Tarpan cultivator – model range and technical parameters

Tulamashzavod offers its customers not only walk-behind tractors, but also cultivators.

These two concepts should not be confused. Tarpan walk-behind tractors are widely used equipment that can operate additional attachments (we will talk about them below).

This walk-behind tractor is easy to use. It is equipped with a Briggs and Stratton four-stroke gasoline engine producing 5.5 horsepower.

Motoblock Tarpan MB 07-01

The Tarpan 07 01 walk-behind tractor allows you to carry out a wide range of agricultural work on small and medium-sized areas: cultivating the land, mowing grass, removing snow and leaves, transporting goods, etc.

There is already a whole line of Tarpan motor cultivators, which mainly differ in the installed engines.

This machine is equipped with a gasoline engine with a power of 5.5 horsepower, and is designed to facilitate dacha work - plowing, weeding beds, planting and hilling potatoes, preparing soil for planting crops.

Motor cultivator Tarpan engine Briggs&Stratton

The Tarpan motor cultivator is a universal small-sized unit designed for mechanization of heavy physical labor for cultivating soil on personal plots.

The recommended cultivated area is up to 0.2 hectares.

Tarpan motor cultivators are produced in the city of Tula at the Tulamashzavod plant.

A distinctive feature of the cultivator is the ability to disassemble it into two parts and fit in the trunk of most sedans.

The MK can be transported by disconnecting the power unit 1 (see figure below) from the executive unit 2. To do this, it is necessary to release the hinged bolts 3. When transporting the MK, it is necessary to lay it in such a way as to prevent oil from spilling out of the gearbox (through the hole in the filler plug), from the engine crankcase and residues, fuel from the fuel tank.

| Main settings | Meaning | |

| Overall dimensions, mm, no more (control handles folded) | length 1300 (760) width 700 height 1060 (760) | |

| Weight, kg | 45 | |

| Tillage width, mm | 560 | |

| Cultivator cutter diameter, mm | 320 | |

| Productivity, ha/h (with normal soil and loosening depth of 180 mm) | 0,06 | |

| Loosening depth max., mm | 200 | |

| Limit angles of inclination during operation, degrees, longitudinal and transverse, no more | 15 | |

| Engine | briggs stratton | honda |

| Model | 12j802 | GCV-160 |

| Type | 4-stroke, carburetor | |

| Working volume, cubic meters cm. | 190 | 160 |

| Max. power, hp, not less | 5,5 | 5.5 |

| Fuel tank capacity, l | 1,1 | |

| Oil fill volume, l | 0,6 | 0,55 |

| Fuel and oil in accordance with the Engine Operating Manual | ||

| Hourly fuel consumption, l/h, no more | 1,1 | |

| Clutch | Dry automatic centrifugal | |

| Start | Manual action | |

| Shutdown | Remote throttle lever | |

| Gearbox | Single stage worm | |

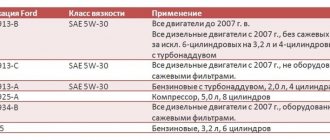

| Worm gear lubrication oil - TAD-17I GOST 23652-79. Allowed replacement - transmission oils of class SAE 90, SAE 75W/90, API categories GL-4, GL-5 | ||

| Oil volume in the gearbox, l | 0,35 | |

| Sound level at the operator's workplace, no more than dBA | 81 | |

| Correction level of vibration velocity on the control handle, no more than dB | 118 | |

| Number of speeds | 1 forward |

The Tarpan MK is equipped with an engine model 12j802 or model GCV-160

— working volume: Briggs & Stratton — 190 cm3; Honda - 160 cm3

— maximum power of at least 5.5 hp.

You can find out what kind of fuel and oil to fill into the Tarpan cultivator from the user manual for the engine or from the table in the instructions.

The Tula Machine-Building Plant produced Tarpan cultivators in 1991. The first models were equipped with low-power domestic engines, so they did not arouse much interest among farmers. In 1997, cars with American four-stroke engines appeared on the market. The demand for equipment began to increase, and the owners were able to appreciate it.

Tarpan cultivators are operated on an area of up to 15 acres. Sophisticated design and good technical performance made them competitive.

Tarpan machines have been on the market for about 25 years. Positive reviews from owners confirm that the units have numerous positive characteristics:

- Disassembles into two parts. This greatly facilitates transportation;

- A high-quality engine and durable elements combine well, providing the ability to process even heavy soils;

- High speed of plowing of land - about 2 acres per hour;

- The motor in a vertical position can be easily removed;

- Ability to use different attachments;

- Minimum number of settings. The unit is easy to operate. No need for regular maintenance;

- Light weight and compact. The motor cultivator easily turns in any direction. The assembled unit takes up minimal space. When disassembled, it can even fit into the trunk of a car.

There are certain disadvantages in the design:

- The cutters are located at right angles, so they quickly become clogged;

- No reverse speed;

- Before changing the engine oil, the clutch is removed and the fastenings are unscrewed.

All systems and components of motor cultivators are well thought out, therefore reliable and durable. The manufacturer sought to create universal equipment for solving various agricultural problems.

Features of the Tarpan technique:

- Almost all units are equipped with a Briggs&Stratton engine, the power of which is 5 - 6 hp. With.;

- One or two speed transmission;

- Air cooling protects the power plant from overheating and reduces the number of breakdowns;

- Improved grip with reliable spark plugs;

- Worm gear. It is more reliable than belt or chain transmission. The mechanism works with it for a long time without replacing this element;

- Plowing is performed at a depth of 16 - 25 centimeters;

- Surface working width 25 - 100 centimeters;

- Two pneumatic wheels for easy transportation;

- The handles are height adjustable to suit the operator's height;

- The handles with rubber pads are comfortable, the angle of the steering rod is adjustable;

- Replacement of spare parts in case of malfunction. They can be purchased at a specialty store at an affordable price.

We suggest you familiarize yourself with How to make canned river fish at home

Engines for Tarpan motor cultivators are four-stroke single-cylinder:

- Champion. American engine with a power of 5.5 liters. With. Provides an efficiency of 0.06 hectares/hour;

- Briggs & Stratton. Power in the range of 5.5-6 liters. pp., productivity reaches 0.06 ha/hour;

- Honda. The engine is considered the most reliable. Power up to 5.5 l. With.

Excellent parameters make the equipment durable and repairable.

Model TMZ-MK 03 is in great demand. Thanks to the modular design, equipment can be stored in a summer cottage and transported in the trunk of a car. Not only canopies are removed, but also the power plant.

Features overview:

- Four-stroke gasoline engine with a power of 6 hp. With.;

- Engine capacity – 190 cm3;

- Gearbox – 1 speed forward;

- Number of cutters – four pieces;

- Working width – 35, 70, 100 centimeters;

- Cultivation depth – 20 centimeters;

- The weight of the unit is 45 kilograms.

Tarpan TMZ-MK 03 is complemented by various attachments:

- Plow;

- Rake

- Hiller;

- Lawn mower;

- Rotary cutter.

Working with attachments is easier due to their compact size and handles that adjust to the operator.

The proposed video will allow you to familiarize yourself with the design characteristics and specific operation of the unit.

The Tarpan petrol cultivator loosens normal and heavy clay soils, introduces fertilizers, and removes weeds. The vehicle has high traction force and good maneuverability thanks to the installed power plant from an American manufacturer.

The worm gearbox and automatic centrifugal clutch allow the unit to be operated regardless of conditions.

Technical specifications:

- Four-stroke gasoline engine with a power of 6 hp. With.;

- Engine capacity – 190 cm3;

- Gearbox – 1 speed forward;

- The number of cutters (crow's feet) is four;

- Plowing width – 56 centimeters;

- Cultivation depth – 20 centimeters;

- Weight – 43 kilograms.

Tarpan electric cultivators are also worth attention. They operate on an electric power plant with a power supply of 220W. Email The Tarpan cultivator has slightly less power than the gasoline model. But the soil treatment parameters and design features are no different.

When using equipment, it is important to study the operating instructions. Based on it, maintenance and care of the unit is performed.

Cultivator Tarpan

Tarpan LLC is a subsidiary of the Tulamashzavod production association, designs, produces and sells mini-farm equipment for various purposes.

Tarpan cultivators are affordable, well-assembled, and equipped with reliable power units supplied by companies in the USA, Japan and China.

The torque from the gasoline engine is transmitted through the clutch mechanism and worm gearbox to the shaft of the working cutters, which, rotating, loosen the soil layer and move the unit along the strip.

The product belongs to the middle class of cultivators; it cultivates any soil density, including heavy ones, in areas of up to 20 acres.

Sufficient power of the power plant, the ability to process a working strip up to 1 m wide, and a set of additional attachments make the device a productive and multifunctional assistant to the owner of a land plot.

For convenient transportation, the machine can be quickly divided into blocks:

- Energy, which includes:

- engine;

- clutch mechanism;

- docking station;

- steering.

- Executive, consisting of:

- worm gearbox;

- right and left rotary cultivators (working cutters);

- loosening depth regulator;

- mounting bracket;

- protective casing.

Most models use four-stroke gasoline engines with a vertical crankshaft manufactured by B&S or Honda. Units with a Chinese Champion engine are offered at a lower cost.

The clutch device is assembled according to a friction scheme, automatic type. The mechanism is smoothly activated to transmit torque as the engine speed increases.

The lineup

Motor cultivator Tarpan TMZ-MK 03

Model TMZ-MK 03 is in great demand.

Thanks to the modular design, equipment can be stored in a summer cottage and transported in the trunk of a car. Not only canopies are removed, but also the power plant. Features overview:

- Four-stroke gasoline engine with a power of 6 hp. With.;

- Engine capacity – 190 cm3;

- Gearbox – 1 speed forward;

- Number of cutters – four pieces;

- Working width – 35, 70, 100 centimeters;

- Cultivation depth – 20 centimeters;

- The weight of the unit is 45 kilograms.

Tarpan TMZ-MK 03 is complemented by various attachments:

- Plow;

- Rake

- Hiller;

- Lawn mower;

- Rotary cutter.

Working with attachments is easier due to their compact size and handles that adjust to the operator.

The proposed video will allow you to familiarize yourself with the design characteristics and specific operation of the unit.

Description

Tarpan walk-behind tractors are assembled at the Russian holding company Tulamashzavod (TMZ). This is one of the largest enterprises in its region. It includes more than 20 different companies producing both civilian and military equipment.

One of the subsidiaries of this holding is Tulamash-Tarpan. This enterprise produces small agricultural machinery. The main sales markets of this company are in Russia and the CIS countries.

There is an extensive dealer network in our country, which includes more than 70 points. Due to this, the demand for products is constantly increasing.

Tulamashzavod's walk-behind tractors are in demand due to the high quality of components, the comfort of work and high technical characteristics. Tarpan can be called a global brand of small agricultural machinery with a Russian face.

Tarpan cultivator – model range and technical parameters

Cultivator Tarpan

The Tarpan cultivator has a history of more than 25 years. The first models of the family of units were not very reliable, so they wanted to abandon their production.

However, over time, the manufacturer began to introduce more advanced technologies into production, due to which the design of the models was constantly improved.

Modern representatives with Honda engines are distinguished by their high reliability. They are equipped with an almost eternal worm gearbox.

A powerful motor is also capable of pleasing buyers. In its current configurations, the Tarpan cultivator is available with 5.5 and 6 hp engines. With.

Among the main advantages of the unit are:

- The presence of an automatic centrifugal clutch, which allows you to fold the cultivator into 2 parts to make it easier to transport;

- The excellent combination of an imported engine and durable domestic hardware allows you to process even heavy soils;

- Good processing speed - the cultivator is capable of plowing up to 10 acres in 5 hours;

- The unit requires minimal maintenance and adjustments, it is easy to operate;

- The cultivator is lightweight, so it can be turned over alone;

- Perfectly sharpened reliable cutters;

- The vertical motor is easily and quickly removed;

- A wide range of attachments can be used.

In addition to all the advantages, the Tarpan motor cultivator also has some disadvantages. Firstly, the manufacturer did not provide for reverse gear, which makes using the model in small and abundantly planted beds very inconvenient.

We invite you to familiarize yourself with Normal viscosity: Natural blood thinners

Secondly, the thumb quickly gets tired from constantly pressing the gas lever. Thirdly, the cutters quickly wind up weeds, as they are located at right angles.

Fourthly, it is inconvenient to change engine oil - you need to constantly remove the clutch and unscrew the nuts.

Russian motor-cultivators of the Tarpan brand are optimally suited for farmers who own plots of no more than 15 acres. This technique has earned recognition due to its reliable motor and high-quality assembly. Most models are equipped with American Briggs & Stratton engines with a capacity of 5 to 6 hp. With. The main features of the units include:

- Almost eternal worm gearbox;

- High-quality transmission, which makes it possible to move at several speeds;

- Plowing depth ranges from 16 to 25 cm;

- The width of the strip ranges from 25–100 cm;

- Improved grip due to the use of more reliable spark plugs;

- Ability to use multiple attachment options.

These Russian cultivators can be used even in virgin lands. At the same time, the manufacturer promises fairly high productivity - about 2 acres per hour of operation.

More modern models of the Tarpan brand are equipped with improved Honda, Zongshen and Champion engines. They are less powerful, but the high quality of their assembly allows you to use the cultivator without worrying that it will stall due to overheating.

The Tarpan motor-cultivator in the old configuration is equipped with a four-stroke gasoline engine of the Briggs & Stratton Quantum brand, produced in America, although every year the manufacturer produces more and more models with Japanese Honda engines. The power of the American engine is 6 liters. s., and Japanese - 5.5 l. With.

Each engine is equipped with an air cooling system, which allows carburetor repairs to be carried out much less frequently than with cultivators of other brands. This is due to the fact that air enters not only the engine for cooling, but also into the carburetor, enriching the fuel mixture.

This process has a positive effect on the durability of the carburetor.

The unit controls are located on the steering wheel, which can be adjusted in height. The handlebar grips have a rubber coating and are quite comfortable to grip. The tilt of the steering rod can be adjusted to change the tilt of the unit or turn it around.

The most popular configurations are Tarpan TMZ-MK 03 and Tarpan TMZ-MK 04.

This cultivator was invented by Tula engineers in 1991 as a simpler and more reliable replacement for the Rus walk-behind tractor produced by Tulamashzavod.

At first, the Tarpan turned out to be not very profitable to produce, but after it was improved and equipped with an American powerful engine, things began to improve. And since 1997, the production of the cultivator has become widespread.

Distinctive features of this simple machine: a strong, reliable and almost eternal worm gearbox, as well as high engine power (5.5 or 6 horsepower).

The use of an automatic centrifugal clutch makes it easy to fold the cultivator into two halves, placing it in the trunk of a regular car.

The main advantages of the model can be identified:

- A successful combination of an imported strong motor and domestic unbreakable hardware. Even heavy soils can be processed without difficulty.

- Quick processing of plots - ten acres can be plowed with smoke breaks in five hours, or even less.

- Minimum settings, ease of control, minimum maintenance.

- A worm gearbox, which is much more reliable and durable than a belt or chain drive.

- Light weight, allowing the unit to be easily turned by hand.

- The cutters are of excellent quality - one sharpening lasts a very long time.

- The engine, located vertically, is extremely easy and quick to remove.

- Compact and can be disassembled into two parts.

- There is a good selection of attachments.

Now about the disadvantages that also exist:

- The main disadvantage is the lack of reverse gear, which cannot be provided for in a worm gear with such a high gear ratio. Therefore, where everything is planted, it can be inconvenient to use the unit.

- The thumb of the right hand, under which the gas lever is made, quickly gets tired.

- The cutters are bent at right angles, which is why they wind up the grass, pressing it first into the soil. In overgrown areas, you have to constantly clean the cutters.

- It is not very convenient to change the oil in the engine. To do this, you need to remove the clutch and unscrew the three nuts located on the frame.

- Do not hold (or transport) the device for a long time in an inclined position at an angle of more than 15 degrees. Oil may leak onto the air filter.

- The emergency stop is poorly thought out: to do this you need to keep the “stop” button pressed all the time. But the throttle lever does not stop the cutter immediately.

Device

The car has a four-stroke gasoline engine with air cooling. This is mainly a Briggs & Stratton Quantum I/C 650 motor, originally from the USA. Its power is 6.5 horsepower.

A number of models are equipped with the Japanese GCV-160 Honda engine, which is slightly less powerful (five and a half horsepower).

Recently, to reduce the cost of the unit, they began to install Chinese Champion engines, the power of which is the same as that of the “Japanese”.

The worm gearbox transmits the motor power to rotary cutters equipped with a plowing depth regulator. It allows you to loosen the ground, going 20 centimeters deep.

The plowing width can be 35, 70, or 100 centimeters (in the latter case, underground floors are used). There are two wheels for moving around the site.

The Tarpan's steering wheel is equipped with controls. It is height adjustable, and its handles are rubberized and easy to grip. The steering bar allows you to fully turn around and change the tilt.

The following types of attachments can be used with Tarpan cultivators:

- The weeder is used when it is necessary to destroy weeds between rows, the size of which is from 30 to 40 centimeters.

- The hiller is used together with weeders. With its help you can mark out beds, make furrows, and plant potatoes.

- The “String” attachment is designed for mowing grass.

- Lugs are needed so that the machine has better traction with the soil and does not slip.

- A special frame with wheels is used for easy movement of the unit.

- The plow is used for deep plowing.

- A cutter called "Crow's feet"

- Attachment for snow removal (used only with walk-behind tractors MB-07).

- A hitch that is used to attach third-party attachments.

We suggest you familiarize yourself with How to solder polyethylene

The most popular variations are TMZ-MK-03 and TMZ-MK-04. They can have an American or Japanese engine. Accordingly, B&S or Honda is added to the name (the latter is more expensive). MK-03 and MK-04 differ from each other only in the gearbox (its gear ratio).

Since both of the above-mentioned engines are not cheap, the manufacturers decided to create a more budget option, equipping it with the Chinese “Champion” G160 engine with a power of 5.5 horsepower. The modification was named TMZ-MK-03-Champion. There is another “Chinese” of the same power - the Zongshen XP200 motor, but it is installed much less frequently.

Photo of Tarpan cultivator TMZ-MK-03

The TMZ-MB-07 walk-behind tractor is distinguished by its large dimensions and is also more weighty. In addition, you can attach a snow blower to it (this is not provided for on the MK-03 and MK-04). But the cost of the walk-behind tractor is higher than previous models, so it is in less demand.

The mini-variation called TMZ-MK-031 is not particularly popular. It is weak (three and a half horsepower) and expensive, and has less depth and width.

| Characteristics | Indicators | Unit measurements |

| Common parameters: | ||

| Type of fuel used | Gasoline A-92 | |

| Gearbox type | worm | |

| Tillage depth (maximum) | 20 | cm |

| Cultivation width (maximum) | 35 or 70 | cm |

| Tillage width (with weed pads) | 100 | cm |

| Performance | 600 | m2/h |

| Cutter size (diameter) | 32 | cm |

| For models MK-03 and MK-04: | ||

| engine's type | Briggs&Stratton or Honda | |

| Engine power | 6 or 5.5 | |

| Cutter size (diameter) | 32 | cm |

| Weight | 45 | kg |

| Dimensions | 78x70x75 | cm |

| For model MB-07: | ||

| Engine model | Briggs&Stratton | hp |

| Engine power | 6 | |

| Dimensions | 140x56x109 | cm |

| Weight | 67 | kg |

| For the MK-03 “Champion” model: | ||

| engine's type | Champion | |

| Engine power | 5,5 | hp |

| For mini-model MK-031: | ||

| engine's type | Briggs&Stratton | |

| Engine power | 3,5 | hp |

| Cutter size (diameter) | 24 | cm |

| Tillage depth (maximum) | 14 | cm |

| Cultivation width (maximum) | 14 | cm |

| Weight | 28 | kg |

| Dimensions (length, width, height) | 121x51x102 | cm |

Device

The Tarpan motor-cultivator is based on a welded structure to which the crankcase of a gasoline or electric engine is attached. The internal combustion engine transmits torque to the chain gearbox using a manually operated belt clutch. Some modifications use a two-stage gearbox with additional speed for moving backwards. On electric cultivators and simplified models with a gasoline engine, a worm gearbox with an automatic centrifugal clutch is used.

The equipment plows the soil with metal cutters located on axle shafts. A metal stop is installed under the control handles to regulate the depth of soil cultivation. Instead of cutters, it is allowed to install metal wheels or rollers with rubber pneumatic tires. To store the fuel supply, a steel tank located on the top of the engine is used. The design of the equipment provides for the installation of protective shields that reflect clods of soil and stones flying from under the cutter.

Attachments

The company offers a wide range of attachments for cultivators:

- metal lattice wheels designed for movement on soft ground;

- device for towing additional trailers;

- milling cutter with working elements of the “crow’s feet” type;

- attachment for automatic weeding (installed instead of a milling cutter);

- protective discs that prevent damage to plants by rotating tools;

- plow with a fixed share position;

- rotary mower of the Zarya type, driven by the engine crankshaft;

- frontal blade for snow removal;

- hiller plow.

Attachments

Tarpan walk-behind tractors with Briggs and Stratton engines can support a wide range of attachments.

The delivery package for Tarpan walk-behind tractors includes a set of cutters, which are made of high-quality self-sharpening metal. They are able to work for a long period of time. The cutters are installed in place of standard pneumatic wheels.

Another option for attachments is active cutters. They are installed behind the walk-behind tractor. Thereby giving the device additional balance, stability and safety, since it is virtually impossible to be damaged by an active cutter.

Milling cutters can only process prepared soil. When working on hard rocks, they cannot enter the ground and jump over the ground. For virgin lands, it is still better to treat the surface with plows and then with cutters.

Plow Tarpan Plow PN-1-20MB

The first of them break up the soil, and the second crushes it.

Mowers and rakes

Tarpan walk-behind tractors support work with a rotary mower. It cuts the grass using rotating knives. Rotary mowers help in maintaining the surrounding area or park areas in order.

Rotary mower Zarya Rotary mower Patriot KKR-4

Mown weeds can be collected to make hay for the winter using a rake that is connected to the device and collects.

To facilitate work with potatoes, Tarpan walk-behind tractors can operate a potato digger and a potato planter.

Potato planter Potato digger for walk-behind tractor KKM-1

The most popular version of the potato digger is the screen one. Its active knife plunges into the ground about 20 cm, picks up a layer of soil along with the fruits, and then uses screens to break up the soil and leave only tubers on the surface.

Hillers

This attachment is used for processing crop rows. While working, they not only throw soil onto the bushes, but also weed the weeds.

Single-row hiller Potato digger

During the winter season, our country experiences heavy snowfalls, and snow removal at dachas or in rural areas requires a lot of physical effort. Tarpan walk-behind tractors can help in carrying out these works.

Snow blowers are a special attachment that picks up a layer of snow and throws the snow at a distance of about 6 meters.

Snow blower

Blade-shovels are used to clear the local area from snow precipitation.

As standard, the Tarpan walk-behind tractor has pneumatic wheels with a wide tread. They go deep into the ground and provide a smooth ride for the machine.

In order to improve adhesion to the surface, metal lugs can be installed. This is a special steel rim with welded plates, which go into the ground while riding and improve the cross-country ability of the Tarpan walk-behind tractor.

Track modules are installed when driving a walk-behind tractor in winter. They increase the contact area with the surface and improve control when driving on ice or snow.

Weights

Tarpan cultivators are light in weight, so to make working with them easier, it is necessary to increase the weight of the machine. One solution to this problem is to install weighting materials. They are made in the form of pancakes and hung on the wheel axle.

Trailer

Tarpan walk-behind tractors can be used for transporting goods thanks to trailers. The most popular are dump trailers, which are capable of unloading cargo by simply lifting from the front.

User manual

The purchased cultivator must be assembled in accordance with the recommendations set out in the documentation. It is recommended to check the tightness of threaded connections and the oil level in the gearbox and engine crankcases.

To extend the service life, it is necessary to run-in the equipment with reduced loads.

The deepening of soil milling machines is carried out by applying force to the handles. The installed plowing depth regulator also goes into the ground and creates additional movement resistance, adjusting the speed of movement. If the cutters begin to dig into the ground, and the speed drops to zero, then it is necessary to reduce the depth of the tool into the soil. To rotate, the cultivator tilts left or right using the handles.

The documentation provides a list of routine maintenance; the intervals depend on the type of motor installed. For example, the initial oil change in the engine is performed after the unit has been run-in, the duration of which depends on the modification of the engine. During operation, it is recommended to check the oil level; some engines are equipped with an emergency ignition switch, which is activated when the fluid volume decreases.

Malfunctions and their elimination

If it is difficult to start a gasoline engine or there are interruptions in operation, you should check the operation of the carburetor and the standard speed controller. To carry out repairs yourself, you need to adjust the regulator in accordance with the manufacturer's recommendations and check the presence of fuel in the tank. Additionally, the condition of the connecting line and the valve is monitored, and then the gap between the spark plug contacts is checked.

Overheating of the power unit indicates that the cultivator is overloaded or the air filter and fins are clogged with dirt. To restore performance, you should reduce the loosening depth or change the filter. If the problem persists, then inspection and cleaning of the external part of the engine from accumulated dirt is required. A common defect, according to reviews from owners, is oil leakage through the junction line of the gearbox housing halves. The defect occurs due to a crack or wear of the gasket or seals. Repair consists of purchasing and installing new parts.

Vibration during operation indicates stones getting between the cutter teeth or damage to the tool. It is necessary to stop the engine, inspect the cultivator and replace worn parts. Additionally, it is recommended to check the tightness of the bolts securing the engine.