Motoblock MTZ and its purpose

The MTZ walk-behind tractor, or in other words Belorus 05, is one of the first walk-behind tractors produced by the Minsk tractor plant. Production of such equipment continued until the beginning of 1992, after which it was suspended and finally ended. The MTZ consists of a chassis with two wheels, which has a reversible steering bar, as well as a single-cylinder engine and power train.

This device can be characterized exclusively as agricultural equipment, with which you can easily:

- mow the grass;

- perform harrowing;

- hill up some vegetables: potatoes, beets;

- plow light soil;

- transport small items and cargo.

This model can be used to cultivate such small plots of land as vegetable gardens, various gardens, as well as areas located near estates, schools, and houses.

Useful videos

Different branded walk-behind tractors produced by well-known brands differ from each other in the design of the built-in ignition system. To know how to properly adjust this important element, we offer videos that contain the correct procedure for setting up the ignition system on the most common models of walk-behind tractors.

For walk-behind tractors of the Neva brand:

For models of the Agro brand: For agricultural units produced by the Ural brand; For Mole walk-behind tractors: For Zubr models: For Salyut brand walk-behind tractors: For Honda agricultural implements:

What should you pay attention to when purchasing a “Belarus 05”?

If you want to purchase a similar model of transport device, then you should pay attention to the following spare parts for the MTZ walk-behind tractor:

- Gearbox - the reliability of the entire device and its service life will depend on its design. If the walk-behind tractor is equipped with a non-removable gearbox option, then if it malfunctions, you will be forced to purchase new equipment, because it will no longer be possible to repair this vehicle.

- Engine. The engine is an integral part of this type of technology. The motor resource, as well as the power and strength of the unit itself, depend on this element.

How to set the ignition on a walk-behind tractor?

The following signs will indicate the need for urgent adjustment of the gap in the ignition system:

- the need to frequently pull the starter cord to no avail;

- delayed reaction of the walk-behind tractor engine to manipulations with the starter;

- complete lack of starting the internal combustion engine of the agricultural unit.

Each of these malfunctions indicates that the operator must install the ignition of the walk-behind tractor used on the farm. The correct procedure for this can be found in the operating instructions for the existing equipment. However, the operator does not always have the manual at hand. In this case, the gap between the built-in ignition module and the flywheel can be set in the following sequence:

- First, the operator must close the spark plug with a special square;

- Then its body will need to be pressed against the head of the standard cylinder of the internal combustion engine;

- Next, the spark plug must be turned in the direction opposite to the hole provided in the end of the chrome-plated cylinder;

- After this, you need to carefully turn the crankshaft of the internal combustion engine of the walk-behind tractor - to do this, just pull the trigger cord;

- As a result of these actions, a bright blue spark should jump between the built-in electrodes. If this does not happen, then it is necessary to check the distance between the magneto and the starter of the walk-behind tractor - it should be from 0.1 to 0.15 mm. If these requirements do not meet these requirements, the gap between the elements will need to be adjusted.

Many experienced users adjust the ignition of a walk-behind tractor by ear. Both contact and non-contact magnetos are suitable for this. To configure the system yourself, you must:

- Start the engine and slightly loosen the standard distributor;

- Slowly turn the breaker in each of the possible directions;

- Achieve maximum speed of the factory engine and quickly secure the structure;

- Listen and find the moment at which a spark instantly appears;

- Turn the breaker until there is a clear clicking sound;

- Fix the standard distributor fasteners.

Replacing the engine on the 05 Belorus

The Lifan engine is quite simple in its design and design; it runs perfectly on regular gasoline and does not require special costs or effort. The main and main advantage of this part is the availability of spare parts, as well as components necessary for repair work.

There is often a situation when one engine malfunctions and requires urgent replacement. Many are lost and do not know how to efficiently and correctly replace the engine on an MTZ walk-behind tractor. And it’s quite easy to do.

More and more often, people are starting to use walk-behind tractors at home and are experiencing breakdowns. Since it is now quite difficult to find Soviet-made spare parts, owners are forced to purchase and install modern or foreign models. The question arises: how to replace the engine on a MTZ walk-behind tractor with an imported one?

And here you should act according to the following plan.

- Replacing the engine begins with carefully disconnecting the gas cable, as well as the magneto wire, after which it is necessary to remove the fuel tank.

- Drain all existing oil.

- Disconnect the required part from the gearbox by unscrewing the 6 bolts connecting the gearbox to the engine itself.

- Next, install the Lifan engine and (if necessary) fill in the required amount of oil. For fastening you need to buy a new plate with a hub, cable and bolts.

- Check the condition of all parts.

- Connect the part being installed to the gearbox and install a new gasket. Tighten the bolts tightly. Install the cable.

- Connect the wire used for ignition and screw on the stand.

- Start the device, adhering to all the rules.

Walk-behind tractor ignition device

The ignition system is one of the most important components of both branded and homemade walk-behind tractors. Its main function is to generate a spark, which is needed for ignition and gradual combustion of fuel in the chrome-plated cylinder of the internal combustion engine.

The simplicity of the factory design of the unit allows you to perform your own repair of the ignition of a walk-behind tractor, which, most often, involves setting a gap between its elements. However, to do this correctly, you need to study the design of the unit.

The ignition device of any household agricultural unit includes a coil, which is initially connected to the electrical power supply of the system, as well as a magneto and spark plugs. When starting the power unit of the walk-behind tractor, voltage is supplied, as a result of which a pronounced spark is formed between the magnetic “shoe” and the standard spark plug. It is necessary for instant ignition of the fuel, which at this moment is in the combustion chamber of the engine. The photo will tell you more about the structure of the ignition system of the walk-behind tractor used.

The electronic ignition system of a walk-behind tractor is also often equipped with breakers that are triggered automatically when any unit malfunction occurs. This leads to an emergency shutdown of electrical power in the network.

Mini tractor from MTZ

Many MTZ owners upgrade their walk-behind tractor into a mini tractor. The easiest way to do this is with an adapter. It allows you to do most of the work while sitting on it.

For Belarusians there are special Horse type adapters. When modernized, the walk-behind tractor no longer resembles much of its former self. This turns out to be a regular smaller tractor. If you install it, then the speed of Belarus will change slightly, since he will have to not only carry the weight of the hitch, but also the Horse itself. But this loss will be insignificant, since Honda engines allow you to work with a load of up to half a ton. And Horse's weight is about 100 kg.

You can try to assemble and install the mini tractor yourself. There are a large number of different diagrams and drawings on how to do this. However, it is recommended to do this on your own only if you are confident in your abilities. Otherwise, the chances of modernization are extremely small.

With careful attention to work and timely maintenance of the MTZ walk-behind tractor, it will serve you for a long time.

source

Advantages and disadvantages

Among the advantages are the following:

- The gearbox is manual, stepped with 2 reverse gears and 4 forward gears.

- High speed of movement during operation.

- Economical consumption of fuel and oil in the walk-behind tractor.

- Availability of all spare parts on the market, which allows you to speed up equipment repairs.

- Wide selection of additional equipment.

- Low cost.

- Unpretentiousness to fuel quality.

- Long service life.

- Reliable construction made of cast iron.

- Multi-plate clutch with friction clutch.

- Reduced noise level during operation.

- Pneumatic wheels.

- Maneuverability and compactness.

- Convenient location of valves.

- Ease of operation.

- Steering wheel lock available.

- The unit operates even at low temperature conditions.

- It is possible to adjust the carburetor.

Disadvantages of this model:

- Difficulties in installing trailed equipment.

- Difficulty changing gears.

- Problems occur when disabling the differential lock.

- The oil must be changed every 100 operating hours.

- High cost of attachments.

This model was very popular in Soviet times, and remains popular to this day. It was produced from 1978 to 1992, and was used for preparing soil for sowing, cultivating crops, removing weeds and transporting various goods.

Features of the MTZ-05 walk-behind tractor

- The walk-behind tractor operates using one axis. MTZ-05 was developed as an alternative to full-fledged tractors if there is no need to carry out work on large areas. It can easily transport loads weighing up to half a ton.

- Belarus-05 has a power take-off shaft that can rotate at speeds of up to 1000 rpm.

- The weight of the structure is 135 kg.

- It has proven itself well when working with various attachments: cultivators, plows, trailers, mowers, hillers and harrows.

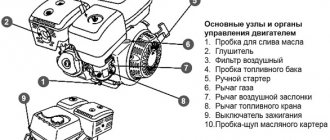

- Control occurs thanks to a convenient rotary steering block. All control levers are located on the steering wheel, which makes it as convenient to operate as possible.

- The track size is adjustable and can be 425, 600 or 800 mm.

- The MTZ-05 walk-behind tractor has a single-cylinder four-stroke engine with a power of 5 horsepower.

Some MTZ models were equipped as standard with a two-cylinder engine producing 8 horsepower.

Motoblock MTZ-05 history of my operation (part 2)

Now I will tell you what I changed in the walk-behind tractor and how, methods for repairing it, at the same time inexpensive and reliable, so as not to “get” extra money. I want to warn you right away, don’t look at the fact that I repaired the walk-behind tractor so much. In fact, it is quite reliable, I just used it for a long time, harshly, and sometimes incorrectly. Now there is a bad trend towards a general increase in prices, this is also reflected in motor vehicles, attachments and spare parts, so repairing a walk-behind tractor without “savvy” can be expensive...

Initially, the walk-behind tractor and cart were made from the factory in such a way that they were not compatible with each other. Thanks to BobruiskSelMash - we welded a larger diameter pipe to the drawbar of the trailer, which pressed on the clutch rod of the walk-behind tractor when the kingpin was inserted into it, while the walk-behind tractor could not move (of course, with the clutch depressed). I had to immediately pick up a file and grind off the excess metal. In principle, the rest of the equipment was compatible, the only thing was that in the first year it was necessary to strengthen the PU-00.000-01 plow and the STs-00010 universal hitch by welding additional iron rods or sheets. Otherwise, everything would bend during work, but my soil is heavy clay, so it’s not a fact that this could happen again. Moreover, how much time has passed since the purchase and if the quality of the attachment has increased as well as its price, then you are purchasing an almost eternal product. Here, of course, I’m lying. The UD-15 engine has proven to be quite reliable, unpretentious, noisy and voracious. Of course, in the USSR army it was used as a drive for various machines and units, such as pumps and generators. It was produced by the Petropavlovsk Small Engine Plant, which is now located in the independent state of Kazakhstan. UD engines are low-powered carburetor engines and are characterized by a high specific gravity - about 9 kg/hp. The engine design is designed for continuous operation at rated power in difficult conditions (low or high air temperatures). The engine life before major overhaul is about 3000 hours. I initially operated the engine using A-72, A-76 gasoline, and then A-80. I also poured AI-92 into it, it also worked a little and without consequences, but this is a violation of the operating rules. The operating instructions stated that the UD-15 and UD-25 (the same only two-cylinder) were unified in their parts and components with the engines of ZAZ cars. This information helped me a lot in finding spare parts. What broke during the first years? The engine ran almost without problems. In 1994, fuel leaked from the fuel pump. I took it apart and realized that its membrane had leaked. I went to the market in the Southern Port and bought a repair kit for a Zaporozhets 30 hp fuel pump. The pumps, as it turned out, were unified. Then, I had to change the spark plug. I couldn’t find my original A10 in 1995 (the model is too old), so I had to install the A11, which is close in characteristics. This did not affect the operation of the engine in any way. The carburetor faucet was leaking, I took it off, looked, it turned out the rubber ring was leaky, I tried to cut something similar out of rubber (well, I couldn’t find one like that in a spare parts store), I cut it out and installed it. After a couple of weeks of use it started leaking again, the gasoline corroded the gasket and started leaking. I found a faucet from a friend's motorcycle, exactly the same as it was - installed it... and forgot about this problem. After seven years of operation, the engine began to have difficulty starting and stalling. The symptoms were as follows: under load it stalls, you immediately set the idle speed and it works. After some experiments I realized that the engine did not have enough gasoline. I disassembled the carburetor, there was a lot of dirt there, especially in the float chamber - I cleaned it. I unscrewed the tube that goes from the fuel pump to the carburetor (metal), blew into it, it almost didn’t blow - it seemed clogged. I had to take a thin copper wire and pick it. In the end I cleaned it. I assembled the system - it was leaking from under the top cover of the carburetor float chamber - the paronite gasket no longer held, after some thought, I cut one out of ordinary single-layer thick cardboard - it held perfectly. What I would like to note is that the UD-15 engine (like the UD-25) is equipped with a single-mode centrifugal speed controller. That is, 3000 rpm is maintained there automatically. There is an idle speed, but it seems to be foreign in this engine; according to the instructions, it can only be used for warming up; in fact, there is only one mode - 3000 rpm. Then trouble happened - the oil centrifuge gaskets and the front crankshaft oil seal leaked. I had to go to the Southern Port again, the gaskets and oil seal were found within an hour, partly from the 30-horsepower Zaporozhets, partly from other cars. It was very difficult to get the key on which the flywheel-fan is attached; after some time, by carefully knocking it out and using pliers, it was removed, but damaged. I had to make a similar homemade one from a piece of metal. Lubricated it and put it back together, everything works. But apparently it was put together poorly, because after 2 years of operation the oil started leaking again. Another trip to the South Port, half of the gaskets were never found. I contacted the manufacturer in Petropavlovsk, Kazakhstan - I called, they sent me an invoice for a considerable amount of 1200 rubles, but I ordered more, to be honest, more spark plugs and gaskets for the fuel system. I spent a long time running to banks to pay bills for spare parts. The bank was from another state. After paying and sending payment orders to the manufacturer, I began to wait. I waited half a year, but never received the spare parts; calling the factory and going to the post office did not bring any results. Because the work needed to be done, a new Briggs and Stratton Vanguard 7.5 HP engine had to be purchased. But this is a slightly different story. Below I have posted photographs (not mine) of the MTZ-05 walk-behind tractor with the original UD-15 engine. And also a drawing of the UD-15 itself, with all the significant structural components. To be continued…

- Author: Olga

Rate this article:

- 5

- 4

- 3

- 2

- 1

(2 votes, average: 5 out of 5)

Share with your friends!

Device

The MTZ-05 walk-behind tractor was developed almost 50 years ago. Since then, technology has come a long way. Despite the fact that this Belarus is practical, sometimes you may want to replace the motor. In this case, there should not be any special problems.

Engine

There are a large number of motors of different manufacturers and power on the market. The simplest Chinese motors are equivalent in quality to Russian ones, but their price is lower. One of them is Lianlong. It is certified to comply with all European quality standards and is of high quality.

But it is clearly inferior to the Japanese Lifan and Honda in terms of operating hours. Manufacturers from the Land of the Rising Sun are considered the best in this business.

Lianlong LL-160F engine Honda GX160 engine Lifan 168 F-2 engine

When choosing a motor, you should pay attention to the following characteristics:

- number of cylinders;

- power;

- maximum speed;

- maintainability.

As a result, you need to find the perfect balance in terms of price and quality.

Valves

Under prolonged or heavy loads on the MTZ-05 walk-behind tractor, the valves shift. As a result, the amount of fuel supplied changes, and Belarus-05 begins to work incorrectly.

In normal condition, the valve clearance should be from 0.1 to 0.15 mm.

If the gap is increased, then specific noise appears from the engine, and the required amount of fuel does not flow into it.

Adjusting valve clearance

If you have any doubts about this, you should check them immediately. Using a thin blade, thickness from 0.1 to 0.15 mm, you can adjust the position of the valves:

- Loosen the nut a little;

- Place a blade under it and return the nut to its original position;

- Turn the flywheel several times;

- The valve must operate freely, but no gap is allowed;

- If a gap appears or the flywheel does not rotate, perform the adjustment again.

Carburetor

If the MTZ walk-behind tractor produces unstable engine speeds, then the carburetor should be adjusted. It is recommended to carry out this work before the start of sowing, when the equipment has been unused for a long time.

Carburetor adjustment:

- Screw in the bolts that regulate the minimum and maximum amount of gas completely and then unscrew them half a turn;

- Then move the power plant control lever to the minimum position, while the engine operation should not stop;

- The throttle adjusting screw will help you adjust the idle speed so that the engine runs correctly without any extraneous noise;

- Using the screws, you should correctly adjust the amount of fuel supplied. If you tighten it, it decreases, if you loosen it, then the flow of fuel increases.

To check whether the carburetor on the MTZ-05 walk-behind tractor has been configured correctly, let the engine run and then remove the spark plug. If it is clean without foreign impurities, then this indicates the correct setting.

Important!

Before starting adjustments, you should always warm up the walk-behind tractor engine.

If carbon deposits appear on the spark plug, the cause may be either the carburetor or more serious failures.

Clutch

An important element during engine operation is the clutch. Therefore, you should know how to configure it correctly.

Two options for clutch failure:

- When the lever is fully depressed, the MTZ-05 tries to move. This means that he is being led. In this situation, tighten the adjusting screw slightly.

- When the clutch is lowered, the walk-behind tractor slips, that is, it either does not produce the necessary power or stops altogether. In this case, the adjusting screw should be slightly tightened.

Video review of precise clutch adjustment on the MTZ-05 walk-behind tractor

checkpoint

The gearbox on the MTZ-05 walk-behind tractor has 6 steps: 4 for driving forward and 2 for moving backward.

Below is the maximum speed in each forward gear:

- Stage I – 2.15 km/h;

- Stage II – 3.8 km/h;

- III stage – 5.35 km/h;

- IV stage – 9.6 km/h.

Maximum gearbox speed when driving backwards:

- Stage I – 2.5 km/h;

- Stage II – 4.46 km/h.

Video review of the gearbox design for the MTZ-05 walk-behind tractor

Transmission repair

Gear

When the operation of the gearbox is accompanied by noise in the gearbox, this is a sign of a shortage or incorrect choice of oil. If it is not there, then you need to add it to the carburetor; if it is, try draining the old oil and adding new oil in accordance with the recommendations in the instructions for use.

If the noise remains, it means the gears have failed. If they are not replaced in time, the consequences can be even worse. It is necessary to periodically check the performance of the gearbox and carry out preventive repairs.

Electric starter

Electric starter

Many owners of MTZ-05 install an electric starter on it instead of the factory one. This makes the process of putting the engine into operation much easier. Because at sub-zero temperatures it often refuses to start.

In order to replace the electric starter, you must first install a battery, since without it the electric starter will not work.

Another important addition to the MTZ is the headlight. It allows you to carry out work even at dusk. It's not included as standard, but it works great with a battery.