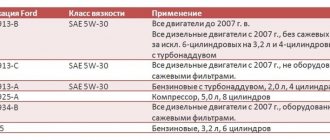

| GAZ-AA | |||||||||||||||||||||||||||||||||||

| Total information | |||||||||||||||||||||||||||||||||||

| Manufacturer | GAS | ||||||||||||||||||||||||||||||||||

| Years of production | 1932—1938 | ||||||||||||||||||||||||||||||||||

| Assembly | GAZ (Gorky, USSR) KIM (Moscow, USSR) | ||||||||||||||||||||||||||||||||||

| Class | 1.5 tons | ||||||||||||||||||||||||||||||||||

| Other designations | “Gazik”, “lorry”, “polundra” | ||||||||||||||||||||||||||||||||||

| Design | |||||||||||||||||||||||||||||||||||

| Platform | Ford AA 1930 model | ||||||||||||||||||||||||||||||||||

| Layout | front-engine, rear-wheel drive | ||||||||||||||||||||||||||||||||||

| Wheel formula | 4 × 2 | ||||||||||||||||||||||||||||||||||

| Engine | |||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||

| Transmission | |||||||||||||||||||||||||||||||||||

| 4-st. Manual transmission | |||||||||||||||||||||||||||||||||||

| Weight and dimensions characteristics | |||||||||||||||||||||||||||||||||||

| Length | 5335 mm | ||||||||||||||||||||||||||||||||||

| Width | 2030 mm | ||||||||||||||||||||||||||||||||||

| Height | 1870 mm | ||||||||||||||||||||||||||||||||||

| Clearance | 200 mm | ||||||||||||||||||||||||||||||||||

| Wheelbase | 3340 mm | ||||||||||||||||||||||||||||||||||

| Weight | 1750 kg | ||||||||||||||||||||||||||||||||||

| On the market | |||||||||||||||||||||||||||||||||||

| Related | GAZ-MM, GAZ-AAA | ||||||||||||||||||||||||||||||||||

| Other information | |||||||||||||||||||||||||||||||||||

| Load capacity | 1500 kg | ||||||||||||||||||||||||||||||||||

| ← Ford Model AA 1930 GAZ-MM → | |||||||||||||||||||||||||||||||||||

| Media files on Wikimedia Commons | |||||||||||||||||||||||||||||||||||

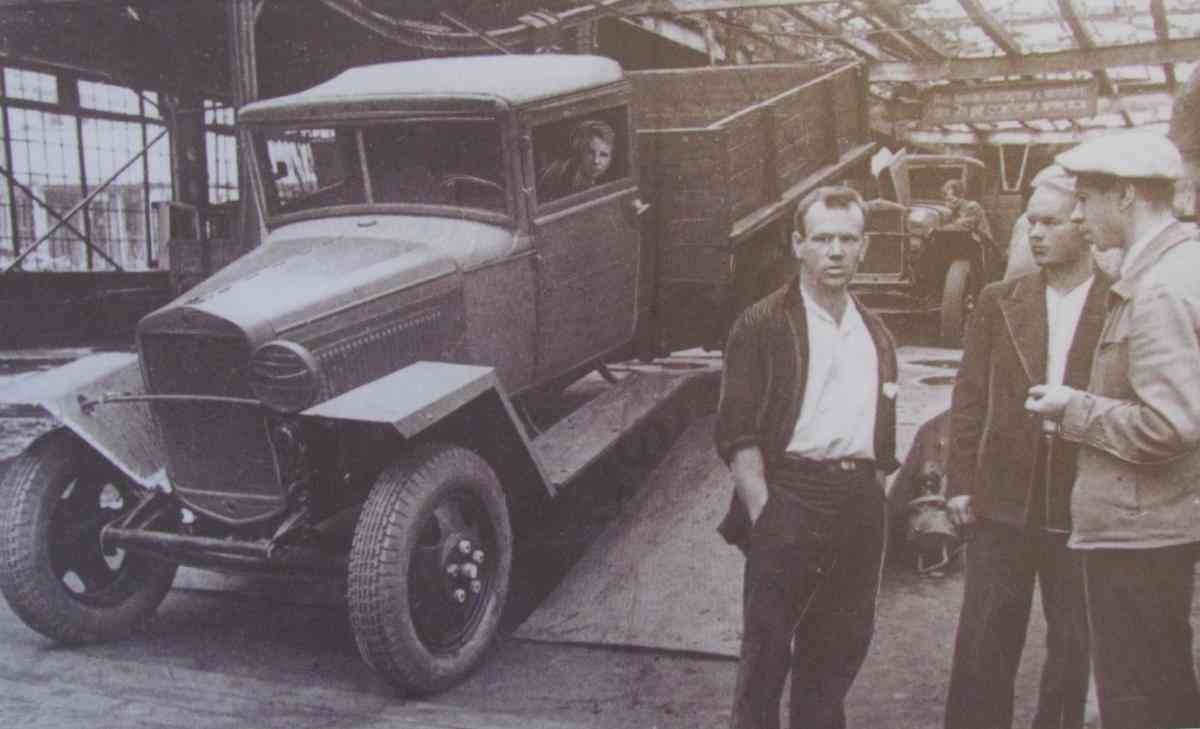

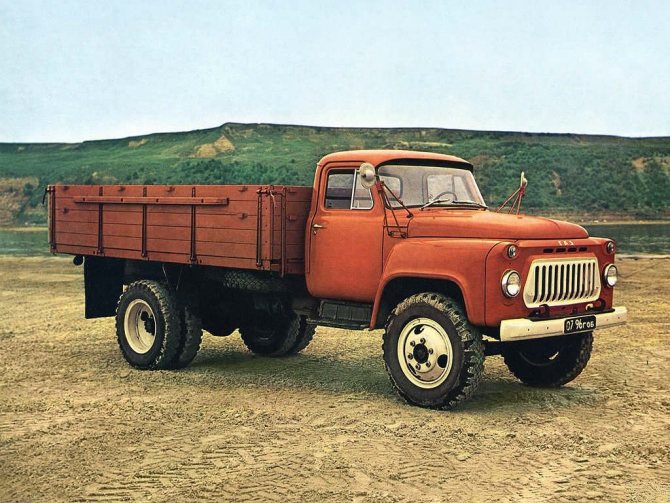

GAZ-AA produced 1934-1938.

USSR postage stamp (1974) GAZ-AA

(

"lorry"

) - a Soviet truck from Nizhny Novgorod (in 1932), later from the Gorky Automobile Plant, with a load capacity of 1.5 tons (1500 kg), known as

a lorry

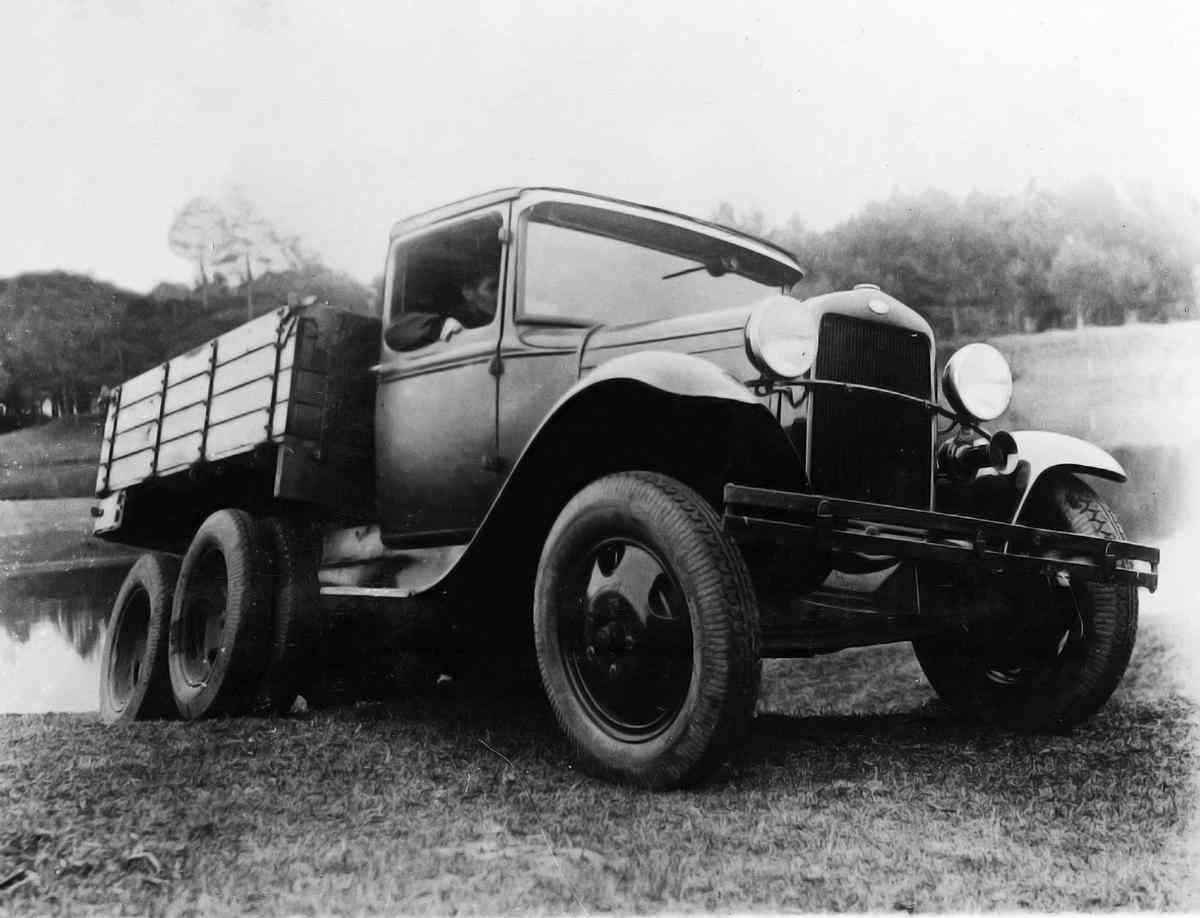

. The model was an American Ford model AA truck from 1930, but was subsequently redesigned according to domestic drawings.

Story

Initially, 10 samples of the American Ford model AA truck of the 1930 model were produced in Kanavin, but subsequently, before the launch of the Nizhny Novgorod Automobile Plant (NAZ), Soviet engineers prepared their own drawings, revising the design, components, platform, and already the first serial NAZ-AA rolled off the assembly line NAZ January 29, 1932. By the end of the year, the plant, renamed after the city as Gorky Automobile, was producing 60 GAZ-AA trucks per day. Unlike the American Ford model AA, the GAZ-AA had a strengthened clutch housing, steering mechanism, an air filter, and an onboard body was designed back in 1930 according to Soviet drawings. GAZ-AA has been assembled entirely from Soviet components since 1933. Until 1934, the cabin was made of wood and pressed cardboard, and then was replaced by a metal cabin with a leatherette roof.

In 1938, the truck was modernized and received a GAZ-MM engine with a power of 50 hp. p.[1] (its GAZ-M modification was installed on the GAZ-M1 Molotovets-1 passenger car, better known as Emka), reinforced suspension and a new steering mechanism and driveshaft. There were no external differences between the GAZ-AA and the GAZ-MM.

There was also a modification of the GAZ-AA with a dump body, at the beginning of production it was called GAZ-S1, later GAZ-410. The principle of operation of this dump truck was quite interesting: the load, evenly distributed in the body, should have tipped the platform back under its own weight, if not for a special locking device, the handle of which was located in the middle of the left side.

To unload, the driver released the handle, the cargo was poured back, and the empty body returned to a horizontal position under the influence of gravity, after which it was fixed using the handle. [ source not specified 379 days

]

Soon after the start of the Great Patriotic War, due to a lack of thin cold-rolled steel and a number of components supplied by third-party companies, GAZ was forced to switch to the production of a simplified military truck GAZ-MM-V (in-house index MM-13) with non-folding side walls, which has doors were replaced by triangular side barriers and rollable canvas doors, the fenders were made of roofing iron using a simple bending method, there were no brakes on the front wheels, and only one headlight was left.

In 1944, the pre-war equipment was partially restored: wooden doors appeared, that is, the cabin again became wooden and metal (and remained so until the end of the truck's production), later front brakes, folding side walls and a second headlight appeared again. The last GAZ-MM rolled off the Gorky assembly line on October 10, 1949.

For another year (and according to some sources, until 1956), the “lorry” was assembled in Ulyanovsk, where they were produced since 1947.

Years of production of NAZ (GAZ)-AA/GAZ-MM: at NAZ/GAZ - 1932-1949; at the Moscow KIM plant - 1933-1939; at the Rostov Automobile Assembly Plant - 1939-1941; at UlZiS - 1947-1950. 985,000 copies of GAZ-AA, GAZ-MM and their derivatives were produced, including 138,600 during 1941-1945.

By the beginning of the Great Patriotic War, there were 151,100 such vehicles in the ranks of the Red Army. Thus, the “lorry” became the most popular Soviet car of the first half of the 20th century; they could be found on the country’s roads until the end of the 1960s [ source not specified 1127 days

].

GAZ-AA. The first legendary truck

Double "A"

Initially, the abbreviation NAZ: Nizhny Novgorod Automobile Plant appeared on the radiator lining of this small-capacity, but historically very significant truck. Because its first copies came out of its gates on January 29, 1932, and the renaming of Nizhny Novgorod to Gorky occurred a few months later, on October 7. Accordingly, the automobile plant became Gorky, and the cars it produced received the GAZ brand.

At first, the newly built enterprise produced only two models: the GAZ-A passenger car and the GAZ-AA truck. Both were significantly unified among themselves and had their own overseas prototypes: the American Ford A and Ford AA (our country concluded an agreement on the transfer of licenses and technical documentation, as well as assistance in organizing and establishing their mass production with the Ford Motor Company on May 31, 1929) .

The Americans helped design the future plant, and while its buildings were being built, in February 1930, the semi-truck began to be assembled in the same Nizhny Novgorod, but at, which was renamed the First Auto Assembly. The machine kits for it were supplied from overseas; only the wooden onboard platform, which was made by Red Etna, was localized.

At first, the production of GAZ-AA faced very great difficulties: the supply of semi-finished products and foreign components was interrupted, but most importantly, there was no metal of satisfactory quality in the required volumes. And yet, by the end of the first year of operation, the Gorky Automobile Plant began to make up to 60 lorries a day. Why, by the way, one and a half? Because the car was designed to carry 1.5 tons of cargo in the back. Moreover, its total mass was about 3.3 tons.

Better and more perfect

Naturally, the design of both American models was adapted as best they could to the conditions of our country. For example, GAZ-AA received a reinforced clutch housing and steering mechanism. However, this was only the beginning: throughout its entire production life, the lorry was improved, modified, and modernized.

The car was powered by an in-line 4-cylinder gasoline engine that developed 42 hp. It was not equipped with a fuel pump (the tank was located above the carburetor) and could run on the cheapest low-octane gasoline. Gearbox – 4-speed, without synchronizers. The front suspension used a transverse spring - one for both wheels, and the rear suspension used longitudinal cantilever springs, that is, attached with their central part and one end to the frame, and the other end to the sprung axle. Brakes are mechanical, cable driven, without the use of boosters. Beginning in 1938, some of the semi-trucks produced began to be equipped with a more powerful engine that developed 50 hp. – it was borrowed from the GAZ-M1 passenger car, which was launched into production and replaced the GAZ-A. Later, with the beginning of the war, the design of the car was simplified as much as possible: the cabin became wooden, lost doors and one of the two headlights, the stamping of the wings gave way to bending, only the rear side of the platform was left foldable, and the brakes were removed from the front wheels. In addition to transporting personnel and cargo during the war, GAZ-AA and GAZ-MM were often used in the air defense forces, mounting anti-aircraft or searchlight installations or quad Maxim machine guns on them.

In different modifications

The Gorky Automobile Plant began creating a model range based on the GAZ-AA as soon as the lorry was put on the assembly line. A year later, a service bus was released, designated GAZ-03-30 - it began to be made in April 1933 in a bus workshop organized at the base. In November 1934, there was another addition to the family of Gorky trucks: production of the three-axle modification GAZ-AAA began, with a load capacity of two tons. This vehicle was intended primarily for the Red Army: two drive axles increased cross-country ability. Subsequently, even armored cars were made on its basis. And in 1938, the family was replenished by the half-track GAZ-60, which was supposed to be used primarily as an artillery tractor.

The model line also developed in the interests of the national economy: in the mid-1930s, the production of GAZ-410 dump trucks, road sweepers, fire ladders, as well as grain, manufactured goods and other vans began on the GAZ-AA chassis. In 1937, one of the branches of the Gorky Automobile Plant began production of the GAZ-55 ambulance bus. Also in those years, the GAZ-42 gas generator truck was created.

When, at the end of the Great Patriotic War, the Gorky Automobile Plant began to prepare for the development of the next-generation GAZ-51 car, it was decided to transfer the production of the lorry to Ulyanovsk, where it began in October 1947 and continued for another seven years. GAZ itself produced more than 800 thousand lorries, and taking into account production at other factories, their total number exceeded a million! This small and not very heavy-lifting machine in modern times, largely primitive in design, pulled out collectivization, ensured industrialization and played one of the leading roles in the victory over Germany and over the post-war devastation. It’s not for nothing that in many regions of the country, semi-trucks are placed on pedestals, becoming one of the most eloquent monuments of their era!

Tweet

Design Features

| This section is missing references to information sources. Information must be verifiable, otherwise it may be questioned and deleted. You may edit this article to include links to authoritative sources. This mark was set on August 12, 2020 . |

Structurally, the GAZ-AA truck is simple and technologically advanced and was made according to the classical design on a frame chassis with spring suspension. The cabin plumage is unified with the GAZ-A passenger car.

A special feature of the design was the design of the rear suspension and transmission, where the so-called push tube (English torque tube) was used as a longitudinal thrust, inside of which there was a closed driveshaft, which rested against a bronze bushing, subject to rapid wear and the need for frequent repairs. The fastening of the reaction rod of the front suspension, which absorbed the force during braking, also had insufficient survivability. Accordingly, the failure mileage of the “one and a half” was significantly less than that of the “three-ton” ZIS-5, moreover, the “one and a half” was almost always operated with a significant (up to twofold) overload.

Thanks to the low compression ratio (4.25:1), the unpretentious and repairable GAZ-AA and GAZ-MM engines could be operated on the lowest grades of fuel, including naphtha and even kerosene (in the warm season and on a warm engine) and low-quality industrial lubricating oils (autols and nigrols).

Scarce starters with a battery had a low resource (on a rare car they lasted more than six months), so in real operation the car was started with a “crooked starter,” that is, with a crank.

Tires with low mileage were a particular shortage (8-9 thousand km compared to the standard 20 thousand km), so in the late 1930s and during the war, semi-trucks often rolled off the assembly line with only two rear wheels, that is, with a single tire rear axle, which, accordingly, reduced the load capacity. Wheels - 6.5-20″, I-4.

Nevertheless, thanks to mass conveyor production, the GAZ-AA/MM was the most popular truck, and indeed car in general, in the pre-war USSR and in the Red Army (over 150 thousand as of 06/20/1941).

Its chassis served as the basis for the creation of a number of specialized and special modifications for military and civilian purposes: charging and lighting power stations, radio stations, the RUS-2 early warning radio system, radio workshops and repair “flights”, auto laboratories for sanitary, hygienic and anti-chemical purposes, fuel and oil refillers , airfield launch vehicles, acoustic and light air defense installations, various tanks, watering machines, ambulances, etc.

GAZ-AA and -MM units were widely used in the creation of military vehicles, including light tanks T-37 and T-38, armored vehicles BA-6 and BA-10, self-propelled gun SU-12 with a 76.2-mm regimental gun, artillery tractors , "Katyusha" BM-8-36 and other equipment.

- Rear axle on longitudinal semi-elliptic springs (cantilever suspension)

- The propeller shaft runs in a pipe, which also serves as a torque rod for the rear axle

- Fastening the pipe with the driveshaft to the gearbox, the flexible speedometer drive cable is visible

- Front axle on a transverse semi-elliptical spring, visible traction to the brake mechanism

- GAZ-AA, engine, right side

- GAZ-AA, engine, left side

- GAZ-AA, distributor with remote adjustment of ignition timing

Release history

The car was the most popular truck of the Union republics. There were 4 million conventional, dump truck and specialized vehicles operating on the country's roads. In 1961-1967 GAZ-53F was produced. Six-cylinder 82 liters. With. The GAZ-11 engine with a four-speed gearbox ensured the transportation of 3,500 kg of cargo, consuming 24 liters of low-octane gasoline for a run of 100 km. By the planned release time of the model, the V-shaped eight-cylinder power unit was not in production. For the 53F, the six-cylinder GAZ-11 was boosted, increasing the compression of the mixture. There was no ready-made hypoid rear axle, so they installed a mechanism with bevel gears from the 51A model (the car is shown in the photo). Objectively, in terms of its technical characteristics, the GAZ-53F car was a transitional model between the 51A series (with a load of 2,500 kg) and the SAZ-53B series (with a load capacity of a ton more), which was achieved by an increased base to 3.7 m and new tires 8 ,25-20, mounted on steel disks. The car was used not only as a dump truck, but also a sewage truck, fuel trucks and milk tankers were common. The GAZ-53 was not a complete design; due to frequent failures of parts and mechanisms, it was not popular among drivers and repair workers of motor transport enterprises. The truck with a clearly weak engine and an unreliable axle was produced until 1967. From 1964 to 1983, models of the 53 and 53A series with a cargo load of 3,500 and 4,000 kg hit the roads. More powerful power unit ZMZ-53 with 115 hp. With. ensured an increase in the speed parameter to 85 km/h with gasoline consumption of 25 liters per 100 km.

Main modifications based on GAZ-AA and GAZ-MM

Trucks: AMO-F-15, GAZ-AA, ZIS-5V. Russian postage stamp, 2007

- GAZ-AAA is a six-wheeled (three-axle with a 6 × 4 wheel arrangement) off-road truck, payload capacity 2.0 tons. Created on the basis of a licensed Ford-Timken truck of the 1931 model. Years of production: 1934—1943. In 1937, it received a more powerful (50 hp) engine and other components from GAZ-MM. The total output until 1943 was 37,373 units. On the basis of GAZ-AAA, the GAZ-05-193 headquarters bus (1936-1945), as well as serial armored vehicles BA-6 (1936-1938, 394 units), BA-10A (1938-1939) and BA-10M ( 1939-1941, a total of 3331 units). At the end of the 1930s, the armored hulls of worn-out armored vehicles of early series were transferred to the shortened GAZ-AAA chassis, thus the BA-27M (1937-1938), BAI-M and BA-3M (1939-1940) armored vehicles were obtained. In addition, experimental BA-6 m and BA-9 were created; experimental amphibious armored vehicles PB-4 (1933-1934, 6 units) and PB-7 (1936/37, 1 unit). The BKhM-1 chemical combat vehicle was produced (1935-1937), and an experimental ambulance BA-22 armored personnel carrier for 10 wounded was created (1937).[2]

- BA-10 - in the fall of 1941 - in the spring of 1942, the remaining batch of BA-10M armored hulls remaining at the Izhora plant was delivered to the GAZ-MM two-axle chassis. These armored vehicles were delivered only to the Leningrad Front.

- GAZ-410 is a dump truck on the GAZ-AA and GAZ-MM chassis, load capacity 1.2 tons, all-metal body of self-unloading type. Years of production: 1934—1946.

- GAZ-42 is a gas generator modification that used wooden lumps as fuel. Engine power - 35-38 hp. pp., rated load capacity is 1.0 t (the actual one is less, since a significant part of the shortened platform was occupied by a 150-200 kg supply of lumps). Years of production: 1938—1950.

- GAZ-43 is a coal-fired gas generator version. It was distinguished by the smaller dimensions of the gas generator installation. Produced in small quantities in 1938-1941.

- GAZ-44 is a gas-cylinder version using compressed gas. Gas cylinders were located under the cargo platform. Released in a small batch in 1939.

The first production cars were equipped with a NATI-SG6 gearbox, which was later replaced by a NATI-SG19 gearbox. The double-diaphragm reducer NATI-SG19 was more compact than the single-diaphragm NATI-SG6. All equipment was located under the engine hood. The gearbox was placed above the engine, which gave it sufficient heating to prevent freezing. To monitor the gas reserve indicator in the cylinders, a pressure gauge was placed on the lining of the front beam of the cabin. 60 cubic meters of compressed gas were stored in six cylinders. The mass of the gas installation was 420 kg. Gas equipment was produced by the Kuibyshev Carburetor Plant. The average mileage of a car without replenishing gas reserves depended on the fuel and was: 150 km on coke oven and lamp gas, 200 km on synthesis gas, 300 km on methane.

- NATI-3 is an experimental half-track modification with a rubber-metal track with idler drive from a standard axle. Tested in 1934-1936.

- GAZ-60 is a serial half-track modification with a rubber-metal track with sloth drive from a standard axle. Years of production: 1938—1943.

Fire truck PMG-1

- GAZ-65 is an all-terrain modification with a tracked-wheel drive driven by standard rear wheels. In 1940, a pilot industrial batch was produced, which showed the complete unsuitability [ source not specified 936 days

] of this scheme for the conditions of actual vehicle operation, both at the front and later at the rear (fuel consumption exceeded 60 l/100 km). - GAZ-03-30 is a 17-seater general purpose bus with a body on a wooden frame with metal cladding. Produced at the facilities of GAZ's related company - GZA (Gorky Bus Plant, formerly). Years of production: 1933-1950, with a break in 1942-1945. The most common model of the Soviet bus of the pre-war period.

- GAZ-55 (M-55) - an ambulance, equipped with rear axle shock absorbers. Capacity: 10 people, including four on stretchers. Years of production: 1938—1945.

- PMG-1 - fire truck (line). Years of production: 1932—1941 (?).

History[ | ]

Initially, 10 samples of the American Ford model AA truck of the 1930 model were produced in Kanavin, but subsequently, before the launch of the Nizhny Novgorod Automobile Plant (NAZ), Soviet engineers prepared their own drawings, revising the design, components, platform, and already the first serial NAZ-AA rolled off the assembly line NAZ January 29, 1932. By the end of the year, the plant, renamed after the city as Gorky Automobile, was producing 60 GAZ-AA trucks per day. Unlike the American Ford model AA, the GAZ-AA had a strengthened clutch housing, steering mechanism, an air filter, and an onboard body was designed back in 1930 according to Soviet drawings. GAZ-AA has been assembled entirely from Soviet components since 1933. Until 1934, the cabin was made of wood and pressed cardboard, and then was replaced by a metal cabin with a leatherette roof.

In 1938, the truck was modernized and received a GAZ-MM engine with a power of 50 hp. p.[1] (its GAZ-M modification was installed on the GAZ-M1 Molotovets-1 passenger car, better known as Emka), reinforced suspension and a new steering mechanism and driveshaft. There were no external differences between the GAZ-AA and the GAZ-MM.

There was also a modification of the GAZ-AA with a dump body, at the beginning of production it was called GAZ-S1, later GAZ-410. The principle of operation of this dump truck was quite interesting: the load, evenly distributed in the body, should have tipped the platform back under its own weight, if not for a special locking device, the handle of which was located in the middle of the left side.

To unload, the driver released the handle, the cargo was poured back, and the empty body returned to a horizontal position under the influence of gravity, after which it was fixed using the handle. [ source not specified 379 days

]

Soon after the start of the Great Patriotic War, due to a lack of thin cold-rolled steel and a number of components supplied by third-party companies, GAZ was forced to switch to the production of a simplified military truck GAZ-MM-V (in-house index MM-13) with non-folding side walls, which has doors were replaced by triangular side barriers and rollable canvas doors, the fenders were made of roofing iron using a simple bending method, there were no brakes on the front wheels, and only one headlight was left.

In 1944, the pre-war equipment was partially restored: wooden doors appeared, that is, the cabin again became wooden and metal (and remained so until the end of the truck's production), later front brakes, folding side walls and a second headlight appeared again. The last GAZ-MM rolled off the Gorky assembly line on October 10, 1949.

For another year (and according to some sources, until 1956), the “lorry” was assembled in Ulyanovsk, where they were produced since 1947.

Years of production of NAZ (GAZ)-AA/GAZ-MM: at NAZ/GAZ - 1932-1949; at the Moscow KIM plant - 1933-1939; at the Rostov Automobile Assembly Plant - 1939-1941; at UlZiS - 1947-1950. 985,000 copies of GAZ-AA, GAZ-MM and their derivatives were produced, including 138,600 during 1941-1945.

By the beginning of the Great Patriotic War, there were 151,100 such vehicles in the ranks of the Red Army. Thus, the “lorry” became the most popular Soviet car of the first half of the 20th century; they could be found on the country’s roads until the end of the 1960s [ source not specified 1127 days

].

Links

| Trucks, buses and all-terrain vehicles of the Gorky Automobile Plant | |

| GAZ trucks |

|

| GAZ buses |

|

| GAZ special equipment |

|