokes/min) with smooth operation and minimal wear, increasing productivity.

Separate grain combining

When harvesting conditions require it, PALESSE combines are equipped with a grain pick-up platform. Just like the header, this adapter is well adapted to work on uneven fields and ensures longitudinal and transverse copying of the field topography. Its design prevents the picked material from clogging, wrapping and blowing away. The pick-up cleanly collects cut and windrowed grain using windrowers also made by .

Harvesting rapeseed.

The use of a device for harvesting rapeseed allows you to expand the header table. Active side dividers with fingerless cutting devices clearly cut the harvested rape along the edge of the pen. In combination with rapeseed reflectors, this reduces rapeseed loss to a minimum.

Harvesting corn for grain.

Harvesting corn for grain becomes an easy task using a special set of equipment.

It includes a header with a cob separator and a stalk chopper, a reduction drive for the threshing drum, a replaceable concave and additional equipment for the combine's working systems. The cobs are carefully separated and served for threshing, and the stems are finely crumbled. The field remains completely ready for plowing. palesse_gs10.pdf

Technical characteristics of the combine harvester Polesie KZS 1218

Also check out these articles

- Fungicide Quadris

- Water-filling skating rink

- Motor cultivator Neva MK-80

- Fertilizer urea (urea)

| Characteristic | Unit change | Meaning |

| Engine | ||

| Brand | YaMZ-238DE-22, YaMZ-238DE2-27, DTA530E, DTA570E | |

| Engine rated power | kW (hp) | 243 (330) |

| Thresher | ||

| Threshing drum width | mm | 1500 |

| Threshing drum diameter: | ||

| - first | mm | 600 (pre-accelerator) |

| - second | mm | 800 (threshing drum) |

| Drum shaft rotation speed | rpm | 440-875 |

| Straw walker type | 5-key | |

| Separation area, not less | m2 | 6,15 |

| Total area of cleaning sieves, not less | m2 | 5 |

| Total separation area of the concave, not less | m2 | 2,39 |

| Cleaning | three-stage with cascade purging | |

| Grain bunker | transformable, with automatic filling alarm and forced unloading | |

| Bunker volume, not less | m3 | 8 |

| Loading height of unloading auger, not less | mm | 4400 |

| Length of unloading auger reach, not less | mm | 3300 |

| Unloading auger control | electrohydraulic from the operator's seat | |

| Angle of rotation of the unloading auger, not less | hail | 101 |

| Throughput capacity for grain mass, not less | kg/s | 12 |

| Grain productivity per hour of main time, not less | t/h | 18 |

| Header working width | m | 6,0; 7,0; 9,2 |

| Pickup width | m | 3,4 |

| Fuel tank capacity, not less | l. | 600 |

| Dimensions and weight | ||

| Overall dimensions in the basic configuration (self-propelled thresher, grain header with a working width of 7 meters) in working position, no more: | ||

| - length | mm | 10850 |

| - width | mm | 7600 |

| - height | mm | 4500 |

| Weight as standard (excluding transport trolley) | kg | 16600 |

| The following can be supplied as options: | ||

| Devices for harvesting rapeseed. Working width | m | 6,0; 7,0 |

| Equipment sets with a header for harvesting corn for grain. Number of rows to be harvested | PC. | 6; 8 |

| Harvesters for sunflower harvesting. Number of rows to be harvested | PC. | 8; 12 |

| Reapers for soybean harvesting. Working width | m | 6,0; 7,0 |

| Drum speed reduction gearbox |

Technical characteristics of the combine harvester Polesie KZS 1218

Combine harvester KZS-10K "DESNA-POLESIE GS10"

The grain harvester KZS-10K “DESNA-POLESIE GS10” is, on the one hand, a classic single-drum threshing and separation scheme that combines stability and quality of threshing with economical operation. On the other hand, these are advanced technical solutions, such as a header with the best cutting device in the world, three-stage cleaning and a high level of automated control of harvesting parameters. The combination of these qualities, taking into account the moderate price, gives every reason to consider the GS10 the “golden mean” in grain harvesting.

Using the GS10, in addition to harvesting cereal grains, with adapters for harvesting various crops makes it possible to increase its seasonal load from 180 to 300 engine hours, which ensures a reduction in direct operating costs per unit of operating time by at least 1.4 times.

The Big Drum threshing apparatus with a high-inertia drum with a diameter of 800 mm gives excellent results when harvesting in conditions of normal humidity and average straw content, providing high throughput of the combine.

The presence of seven cascades with an optimal height difference on each of the five straw walker keys and a large amplitude of the counter movement of the keys improve the separation of grain from the straw heap, maintain stable productivity and reduce losses.

A three-stage fine cleaning system with electrically adjustable air flow intensity from the cabin guarantees high purity of the bunker grain.

The grain unloading system with a top-mounted unloading auger allows you to quickly load car bodies with high sides with grain, saving time on cleaning.

A large-volume cabin (2.6 m3), with panoramic glass, equipped with air conditioning, a fully adjustable operator’s seat - this is real comfort at a high level.

In the updated GS10 combine, the hydrostat handle has become even more functional. To the functions that can be controlled with one hand and require quick decision-making, in addition to controlling the speed of movement, the position of the reel and its rotation speed, the position of the feeder chamber and instantly turning off its drive, the ability to control the grain unloading system has also been added.

When started, the on-board computer automatically checks the circuits of sensors and mechanisms for serviceability, provides viewing of an electrical diagram with circuit numbers and tips for troubleshooting. Automatic adjustment of the working elements (threshing gap, threshing drum speed, cleaning fan speed) is performed by a computer based on the crop being harvested and its condition, or from previously stored settings.