Saw manufactured in 2010. It is used mainly in the country and on annual trips to Karelia in August. I wouldn’t say that I completely trashed it; rather, it was used sparingly and sparingly. I didn’t build her a house from timber. So, fell the tree, saw off the pillar... And for a year now I have been suffering from this problem: there is always a puddle of oil under the saw. Leaking from the chain lube reservoir. I changed the pump 2 times, changed the rubber band into which the pump piston is inserted - one hell of a leak. In the summer, a full tank can leak overnight. After a long period of experience, I established that the leak was not from the pump, but from under the metal strip, which is under the “tire”. Behind it at the top there is a hole with a piece of PVC pipe inserted into it, which goes into the oil tank.

So, it constantly flows from there. I tried to leave the saw on its side, and twisted it this way and that... No matter what you do, there’s a puddle under the saw. Has anyone encountered something similar? Is it really possible to cure or will I continue to suffer forever? Nothing was flowing before...

Chainsaw Shtil 180 oil supply repair

The STIHL MS 180 chainsaw is an indispensable tool designed for harvesting wood and other wood construction work. It is one of the most recognized gardening devices that is armed with functional capabilities.

The weight of the tool is about 4 kg. The power reaches 1.5 kW, and the bus length is 35 cm.

Note that this saw model received electric ignition and a fairly fast chain tension from the semi-professional device. saw chain from a chainsaw. you will understand why it leaks: Why oil leaks from under. In addition, the STIHL MS 180 saw has 2 tanks, designed for gasoline and for oil consistency.

One of the main features is reduced vibration.

This result is achieved thanks to 4 shock absorbers. It is no secret that high depreciation has a harmful effect on human health and Europe has been fighting it for a long time.

It must be emphasized that it is not better to disassemble this saw without the help of others without special instructions; in this case, it is better to entrust the device to the craftsmen.

STIHL MS 180 oil supply repair

Owners of this model of tool should be prepared for the fact that they may encounter such a nasty moment as a leak of oil to lubricate the chain. It's definitely not leaking from the chain, it's leaking from under the linings. Oil leaks from the very beginning. Well I do not know. Oil can leak out while working with equipment and even when just lying idle.

What is the reason for this phenomenon? The fact is that oil leaks due to density problems in the area where the hose from the oil tank and the pump connects.

In order to solve the STIHL MS 180 problem related to the oil supply, purposefully disassemble the device.

Solution to the problem:

- Check the hose; if it is damaged, replace it with another one. Or try to degrease the hose, wash it, and put it on sealant, everything should work.

- Check the filter oil for damage, clean it (if you filled in waste oil)

- It may also be due to a clogged ignition, which creates a vacuum in the fuel tank and affects the fuel supply. The problem may be in the adjustment of the carburetor and the channels, or the air filter, may be clogged; you need to thoroughly clean the filter and carburetor channels.

How to disassemble and assemble a Shtil 180 chainsaw: algorithm, nuances, video

Stihl MS 180 is a reliable and unpretentious tool, but sometimes it requires repair, like any equipment. In this article we will look at how to disassemble the Shtil ms 180 chainsaw, which is necessary in case of major engine repairs.

Preparatory stage

Repair of any equipment must begin with the preparatory work stage, and the Stil 180 saw is no exception.

At the preparatory stage, before disassembling the Shtil 180 chainsaw, it is necessary to remove the side cover, chain and tire from the chainsaw.

Next, using a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil stains and other things.

When cleaning the saw, special attention should be paid to the place where the chainsaw drive sprocket is located, since this is the most contaminated area.

In places where there is a large accumulation of oil, you can wash it with clean gasoline.

Removing the handle

Direct disassembly of the Shtil 180 begins with removing the handle, which is attached to the chainsaw body using three rubber shock absorbers.

To remove it, you need to remove the plastic plugs from the internal cavity of the shock absorbers, then using a powerful screwdriver, first press out the upper shock absorber, then the one closer to the rear handle.

At the rear of the handle there is a throttle trigger, which is connected to the carburetor through a wire rod; in order to disconnect the rod from the gas trigger, you need to unscrew two screws and disassemble the handle.

When the handle remains on one shock absorber, you need to unscrew the chainsaw body from the inside of the handle and, bending it to the side, remove the body from the last rubber band.

Removing the starter

At the next stage, the top housing cover is removed and the 4 starter mounting screws are unscrewed, after which it is necessary to remove the covers of the oil tank and fuel barrel. The starter is removed quite simply and there should be no problems.

After removing the starter, the opened internal cavity of the chainsaw must be cleaned, since there is usually a large amount of compressed small sawdust on the body under the starter.

Removing the flywheel

The flywheel of the Shtil 180 chainsaw is twisted with great force, so to remove it you will need a head with a metal knob. The nut holding the flywheel is unscrewed with a 13mm head.

To block the crankshaft from turning, you need to unscrew the spark plug and install a piston stopper through the spark plug hole; if there is none, you can use an old cord from the starter, with knots tied to it and immersed in the cylinder through the spark plug hole.

It is strictly forbidden to keep the flywheel from turning by installing a power screwdriver or other tools between its ribs and the body; with this method of blocking from turning, the flywheel blades are not able to withstand the load and break off.

Once the piston in the cylinder is locked, you can unscrew the flywheel nut. The thread in the nut is normal, so you need to turn it to the left.

Having loosened the nut, you do not need to remove it completely; just unscrew it until its upper edge is level with the tip of the shaft, after which a soft metal drift is installed on the nut and a sharp blow is made on it.

Thus, the flywheel jumps off the shaft from a sharp impact and can be easily removed without the help of additional tools.

Removing the clutch and oil pump drive

Before disassembling the clutch, it is necessary to remove the drive sprocket. To do this, carefully remove the lock washer from the grooves on the shaft and remove the sprocket and needle bearing.

With a high head of 19, you need to unscrew the clutch. The thread on it is left-handed, so it unscrews towards the bar, and not towards the rear of the Shtil 180 saw.

Having unscrewed and removed the clutch, you need to immediately remove the reflecting plate and the oil pump drive; this is easy to do, since they are put on the shaft without any fastening.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have a socket 8 and an extension, with which it is convenient to unscrew the nuts securing the carburetor and air filter.

Before dismantling the carburetor, it is necessary to disconnect the ignition wire and choke rod from the engine control lever and remove the lever, only after this the air filter and carburetor are removed.

The Shtil 180 muffler is secured with two nuts, which you need to unscrew to pull it towards you, it can be easily removed.

The coil is secured with two screws; to remove it you just need to unscrew them.

Removing and disassembling the engine

The engine is held in place by 4 screws installed on the bottom of the Shtil 180 chainsaw. To remove it, you need to unscrew them, and then carefully remove the engine from the seat and the rubber carburetor pipe.

To disassemble the engine, 4 crankcase screws are unscrewed and it is removed, then you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings were pressed onto the shaft with force, then a special puller will be needed for dismantling.

To remove the piston from the connecting rod, you will need to remove the retaining ring from the seat using a thin screwdriver, then press out the piston pin from the opposite side, after which the piston is removed to the side.

Assembling the Shtil 180 chainsaw

Putting the stihl ms 180 saw back together is quite simple, the main thing is to adhere to the following algorithm:

- Install the piston on the connecting rod, the arrow on the piston should point in the direction of the Shtil 180 chainsaw, and to the left of the piston should be the side of the crankshaft, which is intended for installing the flywheel;

- Carefully insert the piston back into the cylinder, the place for mounting the coil should be on the side where the flywheel is installed on the crankshaft;

- Install the bearings, seals, retaining ring on the shaft and lower the entire assembly into the seat in the cylinder;

- Next, degrease the crankcase installation site and the crankcase itself, then coat it with sealant and, once installed, tighten the 4 fastening screws;

What kind of oil to fill for the Stihl 180 chainsaw (stihl 180)

- Don't spare money on original oil. Stihl HP 2-stroke oil costs a little more, but cleaning costs even more.

- You need to pour high-quality fuel into the fuel, you can use Mobil 1, and three-phase is suitable for lubrication; under no circumstances should you pour waste oil into it.

- Of the inexpensive options, mineral oil is 15-40, in winter 10-30. You can use M8, for example, or M10.

Remember personal safety when working with a chainsaw.

Remember that the performance of the chainsaw is affected by the quality of the oil being poured. Advantages of the Husqvarna 240 chainsaw. Why does gasoline leak from the Husqvarna 240 chainsaw? Poor quality oil can cause the tool to operate ineffectively and adversely affect its parts.

To ensure that the STIHL MS 180 oil pump delivers oil without difficulty, check and clean the pump periodically. OIL IS LEAKING Oil is leaking from the chainsaw. A brief overview of why there is oil in a chainsaw. Thus, the oil supply process will be normal.

Semi-synthetic oil of the Stihl brand

Very often, owners of such chainsaws wonder what kind of oil can be used for the saw. Its operation may be affected by:

- cutting set;

- climate;

- wood species

To solve this problem, the Shtil company developed a universal semi-synthetic oil. It is suitable for all high-speed chainsaws. Under any conditions, chains can be lubricated with this oil. The tool will work flawlessly.

Read also Kakra recipe with photos

Since Shtil semi-synthetics are intended for chains, they are made from special high-quality materials and do not contain various toxic substances that can cause cancer. The oil fully meets the most stringent environmental requirements.

The Russian climate is quite harsh. There are areas in our country where frosts often exceed -20°C. The latest Stihl chainsaw chain oil has been specially developed for use in cold conditions. In such frost it demonstrates excellent fluidity.

Special additives included in the oil prevent the cutting set from becoming oily; they will extend the life of other lubricated parts. A saw with this oil starts easily even after long-term storage.

The use of such chain lube reduces wear on the saw chain. Due to the high endurance of the oil at high temperatures, the cutting set is ideally protected. This oil is not afraid of peak temperature loads. Smoke almost never appears.

Of course, anyone who owns a chainsaw knows how important good quality oil is. And, everyone dreams, there is no need to say what it really is, that this is the typical “life force” of a given device for producing real and effective work. Today there is an unlimited number of oils and, as the saying goes, the choice is very large.

But, often, not every owner of electrical equipment of this kind knows what kind of oil to use for his steel friend, so that the operation of the chainsaw is not only easy, but also productive. Therefore, below we will discuss the issue regarding the correct choice of the manufacturer of the calm. Also, what it is to help the chainsaw in its time of its specific activity, and not harm. Let's get started with what we need.

Carburetor STIHL MS-180

The STIHL MS-180 carburetor is equipped with one idle speed adjustment screw. The full load jet is not adjustable, meaning it cannot be changed.

You need to know the basic rules for setting the idle speed:

1) check the air filter, if necessary, change it;

2) check the spark-proof grille, if necessary, change or clean it. You can then turn on the engine and then warm it up.

STIHL MS 180 carburetor repair

Repairing a STIHL MS 180 carburetor is a very difficult process. Note that during repairs there is practically no risk of sudden changes in the cylinder-piston group.

If the chainsaw does not start, then follow these steps:

1) open and close the gas tank cap;

2) it is advisable to remove the candle and then dry it;

3) ventilate the combustion chamber.

If after this there are no positive results, then it is better to check the condition of the air filter, the gasoline supply process and the functioning of the spark plug.

This problem is associated with a valve (slepun), which becomes clogged, and as a result a vacuum is formed. Everything about repairing a chainsaw with your own hands. My chainsaw is leaking oil for no reason. To eliminate this inconvenience, you need to clean the valve (slepun) with a needle.

Systematically check the filter; if the muffler is clogged, the device will not be able to deliver the power that is put into it.

If the chainsaw was purchased with a warranty (as a rule, there is no other option), immediately take it to the service center.

Thus, the STIHL MS 180 chainsaw is very easy to use, has good ergonomics and a number of significant advantages.

One of the important chainsaw systems, without which work is impossible, is the forced lubrication system of the chainsaw chain. It's no secret that when the saw is running, the chain rubs against the chainsaw bar, which causes it to heat up and cause premature wear. To soften friction, the chain mechanism must be constantly lubricated.

Repair Chainsaw Shtil MS 180 Do It Yourself

With all the variety of modern building materials, wood species remains very important. That’s why woodcutters, landscaping workers, and summer residents are interested in woodworking tools, in particular chainsaws.

The Shtil chainsaw is easy to use, inexpensive, reliable, and has a long service life.

Different people prefer different brands. Someone is interested in the Partner chainsaw, someone is interested in the Shtil brand device, someone is interested in something else. Alas, they break periodically, and their breakdowns are both similar and different. Next, we’ll look at repairing a Shtil chainsaw in makeshift conditions.

This brand is well known both among experts and among individuals involved in arranging their own living space. The great popularity of the Stihl chainsaw determines the frequent practical use of this tool and forces one to find methods for an effective snowball fight with its usual breakdowns.

Design of the Shtil chainsaw.

Before you begin disassembling the faulty mechanism, you should prepare the proper tools. Because a chainsaw is a relatively simple device at a technical level. This common rumor list is small and includes:

- Screwdriver Set;

- spanners;

- set of socket wrenches;

- igloo

In order to carry out a real high-quality restoration of the working condition of the Stihl chainsaw in artisanal conditions, you need to accurately determine the reasons for the breakdown. Since the designated chainsaw refers to mechanisms driven by a gasoline engine, the main malfunctions are associated with this unit.

The most common faults encountered in operation of a Stihl chainsaw are the following:

- no engine start;

- unbalanced operation of the internal combustion engine immediately after startup, under the influence of which, after short-term operation, the unit spontaneously turns off;

- the running engine does not reach full power;

- oil is leaking.

Shtil chainsaw carburetor design

One of the frequent breakdowns of the sawing device is also a break in the working chain. However, it does not apply to the dilemmas that arise during the operation of the motor accounting system. Usually, repairing a broken chain comes down to replacing it with a new one.

Finding the fault that caused the chainsaw to fail is done in the following order. First of all, check the gasoline level in the tank. If our client’s level remains fine, proceed to inspect the starting device. If the trigger mechanism does not show signs of failure, you need to check the spark plug.

READ Launch of Chainsaw Shtil MS 170 Show Video

If, upon completion of a painstaking inspection and checking the correctness of the gap, it is determined that the spark plug is completely serviceable, then the carburetor may be the cause of the problems that force the chainsaw to be repaired. This often happens because the device routinely gets clogged.

But if the old spark plug is replaced with a new one, the carburetor is completely cleaned, and the chainsaw in any case does not start, or, in other words, once it starts working, it quickly stalls, then in all cases you will be more likely to blame a faulty cylinder-piston group (CPG). To be able to thoroughly check the entire group, you will have to spend a couple of weeks disassembling the designated system 100 percent. Under such circumstances, the technical condition of the cylinder, piston and piston rings is checked.

And now we will look at each malfunction in a little more detail.

As mentioned earlier, the examination of a faulty sawing tool should begin with establishing the presence of gasoline in the fuel tank, and additionally with determining the technical condition of the breather.

Stihl ms 180 carburetor repair

Repair of a Shtil chainsaw in case of a malfunction of the fuel supply accounting program.

When checking the fuel level, be sure to open the gas tank cap. This should be done even if there is a passage, if the owner of the tool can be sure that there is gasoline in the tank.

Often the saw is unable to start due to fuel not entering the combustion chamber. The prerequisite for this in most cases is the usual clogging of the breather - a special bypass valve that serves to equalize the pressure in the container with the gradual consumption of gasoline. Then repairing a chainsaw comes down to carefully cleaning the breather with a regular sewing needle.

A prerequisite for the failure of the entire tool will most likely be an inoperative starting mechanism or problems in the ignition system. If it turns out that the starting device works as usual, then you need to make sure that the spark plug is working properly. If you set a goal to do this, unscrew the spark plug from the socket and carefully inspect it, looking for the presence of foreign deposits on its electrodes.

Chainsaw starter device.

It should be noted that the presence of traces of a certain characteristic at the site of spark formation speaks very eloquently about the sources of “disease” of the entire starting accounting system. Such a source, namely, and possibly a carburetor. Thus, the complete absence of any signs of fuel on the spark plug (its complete dryness) probably indicates that fuel does not pass into the combustion chamber due to the carburetor being clogged.

READ How to Replace the Breather on a Husqvarna 357 Chainsaw

On the contrary, gasoline is fixed on the spark plug of the chainsaw, but the cutting device itself does not work normally, this indicates an excess of air-fuel consistency. The prerequisite for this condition is a failure in the carburetor adjustments, clogging of its jets, and incorrect starting of the mechanism. For which the design is intended to fix the corresponding carbon deposits on the spark plug, of course, one can speak with sufficient confidence about the incorrect functioning of the carburetor; otherwise, about the use of low quality gasoline.

The STIHL MS 180 chainsaw does not start easily. carburetor repair. Repair and carb tuning

If all of the above signs are reflected on the spark plug, you need to remove the carburetor and check its technical condition. If a blockage is detected, the carburetor should be carefully cleaned, then the device should be adjusted according to technological requirements and the gasoline used in the tank should be changed. With all this, you must always keep in mind that a carburetor is essentially a rather complex unit, consisting of a huge number of small components, parts and channels. Therefore, its repair must be carried out with special care and precision.

In addition to restoring the carburetor, you need to check on the panel the functionality of the spark plug itself, if necessary, set the correct gap there. On the contrary, I don’t like the candle and its work at all; it is recommended to replace it with a new candle.

When the tool engine does not start or operates with obvious interruptions and without reaching the rated and maximum power due to a malfunction of the cylinder-piston group. In this case, repairing a chainsaw at home is done in the following sequence.

The 4 bolts on the cylinder head are unscrewed, after which the cylinder is removed from the block. The piston is carefully checked for the presence of chips, scratches, and burrs. Their presence is unacceptable and requires a piston change. Therefore, there is no slightest mechanical damage on the cylinder itself. Of course, it can either be repaired by boring the mirror to the repair size of the piston, or replaced with a new one assembled with the piston.

READ Adjusting the Idle Speed of a Hooter Chainsaw

Of great importance for ensuring rational pressure in the combustion chamber is the absence of signs of wear on the piston body and piston rings. For this reason, the normal functioning of the chainsaw motor largely depends.

You can find out the degree of wear of parts only after removing the piston group from the engine. The rings themselves must be quite tight and at the same time sit freely on the piston. In the assortment set, as it is also called, the absence of wear on the piston and rings can be verified by an experimental method. For this purpose, the piston inserted into the cylinder should be slightly swung in different directions. A very free piston stroke probably indicates wear.

stihl 180 carburetor repair

To eliminate the indicated drawback, either they bore the cylinder and install repair parts, or change the entire set of CPGs. Otherwise, the chainsaw will not develop the required power.

Repair of the chainsaw is required and for which the design is intended, unless of course there are problems with the lubrication system. In most cases, they are carried out without supplying oil to the chain; this fact is evidenced by the obvious dryness of the chain, as it is also called when oil leaks.

The lubricating fluid either poorly or does not flow to the chain at all, usually due to clogging or blockage of the oil supply channels. To identify places where the oil flow is blocked, you need to carefully examine the oil hose and its connection points. Today, you should definitely clean the oil filter.

If oil leaks, this indicates a violation of the tightness of the oil channels or hose. This usually occurs due to mechanical damage. In most cases, the unusable hose is removed and a new one is installed in its place. However, from time to time, the least specific method is used, treating the warped hose with a suitable sealant.

Thus, the repair of the Stihl chainsaw, due to the relative simplicity of its design and the fundamental similarity of its unit with many other internal combustion engines, is carried out on its own. Moreover, this can be done in an ordinary home environment, without resorting to the help of repair specialists.

Source

Chainsaw chain lubrication system

To supply oil to lubricate the chainsaw chain, the tool uses a special pump, which delivers lubricant to the saw bar in a dosed manner, depending on the number of engine revolutions.

The system uses oil to lubricate the chainsaw chain, which has increased adhesive properties; this is necessary for uniform distribution of oil along the entire perimeter of the bar and retention on it even at high rotation speeds of the chain. Let's take a closer look at the oil supply system implemented in modern chainsaws.

How to remove and replace a sprocket from a chainsaw?

Many owners of gasoline chain saws, after a breakdown of the device, are concerned about the question of how to remove the chainsaw sprocket.

When replacing a sprocket, all work must be carried out carefully and with caution.

The design of the chainsaw device is a classic mechanism that is driven by an internal combustion engine. The design of the unit uses one of the simplest single-cylinder two-stroke carburetor engines that runs on gasoline.

The simplicity of the engine design and the design of the chainsaw as a whole is the key to trouble-free and reliable operation of the device in difficult operating conditions. Operating a chainsaw does not require a large amount of knowledge and skills from the operator.

The only condition for long-term and uninterrupted use of the device is regular technical inspection and maintenance of the device. While working with the device, it is necessary to regularly replace wearing parts.

To reduce tool wear, you should monitor the quality of saw chain lubrication, its tension, the degree of chain wear and the degree of wear of the drive sprocket.

Before repairing a chainsaw, you should study its design. To replace one of the main structural elements of the device - the drive sprocket - it is necessary to study the mechanism of operation of the unit's clutch.

Unit clutch design

Chainsaws are units that are equipped with drive sprockets, which are a single complex with a clutch basket.

The clutch operates automatically, depending on the engine speed.

The units are equipped with a centrifugal clutch, which operates automatically, depending on the number of engine revolutions.

When the engine of the unit is running at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the radial direction.

The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

When the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of elements with friction linings. These elements are pressed against the inner walls of the drum under the action of centrifugal force.

Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool. The chainsaw sprocket can be located either outside the tool or under a special cover, which protects the mechanism from damage and the operator of the device from injury.

The main advantage of this type of clutch is that when the saw chain jams, elements with friction linings slip, which protects the internal combustion engine from serious damage.

The main reasons for replacing the drive sprocket

The Allen wrench is the main tool you will need when replacing the sprocket.

The most common reasons that force tool repairs associated with replacing the drive sprocket are:

- chain jamming due to defects occurring during operation of the unit;

- high sprocket wear as a result of long-term operation of the unit.

With regular use of the device, increased wear of the drive sprocket occurs as a result of increased loads placed on it during the process of sawing wood. There are two ways to operate the device:

- use of one saw chain;

- using several saw chains alternately.

When using the first method of operation, the chain is operated until it is completely worn out. This method has several disadvantages. The main one is the problem with monitoring wear during intensive operation of the unit.

When using two or more chains in the process, it is possible to achieve uniform wear of the chains and sprocket, which allows you to extend the period of operation of the device before repairs, which involve replacing the sprocket.

In addition to sprocket wear, you should not forget about the bearing that is installed in the sprocket. This structural element operates at any engine speed. When replacing the sprocket, the bearing must also be replaced at the same time.

The coupling complete with sprocket must be replaced promptly.

If repair work is not carried out in a timely manner during operation, the tool experiences increased vibration, which leads to increased wear of the bearings installed in the internal combustion engine on the crankshaft axle shafts.

The maximum wear depth of sprocket teeth should not exceed 0.5 mm. The life of a sprocket is twice as long as one chain, so two chains should be used during operation. After the life of the chains has expired, the chains and drive sprocket should be replaced at the same time.

Algorithm for replacing the clutch drum

For trouble-free use of the chainsaw, regular technical inspection is necessary.

When replacing the clutch drum, only a strictly defined type of structural element of the device should be used for installation. When replacing the drum, the bearings of the structural element should be changed at the same time.

To carry out repair work, you should purchase a special repair kit, which contains a drive sprocket and a bearing.

After purchasing a repair kit, you should prepare the materials and tools required for repairs.

The main tools that will be required when carrying out repairs are the following:

- a universal key that comes with the chainsaw;

- piston stopper, can be made of plastic or metal;

- special puller for the centrifugal mechanism or clutch drum.

The work procedure consists of several stages. Each stage has its own characteristics depending on the design features of the chainsaw, but the scheme and sequence of work is the same for any model of the unit.

At the first stage, the saw set is dismantled and the cover of the guide bar is removed. After removing the cover, the guide bar and saw chain are dismantled. Unscrewing the fastening nuts is carried out using a universal wrench, which is included in the delivery package of the unit.

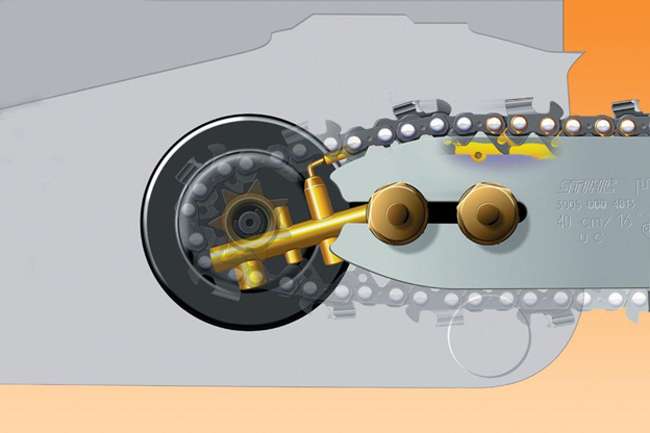

Lubrication system design

Depending on the brand of chainsaw, the parts of the lubrication system may vary slightly in design, but their total number and connection diagram remain the same.

The main components of the lubrication system are:

- an oil tank located, as a rule, in the engine crankcase.

- The filter element is installed in the tank.

- The oil line is a small diameter hose made of oil-resistant rubber.

- The heart of the system is the oil pump.

- The worm gear transmits force from the engine to the pump.

- The chainsaw tire can also be considered an element of the lubrication system, since it has special holes for supplying oil. By the way, the chain itself is involved in transporting oil and, accordingly, also has some elements designed specifically to provide lubrication.

Principle of operation

The main unit of the system is the pump. The principle of its operation is as follows. As engine speed increases, a gear mounted on the main shaft drives the pump shaft through a worm gear. In turn, the rotation of the shaft creates a certain pressure in the oil line, which forces the oil to move along it towards the tire.

The end of the oil channel is located at the point of contact of the tire with the tool housing, where there is a longitudinal groove into which, when installing the tire, its oil channel falls.

The groove is necessary to ensure the supply of oil to the bar, regardless of the degree of tension of the chainsaw chain. Simply put, no matter what position the tire is in at the time of operation, oil will get onto it through the groove.

Next, the lubrication process includes a chain, on the links of which, depending on the chain model, there is either a groove or a hole through which the oil is dispersed throughout the tire. As engine speed increases, the oil flow rate also increases.

Some models of chainsaws are equipped with pumps that additionally have capacity adjustment, and if necessary, the amount of oil supplied by the lubrication system can be increased or decreased.

This function is quite convenient, because it allows you to save money and not waste extra oil.

Main characteristics

The Shtil chainsaw chain lubrication system consists of:

- guide bar;

- saw chain;

- oil pump.

The oil supply by the pump has a special adjustment. The chainsaw chain is lubricated constantly during operation of the device. Therefore, chainsaw chains have a long service life.

During operation, the chain requires a constant supply of lubricant. Its continuous supply must be ensured. This is required by the design of the device. While the chainsaw is running, the oil leaves the bar groove and is instantly absorbed by the sawdust.

For this reason, the chain is lubricated automatically. Some chainsaw chains are equipped with a system that regulates the exact amount of lubricant supplied. The cheapest devices are equipped with a hand pump, which is powered by a drive located on the handle.

Scheme for checking the operation of the chain lubrication system.

A special oil has been specially developed for good chain lubrication. After use, it quickly decomposes, so there is no disruption to the ecological system. You can also use the following brand oils:

The gear lubricant is absolutely not suitable for the job. In winter, it hardens, as a result the oil system becomes clogged, and you have to clean it completely.

In winter, chain lubrication requires special attention. in severe frost it thickens and resembles Vaseline. Therefore, to operate in winter, it is necessary to lubricate chainsaws with special winter oil, which has a thinner consistency.

It is not always possible to purchase such a lubricant. To solve the problem, diesel fuel is mixed with oil, the viscosity is reduced. However, if the previously filled oil remains in the crankcase, then adding diluted oil will not have a positive effect; the system channels will remain clogged. There is only one way out - heating the chainsaw in a warm room.

Read also Gray-trunk birch 4 letters

If the chain oil does not solidify too much, you can try to melt it by running the saw at low idle speed.

Lubrication system malfunctions and how to fix them

The main malfunctions of the oil supply system on a chainsaw can be divided into two main types: these are general malfunctions inherent in all chainsaws and individual ones, which may vary depending on the type of pump and worm gear installed on a particular model. Let's begin to understand the faults in order.

Operating a chainsaw without lubricating the chainsaw chain is prohibited. This has a detrimental effect on the bar, drive sprocket and chain, and can result in significant repair costs.

Signs of a malfunction of the lubrication system, checking its performance

- The chainsaw chain is dry and has a pale tint without shine.

- The chain stretches relatively quickly.

- The tire is very hot and may even partially melt the paint.

- The oil from the tank is practically not reduced.

- Reduced cutting efficiency on a sharp chain