Tatra-111

The design of trucks in the early post-war years was determined by wartime developments. In particular, the plant created a family of air-cooled diesel engines and refused to produce any other energy sources for medium and heavy trucks. The base engine was a 12-cylinder diesel engine with a displacement of 14.8 liters and a power of 180 hp. at 1,800 min–1. The engine had separate cylinders with individual heads, which made it possible to create many modifications with different numbers of cylinders with a high degree of unification. The following were developed and prepared for production: in-line 4-cylinder engines for the promising Tatra-114 and -115 with a load capacity of 3.0 tons; in-line 6-cylinder diesel engines for Praga trucks models V3S and S5T; 8-cylinder V-shaped diesel engines for the Tatra-128 trucks and an in-line horizontal 6-cylinder diesel engine for the experimental 7-ton Tatra-116 truck.

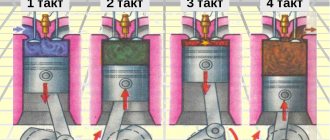

During the war, the 12-cylinder engine was installed on some military special vehicles. The experience of their operation made it possible to create in 1942 the most successful and famous triaxle of the G. Ledvinka Engineering Center - Tatra-111, the pinnacle of creativity of both the legendary designer and his entire team. The engine of this car also went down in automotive history as an outstanding achievement. Diesel cylinders with dimensions of 110x130 mm were arranged in 2 rows at an angle of 75°. This angle was chosen due to the fact that between the rows there was a fuel pump, which occupied an impressive volume. The diesel engine had direct fuel injection.

The initially used hemispherical combustion chamber was soon replaced by a toroidal one, which provided more intense air swirl. The maximum torque of the diesel engine was 74 kgf m at 1,500 rpm, and its weight with equipment was less than a ton (986 kg). To make starting easier in frosty weather, the fuel pump drive was supplemented with a gear drive, which made it possible to turn the pump by hand when the engine was not running. The crankshaft with six cranks was mounted on seven roller bearings.

Particular attention was paid to the reliability of the dry sump lubrication system, serviced by two oil pumps. One of them pumped oil from the sump to the oil tank, and the second ensured the operation of the lubrication system. The gas distribution mechanism with overhead valves and push rods was driven by three camshafts, which, like the fuel pump, were driven by gears from the crankshaft. The cooling system was served by two axial fans driven by a V-belt drive from the front end of the crankshaft. The piston compressor installed in the front of the engine had a similar drive.

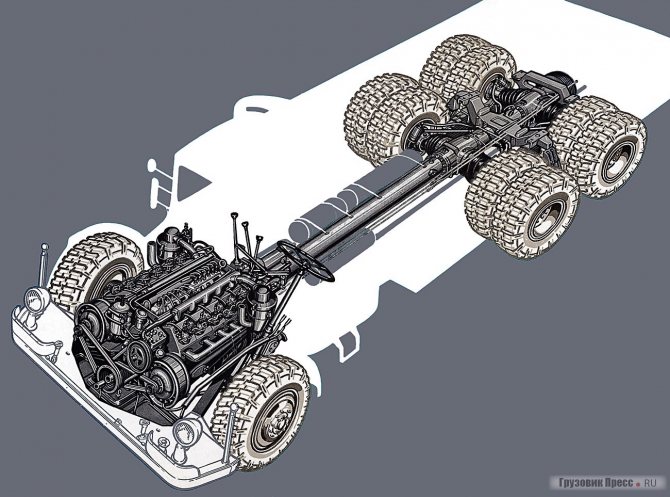

It so happened that most models of this family of trucks with air-cooled diesel engines were not in demand. Thus, the total production before the discontinuation of the “114” model (1947–1948) was 407 units, the “115” model – 602 cars, the “128” model (1951–1952) – 4,060 cars. And only the basic Tatra-111 with a load capacity of 10.0 tons - the only truck in the world with such a load capacity with independent suspension on all wheels, was produced from 1945 to 1962. At the same time, the total number of vehicles produced was 32,243. Thanks to the tubular frame and swing axle shafts, the Tatra-111 had a higher average off-road speed than their competitors with rigid beam axles.

The rear axle final drive housing of the Tatra-111 had a horizontal connector plane. The axle shafts on the inside end with a fork with a sliding fit in the axle housing. The axle shafts are sealed on the outside with rubber covers, to protect which there are steel sheets underneath. In order for the size of the disc gears to be the same, the left axle shafts (and, accordingly, the wheels) are shifted forward by 45 mm relative to the right ones. This did not affect performance. Accordingly, the axle fork of the left wheel had a shorter lever forward, and the fork of the right wheel had a longer one. The rear wheel suspension is balanced, leaf spring. The ends of the springs were connected to the axle shafts by earrings with support crackers that did not require lubrication. The transmission parking brake applied the brakes to a drum located at the end of the central pipe. The differential with spur gears was located in front of the main gear and was therefore unloaded.

The drive shaft from the gearbox passed through the central tubular frame, and its rear end was connected to the differential housing and the transmission parking brake drum. Cylindrical differential pinions transmitted torque to the main gears, driven through hollow shafts. The differential, if necessary, could be locked by the driver using a gear clutch. A 12-cylinder diesel engine was cantilevered over the front drive axle to the gearbox housing through a flange. Approximately in the middle of the frame there was an additional gearbox and the main gearbox assembled with the engine was attached to it. All of the listed units formed a single, rigid unit, onto which the cabin with tail and body were then installed.

Tatra-111 were supplied to the Soviet Union in large quantities. Throughout its entire territory, as well as in equatorial Africa and in countries beyond the Arctic Circle, the engine of these machines worked perfectly. Swinging axle shafts provided the wheels with long travel; the entire structure was distinguished by high reliability, strength, and endurance. There is a known case when a Tatra-111 dump truck that had fallen through the ice at the beginning of winter in Siberia was taken out in the spring and, surprised that water did not get into the vehicle’s components, they quickly started it up and then began to operate it again. It is not for nothing that there is a monument to this wonderful car near Magadan: the Tatra-111 dump truck is installed on a pedestal, thereby paying tribute to Czech automakers, including its chief designer G. Ledvinka. However, the fate of this man was such that he did not have to live in Czechoslovakia for the last years of his life. After the war, he was imprisoned for 6 years for collaborating with the German occupation authorities, then expelled from the country and died in 1967 in Munich (Germany).

In parallel with the creation of a huge number of modifications of the basic Tatra-111 model, the most interesting of which, in our opinion, is the Tatra-141 ballast tractor, G. Ledvinka’s followers already in the mid-50s began developing a new range of heavy trucks to replace the “ 111".

Story

Designed to replace the T148, the T157 prototype was manufactured in 1970. Next, in 1970 - 1974, several more prototypes were made, but none of them went into series: due to protests from another Czech truck manufacturer, the LIAZ plant (which was entrusted by the Czechoslovak State Planning Committee with the production of trucks of a similar class to the T157), Tatra closed the development program for this truck and switched to the production of heavier equipment to replace the T813 and T148 vehicles.

In 1989, the Tatra plant modernized the T815 model and introduced its new modification T815-2. The truck was subsequently modernized in 1994, and just three years later - in 1997 - it received a new Terr cab No. 1. The next modernization was carried out in 2000. Among other things, the truck received a new dashboard, cab mounting, and the ability to install a liquid-cooled diesel engine - for the first time in the history of the development of the Tatra plant. After this, the modernization was carried out five years later - in 2005.

Due to increased requirements for the content of harmful substances in the exhaust, in 2003 the Tatra plant developed a V8 T3C diesel engine that complies with Euro III standards - like other engines of this automaker, the new diesel engine is air-cooled. A further development of this engine is the T3D diesel, launched into production in 2006. It meets SCR and Euro IV standards.

YaMZ engines were often installed on Tatras supplied to the USSR and Russia. Also, during operation in Russia, vehicles were converted to use water-cooled KAMAZ engines.

History of the Tatra brand

The car had a two-disc clutch, a four-speed gearbox and a two-speed transfer case, a spinal tube frame, a pneumatic braking system, independent leaf spring suspension on all wheels, locking rear axle differentials and an angular wooden cabin; it reached a speed of 75 kilometers. On its basis, the SWS half-track tractor was produced for the Wehrmacht, and the TYUZ engine was installed on heavy German four-axle armored vehicles Sd.Kfz.234.

The post-war period also became quite fruitful in history. Production of cars was resumed on May 8, 1945 and was completely completed in 1951. Since 1946, production of the 10-ton civilian truck “Tatra-111R” (6x6) with an all-metal cab continued, which became the only serial product of the plant. It was offered in several versions: “111NR” with high sides, “111C” tank truck with 7 thousand liters of fuel, “111S” and “111S2” dump trucks. A total of 33,690 of them were produced until 1962.

On the Tatra-111 chassis in 1951-52, a two-axle three-ton truck "T128" (4x4) with a diesel engine "T108" V8 air-cooled (9883 cm3, 130 horses) was produced, and its reinforced three-axle version "T130" ( 6×6) remained a prototype. Since 1957, a 185-horsepower ballast tractor “L41” with a curb weight of 12.1 tons and a double cabin, intended for road trains with a gross weight of 100 tons, was assembled at the plant in the town of Banovce. The result of the first attempts to create a second two-axle range of trucks in 1947-49 were the three-ton models “T114” and “T115” (4x2) with a four-cylinder diesel engine (4940 cm3, 65 horses) and hydraulic brakes.

Only a little more than a thousand copies were built, plus two prototypes - the T116 truck with a cab over the engine and the T117 dump truck. The second and final exception to the rule in 1955 was the two-axle all-wheel drive two-ton Tatra-805 (4x4) with a V8 air-cooled gasoline engine (2545 cm3, 75 horses) from the prestigious T603 passenger car, eight-speed gearbox, wheel gears, front independent torsion bar suspension, all-metal cabin above the engine. Since 1956, they have been assembled on cars (Skoda) in the city of Mlada Boleslav.

On two such specially modified cars, famous Czechoslovak journalists Jiri Hanzelka and Miroslav Zikmund traveled through the countries of Europe and Asia, including the USSR. Until 1960, 7,214 T805 vehicles were assembled, with which the era of middle-class two-axle Tatra trucks ended. The implementation of the policy of one heavy three-axle model with a wide selection of standardized modifications began. In 1959, the Tatra-111 truck was replaced by more advanced twelve-ton hooded vehicles of the T138 series (6x6), which received a cab with a curved windshield and a more modern streamlined tail.

They were equipped with a new air-cooled T928 V8 diesel engine (11,762 cm3, 180 horses), created on the basis of the previous T111 engine by reducing the number of cylinders and increasing their diameter from 110 to 130 millimeters while maintaining the same piston stroke (130 millimeters) . Other differences were an overhead camshaft and an axial fan with a fluid coupling. The double-disc clutch was equipped with a hydraulic release, a number of models offered a five-speed gearbox, the transfer case was equipped with an electro-pneumatic switching device, and the front independent suspension became torsion bar.

The maximum speed of the car was 70 kilometers per hour. In addition to the “T138N” flatbed truck, this series offered dump trucks 713851″ and “T138S3” with rear and three-sided unloading, a “T138NT” truck tractor for road trains with a gross weight of up to 31 tons, an army version “T138VN” and a two-axle “T137” (4 ×4) with a lifting capacity of 7.65 tons. Until 1972, 48,222 T138 chassis were produced. Since 1969, the T138 series began to be replaced by the modernized Tatra-148 range, which was externally distinguished by a higher front part of the hood, under which was placed the new air-cooled diesel engine T2-928 V8 (12667 cm3, 192-212 horses).

Another new feature was the center differential in the rear bogie. The main versions were fifteen ton; dump trucks "T148S1" and "T148S3". The T180A single-axle construction tractor for the scraper, which reached a speed of 40 kilometers, was unified with them. Until 1982, the plant produced 113,647 cars of the T148 series. The vehicles arrived in large quantities to socialist countries and the USSR, for which a special Arctic version was offered. Between 1956 and 1977 alone, 25 thousand Tatra trucks arrived in Soviet countries. In 1967, the plant began production of a new family of unified all-wheel drive chassis of the T813 series, first presented in the Koloss version with an 8x8 wheel arrangement.

This was the first attempt to produce a single basic model, offered in two, three and four-axle versions with a carrying capacity from 5.4 to 18 tons for work in the national economy and army as trucks, tractors and special chassis, reaching speeds of up to 90 kilometers. All options were equipped with an air-cooled diesel engine “T930-3” V12 (17640 cm3, 250-257 horses), a twenty-speed transmission, independent suspension on all wheels, and an all-metal four-door cabin above the engine. Some vehicles had front torsion bar or leaf spring suspension, differentials with electromagnetic locking, and for the first time were equipped with a centralized tire inflation system.

Such chassis became the basis for the T813TR (6x6) road tractors with two front steered axles and a winch with a traction force of 17.5 tons, as well as the first four-axle T813S1 (8x8) dump trucks with a lifting capacity of 21 tons. A total of 11,751 cars of the T813 series were produced. The development of the T813 series occurred during a period of rapid socialist integration. In May 1971, the CMEA decided to secure the production of heavy vehicles with a carrying capacity of over 12 tons. This allowed the reconstruction and expansion of the main plant in Kopřivnice, as well as its branches in Přibor, Čadc and Banovec, to begin next year.

Over time, the annual production capacity was to reach 15 thousand chassis. In 1983, having completed production of the T148 and T813 series, Tatra launched production of the new and only T815 range with a backbone frame and independent suspension, which was conceived as the basis for a number of standardized vehicles for various purposes with 4 wheel formulas ×4, 6×6 and 8×8.

For them, based on the basic T2-928 engine, a range of unified air-cooled diesel engines with direct fuel injection and the same cylinder diameter and piston stroke (120×140 millimeters) was created: TZ-928 V8 models (12667 cm3, 231 horsepower) , “TZ-929” V10 (15825 cm3, 283 horses), “TZ-930-30” and “TZ-930-53” V12 (19001 cm3, 320 and 360 horsepower). The first were the three-axle dump trucks “T815S1” and “T815S3” (283 horses) with rear and three-sided unloading with a lifting capacity of 10.7-15.3 tons and a shortened cabin above the engine.

The “T815NT” (4x4/6x6) truck tractors for road trains with a gross weight of 45 tons and the 20-ton “T815S1” (8x8) dump trucks were equipped with the most powerful engines, rear air suspension and a cabin moved forward with sleeping places. The program also included low-frame crane chassis “T815PJ” with a lifting capacity of 12-40 tons with a wheel arrangement from 4x4 to 10x8. Since 1987, a modernized version of the “T815-2” has been produced with a payload capacity increased by 2 tons and efficiency increased by 10%, meeting international requirements.

By this time, the entire range already numbered over 100 options. The high quality of Tatra-815 cars was confirmed by their convincing performances in 1986-2001 in the Paris-Dakar, Grenada-Dakar and Paris-Beijing rallies, where they invariably took prizes. For this purpose, single copies of 4x4 vehicles were built with engines with a capacity of 407-543 horses, reaching a maximum speed of 150-160 kilometers per hour. After the division of Czechoslovakia, the loss of the vast markets of the former socialist countries and privatization, it became a joint-stock company, but the state remains the owner of 90% of its shares.

He set about creating new equipment and solving the problem of compliance of Tatra cars with international requirements, primarily Euro-2 environmental standards. As a result, by the mid-90s. uncompetitive models were discontinued, and all previous engines were replaced by the new “TZV-928” V8 with turbocharging and intercooling with a capacity of 308-362 horsepower, as well as a number of foreign power units and chassis elements.

With the change in the marking of models, their indices reached fifteen digit combinations of numbers and letters. The range of basic chassis "T815-2" included 9 options with different cabins and wheel arrangements 4x4, 6x6 and 8x8 (models from "R41" to "R91") with a payload of 11-24 tons and engine power of 308 -362 horses, 8 dump trucks (from “501” to “S81”) with a carrying capacity of 9.1-21.5 tons and 8 truck tractors (from “N51” to “N34”) for road trains with a gross weight of 43-85 tons.

In addition, special trucks and tractors “T815-2 Armax” (Armax) are produced for the army. In 1997, he began production of the T815-2 Terrnod series, the name of which is derived from the English word “Terrain” - “rough terrain” and the index “No1” - “first”. They differ from the previous range by new, more attractive cabins of increased comfort and the ability to install an American 350-horsepower Detroit Diesel engine of the 60 series.

At the same time, at the Brno Motor Show, the debut of the original hooded twenty-two-ton dump truck “T815-24BSK8 36.270” (6x6) or “Jamal” with a 362 horsepower engine, created specifically for work in Siberia and the far north of Russia, took place. Since 2000, it has been offered in two versions with different bodies under the designations “T163/3605K4” and “SK8”. Since 1997, a new series of “T816 Force” (Force) 8x8 has been produced with German diesel engines “Deutz 1015C” V8 or MTU (MTU) V12 with a power of 544 and 830 horses and an American automatic six-speed “Twin Disc” transmission. .

The most powerful tractor “T816-6VWN9T”, designed for road trains with a gross weight of up to 120 tons, is equipped with a new double cabin for 6-8 people and two winches with a pulling force of 25 tons each. It reaches a maximum speed of 85 kilometers per hour. Unlike many heavy truck manufacturers from former socialist countries, the situation continues to strengthen, although annual production volumes are only 2,500-3,000 vehicles. In Russia at the end of the 20th century, 14.5 thousand Tatra cars were in operation.

author: Evgeny Smolnikov

source: truck-auto.info

READ MORE: 2

Technical features

Equipped with an air-cooled engine. The gearbox was located in front of the rear axle.

The driving performance of the Tatra is difficult to describe in a nutshell. On the one hand, thanks to good aerodynamics, the car developed a very respectable speed for those years - up to 150 km/h - with an engine power of only 75 hp. s., and at the same time consumed about 15 liters of gasoline per 100 km, which was an outstanding indicator: other cars in this class consumed one and a half to two times more fuel. On the other hand, the accelerating dynamics of a heavy car with a wooden body on a frame and a low-power power unit was not at all impressive, and the handling at speed due to the imperfections of the chassis and an overloaded rear end was not modern [ when?

] by standards is completely dangerous to the life of the driver and passengers [

source not specified 234 days

].