To improve the transport capabilities of the equipment, tracks for the walk-behind tractor are used. Thanks to them, the unit can be operated even in winter, since there will be no problems with its maneuverability.

A ready-made triangular GP N1 tracked drive is not cheap, so you can assemble the structure yourself from scrap materials. Drawings are drawn up in advance or you can use ready-made sketches. If you organize the work correctly, the caterpillar will be reliable and stable.

Compared to a wheeled vehicle, a caterpillar vehicle uses a larger coverage area when moving.

Thanks to this feature, it is ensured:

- Uniform load distribution;

- Reducing the pressure of the unit's mass on the ground.

- Excellent maneuverability of the equipment;

- Long-term operation of the device without interruption;

- Increased movement speed;

- Performance regardless of the weather.

Tracked equipment will not get stuck in sand, snow or heavy mud.

Crawler attachment device

The caterpillar module for the walk-behind tractor is manufactured one at a time with two options. Each has its own design features.

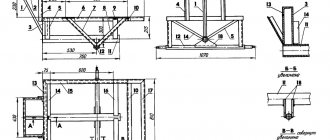

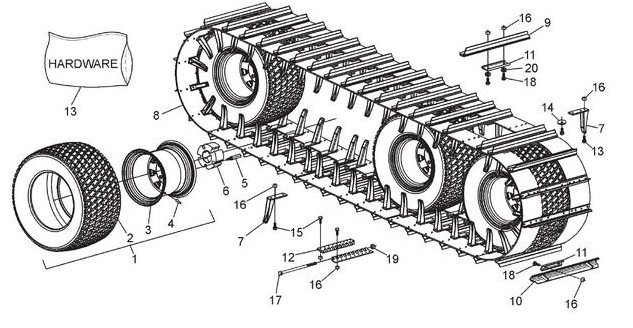

Option one:

- Axle with four rollers at the bottom. They create tension on the track;

- There are two gears on the left and right edges. They are needed to tension the tracks and provoke the module to move in a horizontal position. For this purpose, a special frame is secured with bolts;

- A gear transmission is welded to the shaft;

- With the help of a chain and an articulated drive, the entire tracked installation is driven;

- A caterpillar track with V-shaped stakes. The tip is directed behind the movement of the unit.

Second option:

- The large gear is fixed to the axle, there are eight rollers on the frame that keep the belt taut and the uninterrupted movement of the walk-behind tractor;

- When raising and lowering the gear, the level of belt tension is controlled;

- You don’t need to assemble the tracked attachment yourself; it’s better to purchase one. This eliminates breakdowns that may be associated with incorrect assembly.

Crawler module for walk-behind tractor

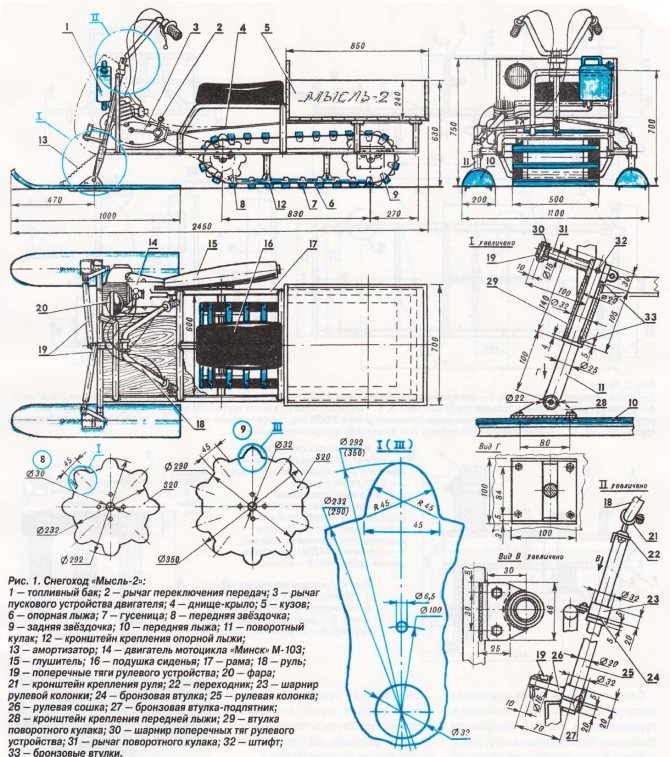

A tracked module for a walk-behind tractor is an attachment that will allow you to convert your equipment into a snowmobile or motorized towing vehicle. Moreover, this can be done in a matter of minutes.

It is beneficial to have tracks for a walk-behind tractor for those who already have a walk-behind cultivator. Having such an attachment, you can put on caterpillar tracks not only the Neva walk-behind tractor and other brands of similar equipment, but also motor cultivators with a working shaft diameter of 30 mm.

To make a caterpillar drive for a walk-behind tractor with your own hands, you may need a drawing.

Under the Krutets brand, caterpillar tracks are produced that, regardless of the power and weight of the cultivator, are suitable for walk-behind tractors of any manufacturer. They have a durable frame and can be used in any season. The attachment is installed on the walk-behind tractor using keys.

Well-known attachments for walk-behind tractors include the domestic “Lynx”, “Ant” and “Buran”. Imported ones include: Talon 380, Talon WT, etc.

As for the caterpillar made by yourself, you need to remember that its high height increases the center of gravity of the unit. This threatens instability and rollover on turns and problem areas. For stability, you need to raise the additional axis.

If the wheelbase is narrow, then it needs to be widened. A bushing must be installed on the drive shaft. It can be purchased at any auto parts store.

If you use a triangular rotary extension (in the absence of a differential), there is a chance to increase the maneuverability of the equipment. Please note that the air-cooled engine unit is not suitable for crawler drives.

It simply cannot cope with a heavy load. Water-cooled walk-behind tractors are ideal. The motor does not overheat with this cooling.

Caterpillars for walk-behind tractors allow winter active recreation enthusiasts - fishermen and hunters - to get to the desired location without hindrance. Such a machine can also transport various cargoes, hay or firewood.

Reviews about homemade caterpillars are positive. When making tracks yourself, you can’t skimp on little things and parts, otherwise the walk-behind tractor will turn out to be unreliable. Or you need to purchase homemade attachments from craftsmen who have repeatedly made tracks for walk-behind tractors.

If you are not confident in your abilities, it is better to purchase a ready-made console. Its only downside is the high price.

How to make tracks for a walk-behind tractor with your own hands?

A caterpillar attachment for a walk-behind tractor can be made with your own hands, even without experience in this matter. When choosing a material, you need to take into account the level of the upcoming load. Finished tracks must be durable, maximum light, not deteriorate during use, and not overload the engine.

When designing a structure, it is worth taking care of attaching a pair of wheels of equal dimensions. Each wheel axle will have a fixed tape. You can use a conveyor belt, tires from a truck, belts and chains.

There are several ways to make tracks for a walk-behind tractor. Having considered the features of each of them, you can choose the most relevant one.

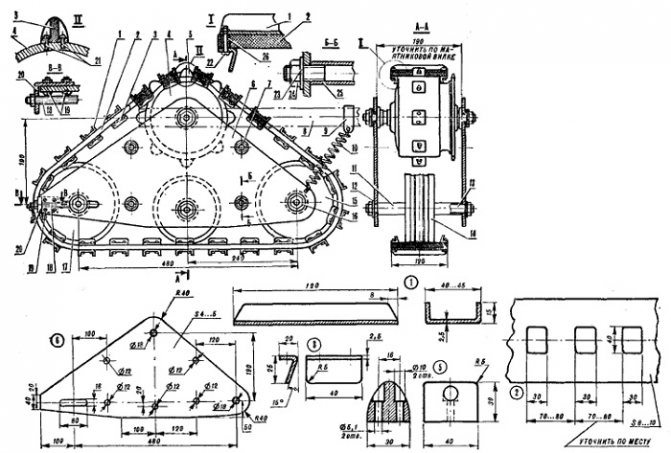

Scheme for making a caterpillar using a toothed conveyor belt:

- Using a fishing line with an awl or a thickened needle, a strip is sewn along the edge of the tape to prevent fraying;

- The bushing-roller chain is mounted internally for good adhesion to the driving elements;

- The stitched tape is sewn into a ring that tightly covers the wheels.

This is the easiest way to remake the unit and does not require special skills. It is important to take tape no thinner than seven millimeters so that it does not deteriorate during use. The universal crawler platform can be of any size.

To construct a tracked attachment, you can use truck tires with pronounced treads. You will have to use a sharp knife and a jigsaw. It is important that the inner diameter of the tires used matches the circumference of the wheels. If all materials and tools are ready, we begin to manufacture the structure.

Scheme for making a caterpillar using truck tires:

- The edges of the tire are cut off with a jigsaw;

- The inside of the tire is cleared of various protrusions;

- The finished tracks are immediately installed on the tires of the unit’s wheels.

There are also more complex manufacturing options, when a sprocket is used instead of wheels.

The track attachment to the walk-behind tractor is made of belts and chains according to the following principle:

- The bushing-roller chain is replaced by two equal pieces of conventional chain. Parts of a belt with a wedge-shaped profile are attached to them;

- Steel lugs are bolted to the belt;

- The caterpillar track is connected, the outer links are welded so that the structure is as strengthened as possible.

This design is distinguished by its versatility, therefore it is suitable for many models of walk-behind tractors. Equipment of the Neva and Salyut brands is often subjected to such modifications.

Lugs are made not only of steel, but also of wood and plastic. For this, wooden blocks and plastic pipes are used. The choice of material is based on the specific purpose of the walk-behind tractor. If the load on the unit is small, it is worth choosing a lighter material. Thus, devices made from bars or pipes are suitable for walk-behind tractors with low-power motors. If the unit plays the role of a mini-tractor with a powerful engine, then preference should be given to steel elements.

Popular factory models

This agricultural equipment is produced by both domestic and foreign manufacturers. Let's list some models:

Talon 380 Track Attachment

Characteristics:

- track height - 300 mm;

- track width - 190 mm;

- total length - 1035 mm;

- total width - 680 mm;

- track track - 300 mm.

Talon WT track module for walk-behind tractor

Characteristics:

- The nature of the engagement is lantern

- Number of steps - 62

- Caterpillar weight - 34 kg

- Dimensions: Length - 154″ (3886 mm)

- Width – 20″(500 mm)

- Pitch - 2.86″(73mm)

- Grouser height - 1.25″ (32 mm)

Crawler drive “Lynx-500”

Characteristics:

- Length: 3937mm.

- Width: 500mm.

- The lug height is 22.5mm.

- Manufacturer Composite.

Motoblock crawler attachment “Buran”

Characteristics:

- Length: 3686 mm.

- Width: 380 mm.

- Grouser height: 17.5 mm.

- Manufacturer Composite.

Attachment “Ant” to the walk-behind tractor

Characteristics:

- The nature of the engagement is lantern

- Number of steps - 44

- Caterpillar weight - 7.7 kg

- Length - 2222 mm

- Width - 220 mm

- Pitch - 50.5 mm

Track attachments CAM

CAM tracked attachments are aggregated with almost all walk-behind tractors from domestic and foreign manufacturers.

Proper caterpillar care

Homemade caterpillars will last much longer if you take care of them comprehensively.

General care recommendations:

- It is necessary to control the level of adjustment and tension of the chain;

- When driving a finished unit, you need to ensure that the chain is intact and without damage;

- All rubbing parts must be constantly wiped with machine oil to prevent damage.

Simple care recommendations will help prevent failure of finished structures. A crawler walk-behind tractor will become a universal assistant for solving various problems.

What are tracks on a walk-behind tractor and their features?

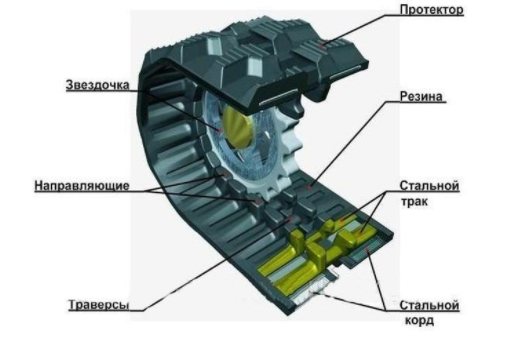

Caterpillars on a walk-behind tractor are universal agricultural attachments for walk-behind tractor equipment (winter-summer). A modern crawler attachment is similar to a snowmobile attachment. This device has a roller suspension instead of a slide suspension, so this agricultural device can be used perfectly in any weather and at any time of the year. It is demi-season. At the same time, the modernization did not in any way affect the quality and technical characteristics of the tracked attachment to the walk-behind tractor.

A modern attachment to a walk-behind tractor on tracks allows year-round:

- cope with any water obstacles (the depth of the latter is limited only by the distance to the engine);

- move through any confusion.

Different operating conditions are the key advantage of this professional equipment. That is why tracked attachments to walk-behind tractors are indispensable in the work of foresters, fishermen, and hunters.

This agricultural device does not require modifications either from the console or from the walk-behind tractor. The equipment is completely ready for operation.

List of required materials

To turn wheeled walk-behind tractors into tracked walk-behind tractors, you will need a powerful motor. It must have an axial lock. Power matters because the motorball is planned to be used on difficult surfaces. Without additional technical parameters, it will not be possible to achieve good cross-country ability. Basic materials that will be required for such work:

- walk-behind tractor with gearbox, equipped with a four-stroke engine and axle locking function;

- several additional wheels that allow you to pull the caterpillar on them;

- directly caterpillars made from improvised materials.

Depending on the material used in production, two large tires and a conveyor belt may be required. All this together allows us to make a functional device.

If you add a cargo platform here, you can equip a full-fledged mini-tractor. An additional platform on skids makes it possible to use the device as an all-terrain vehicle in the snow.

From wheeled to tracked and back

The purchased wheeled model can, if desired, be converted into a tracked one: to do this, attach an additional pair of wheels, connecting them in pairs with tracks. Such restyling will not be cheap, but if you wish, you can look for the necessary spare parts on the farm, ask your friends, and save significantly on purchases.

Read also Draniki with saury recipe

When the tracks are not needed, they can be removed. By making the second pair of wheels add-on, you can easily return the walk-behind tractor to its original appearance if necessary. True, such a rework will be more labor-intensive. In most cases, this option is implemented by attaching wheels to an existing axle through a transmission. The transmission can be flexible or rigid.

The mounting method will require a lot of thought, but it will eliminate the need for welding. Yes, and ready-made drawings can be found freely today if you have access to the Internet. Have you decided to improve your walk-behind tractor? Consider what type of track will suit the equipment you have.

Design features of the device

Making homemade caterpillar components for a walk-behind tractor with your own hands allows you to save money on the purchase of factory devices and further operation of the equipment. If everything is done correctly, then self-made tracks for a walk-behind tractor increase the cross-country ability.

Compared to their wheeled counterparts, tracked walk-behind tractors are not as widespread. This is explained simply. Wheel units from Texas, Patriot, Cayman, Viking, Forza are best suited for plowing land. This design is best suited for soil-related work.

Remaking a wheeled walk-behind tractor is a job consisting of attaching one additional wheel on each side. It turns out to be a four-wheeled walk-behind tractor on which you can put tracks. They can, in turn, be purchased or homemade. Additional wheels can be made removable. This allows you to promptly transform the unit into a standard walk-behind tractor, ideal for working in the garden.

To do this, the wheels are attached to the axle, which are already provided in the design, by means of a rigid or flexible transmission. This solution is considered appropriate, since the need for installing additional fasteners disappears. As for the design of these walk-behind tractors, they fully comply with the parameters of wheeled modifications:

- Engine. It is powerful, four-stroke. It has an axis locking function. Due to this, the tracked walk-behind tractor can turn in place without describing a full circle.

- Transmission. The standard set includes a gearbox, clutch system and gearbox.

- Chassis. Caterpillars are used here. They replace the wheelbase. If a modification is made, then one roll is added to the existing pair of wheels on each side. They put a homemade caterpillar on them.

- Control bodies. Located on the control handle. Includes emergency stop mechanisms and various types of clutch levers.

Before starting your own production, you need to evaluate the offers in stores specializing in the sale of such equipment. Particular attention is paid to the price of certain types of tracks for well-known manufacturers of walk-behind tractors. Let’s say a caterpillar for a Neva walk-behind tractor costs about 28,000 rubles. This is a fully functional snowmobile attachment. You can buy a seat for drivers separately, thanks to which the walk-behind tractor takes on the features of a mini tracked tractor, albeit with less impressive performance characteristics. The technical parameters here are:

- develops a speed of about 18 km per hour;

- The total weight of the console is 37 kg;

- width - 60 cm;

- length - 100 cm;

- height - 34 cm.

Accommodates one driver and one passenger on board. In addition, on sale you can find an attachment to a walk-behind tractor on tracks, which is intended for the Salyut and Agat models. Its cost ranges from 25 to 27 thousand rubles. This design does not provide for attaching a driver's seat. Because of this, some restrictions are imposed on the functional features of this device. But for driving on off-road and snow, such a vehicle is quite suitable.

Online stores offer a large number of different models of snowmobile attachments mounted on tracks to a walk-behind tractor. This indicates the popularity of such models.

Their feature is the ability to control not only with two hands, walking behind a walk-behind tractor, but also while sitting in a folding sleigh. The latter will have to be purchased separately. Considering that the average cost of a set-top box is about 30 thousand rubles, not counting the price of folding sleds, we can say that making tracks yourself can save a lot of money.