Oil Pump Faults Shtil 180 Chainsaw

How to independently repair malfunctions of a Shtil chainsaw: tips

repair a Shtil chainsaw independently due to the simplicity of the design. The tool, proven in the construction segment, has a power of 1400 W, an engine capacity of 31 cubic meters. cm.

The cost of repair work in the service is quite high. In many cases, their own technical knowledge allows consumers to repair the Shtil 180 chainsaw with their own hands.

The most common types of chainsaw malfunctions

The Shtil 180 chainsaw is operated in accordance with the instructions supplied with the tool. The user turns on the starting system after he is convinced of the presence of oil, gasoline, and makes sure that the chain tension is correct.

Work with the tool begins after it is securely fixed in your hands. If a failure of the tool is detected, it is necessary to determine what caused the malfunction of the Stihl chainsaw.

The reasons that caused to malfunction may be:

- the appearance of a leak in the oil system;

- formed breaks in the crankcase cord;

- carburetor malfunction;

- air entering the crankcase through the seals;

- worn condition of the worm gear in the oil pump;

- a spark does not appear at the ignition cross section;

- drive sprocket wear;

- violation of the integrity of the eye under the control lever.

To carry out independent repairs of a broken Stihl chainsaw, we use tools that are available to each consumer.

- screwdrivers;

- socket and wrenches;

- hexagons;

- a vacuum gauge used to determine defects in oil seals, carburetor, crankcase;

- an air compressor used for purging and cleaning components and assemblies;

- T-key STIHL Torx 27;

- a stopper that limits the stroke of the crankshaft;

- bearing puller.

Actions if a malfunction is detected in various parts of the unit

Such unpleasant phenomena as loss of power, lack of connection, and idle support are common. The reasons for this behavior of the tool are malfunctions of the chainsaw carburetor. This is expressed in contamination with particles of dust and sawdust. Such a breakdown can be easily repaired on its own.

The carburetor is cleaned using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

Replacing the Starter Cord of the Shtil 180 Chainsaw

Content

Repair of Shtil 180 chainsaw: faults and their elimination

Chainsaw Shtil MS 180 is considered one of the most reliable models in its segment. But technology is technology, and sometimes malfunctions arise that may require stihl ms 180 repair to resolve.

IMPORTANT. An experienced electrician leaked to the network the secret of how to pay half for electricity, a legal way. Read more

You will learn more about repairing components by reading the article.

Is it possible to repair a saw with your own hands?

This is the very first question that arises before the owner of a Shtil 180 chainsaw, which for some reason has stopped functioning normally. There is no clear answer to this question. It would be correct to say: it is possible, but is it necessary? Repairing a chainsaw in a service center is of course more expensive than trying to fix problems yourself, but by using the services of specialists, you receive guarantees and confidence that the chainsaw will be properly configured and adjusted. In general, the choice is yours.

Another small nuance regarding the choice to repair it yourself or not is that in order to diagnose a chainsaw and its further disassembly and repair, you need to have some specific tools and certain knowledge of the design of the saw. Otherwise, you will not be able to even unscrew and remove the flywheel without damaging it.

Replacing the starter cord of a Shtil chainsaw.

When carrying out independent saw repairs, the aluminum fan blades located on the flywheel very often break off. This happens because during disassembly they do not use a special crankshaft stopper, but try to fix it by installing a screwdriver between the saw body and the flywheel blades, which leads to dire consequences. The flywheel nut has a serious tightening torque, and the blades are fragile and cannot withstand such force.

Repair tools Shtil 180

To carry out a relatively high-quality repair of the Shtil MS 180 chainsaw yourself, you will need to have:

- air compressor (for cleaning the chainsaw and blowing out the main components and assemblies);

- a vacuum gauge is necessary to check the tightness of the crankcase and carburetor, as well as to identify defective seals;

- piston stopper to limit the stroke of the crankshaft;

- electronic tachometer in order to correctly adjust the chainsaw carburetor;

- T-key STIHL Torx 27 or equivalent;

- puller for crankshaft bearings.

Only with these tools can you repair a chainsaw

Calm 180 with your own hands, can be done quite well.

Common breakdowns Shtil 180

Common problems with chainsaws

can be attributed:

- Broken starter cord;

- Worn drive sprocket;

- Leaks in the oil supply system for chain lubrication;

- Worn oil pump worm gear;

- Air leakage through the seals into the engine crankcase;

- No spark at the spark plug;

- Lack of fuel supply in case of malfunctions in the carburetor (we will not dwell on them, since repairing and adjusting the carburetor of a chainsaw is a fairly broad issue and will be discussed in a separate article);

- Breaking off the eye of the seat under the engine control lever.

READ How to Adjust the Carburetor on a Husqvarna 137 Chainsaw

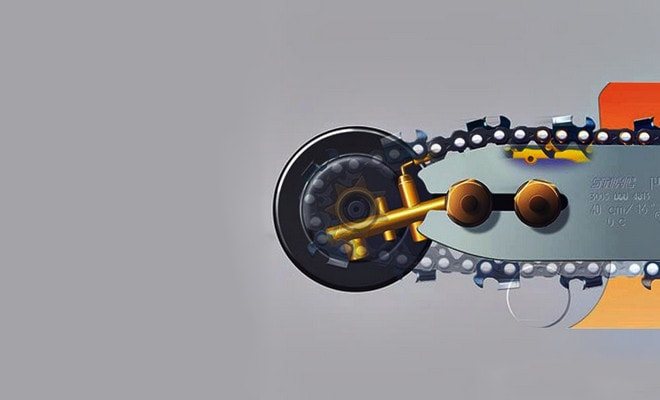

Now let's look at the faults in more detail and start with repairing the oil pump.

Oil supply system repair

If there is no oil supply to lubricate the chain, it is necessary to diagnose the entire system and determine the reason why the oil is not supplied. There may be several main reasons:

- Clogged oil filter or oil system;

- Missing thread on the oil pump worm gear;

- Blockage or malfunction of the pump itself;

- Depressurization of the oil system (there will be oil leaks on the bottom of the chainsaw).

To check the threads on the worm drive of the oil pump, you will need to remove the chainsaw drive sprocket and unscrew the clutch. To do this, the spark plug is unscrewed and a piston stopper is installed in its place, thereby ensuring reliable fixation of the tool’s crankshaft from turning.

Replacing a piston chainsaw Shtil 180 video.

Next, remove the cover from the side of the bar of the Shtil 180 chainsaw, and using a screwdriver, remove the retaining ring holding the drive sprocket, after which the sprocket itself is removed.

In this way, the sprocket of the Shtil 180 chainsaw is also replaced if necessary.

The clutch is untwisted using a 19mm socket and a wrench. It is necessary to unscrew the clutch clockwise, since the thread is left-handed. There is a reflective plate behind the clutch, this also needs to be removed. The next part is the worm drive of the oil pump. Having examined and discovered the absence of a plastic thread, you can safely throw out the part and install a new one in its place, since it is impossible to restore it. Assembling the Shtil 180 chainsaw is carried out in the reverse order.

Replacing the starter cord on a STIHL MS 180 chainsaw

Find out more on our website: Subscribe to our YOUTUBE channel! Let's be friends on social media.

If the gear is in normal condition, disassembling the saw continues; for this, the corkscrews are removed from the shock absorbers, the rear handle is untwisted and the throttle control rod is disconnected, after which the handle block is removed from the shock absorbers using a powerful slotted screwdriver.

It is necessary to remove the handles to provide access to the bottom where the oil pump is installed.

At the next stage, the oil hose coming from the oil tank is removed from its seat on the body and the line is checked for blockages by supplying air through the oil hose into the oil tank body. If a blockage is detected, it must be cleaned; if this is not possible, the faulty hose must be replaced.

Next, the oil pump is removed from the body of the Shtil 180 chainsaw and washed in gasoline.

As a rule, calm oil pumps rarely become unusable and require replacement. Basically, the reason for the lack of oil supply is a blockage, so by washing and checking the pump gear for turning, you can be sure that after reassembling the Stihl chainsaw

180 problems with oil supply will disappear.

READ Husqvarna St 268 Ep Oil Change

After repair, we assemble the Stihl 180 chainsaw in the reverse order. An important point is to seal the oil hose at the installation site, into the seat on the housing. It is necessary to rinse the hose and the hole for its installation with gasoline, then blow with compressed air until completely dry and coat it with sealing oil-resistant sealant, and then install it in place.

The control key of the Stihl 180 chainsaw is broken - how to fix it

A frequent breakdown of the Shtil chainsaw, which occurs due to the operator’s fault, is a malfunction in the operation of the engine control mechanism. More precisely, when the seat for the control lever breaks off due to its design features, solving this problem will require replacing the saw body, which is quite difficult to do on your own. Let's look at the do-it-yourself repair algorithm that involves replacing the chainsaw body:

- The body is freed from the handle block;

- The starter is removed; to do this, remove the caps from the fuel and oil tanks and unscrew the starter mounting screws;

- Next, a piston stopper is installed into the cylinder through the spark plug hole, the flywheel is untwisted and removed from the engine shaft;

- The drive sprocket is removed and the clutch is released;

- Unscrew two 8 mm nuts holding the air filter housing and carburetor, and remove the modules from their seats;

- At the next stage, the 4 screws holding the engine to the body are unscrewed. Special bushings are mounted into the body of the Shtil 180 chainsaw at the location where the engine mounting screws are installed, which can fall out on their own and get lost.

- The last point is to remove the oil pump, carburetor rubber elbow and fuel and oil tanks.

The parts must be installed in the new housing in the reverse order. In parallel with eliminating the main malfunction, you can check the rubber elbow of the carburetor; a part that has exhausted its service life and has lost its elasticity must be replaced.

Replacing oil seals

How to repair a Shtil 180 chainsaw if the seals need to be replaced? It is necessary to disassemble the engine, which will first require removing it from the chainsaw. Removal is carried out according to the algorithm described in the paragraph: “The control key of the Shtil 180 chainsaw is broken - how to fix it.”

After the engine is removed, the 4 screws securing the engine pan are unscrewed, after which it is removed. Thus, by removing the pan, we gain access to the seals and bearings of the crankshaft.

An important point when replacing oil seals is to reinstall and seal the pan.

To carry it out efficiently, it is necessary to clean and degrease the pallet and its installation location on the saw cylinder, and then coat it with sealant and install the pallet, tightening it crosswise to the required force.

When installing the pan, it is important not to confuse the location and install it in such a way that the casting to hold the oil pump is located in the opposite direction from the flywheel, otherwise it will be impossible to put the engine back into the saw body.

READ Carburetor Adjustment for Carver Chainsaws

Reassembling the chainsaw after repair is carried out in the reverse order.

How to Replace the Starter Cord

Quite often the starter cord needs to be replaced due to a break. Let's figure out how you can replace it without contacting a service center.

Removing the starter from the Shtil 180 chainsaw is quite simple, without even removing the handle block; to do this, you will need to unscrew the mounting screws and remove the covers of the oil and fuel tanks. Then, slightly lifting and turning the starter, remove it from its seat.

The starter cord is wound on a special drum, which is installed in the body of the part. To replace the cord, there is no need to remove the drum; just remove the broken cord and wind a new one.

Use original Stihl cord of the correct diameter for replacement. If the cord is thicker, the number of turns of cord wound on the drum will decrease, which will lead to a decrease in the starter stroke.

After the cord is wound on the drum, it is necessary to pass it through the starter body and install the handle and secure it with the help of several knots made one after another. Next, the working stroke of the starter is checked, and if everything is in order, the part is installed in place.

Video showing how to replace the starter

You can see it yourself below. The master comments in detail on all stages of the replacement, starting from removing the starter and ending with installation.

Starter malfunctions and their elimination

What other problems occur with the starter? One of them is the failure of the return spring, the restoration of which is impossible and the part will need to be replaced.

It is recommended to do this at a service center, because... The process is quite complex and requires some practice.

Another method that can be used to eliminate a starter malfunction is a complete replacement. As a rule, an assembled starter can be easily purchased at a specialized store, and replacing it as an assembly can be done without any experience.

Ignition adjustment Stihl 180

Shtil MS 180 chainsaws are equipped with an electronic ignition system, the adjustment of which boils down to setting the gap between the flywheel and the ignition coil of the Shtil 180 saw. To adjust, you need to remove the starter, loosen the two screws securing the ignition coil and install a strip cut from a plastic bottle between the flywheel and the coil contacts tighten the fastening screws.

Replacing the starter cord of a Shtil 180 chainsaw.

To check the gap, you need to rotate the flywheel and check whether the coil contacts are touching it.

Results

The Stihl MS 180 is a fairly reliable saw, but if used incorrectly, using low-quality lubricants, or due to operator negligence, malfunctions may occur. To repair a saw with your own hands, you must have certain knowledge and a special tool, without which repairs are impossible. Do not forget that the Shtil 180 chainsaw is a technically complex tool and its maintenance is best carried out at a service center.

How to Remove the Oil Pump of a Shtil 180 Chainsaw

Country affairs

Chainsaw Shtil 180 oil supply repair

The STIHL MS 180 chainsaw is an indispensable tool designed for harvesting wood and other wood construction work. It is one of the most recognized gardening devices that is armed with functional capabilities.

The weight of the tool is about 4 kg. The power reaches 1.5 kW, and the bus length is 35 cm.

Note that this saw model received electric ignition and a fairly fast chain tension from the semi-professional device. In addition, the STIHL MS 180 saw has 2 tanks, designed for gasoline and for oil consistency.

One of the main features is reduced vibration.

This result is achieved thanks to 4 shock absorbers. It is no secret that high depreciation has a harmful effect on human and Europe has been fighting it for a long time.

Basic faults

The chainsaw must be used according to the operating instructions, then it will last a long time and will not fail. All possible malfunctions of the Stihl chainsaw can be identified and eliminated independently. Let's look at the main problems that can arise in the components and design of the device, and how to repair the Shtil 180 chainsaw yourself.

Pouring a candle

If you notice that the spark plug on your Shtil chainsaw is flooding, then there may be a malfunction in the fuel system. The engine must run on a mixture of gasoline and oil. If the mixture is lean, then the power decreases, the cylinder overheats and the saw systems wear out. A wet spark plug on a Stihl chainsaw occurs due to an imbalance in the fuel mixture. Lack of air in the mixture prevents the emulsion from burning properly.

Using low-quality gasoline can cause engine wear.

Oiling of the spark plug also causes the use of oil for 4-stroke engines and wear of the pistons. If such a malfunction occurs, you need to remove the gas tank cap and adjust the fuel supply. The air intake should be in good condition. A clogged filter must be blown out with air, or better yet, replaced. How to clean the filters is described in the operating instructions for the chainsaw.

The quality of the mixture can be determined using a spark plug insulator. If a brown color appears on it, this means that the quality of the mixture is normal. White color or soot indicates a poor or over-enriched mixture.

The cause of oiling is the candle. Interruptions in spark formation are observed when the gap is set incorrectly. The repair and operating instructions for the device give the distance between the spark plug contacts. If you do not have such data, then you can set 0.7-1 mm.

If the gap is smaller, then the efficiency of ignition of the mixture decreases; if it is larger, then interruptions in spark formation occur. To eliminate over-enrichment of the mixture, the engine is purged. In this case, you need to remove the spark plug and turn the crankshaft several times with a manual starter.

The chain is not lubricated

When repairing a chainsaw, you may notice that no oil is getting onto the chain. If the chain is not lubricated, it means there is a problem with the lubrication system. There are such malfunctions:

- The chain is dry, light in color.

- The chain stretches too quickly.

- The tire is too hot and the paint on it has melted.

- The oil in the tank does not decrease.

- With a sharp chain, the saw began to cut worse.

Such signs indicate that a violation of the lubrication process has occurred. To check the oil supply to the lubrication unit, you need to remove the tire and turn on the chainsaw. Then increase the speed and observe the end point of the oil line. If oil flows, it means that its volume is not enough for proper lubrication. If there is no supply, you need to clean the filter. The oil supply should also be adjusted. If there are no malfunctions, further diagnostics and DIY repairs are required. If it turns out that the substance is not supplied, then the oil system is repaired.

Let's look at the main faults and methods for eliminating them:

- Broken oil hose. This can be seen upon inspection. In this case, the hose must be replaced.

- If there is no thread on the oil pump shaft, it should be replaced.

- If there are any defects in the thread, it must be replaced.

- If the main shaft corkscrew is missing, you can install a nail of the same diameter in its place.

- The filter may be clogged. This happens often with the Stihl MS 180 saw. You can wash it with gasoline. If this does not resolve the problem, the filter should be replaced.

The Shtil 180 chainsaw often has depressurization of the oil line. This occurs where the oil line coming from the tank is inserted into the body of the tool. A breakdown can be detected by oil leaks at the bottom of the saw.

To fix the problem, you need to remove the saw handle and pull out the hose. After this you need to clean the hose. Then apply sealant to it and place it in the tool body.

Doesn't start

If the chainsaw does not start, the cause may be a breakdown of the ignition and engine starting unit. If no deviations are found when measuring the gap between the module and the flywheel, then you should check the spark plug. They pull it out of the shaft and measure the gap. If fuel enters the combustion chamber, but there are no breakdowns in the ignition system, then the carburetor is faulty.

Doesn't develop speed

If the saw does not maintain idle speed, then the following may have happened:

- filter clogging;

- violation of the ignition system;

- the carburetor has deteriorated;

- engine parts were deformed.

To do the repair yourself, you need to do the following:

- Clean or replace the fuel hose.

- Clean the filter.

- Check the quality of gasoline and oil.

- Check the operation of the carburetor and spark plugs.

When your Stihl chainsaws are repaired, they will work properly.

If the saw does not gain momentum, then this could be caused by:

- faulty engine;

- cylinder wear;

- failure of piston rings;

- spark plug failure;

- coil malfunction;

- unbalance of carburetor screws.

If after testing no defects are found, then check the carburetor.

How to install a bar with a chain on a chainsaw?

Often problems in the operation of a chainsaw arise when the tire is installed incorrectly. This can be determined by the characteristic rattling, vibration and low productivity of the saw during operation. The fastening of the tire to the body is located between the outer plate, fixation is carried out with a special bolt.

This part is popularly called the “engine assembly” and consists of the drive sprocket and locking bolts. Installing the bar together with the saw is not difficult - you need to remove all the protective covers, unscrew the fixing bolts by a third of the length and install the headset. Then tighten all the nuts tightly and turn the tensioner with a special lever.

Tire installation on Stihl and Husqvarna

Models of chainsaws from the manufacturer Shtil may differ during the assembly process. Step by step guide:

- Open the wing nut and remove the protective cover of the chain sprocket. Turn it on the tire all the way to the right.

- Place the chain on the bar, starting from the top, with the cutting tooth on the top side pointing straight ahead.

- Place the assembled tire on the chainsaw and pull the structure onto the sprocket. Slide the guide onto the shoulder bolt. Close the lid by inserting the pins into the holes provided by the manufacturer.

- Turn the wing nut until the sprocket cover touches the engine housing.

- Turn the clamp bolt forward until the drive links fit into the grooves in the bar. Fully tighten the wing nut.

At the end of the work, check the tension; if the headset does not move well, adjust the tension with the nut. The chain brake must be engaged before starting.

The algorithm for installing a bar with a chain for Husqvarna saws is almost identical. The main difference is that in most models, the tension and adjustment of the location of the headset to the body is controlled not by one, but by two wing nuts. It is rare to find a separate adjustment lever on the outer sprocket guard housing, so tension adjustments should only be made with bolts.

Important ! Before starting to work with the chainsaw, you should carefully read the user manual. It describes in detail all stages of setting up and assembling the instrument.

How to disassemble, repair and assemble a Shtil chainsaw

To repair the device, it must first be disassembled. It is necessary to remove the side cover, saw chain and bar. Then clean the tool, blow it out with a compressor and clean all the components with a brush. Then remove the handle. To do this, remove the plugs from the shock absorbers using a screwdriver. After this, remove the shock absorbers and handle.

Then remove the starter. Remove the housing cover and unscrew the starter screws. Remove the part. Then remove the flywheel, unscrew the nut that holds it, and unscrew the flywheel nut. You need to turn left. Remove the flywheel. Then dismantle the clutch, oil pump drive and carburetor.

After this, the motor is removed and disassembled. It is held on by 4 screws on the bottom of the saw. You need to unscrew them and remove the motor. Then the engine itself is disassembled. Unscrew the crankcase screws and remove it. Then the crankshaft, seals, bearings and piston rings are dismantled. Upon completion of disassembly, repairs and troubleshooting are carried out.

After repair, the instrument will need to be put back together. To do this, install the piston on the connecting rod. The arrow on it should point along the chain, and to the left of the piston there will be the side of the crankshaft in which the flywheel needs to be mounted. Place the piston in the cylinder. Install the bearings, seals and retaining ring into the cylinder. After this, degrease the place where the crankcase is fixed and install it in its place. When reassembling, follow the reverse dismantling sequence.

How to remove the clutch

Before unscrewing the clutch, you need to remove the drive sprocket. Remove the corkscrew washer and remove the sprocket and needle bearing. Unscrew the clutch. Remove the reflector plate and pump.

How to remove and replace a sprocket

Replacing the sprocket on a chainsaw is necessary in cases where:

- jams chain movement;

- The drive sprocket has worn out.

To replace, you need to remove the chainsaw sprocket. The sprocket teeth must not deviate from the required dimensions, otherwise the operation of the saw will be accompanied by vibration, which will lead to damage to the crankshaft and bearings. The service life of the sprocket is 2 times longer than the working life of the chain. Use 2-3 chains until their cutting surface wears out. After this, change the sprocket. It is located behind the clutch. Remove the clutch assembly cover.

Remove the bar, chain and clutch. But first you need to fix the crankshaft. Then the puller is placed in the coupling hole and turned clockwise. Remove the coupling. Behind it is an asterisk. Now it is being dismantled. If it is faulty, it is replaced.

Oil pump repair and replacement

Let's look at how to change the oil pump. If the element leaks, the gasket between its two parts should be updated. If this part of the oil pump is not damaged, then it must be wiped and put back in place. Now check the hose. There should be no cracks on it. If the hose is damaged, it is replaced. Then they clean the outlet channels with a compressor.

Replacing the piston

Let's look at how to diagnose and replace the piston group. It is necessary to check the condition of the cylinder and the degree of wear of the piston. After dismantling the engine, unscrew the pan and remove the crankshaft and piston from the cylinder. Unscrew the piston pin stoppers. If the piston is faulty, it must be replaced. The retaining rings are fixed with the cut down. Before installing the piston group into the cylinder, lubricate the piston with oil. Before installing the crankcase, degrease its surface and apply sealant.

How to set the ignition

You need to turn on the ignition on the chainsaw. Ignition adjustment is carried out as follows:

- unscrew the spark plug and evaluate its appearance;

- specify the distance between the magnets and the coil (up to 0.2 mm);

- check the spark.

How to properly put a chain on a chainsaw?

In most chainsaw models, the chain can be easily put on the bar by unscrewing the main screw, then the links need to be placed on the drive sprocket. Before starting work, you should inspect the general condition of all cutting surfaces and the guide groove and installation wheel. Dirt and small chips often accumulate in it, which will subsequently lead to scheduled repairs and deterioration of gliding. Step-by-step algorithm:

- Loosen the screws securing the sprocket protective cover; it is usually tightened with a wing nut.

- Turn the tension sprocket to the right until it stops.

- Place the links on the headset, starting from the top. Drink so that they fall into the appropriate grooves.

- Reattach the chain sprocket mount and tighten the nut. The guides must fall into a special groove.

- Release the chain brake and pull the chain along the line of travel to check the tension. If necessary, tighten the tensioner lever. Figure 4 – Installing a chain on a chainsaw

The installation wheel should turn freely after installing the chainsaw chain. At the end of work, be sure to lubricate all moving parts of the tool to avoid rapid wear.

Important ! Installation of the headset should only be carried out while wearing thick protective gloves. This will protect you from injury and cuts from the sharp edges of the teeth.

Carburetor repair and adjustment

Carburetor adjustment is carried out on a warm engine. If the engine cannot be tuned, then the cause of excess gasoline in the mixture may be a stuck carburetor. To remove the part, you need to unscrew the fastening nuts, disconnect the ignition and linkage from the engine control lever. Then remove the lever. You can then remove the filter and carburetor.

The muffler is secured with two nuts. You need to unscrew them and pull the muffler towards you. Then unscrew the screws of the coil and dismantle it. The Stihl saw has a carburetor with 1 idle adjustment screw. If the idle speed is abnormal, the carburetor needs to be repaired. This is a complex process and difficult to do on your own. You should contact a repair shop.

Oil Pump Faults Shtil 180 Chainsaw

How to independently repair faults in a Shtil chainsaw: tips

repair the Shtil chainsaw independently due to the simplicity of the design. The tool, proven in the construction segment, has a power of 1400 W, an engine capacity of 31 cubic meters. cm.

The cost of repair work in the service is quite high. In many cases, their own technical knowledge allows consumers to repair the Shtil 180 chainsaw with their own hands.

The most common types of chainsaw malfunctions

The Shtil 180 chainsaw is operated in accordance with the instructions supplied with the tool. The user turns on the starting system after he is convinced of the presence of oil, gasoline, and makes sure that the chain tension is correct.

Work with the tool begins after it is securely fixed in your hands. If a failure of the tool is detected, it is necessary to determine what caused the malfunction of the Stihl chainsaw.

The reasons that caused to malfunction may be:

- the appearance of a leak in the oil system;

- formed breaks in the crankcase cord;

- carburetor malfunction;

- air entering the crankcase through the seals;

- worn condition of the worm gear in the oil pump;

- a spark does not appear at the ignition cross section;

- drive sprocket wear;

- violation of the integrity of the eye under the control lever.

To carry out independent repairs of a broken Stihl chainsaw, we use tools that are available to each consumer.

- screwdrivers;

- socket and wrenches;

- hexagons;

- a vacuum gauge used to determine defects in oil seals, carburetor, crankcase;

- an air compressor used for purging and cleaning components and assemblies;

- T-key STIHL Torx 27;

- a stopper that limits the stroke of the crankshaft;

- bearing puller.

Actions if a malfunction is detected in various parts of the unit

Such unpleasant phenomena as loss of power, lack of connection, and idle support are common. The reasons for this behavior of the tool are malfunctions of the chainsaw carburetor. This is expressed in contamination with particles of dust and sawdust. Such a breakdown can be easily repaired on its own.

The carburetor is cleaned using:

- a small amount of gasoline;

- Phillips screwdriver;

- brushes;

- heads, size 8.

Adjusting the Carburetor of the Shtil 660 Chainsaw

Do-it-yourself carburetor adjustment on a chainsaw

Adjusting the chainsaw carburetor ensures efficient operation of the tool at full power with economical fuel consumption. The adjustment must be performed with a clean fuel and air filter. For a larger number of carburetors, adjustment is carried out with 3 screws: for high and low speeds and idle speed .

Screws H and L adjust the ratio of the mixture of gasoline and air determined by the opening of the carburetor . For chainsaws Shtil ms carburetor adjustment instructions for chainsaw Shtil ms 660. When the screws are unscrewed, the mixture becomes richer, and the revolutions drop accordingly; when tightened, the mixture becomes leaner - the revolutions increase.

The designation H refers to the maximum speed screw that controls the main jet, L. to the minimum speed screw that controls the idle jet. Screw S is used to fine-tune the idle . The article discusses in detail the adjustment of the carburetor of a chainsaw with three adjusting screws, as well as the adjustment of the carburetor of a Shtil 180 chainsaw with one screw. Sometimes, to simplify setup, the number of available carburetor adjustment screws is reduced.

Setting up a chainsaw carburetor is divided into two stages - basic (factory settings), carried out with the engine turned off, and final, carried out with the engine running and warm. The exact value of the rotation angles should be taken from the operating instructions for the specific chainsaw. Failure to follow manufacturer's instructions may result in engine damage.

READ How to Adjust the Stihl Fs 55 Trimmer Carburetor

How to adjust a chainsaw carburetor. Chainsaw maintenance. Disassembling the carburetor of the Chinese Calm 660 chainsaw does not adjust the carburetor. Part 11

In this video we will answer the question of how to set up or adjust a chainsaw carburetor

with your own hands

Chinese calm IGNITION and CARBURETOR tuning!!!

In this video I will show you how to properly install the ignition on a chainsaw

and how to adjust

the carburetor

for gasoline.

Basic carburetor adjustment.

The adjusting screws for maximum H and minimum L revolutions are slowly turned clockwise until they stop, and then turned back 2 turns; other settings are also possible

Checking and adjusting idle speed.

We find the highest idle speed, to do this we slowly turn screw L in different directions. After finding the position of the highest engine speed, turn screw L 1/4 turn counterclockwise. The article discusses in detail the adjustment of the chainsaw carburetor with three adjusting screws, as well as the adjustment of the carburetor of the Shtil 180 chainsaw. If the chain rotates at idle, screw T or (S) should be turned counterclockwise until it stops.

READ How to Sharpen a Two-Handed Saw

Checking and adjusting the maximum speed.

Changing the maximum number of revolutions is carried out by screw H. When it is screwed in (clockwise rotation), the speed increases, when turned out. are decreasing. Chainsaw engines have the highest rotation speed from 11,500 rpm. up to 15000 rpm. A higher speed is not ensured by the ignition, in addition, it becomes dangerous for the engine. Limit speeds can be determined by interruptions in ignition. Adjusting the carburetor of the Shtil 250 chainsaw with your own hands. For the small compact mechanism of the Shtil 250 chainsaw, correct carburetor settings play a key role. If they do, screw H is turned slightly counterclockwise.

If the engine operation is not checked for acceleration and maximum speed, then the adjustment of the chainsaw cannot be considered complete.

When you smoothly press the gas trigger, the engine should confidently and quickly pick up speed from idle to maximum speed (from 2800 rev. to 11500-15000 rev., depending on the unit). Adjusting the carburetor of a chainsaw Stihl ms 660 video. If the speed is gained slowly, with a delay, screw L must be slowly turned counterclockwise , but no more than 1/8 of a turn.

READ How to Adjust a Stihl 211 Carburetor

After adjusting the acceleration and maximum speed, you should again check the operation of the saw at idle speed. The engine must run steadily and the chain must not move. The chainsaw adjustment must be repeated if this condition is not met, except for the basic adjustment stage.