UAZ is a common car on Russian roads. Its design features allow you to move without problems on paved areas, as well as off-road. Repairing the front axle of a UAZ is impossible without knowing the diagram of the wheel gearbox, the design of which is similar to a similar part of the rear axle. The key difference is the peculiarity of fastening and installation of the main gear, the design parameters of the ball bearing located in a special compartment-cup.

Device and characteristics

The design of the UAZ front axle in older models has few differences from the similar design in new models (Spicer). The main differences lie in the design of the crankcase, the dimensions of the components of the drive gear and differential, and in a number of units used.

The design of the old model is in many ways similar to the rear axle of the UAZ and consists of the following components:

- The key place is occupied by the split crankcase, consisting of 2 separate parts.

- Each half is equipped with press-in housings with internal axle shafts.

- Safety valves on the casings, responsible for controlling the growth of oil volume in the mechanism.

- The differential and main gear of the casing are made according to the standard design: a small-diameter drive gear is located in the horizontal plane, in contact with the cardan.

- The large driven gear in the longitudinal plane is in mesh with the main gear. It has a built-in differential of 4 satellites.

- The edges of the crankcase housing are equipped with pivot joints made of ball joints with a rotating housing.

A design feature of the Spicer bridge is the presence of a contact system between the wheel hub and the axle shaft. It is a coupling responsible for connecting and disconnecting 2 elements. The mechanism ensures the transmission of torque to the wheel from the differential. The disconnected clutch leads to free rotation of the wheel on the axle, and the vehicle receives a 4*2 wheel arrangement. The engaged clutch leads to the connection of the hub, differential and axle shaft, the car turns into a 4*4 all-wheel drive.

Old UAZ car models were distinguished by the presence of hubs with drum brake units.

Their wheel rotation angle is no more than 29°. The knuckle and linkage arms connected to each other are a wheelbase control tool. In new models (Spicer), the angle of rotation reaches 32°. The rest of the bridge structure is similar.

What is the difference between a UAZ military bridge and a civilian one?

The military axle, unlike the civilian Spicer front axle, is equipped with final drives. This design feature caused the following differences between military models:

- Gear axles are located 4 cm above the wheels. This difference helps to increase vehicle clearance - the distance between the supporting surface and the bottom of the bridge.

- The main pair is smaller in size and has a small number of large teeth, which increases the reliability of the design. The unit weighs more.

- The gear ratio is 5.38 (traction, but not speed).

- The length of the rear propeller shaft is 1 cm shorter.

Advantages of military bridge models:

- increased ground clearance by 8 cm;

- high torque, allowing you to transport heavy objects, tow and move at low speeds over difficult terrain;

- load evenly distributed between the main and final drives;

- larger teeth increase reliability;

- limited slip differential for off-road driving.

The military design of the UAZ was thought out to accompany tank colonies, which indicates the power and reliability of the design.

How the all-wheel drive system works

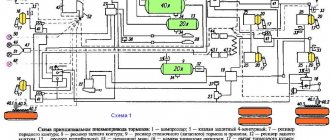

The Patriot's engine is connected to a 5-speed synchronized manual transmission. The secondary shaft of the box transmits torque to a 2-stage transfer gearbox, which is connected to the axles using cardan shafts with needle bearings and movable couplings. Splined couplings ensure the operation of the transmission when the axle moves on a suspension. The drive to the rear beam operates in continuous mode; the driver turns on the front axle when driving off-road.

The classic UAZ transfer gearbox is equipped with gears with straight teeth, which are switched using a lever. The gearbox housing parts are made of cast iron, the primary and secondary shafts are located inside, and there is an intermediate element with a movable carriage. The gearbox cover houses a switching mechanism equipped with two rods and forks. The mechanism is connected to a lever located inside the car.

The Dymos gearbox (with an aluminum crankcase), used since the summer of 2013, uses a chain to transmit power to the wheels, and the design includes a double synchronizer (when all-wheel drive is engaged in direct drive). The manufacturer claims a gearbox life of 200 thousand km, but with frequent use of the vehicle in severe off-road conditions, the unit fails earlier. To change gears, an electric servo drive is used, connected to a control puck.

The car's all-wheel drive distributes torque between the axles in a 50/50 ratio. There is no center differential in the transmission design. The rear axle is equipped with a differential; axle shafts installed inside the axle stockings are used to transmit torque to the wheels. To supply torque to the front wheels, axle shafts and steering knuckles with hinges are used. The units allow power to be transmitted to the steered wheels. The front axle housing also has a cross-axle differential.

On cars manufactured before 2007, factory couplings (hubs) were installed in the front wheel hubs. The devices allow you to disconnect the hubs from the axle shafts and differential, which has a positive effect on fuel consumption. The products are equipped with splined couplings; a special rotary washer in the center of the hub is used to control the position. The plant refused to install hubs in order to simplify the design of the vehicle, but owners of Patriot vehicles can install the hubs themselves.

How to turn on the front axle on a UAZ

Engaging the front gear may be necessary if it is necessary to turn from an asphalt road surface onto a country road or terrain with potholes and mud. In the new conditions, rear-wheel drive will not cope with difficulties. Engaged front-wheel drive is a means of solving the problem.

System startup sequence:

- Stop the car and check the operation of the front wheel quick release clutch. It is turned on by turning the wheels clockwise until they stop.

- Move the rightmost lever forward to switch the front wheels to driving status. Now their rotation will be equivalent to the rear.

If the road condition worsens while driving, it becomes more and more difficult to continue driving, the engine stalls, you need to stop the vehicle and engage a lower gear. To do this, you will need to move the middle lever back. In low gear, all 4 speeds are available, and driving becomes easy and smooth again.

After overcoming off-road conditions, it is immediately better to put the middle lever in its original position and move the transfer gearbox to a higher level. On the highway, it is recommended to stop the front-wheel drive and quick-release clutches to save 2 liters of fuel. The measures help reduce noise levels while driving.

How to Turn on the Front Axle on a UAZ Bukhanka ~ AUTOINTERLINE.RU

UAZ razdatka (loaf): device, principle of operation and reviews

In fact, all all-terrain vehicles produced in Ulyanovsk are equipped with a transfer case. UAZ (“loaf”) is no exception. Despite its unimpressive appearance, this car is capable of almost anything. This is a favorite car of hunters, fishermen, and tourism lovers. The UAZ transfer case (“loaf”), the design of which we will look at in this article, is needed to distribute the torque to all axles and drive mechanisms. In this article we will talk specifically about it.

Transfer case UAZ-452

The transfer case of UAZ-452 cars consists of drive shafts of the drive axles, an intermediate axle, and also 5 gears. All these components are located in a crankcase cast from cast iron. Its connector is perpendicular to the axes of the shafts. The bulk of the parts are in connection with the crankcase cover. When assembling/disassembling the box they are clearly visible. They are comfortable to remove or install.

The kinematic diagram of this unit is such that the gears are put into operation only when the front drive axle is connected. If only the axle is engaged, all the torque removed from the transmission drive shaft will be transmitted to the rear drive shaft. The end of the secondary gear of the gearbox is used as the drive shaft.

Rear axle drive shaft

What does the UAZ transfer case consist of, what are its features? This shaft is mounted on 2 ball bearings. To protect the element from axial movements, it is held by a rear bearing with a stubborn ring and a cover. A gear is attached to the front part of the shaft. Its inner crown has slots. The function of this gear is to drive the front drive axle. Internal splines are needed to engage direct transmission in the transfer case.

A helical gear is also installed on the splines between the bearings. It serves as a drive for the speedometer. The rear part of the shaft is connected to the cardan shaft using a nut with a conical protrusion through a flange. If you tighten this nut, its conical protrusion will bend into one of the grooves that are cut into the threads and stop.

Intermediate shaft

This element is also held in the box by two bearings. A roller one is used as a front one. It is circular type. The holder containing the rollers is pressed into the body. It is covered with a plug. The inner race is mounted directly on the shaft. The 2nd bearing (rear) is held on the intermediate shaft with a nut. The element is equipped with a stubborn ring, which serves to fix it and also to secure the shaft in the housing. The outer part of the bearing is equipped with a cover. The intermediate shaft is a single part with the reduction gear. It also has splines for installing gears. It allows you to engage the rear drive axle.

UAZ transfer case (“loaf”) - front axle drive shaft device

This gearbox is also equipped with this shaft. It is installed in the mechanism on two supports. The latter are ball bearings. To fix the shaft in the direction of the axis, a rear bearing is attached to it. It is installed in the same way as the one on the intermediate shaft.

The front support is not secured in the box body. The element is clamped to the shaft using a cardan shaft flange. The drive element of the front axle is a single piece together with a gear. The front part has slots. Using them, the shaft is connected to the flange on the cardan shaft.

Gears

What other parts does the transfer case consist of? The UAZ (“loaf”), the distribution device of which is described in the article, is equipped with gears with straight teeth. The drive has the ability to move along the splines on the secondary shaft of the gearbox. This gear has two rings. One is an involute type spline. They serve to connect a direct drive to the inner ring of the drive shaft of the rear drive axle. When the driver engages a lower gear, this gear will engage with the one on the intermediate shaft.

How to turn on the front axle and lower gear on a UAZ

The car is UAZ 452d, but there is no difference on which UAZ to turn on the bridge, it’s identical everywhere on the 469, on the loaves and the head...

Malfunctions and repair work

Common malfunctions of the UAZ front axle and possible repairs:

- Leakage of lubricating fluids. Check the tubes and connecting elements for mechanical damage - the cuffs and flange for functionality, the oil container for the optimal fluid level.

- High wear of fasteners.

- Bearing defects caused by the use of poor quality material by the car plant.

- Broken axle teeth. Adjustment will not help; parts need to be replaced.

- Mechanical defects of the beam.

- Wear of elements. The situation is resolved by replacing it with new spare parts.

- Poor grip of the bearings and main gears indicates the need for tension adjustment.

Bridge repairs begin after diagnosing and searching for the cause of problems in the functioning of the mechanism, which are diverse:

- transmission components of a rear-wheel drive vehicle are faulty due to regular movement over difficult terrain;

- use of consumables and lubricants of unsuitable quality;

- Failure to monitor tire pressure can lead to shaft and bearing failures.

Increasing the service life of the structure

There are several ways to increase the service life of the UAZ structure. The presence of a front axle in a vehicle imposes special requirements for operation. If you monitor and disable the hubs of the axle shafts and wheels at the right time, this will help increase the service life of the mechanism parts when the front-wheel drive is turned off. To prevent mechanical damage to drive components, turn on after the couplings. After switching from off-road to highway, you should immediately switch to rear-wheel drive. Another reason that contributes to rapid wear of rubber is constantly working clutches.

Machine maintenance must meet a number of requirements:

- Periodicity.

- Regular check of main components and mechanisms.

- Timely replacement of worn parts.

- Monitoring the level of oil and other liquids.

- Checking and adjusting wheel bearings.

- Monitoring the functionality of the main gear axial clearance components.

- Use of high-quality consumables and mixtures.

Rear axle structure of UAZ 469

The rear axle of the car is structurally different from the front axle. It does not have a wheel turning mechanism. The rear axle is driven by a cardan shaft from the transfer case. The rear axle consists of the following elements:

Carter

The crankcase consists of two halves. They are connected to each other using bolts. At the bottom of the crankcase there is a hole for draining lubricant. From the side of the wheel mechanisms, axle housings are pressed into the crankcase. In the front part there is a hole for installing the drive shaft.

REFERENCE: The UAZ-469 model is equipped with two types of bridges - military and collective farm. Depending on the type of bridge, the crankcase design differs.

Gearbox

The rear axle of the UAZ 469 has a gearbox consisting of a main gear and a cross-axle differential. The main drive gear is small in size. It transmits torque to the driven gear. The gear teeth are angled. This design allows to reduce the noise level during operation of the unit.

On one side, a drive gear is installed on the drive shaft. On the other side there is a flange necessary for attaching the propeller shaft. To prevent slippage of the drive shaft, splines are provided in the flange. The flange is secured with a nut.

The drive shaft is mounted on bearings. The bearings and moving parts of the gearbox are lubricated with gear oil. To prevent lubricant leakage, oil seals and gaskets are installed.

Inside the driven gear there is a cross-axle differential mechanism. It is made in the form of 4 bevel gears mounted on axles. The cross-axle differential allows the wheels of the axle to rotate independently of each other.

Half shafts

The design of the rear axle of the UAZ-469 provides for the presence of axle shafts. They are necessary to transmit torque to wheel mechanisms. The splined part of the axle shaft is included in the cross-axle differential mechanism. On the other side, the axle shaft is connected with bolts to the hub.

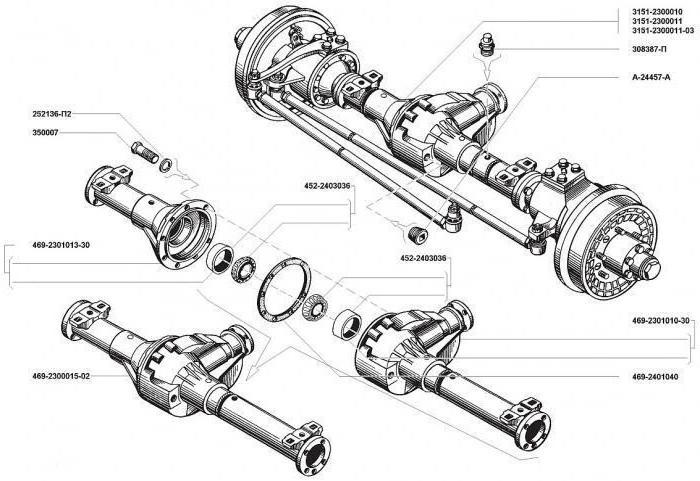

UAZ front axle structure

It consists of a crankcase (sometimes called a stocking), a differential and a final drive. The rear and front axles have no fundamental differences. The only difference is in the direction of the thread of the oil rejection ring located in the main gear. The current design of the UAZ front axle is shown in the picture below. The support placed on the casing is fixed with five hardware. Pin bushings are pressed into the support. A pair of pins “engages” in holding the fist. He also holds the housing cover of the wheel gearboxes. A pin is fixed on it along with a shield on which there are parts of the brake system.

The pins do not rotate in the fist thanks to pin-type stoppers. The fist itself is made with preload (0.02-0.1 mm). The UAZ 469 axle is adjusted using spacers. Location: between the turn lever and the trim (left or right). The spacers are located between the pads and the fist.

One of the features of the described mechanism is that, in addition to increasing cross-country ability, it also turns the wheels. For this purpose, Birnfield ball joints are used. Their cavities contain lubricant that does not need to be replenished throughout their entire service life. The cams, as well as the axis of the pins, are inclined, which allows the wheels to be returned to the middle position after making a turn. The main advantages of the beam (Spicer):

- track is 1.6 m, which has a positive effect on the stability of the car;

- the wheels rotate at an angle of up to 32 degrees, which gives the machine improved maneuverability;

- instead of leaf springs, a dependent suspension on springs is mounted;

- no need to replace lubricant in mechanisms (fists);

- removable cover facilitates access to parts in case of repair;

- the differential together with the gearbox are in one housing - this increases rigidity and service life;

- An improved satellite gear has reduced noise.

Particularly worth mentioning are the hinges, or more precisely the stabilization of angular velocity. This is a design that ensures the stability of rotation of two shafts: the drive and the accompanying. The hinge includes two forks: in their sockets there are 4 balls. In the middle sectors of the parts there is a fifth one, needed for installation operations. In particular, centering the fork. To deactivate the front-wheel drive, there is a special device consisting of a clutch, bolts, and balls.

Front axle UAZ 469

The design of the front axle is different from that of the rear axle. The crankcase is shifted to the right edge in the direction of travel of the car. This is due to the location of the transfer case. The front axle is driven by a driveshaft from the drive shaft. The axle is equipped with rotating mechanisms and steering rods that are used to control the vehicle.

The driver can turn on the front axle on the UAZ 469 without leaving the cabin. To do this, transfer case control levers are installed between the driver and passenger seats. One lever is responsible for turning the front axle on and off. The second is necessary to reduce torque transmission.

Half shafts

The axle shafts have different lengths. This is due to the location of the gearbox. To transmit torque to the wheel mechanisms, regardless of the angle of rotation, CV joints are provided.

IMPORTANT: The design of the front axle of the UAZ 469 provides for disconnecting the axle shafts from the wheel hubs. The connection is made with a specialized screw. This design allows you to increase the service life of the gearbox when driving on good quality surfaces and saves fuel.

Carter

The front axle housing is made of two parts connected by bolts. To avoid pressure build-up when the lubricant heats up, the crankcase is equipped with a breather valve. It allows the air mass to freely escape into the atmosphere. The breathing valve is protected from dust and contamination by a cap.

Steering

The wheel mechanisms are connected to each other by a transverse rod. The rod connection is hinged. To adjust the wheel toe angle, the rod is equipped with ends with threaded connections.

The forces from the steering column are transmitted to the bipod of one of the steering knuckles. The steering knuckles are equipped with king pins.

Existing types of bridges

Improved bridges on UAZ

- Managed. This is, as a rule, the front axle of the car, equipped with either rear-wheel drive, which is outdated today, or all-wheel drive. But there is another option: in transport equipment for public utilities or agriculture, it is the rear axle that is steered, not the front axle. This type of design is divided into two subtypes.

- Uncut. This is a special beam equipped with a mechanism for steering knuckles, fixed on the sides; wheel hubs are placed on the knuckles. The purpose of this design is to control the rotation of the wheels while driving. The most important conditions are the lightness and strength of the continuous beam. That is why, as a rule, it is made of high-strength steel using forged technology.

- Split. This is already a gearbox equipped with drive shafts. The purpose of the cutting mechanism is to transmit torque to the wheels. The split bridge provides ample opportunities for vehicle maneuvering.

- Supportive. This design is used to increase the lifting power of the machine and acts as an additional supporting element. Without this part, a car designed to transport large cargo would simply fall apart within the first kilometer. The support device can be found in such a unique vehicle as a motor home.

- Continuous leader. This is a rather complex structure, consisting not only of a beam, but also axle shafts, bearings, and a differential. On the beam of this design springs and brackets are attached to secure the suspension. Thanks to the continuous drive axle, the drive wheels can rotate at different rates, in addition, the design softens the load and controls the car when cornering. Some bridge parts undergo additional processing to give them greater strength and elastic properties. Thus, the axle shafts are made of high-quality steel and then hardened with high-frequency heat.

Read also: Tagaz Hardy technical characteristics

Return to contents

Node maintenance

The axles of the UAZ 469 are distinguished by their reliability and durability. For normal operation of units, they must be regularly maintained. To do this you need:

- Inspect the crankcase and wheel mechanisms for lubricant leaks;

- Check the degree of tightening of the fastening bolts;

- Replaces lubricant;

- Clean the breathing valve from dirt and check its functionality;

- Check the integrity of gaskets and seals;

- Check the play of the front axle turning mechanism.

Possible malfunctions and ways to eliminate them

You can repair the front or rear axle of a UAZ 469 yourself. This will require a standard set of tools and minimal technical knowledge. Possible malfunctions:

Presence of oil smudges

The appearance of oil streaks on the crankcase body or at the hub mounting points indicates a violation of the sealing of the unit. The cause of the violation may be failure of the breathing valve. When heated, the lubricant expands and pressure is created in the axle cavity. Under the influence of pressure, the integrity of gaskets and seals is compromised.

To eliminate the malfunction, it is necessary to restore the functionality of the breathing valve and replace the failed seals.

IMPORTANT: When installing gaskets, it is necessary to treat their surfaces with sealant. Lubricant should be added after the sealant has completely dried.

Increased noise

An increased noise level during operation indicates severe wear of the rotating parts or water entering the unit. When driving off-road or fording, water enters the axle cavity through the breathing valve. This leads to poor lubrication of rotating parts.

To prevent water from entering, car owners are upgrading the design of the breathing valve.

To do this, remove the standard cap. Connect the outlet of the breathing valve to a rubber hose. The second end of the hose is secured in the engine compartment.

A crunching sound when the unit operates indicates a malfunction of the bearings. To eliminate the malfunction, it is necessary to replace the failed parts.

Gear failure

When the main drive gears or cross-axle differential fail, an increased noise level or incorrect operation of the unit is observed. For repairs, you need to replace worn components with new ones.

ATTENTION: The main gears are replaced in pairs, regardless of the degree of wear of each of them. Replacing one gear will lead to its rapid failure.

Removing the bridge from the car

In order to repair and adjust the unit, it is necessary to remove the UAZ 469 axle from the vehicle. Dismantling is carried out in the following sequence:

- Place the car on a viewing hole or overpass;

- Immobilize the vehicle with anti-recoil devices;

- Remove the shock absorbers;

Transfer case lever positions and their meanings

The classic transfer gearbox is controlled using a separate handle. The lever moves along a path in the shape of the letter P; there are a total of 4 handle positions. The position in which the lever is at the lower left point of the letter P is considered neutral.

When using a gearbox, you should take into account the presence of hubs in the front wheel hubs (installed at the factory until 2007, and then by the owners themselves). If there are elements on the machine, then it is necessary to first activate the drive by turning the handles on the hubs.

Positions of the gearbox control lever on the UAZ "Patriot":

- To disable the drive to the front axle, move the handle to the base position. In this case, torque is transmitted to the rear wheels. This operating mode is intended for operating the vehicle on paved roads in summer or winter. The plant recommends using the mode during everyday use of the Patriot car, since due to the reduced load on the engine, fuel consumption decreases. At the same time, there is a decrease in noise when the machine is moving.

- Moving the lever forward and to the right allows you to turn on the supply of torque to the front wheels (direct transmission is enabled in the transfer gearbox). The mode can be activated while moving (speed up to 60 km/h). When turning on the drive while the machine is standing, difficulties may arise due to the position of the gears in the gearbox; after moving the machine 20-30 cm forward, the drive turns on without jamming. The mode is used when driving along a wet country road and on snow-covered or icy paved roads.

- Moving the lever from position 2 to the right and back to the middle of the stroke allows you to engage the neutral position in the gearbox. In this case, the cardan shafts stop, the car remains motionless (regardless of the position of the lever in the main gearbox).

- Moving the lever to the right and all the way allows you to turn on the lower row in the transfer gearbox while maintaining the transmission of torque to the front and rear axles. The mode is used when driving in difficult road conditions (for example, in snow more than 400 mm deep or in mud reaching the center of the wheel hubs). A lower gear is used when driving in the mountains (including with a trailer) or when crossing swamps or streams.

The manufacturer prohibits the use of a 2-axle drive when driving on dry roads. When driving around curves in the highway or when making turns, the outer wheels travel a greater distance than the inner wheels. To compensate for this effect, a center differential is used, which is not provided on Patriot cars. As a result, the mechanical loads on the transmission components increase, which leads to the destruction of parts and abrasion of the tire treads.

Similar articles

UAZ Patriot rear driveshaft UAZ crosspiece UAZ Patriot instrument panelDo-it-yourself differential lock on UAZ

UAZ is a legendary SUV, popular both in Russia and beyond its borders. The car has been produced for quite a long time, which has proven the reliability of its design. This machine is actively used in the army. There are minor differences between the civilian and military versions. However, both here and there the UAZ front axle showed its best side. There are several modifications: on-board, regular, “loaf”, etc. Also, one cannot fail to note one of the advantages of the car - maintainability and the ability to restore the functionality of any unit, even in “garage” conditions. The mechanism allows you to activate all-wheel drive, which helps you confidently overcome obstacles.

- Transfer case UAZ Hunter: Design and switching

Front and rear axles are almost identical