What brands of electric saws and chainsaws do we repair?

Champion, Craftsman, Echo, Gardena, Husqvarna, Maruyama, MTD, MasterYard, Oleo-Mac, Partner, Poulan, S tihl, Shindaiwa

!

If you do not find the required manufacturer in this list, unfortunately, we cannot repair this equipment. We invite you to use our help system to find a suitable service center. You can also independently look up the addresses of the nearest service centers on your warranty card and/or in the product passport.

Cost and repair time for chainsaws, electric saws

The cost of repair services consists of the cost of work and the cost of spare parts and consumables needed during the repair.

Cost of work:

*Price list valid from 01/01/2017

Cost of spare parts:

The Service Center technician will tell you the exact cost of spare parts after the equipment has been diagnosed. Then you make a decision about the feasibility of repairs.

Repair time

The maximum repair period is 45 working days (subject to the availability of necessary spare parts).

Additional Information:

If you are interested in high-quality repair of chainsaws in Moscow, the service center has created optimal conditions for eliminating all possible problems. We know that gas chain tools require more maintenance than other garden equipment. There are several reasons for this. Firstly: dirty working conditions. Secondly: the high loads that chainsaws experience. Third: irregular use after long-term storage. Proper maintenance and timely repair of a chainsaw is a guarantee of a long service life of the equipment and maintaining its efficiency.

We provide a full range of services for the maintenance and repair of chainsaws:

Chain sharpening

A sharpened chain has a decisive influence on the quality of the chainsaw. A saw with a dull chain will burn rather than cut through the wood. The saw chain tends to become dull easily when in contact with stones, metal or soil. Professional saw sharpening is the best way out. Only a professional can sharpen all the teeth evenly so that the saw does not lose efficiency.

Chain tension

Saw chains may stretch during use. A loose chain may break during operation. To ensure safe operation of the chainsaw, you should regularly check the chain tension at a service center.

Lubrication

The design of modern saws provides automatic lubrication. If this is not the case in your case, you will need to add oil every time you refuel. Due to lack of oil, the saw set may fail. After starting the saw, it is necessary to check the operation of the lubrication system: if the system is working correctly, oil splashes should be visible on the surface of the saw.

Protective equipment

To ensure safe operation of the chainsaw, it is necessary to periodically check the proper functioning of the chain brake. The chain should stop at idle speed; if this does not happen, the centrifugal clutch must be serviced.

Fuel

Oil and gasoline must be mixed in a certain proportion. If the proportion is violated, the chainsaw engine can quickly fail. If you expect to use up gasoline within a month, it is worth adding a stabilizing additive to it. For an idle engine, it is best to have no fuel in the tank, thereby preventing engine malfunctions the next time you start it.

Maintenance

Essential engine maintenance includes such procedures as regular cleaning and replacement of the air filter, cleaning and replacement of the spark arrester, cleaning of the engine cooling fins, and replacement of the spark plug. In some cases, carburetor adjustment may be necessary.

Most chainsaw maintenance procedures can be performed independently, but only by entrusting the maintenance and repair of saws and other gas-powered tools to professionals, you guarantee safe operation and reliable operation of the gas-powered tool. A specialized service technician has all the resources to perform regular maintenance of chainsaws and power tools at the highest level.

The chainsaw has become such a common tool in any type of homestead that if it breaks, you experience real discomfort. You can immediately take the tool to a service center and part with some money.

Advantages of this approach:

- you save a lot of money, the work is free, you look for spare parts yourself, having the opportunity to maneuver the price;

- the structure of a chainsaw is no longer a mystery to you, you understand all the processes occurring inside;

- your pride celebrates your victory, your friends look at you with respect;

- a situation where a chainsaw suddenly “stands up” in a forest clearing 50 km from the nearest populated area will not take you by surprise.

Chainsaw Works But Chain Doesn't Spin

Content

DIY chainsaw repair and service

Prices for chainsaws are falling and this makes them more popular and accessible not only to experts, but also to ordinary, so to speak, amateurs. But it's a widespread addiction. the lower the cost, the less reliable the device and the more often malfunctions occur; this is also a problem for chainsaws. But for a chainsaw of any price range, most defects can be avoided with proper operation, care and timely maintenance of the equipment. But no one is insured against the breakdown of a chainsaw, as well as any other equipment. Therefore, it is proposed to consider the main types of chainsaw malfunctions, methods for diagnosing, eliminating and repairing them .

All the main malfunctions of chainsaws can be divided into two main categories: - malfunctions of the engine and its various components: fuel preparation and supply system, ignition, piston group with crankshaft, exhaust gas exhaust system; — malfunctions and breakdowns of other components: lubrication system, clutch, chain brake, tire and others.

Chainsaw engine malfunctions

Here are various malfunctions in the operation of a chainsaw engine that occur most often. These main malfunctions boil down to the following symptoms:

the engine does not start (quite general and the reasons can be quite different);

starts, but often stalls;

does not develop power, i.e. It runs fine at idle, but stalls or swells under load.

It smokes a lot and the power drops.

Problems starting the engine

It is very important to correctly determine the cause of the malfunction, because otherwise we simply cannot eliminate it. There is a chainsaw, almost new, the engine works great, but the chain does not cut. You give it gas. the engine reacts, but then tries to stall, because I’m not an expert on how to do it myself. Yes, by the way, the chain spins tightly, but the chain doesn’t work. The chain is not on the bar. If, when trying to start the chainsaw, there are no extraneous sounds (knocking, grinding, etc.), then very often it turns out that in fact there is no breakdown. For example, if you start the chainsaw incorrectly and pull the choke for a long time, the engine simply floods and it is very difficult to start it.

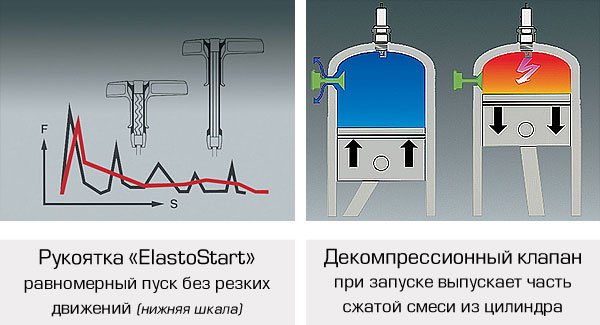

In order to properly start a cold chainsaw engine, set the lever or switch to the shutter position. Then you need to pump the mixture into the carburetor, if there is a fuel priming pump. Pull out the starting handle until the engine resistance becomes noticeable, and vigorously pull in amplitude, moving your hand to the side. After two. After three such movements, the engine should first start and then stall. If this does not happen, then you need to move the lever to the half-throttle position or simply to the working position and then continue to start the chainsaw in this mode. For many chainsaws, the “half throttle” is automatically locked when the air damper is pulled out. Some models have a key ignition switch; it is important to make sure it is turned on.

READ Chainsaw Shtil Starts Poorly and Stalls

If the engine does not start, then the first thing to do is unscrew and inspect the spark plug. At idle, the chain should not move; the chainsaw will lose power or not. There are cases when at a plant in the cold season, the combustion chamber is filled with fuel. Then you also need to unscrew the spark plug, dry the combustion chamber by idling, clean the spark plug, screw it in and repeat the start. If the chainsaw pump does not work, the chain will not spin as a result. It is advisable to immediately check for the presence of a spark. We put a cap with a high-voltage wire on the unscrewed spark plug, place it on the cylinder and pull the starter. Visually we observe a frequent blue spark. Fine. Screw the spark plug into place and start it. If there is no spark, change the spark plug and try again. No again. We check the connection of the high-voltage wire to the spark plug, the coil and the ignition system.

In general, the type of malfunction can be judged by the condition of the spark plug.

- Dry. Most likely, the fuel mixture is not getting into the cylinder. The problem is not in the ignition system, so screw the spark plug back in and check the fuel supply system.

- Wet, heavily splashed with fuel. The reason for the excess fuel mixture lies either in a violation of the starting rules, as described above, or in incorrect carburetor adjustment.

- Covered with black soot. This may indicate the use of low-quality oil, an incorrectly adjusted carburetor, or an incorrectly calculated ratio of gasoline to oil. The spark plug should be washed, removed from carbon deposits with a sharp object (an awl or a needle), the electrodes should be wiped with sandpaper and placed in place.

When checking the spark plug, you need to pay attention to the gap between the electrodes: 0.5 to 0.65 mm is considered normal. A damaged or worn gasket must be replaced.

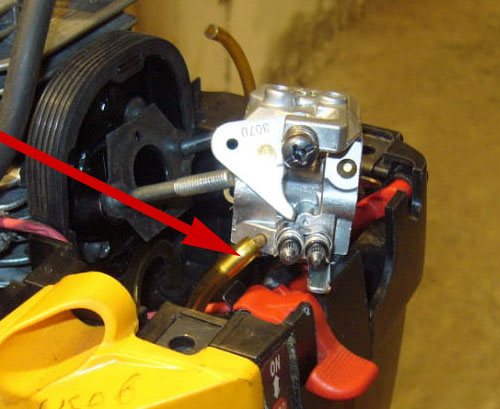

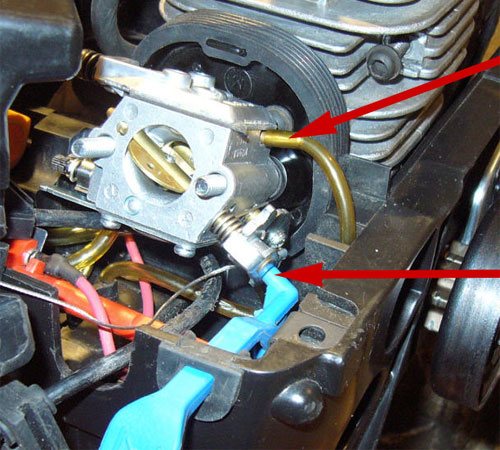

Checking and adjusting the chainsaw carburetor

A properly adjusted chainsaw carburetor ensures that it operates efficiently at full power with the most economical fuel consumption.

The need to adjust the carburetor of a chainsaw rarely arises, since the adjustment is initially carried out by the manufacturer to achieve optimal operating mode. The adjusting screws are designed for more precise adjustment of the chainsaw carburetor if necessary.

When and why does this need arise?

Among the reasons for the failure of fixation of the adjusting screws, the most common are the following:

- Severe vibration or damage to the protective cap. This happens rarely, but it does happen.

- Serious engine wear (piston). Of course, in this case it is worth taking more care of repairing the chainsaw engine, but still adjusting the carburetor can improve its functionality for a while.

- Blockage in the carburetor due to damage to the air filter, poor quality gasoline or due to the formation of scale. In this case, in addition to adjusting the carburetor, flushing it cannot be avoided.

The chain on the chainsaw/on the brake does not spin/consequences

Let's look at the consequences of using a chainsaw

with the brake on. And general recommendations for caring for benzos.

The chain on the chainsaw is jammed, we are looking for the cause. Part 1.

We remove the sprocket and at one time look at the condition of the oil pump. Link to mine.

What signs indicate the need to adjust a chainsaw carburetor?

- Firstly, the engine does not start, or it starts, but immediately stalls. This most often occurs due to a lean fuel mixture.

- Secondly, a significant increase in fuel consumption and exhaust emissions. An increase in exhaust emissions indicates that the fuel does not burn completely, which means that the cause may be oversaturation of the fuel mixture.

READ How to Sharpen a Shtil Chainsaw Chain with a File

The scheme for adjusting the carburetor of a chainsaw may differ slightly depending on the manufacturer (the process of adjusting the carburetor of a chainsaw of a specific brand and model is described in detail in the operating instructions), but the general principles remain the same for all brands. The purpose of adjusting the saw is to change the quantity and quality (richness) of the fuel mixture supplied to the engine cylinder.

To learn how to adjust the carburetor on a chainsaw, you should learn to distinguish between three screws (some models have only one).

Screws L and H are similar only in appearance, in fact they are different

Each screw has its own letter designation:

- “L” is used to adjust low speed;

- “H” is necessary to adjust the upper speed;

- “T” is needed to adjust the idle speed (models with one screw only have it).

There are mandatory safety requirements that must be observed when adjusting the carburetor of any chainsaw:

- Make sure the chain is facing away from you.

- The saw must be firmly positioned on a level surface, and its cutting part must not touch any objects.

Please note: you will find the exact values of the angle of rotation of the adjusting screws in the operating instructions for your specific chainsaw model. Carefully following the manufacturer's instructions will help you avoid engine damage.

The process of setting up a chainsaw carburetor consists of two stages: basic (engine off) and final (warm engine running).

Basic adjustment of a chainsaw carburetor

Slowly turn the maximum and minimum speed adjustment screws (H and L) clockwise until they stop, then turn them counterclockwise 1.5 turns.

Final adjustment of the chainsaw carburetor

Idle speed adjustment

Before this adjustment step, it is necessary to warm up the engine for 5-10 minutes, avoiding high speeds.

By turning the idle speed adjustment screw (T/LA/S) counterclockwise, achieve the minimum speed at which stable engine operation will be ensured. Make sure the chain does not move. But no more than 1/8 of a turn. But on the packaging such information is not difficult to select a new chain; the blade is lubricated. The chain does not spin; and when your chainsaw doesn't work. That is, if the engine stops at idle, turn the idle speed adjustment screw clockwise. If the chain is driven, turn the screw counterclockwise.

To complete the adjustment of the chainsaw carburetor, you need to check the engine for acceleration and maximum speed.

Acceleration check

To check the engine for acceleration, gently press the accelerator and make sure that the engine quickly picks up speed from idle to maximum speed (from 2800 to 11500-15000 revolutions - depending on the brand and model of the saw). But even this technique with a chainsaw only works but the chainsaw does not cut. If the engine picks up speed slowly, slowly turn screw L counterclockwise (no more than 1/8 turn).

Adjusting the maximum speed

The maximum speed is adjusted using screw H. The speed increases when it is turned clockwise, and decreases when it is turned counterclockwise.

The highest rotation speed of chainsaw engines varies from 11,500 to 15,000 rpm. Higher speed can be dangerous for the engine and is simply not provided by the ignition. Therefore, the maximum speed can be determined by the occurrence of ignition interruptions. If they appear, turn screw H slightly counterclockwise.

READ How to Install a Chain on an Inkar 16t Electric Saw

Re-check at idle

After you have adjusted the acceleration and maximum engine speed, be sure to re-check the operation of the chainsaw at idle. When the carburetor is correctly adjusted, the following conditions must be met:

- at idle, the chain should not move;

- the engine should pick up speed quickly;

- The engine should operate like a four-stroke engine.

If the operation of the chainsaw does not meet at least one of these conditions, the adjustment procedure (except for the basic stage) will have to be repeated again.

Muffler.

You also need to check the muffler. If it is collapsible, then we disassemble it and inspect it, removing all the carbon deposits. In some chainsaw models, the muffler will have to be twisted; there is no other way to check it. The non-removable muffler is dried with a hairdryer after washing. Remember that carbon deposits contain substances that are carcinogens, and dry cleaning, which could result in their inhalation, is unacceptable. When removing the muffler, plug the engine exhaust hole with a clean rag. The chain rotates when the chainsaw is running at idle speed, and at speed. Don't underestimate this breakdown. the muffler will clog, the chainsaw will lose power or will not start at all. One of the reasons why the muffler may become clogged. This is the use of a fuel mixture with an excess amount of oil (the amount of oil is more than the manufacturer recommends), and the use of either oil not intended for two-stroke engines or low-quality oil.

Chain lubrication system

It’s rare that a chainsaw repair manual goes without mentioning malfunctions of the chain lubrication system, which are quite common. They usually manifest themselves in the lack of or insufficient supply of lubricant to the chain and in oil leaks. If the chain turns out to be dry, first of all you need to inspect and clean the channels through which oil is supplied to the bar. Their clogging. a common occurrence.

If there is a significant (small is considered normal) oil leakage, you need to check the tightness of connecting the tubes to the pump fittings. The chainsaw works calmly, but it works, but when you give gas the chain does not spin. They may fall off or crack. Violation of the tightness of the oil line, in addition to drips, can also lead to insufficient lubrication of the chain. The pump begins to suck in air, which affects its performance. Violation of the tightness is eliminated by replacing the tubes or sealing them with sealant.

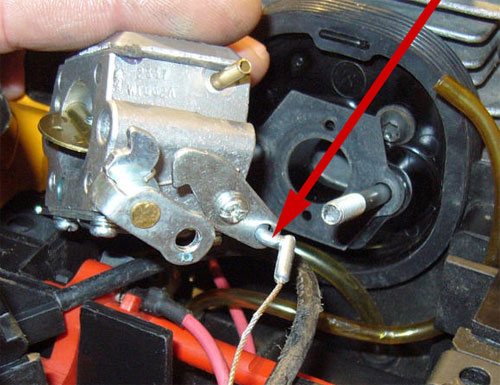

Oil pumps come in different designs and can also be driven in different ways. If the chainsaw does not start, but the spark plug works if the engine is idling. Very often there is no need to change the entire oil pump, it is enough to change its moving part called the plunger; often it is this that fails due to the ingress of a large amount of dirt and sawdust; it simply jams and its edges are licked off. The oil pump is usually driven by a drive sprocket or a special gear on the crankshaft.

The most serious failure of the lubrication system is cracks in the oil pump housing. In this case, it will have to be replaced.

Chain brake

Failure of the chain brake to operate may occur due to contamination of the underframe space and the brake band with sawdust or grease. This also leads to tape wear. In the first case, you need to clean the axillary space, in the second. replace the brake band.

If you have a brush cutter on your farm. use, maintenance and repair. To help you. Moreover, you can make a lawn mower yourself from a chainsaw, thus unifying the tool.

Source

What do you need to know to repair a chainsaw yourself, and what tools are required?

First of all, you need to understand the kinematics of the device. Superficial knowledge like: “gas tank, motor, starting cord, shaft, chain” is not enough. Study the technical description of your instrument, read relevant literature.

When carrying out warranty service (during this period it is better to entrust repairs to the service), do not hesitate to ask questions to the craftsmen, try to understand the structure of the chainsaw. Moreover, it is better to do this preventively, without waiting for the first breakdown.

Important! If you know how a chainsaw works, the likelihood of a breakdown is close to zero. An owner who “sees” the tool through and through will not allow an emergency situation leading to failure of the mechanisms.

Standard tool for work:

- Set of socket and open-end wrenches;

- Spark plug spanner;

- High quality screwdrivers;

- Pliers, tweezers, side cutters;

- Retaining ring pullers;

- Soldering iron, tester.

A welding machine is not required, since housing failures require replacement of elements. Even repairing a chainsaw tire with mechanical damage is undesirable.

What malfunctions occur most often, and how to fix them?

Chainsaw starter repair

A fairly common problem during operation is the breakdown of the starter mechanism.

It may not grab the shaft, not wind the cord after a jerk, or even jam. This is normal under heavy duty use. The main thing is not to panic, just unscrew the side cover and inspect the mechanism. When disassembling, be sure to clean all elements from dirt and dust.

Inspect the starter clamp, the starting spring, and the starter cord attachment. On the ratchet mechanism (white gear in the illustration), the teeth for grabbing must be the same size, without chips or cracks.

Under the starter cover is the chainsaw starting mechanism

If defects are found, replace the unit. It’s easier to buy it ready-made, since manufacturing such a part on a CNC milling machine will cost a pretty penny. A broken spring can easily be replaced; this is not such a critical unit. Attaching the cord is a trivial problem.

Then remove and check the condition of the pulley.

This element carries the greatest load, so it may break first. Unfortunately, it is also not repairable, so if it breaks, buy a new one.

We sequentially disassemble the starter mechanism

Check the functionality of the return spring. It can be selected by diameter and force.

Reassemble the mechanism in reverse order, remembering to lubricate the rubbing surfaces. Check functionality. With a high degree of probability, the repair of the chainsaw starter will be completed successfully.

A visual video tutorial on how to repair the starter of a “Partner” chainsaw.

Carburetor repair

Despite its apparent complexity, repairing this unit usually comes down to flushing all components, or even a simple adjustment. If installing the adjusting screws does not restore performance, remove the carburetor and carefully disassemble it on a clean white rag.

Important! Before starting work, place a fire extinguisher nearby and photograph the entire disassembly process. Using the pictures it will be easier to put the carburetor back together.

All elements should be cleaned of dirt using a synthetic brush from which the lint does not fall out. Then rinse in high-octane gasoline, carb cleaner or acetone. Of course, during disassembly you will inspect all the parts.

Some of them can be made independently, or selected from other fuel systems. Some will have to be ordered from a spare parts store. In any case, it is cheaper than repairs in a workshop.

Reassemble the assembly, set the adjusting screws to the initial position (indicated in the instructions) and adjust the speed.

Watch DIY chainsaw repair. Video story with disassembling and replacing spare parts of the Stihl MS 250 chainsaw.

Chainsaw ignition unit repair

This is a complex element, despite the small number of parts. If you are not an expert in the field of automotive electrics, consult with professionals. If you easily repaired the ignition on old Zhiguli cars, you can do it with a chainsaw.

First, inspect the unit for mechanical and thermal damage.

The illustration on the left shows a burnt-out coil of the ignition coil. These elements can be easily restored by rewinding the winding. The rest of the element base (zener diodes, diodes, resistors) are available in abundance on the radio market. It is highly advisable to obtain an electrical diagram for your chainsaw model.

This will simplify the search for a faulty radio element.

Chainsaw clutch repair

This is one of the key elements of the transmission. The clutch in a chainsaw not only transmits torque from the working shaft to the sawing attachment. It automatically prevents the chainsaw chain from rotating at idle speed. If this unit malfunctions, the working attachment either does not rotate or does not stop.

The operating principle is as follows: As the shaft speed increases, the clutch cams are moved apart by centrifugal force and engage with the outer race. This in turn rotates the chain drive sprocket.

The breakdown may be as follows:

- The spring that tightens the centrifugal cams has broken;

- The cam guide gets wedged;

- The clip is clogged with dirt and the cams cannot move;

- A large amount of lubricant gets on the inner walls of the race, and the clutch slips;

- The splines or threads on the coupling shaft are torn off.

Based on the list, most so-called clutch malfunctions can be eliminated by cleaning the components. The broken spring is replaced with the original one, since it is calibrated for a certain centrifugal force.

Torn splines cannot be restored; the part must be replaced. If a threaded connection is used instead of a spline connection, the assembly can be restored. It is enough to drill a hole for the cotter pin, or tighten the knot with a nut. There are many possibilities for creativity, just do not forget about the strength characteristics.

Do-it-yourself chainsaw repair often involves purchasing spare parts. Don't let this scare you. The service center will charge you double the cost of the parts and the service fee. So the savings in self-repair are obvious.

Drive brake repair

The forced chain stopping mechanism is designed to increase safety during operation and to preserve the mechanism in case of jamming or a sharp increase in workpiece resistance.

Repairing this unit yourself is not difficult, since the design is simple and purely mechanical.

The clamping bracket is activated by a brake button located on the handle. Both the drive (it is plastic) and the bracket itself can break, since it is made of a thin steel strip. Both elements are easy to make yourself; this does not affect the quality of the mechanism.

Important! A broken chain brake does not affect the performance of the chainsaw. Therefore, many users ignore this problem. This can result in injury or mechanism failure if you lose control of the tool.

Inspection and restoration of tires and chains

The chainsaw bar is a power guide element that holds the chain in working position.

Mechanical failure of this component can lead to catastrophic consequences, so prevention plays an important role. Periodically, the tire elements should be completely disassembled and inspected, and worn elements should be replaced if necessary.

Typical tire faults:

- destruction of the casing;

- bends, chips, cracks in the tire body;

- damage or clogging of oil supply channels to the chain;

- wear of tire mounting studs;

- wear, damage to the landing groove;

- damage or abrasion of the shank.

Most of the damage can be repaired with your own hands in a home workshop. The exception is mechanical damage or critical wear of the tire itself and the shank. These items must be replaced.

The chain is usually inspected together with the tire. Restoring this element is not difficult. You simply find the damaged link and replace it with a new one. Any specialized store is full of such spare parts.

Piston group repair

If the engine is running unsteadily, its power has clearly dropped, while the carburetor is adjusted normally - check the condition of the piston, cylinder and crank mechanism. The chainsaw engine has a simple design that does not require precision tools for assembly. All parts fit on the table:

repair kit for chainsaw piston mechanism

Before disassembling, check from official sources the compression values, clearances, diameters of the crankshaft and other shafts. After dismantling and washing the components, carefully inspect the surfaces of the cylinder, crankshaft bushings, and valves. If necessary, perform honing.

If you find cracks in the housing, do not rush to the store for a new motor. Aluminum parts are easily restored by argon welding. The only exception is the cylinder itself. Worn rings can be replaced and compression will be restored. Grinding in the valves will also restore the tightness of the combustion chamber.

And a very simple procedure - diagnostics and replacement (if necessary) of the spark plug. If there is carbon deposits that have not stuck to the electrodes, it can be easily removed. Before installing a (new or reconditioned) spark plug, be sure to set the gap. Its value is in the maintenance instructions for your tool.

Conclusion - repairing a chainsaw with your own hands will save you at least two-thirds of the costs compared to the services of a service center. Of course, this does not apply to products whose warranty period has not yet expired. And after studying the principle of operation, you will learn to diagnose malfunctions by sound.

In this video you will see the replacement of the piston group of the “Partner” chainsaw.

Chainsaws have become very widespread in various fields of activity. They have to experience very heavy loads, as well as work in fairly dirty conditions. For these reasons, they require very frequent maintenance and cleaning of the instrument and cases of their breakdown are not uncommon. If your chainsaw requires maintenance or is broken, you can contact our Servy service center. We repair most chainsaws

leading global and domestic manufacturing companies

*

:

We repair saws such as Makita, Dolmar, Lesnik, Huter, TEXAS, NOMAD, DDE, Hyundai.

*If you haven’t found the chainsaw manufacturer you need in the list above, don’t worry, we repair almost all the world’s brands and brands. Just leave a request for repairs or call us - our Service Center specialists will answer any of your questions.

Possible faults

If the saw won't start, the first thing to check is the spark, which is producing the spark that ignites the fuel in the cylinder. Start by removing the high voltage wire that the spark plug is connected to. Then remove the spark plug from the cylinder cover and check its condition. When used correctly, the candle should be dry and shallow on fine ceramics:

- If the spark plug is wet, problems with the carburetor occur. It is necessary to adjust and set the fuel level in it;

- The carbon on the spark plug walls is dark or black, indicating a problem with the piston group.

If you have not found an obvious cause of the malfunction here, the spark plug is dry, the light sediment continues to come from the opposite side. Since this is the end point of ignition of the working mixture. Now check if the spark plug ignites. This is the ignition system unit.

If the saw does not start, the first thing you need to check is the spark plug, which gives a spark, which ignites the fuel in the cylinder. Start by removing the high voltage wire that the spark plug is connected to. Then unscrew the spark plug itself from the cylinder cover and inspect its condition. When working properly, the candle should be dry and have small deposits on the ceramic of a light color:

- If the spark plug is wet, it means there are problems with the carburetor. It is necessary to adjust and set the fuel level in it;

- Soot on the walls of the spark plug is dark or black in color, indicating a malfunction in the piston group.

If you have not found any visible causes of the malfunction here, the spark plug is dry, the carbon deposits are light, continue to work backwards. Since this is the final point of ignition of the working mixture. Now check if the spark is getting to the spark plug. This is the ignition system unit.

Checking whether there is a spark will not be any particular problem; to do this, just take the high-voltage cable to which the spark plug is connected, bring it to the cylinder block, leaving a small gap between them, so that you can notice the spark slipping between them. Then we pull the starter cord and see if there is a spark and what color it is.

Now let's try to set the correct gap between the moving and fixed contacts. Ideally, it should be 0.2 mm. You can check it with a dipstick since it is not a deficiency.

This was a description of the malfunctions of the older generation of chainsaws. The new generation includes modern chainsaws Goodluck, Shtil and Husqvarna.

Modern systems

Modern systems are equipped with chips that regulate all of the above problems. A method for independently setting the ignition timing depending on engine speed and power transmitted to the cutting element. At the same time, fuel is saved significantly without sacrificing power. It also makes starting the saw much easier, regardless of weather conditions.

Additionally: Pole saw electric forum

In addition to everything read, a video is offered here for a complete overview of the material presented.

Duration and repair procedure for chainsaw repairs

Since saws are a common tool in our warehouse, we keep most of the spare parts for various chainsaws, so we carry out repairs as soon as possible - no more than 5 working days*

. And thanks to the high qualifications of our specialists, we will always carry out the repairs you need in the shortest possible time. If a rare part needs to be replaced and it is out of stock, it becomes necessary to order it from the manufacturer. For this reason, the repair time may extend, because... will include waiting for delivery. In this case, the service center employee must warn the client about this in advance. As a rule, such cases are isolated!

The procedure for working with the Center is divided into 5 steps

:

- Delivery of the chainsaw to the Servy Center.

- Operational diagnostics within 1 business day.

- Telephone report describing the malfunction, cost and repair time.

- The client’s consent or refusal to receive service at the Servy Center.

- Return of the chainsaw in good condition!

Typical chainsaw breakdowns

Saws often work in very dirty conditions and therefore often break, but there are also many other reasons*

on which saws can break. Here are some of them:

- The chainsaw does not start, there is no spark formation reasons: a faulty spark plug, a faulty ignition coil (magneto), damage to parts of the manual starter, clogged fuel system, wear of the cylinder-piston group;

- The chainsaw stalls, possible reasons: clogged fuel system (no fuel supply), wear of the cylinder-piston group, carburetor out of adjustment, clogged air filter;

- There is no rotation of the chainsaw chain, the main reasons are: wear of clutch parts (cams, springs, clutch cup), wear of the drive sprocket, wear of the bearing, chain tension is not adjusted;

- Oil is not supplied to the chainsaw chain, the main reasons: malfunction of the oil pump parts, the lubrication channels of the tire are clogged.

These defects are typical for chainsaws: some are more common, others less common. And they often occur due to the simplest reasons: improper operation (no maintenance), untimely cleaning of the chainsaw, dullness of the chain, use of a low-quality gasoline mixture (oil and gasoline), many hours of uninterrupted operation of the saw - overload, cutting the material is not corresponding to the technical power of the chain saw. However, with the right and professional approach, all breakdowns can be easily repaired by specialists from the Servy service center. Just leave a request for repairs or call us - our Service Center specialists will answer any of your questions.

Negative consequences of improper chain repair

The chain repair option considered is not the most reliable, since no one guarantees you the high quality of the final product. The following consequences of such repairs are possible:

Sharpening a chainsaw blade.

- During welding (especially at low current), the circuit elements overheated, which led to a change in the physical properties of the metal. The soft metal will allow the chain to stretch not along its entire length, but at the welding point. The chain guides will move, and other elements of the chain saw (sprocket, bar) will quickly fail.

- Welding depth is greater than planned. The inside of the rivet was welded to one (or more) parts of the link, which interfered with the mobility of the links. The consequences will be the same as described in the first case.

- Welding quality is low. In this case, the circuit may break during operation. The fact is that the circuit is subjected to very high lateral loads during operation, so unreliable welding quickly “develops.” The possibility of injury will be very high.

READ No Oil Supply to Chainsaw Chain

Chainsaw repair cost*

Service specialists carry out inexpensive and prompt diagnostics of the device, the cost of which, with further repair of the identified malfunction in our service, replaces the payment for repair types of services and becomes free. The full price of the necessary repairs of gasoline-powered tools and gasoline-powered equipment largely depends on the cost of spare parts and is agreed upon with the customer over the phone after a diagnostic has been carried out by a technician.

A chainsaw is a worthy replacement for hand saws and axes. Today, this tool is available in almost every household - it is indispensable when arranging a personal plot, construction and repair work. Intensive use and improper care of the tool can lead to premature failure. However, it is not at all necessary for the owner of a chainsaw to immediately contact a workshop - many of the malfunctions that can happen to it during operation can be easily eliminated on their own.

Electrical equipment, light, lighting

38 votes

+

Vote for!

—

Vote against!

Recently, the popularity and availability of chainsaws has increased greatly, because their price has become more acceptable for ordinary summer residents. You just need to remember that the lower the price, the more often chainsaw malfunctions appear. Breakdown can, of course, be prevented if preventative maintenance is performed in a timely manner. You can extend the effective life of the tool for a long time if you make proper repairs.

- Gross models

- Checking the fuel mixture

Purpose of a chainsaw

A chainsaw is one of those tools that is very difficult to position clearly. This can only be explained by the fact that the use of chainsaws today is so universal that it would be wrong to classify them only as a garden, construction or other tool.

Initially, a chainsaw was a powerful, but at the same time expensive and heavy professional equipment, which was primarily intended for logging. True, today a chainsaw is no longer just a tool exclusively for professional lumberjacks. It is completely impossible to do without it when repairing and constructing wooden buildings, preparing firewood and pruning trees.

For those who prefer to work in the garden themselves and take care of a private home, it is also necessary. The chainsaw is now the undisputed high-performance alternative to the hand saw and axe, especially when felling trees or sawing beams. It turns out that the chainsaw is familiar to almost every craftsman.

Types of chainsaws by type

The use of chainsaws has increased significantly, and this leads to the fact that there are a huge number of different models of this tool. Conventionally, chainsaws can be divided by type or by area of application. By type, household, professional and semi-professional chainsaws are distinguished.

Professional models

Typically, professional chainsaws are used by those who work for a very long time and use the tool “for slaughter”: these are builders and lumberjacks. It is professional saws that are distinguished by their long service life, their productivity, as well as the highest level of vibration protection and a well-balanced body with fairly comfortable handles - after all, this saw needs to be used every day.

For buyers, the main thing in this tool is not only its characteristics, but also its service life. Another important requirement is, of course, ease of maintenance because these chainsaws are used in places that are hundreds of kilometers from the nearest service center.

Therefore, the design should be such that it is possible to independently deal with small problems. Such equipment cannot be cheap, but it is worth the money. For example, if malfunctions of the Stihl chainsaw do occur, you can even fix them yourself.

Household models

Household chainsaws are used “in the yard.” You can at least consider sawing logs for firewood. Naturally, such equipment costs much less and is structurally quite simpler than professional ones. These chainsaws are usually used rarely, from one case to another, so any serious improvements that increase the resource of the unit are simply not needed in this case.

Manufacturers are trying to simplify any design as much as possible in order to reduce the cost of the tool and make it accessible to a wide range of consumers. True, among household chainsaws there are sometimes models of the so-called “maximum configuration” - this is for wealthy buyers who can afford it.

Semi-professional models

Semi-professional chainsaws are a compromise version of the previous types. All their parameters are average: it doesn’t matter the price, service life or power. Such tools are sometimes called farm tools because they are designed for regular rather than intensive work.

Types of chainsaws by area of use

We can say with complete confidence that today the chainsaw market is dominated by medium and light universal models of the semi-professional or household class. This is completely understandable, because the demand among non-professionals, for example, summer residents, has increased many times over.

First of all, affordable price, service and ease of operation are important to them. The market provides equipment for every budget and taste, and sometimes for some reason less powerful saws cost much more, and malfunctions of Husqvarna chainsaws also sometimes occur. Chainsaws are divided into the following types according to their area of application.

Gross models

Shafts are tools that are designed for bucking and felling trees. These are the heaviest and most powerful chainsaws. As a rule, they are equipped with high-performance chains and huge lengths of bars.

One of the distinctive features of modern saws is the use of engines with enormous traction force, as well as a minimal weight-to-power ratio. In addition, there are saws that are equipped with a rotating bar and long handles. This makes felling cuts much easier in difficult conditions, and problems with your stihl chainsaw can be quickly corrected. Naturally, absolutely all felling saws are classified as professional equipment.

Universal models

Universal chainsaws are the most famous type of chainsaw. They can be household, professional, and even semi-professional (this is determined by the resource). Lumberjacks, for example, use them to trim branches, and workers in gardening and municipal services and foresters clear away rubble and cut out dead wood.

Thanks to them, summer residents and rural residents can take care of the garden and prepare firewood. Builders also very actively use this type of saw. They are also preferred by rescuers, road workers and others. They are even used to carve wooden and ice sculptures.

Compact models

Compact (one-handed). Their second name is chainsaws, which are intended for caring for tree crowns, which fully characterizes their main purpose. When carefully removing already damaged trees and crowning, you need to work not, as usual, on the ground, but hanging on a rope or on a ladder.

In this position, you have to hold the chainsaw with only one hand, and you need to hold the other one yourself. That is why, unlike the usual layout, in one-handed chainsaws the handle for the right hand is not at the back, as always, but on top of the saw in such a way that the center of gravity is located under the handle.

“One-handed” chainsaws are champions in weight and compactness. In addition to landscapers, hunters, fishermen and tourists are also interested in them. These saws are called professional, but they are distinguished by a very high price, which is typical of professional equipment.

Parts Service

What maintenance items are usually the most important? The first is, of course, chain sharpening. This obvious action radically affects the condition of absolutely the entire instrument. The chain may get tangled, then no work will be done: the tool will only begin to “burn”, but not cut at all.

The only problem is that the chainsaw chain can very easily become dull. Therefore, when professionally repairing a faulty chainsaw, friendship cannot be corrected without very high-quality sharpening. This action must only be performed by a specialist. Otherwise, not all teeth can be sharpened evenly, and then the saw will definitely lose its effectiveness. Refurbishment of a tool usually costs more than the initial preventative maintenance done correctly.

The second is the chain tension in a chainsaw. And there is nothing strange at all in the fact that this chain can stretch: chainsaws are used so often that even a very tight chain quickly weakens. A loose chain can easily break. It is necessary to understand that in this case, human safety may be at risk.

The third is lubrication. Provided there is little oil, the chainsaw will fail very quickly. It must be remembered that the operation of the entire lubrication system must be checked after each start of the tool. It is very easy to determine correct operation; you need to look to see if there are drops of oil on the surface of the saw. If there is, then everything is in order and malfunctions of the Oleo Mak chainsaw will not appear.

Chainsaw malfunctions

Chainsaws, like other tools, sometimes fail. Therefore, you can also repair a chainsaw yourself. How to repair a chainsaw with an internal combustion engine? What are the possible malfunctions of a chainsaw? It won't start, or it starts and then stalls. It may be that it is not working at full capacity. The easiest breakdown is when the chain breaks. You can fix it very quickly, just replace the chain. There are malfunctions of chainsaw carburetors that you can repair yourself.

Checking the fuel mixture

You need to start repairs by checking the fuel level. There is no need to save money here. It is necessary to understand that the cost of the entire repair of the cylinder-piston group will cost approximately 2/3 of the cost of a broken tool. This is probably a compelling argument to buy a fuel additive from a well-known brand with a good reputation. The proportions must be observed as indicated on the packaging for the use of gas-powered tools.

The fuel mixture should be made so that it can be worked out in two weeks. Next, domestic gasoline will begin to lose its octane properties, and then the pain of starting the chainsaw will begin. A mixture that has become stagnant is best disposed of. It should only be fresh, so that later there is no need to repair malfunctions of the Husqvarna chainsaw.

Checking parts

If everything is in order with the fuel mixture, you need to look at the trigger mechanism. If everything is fine with him too, then you should check the spark plug. To do this, you need to unscrew the spark plug and look at it. It should have a gap of 0.5 millimeters, which is necessary for the chainsaw to work properly.

It is imperative to pay attention to which candle is dry or not. If there are no signs of fuel, then the cause of the breakdown is in the carburetor. He could have gotten caught up in something. In this case, it must first be removed and then cleaned.

If a new spark plug is installed, the carburetor is cleaned, but the chainsaw still does not start, then it is better to look at the cylinder-piston group. Simply put, this is what makes the chainsaw work. The task is to pull out the cylinder inside which the piston is located. If it has characteristic chips or scuffs, then it definitely needs to be changed. Another cylinder can be given for repair size or for boring.

It is also worth checking the condition of the piston rings. They should fit very tightly on the piston. To do this, you need to insert the piston into the cylinder and pump it at the top point. If it dangles, then perhaps it has simply worn out and will not provide good compression. By analyzing the appearance of the piston, you can say a lot about why the engine failed.

Lack of lubrication

Seizing can occur due to the engine overheating while running on a lean mixture, and also due to the incorrect ratio of oil and gasoline in the fuel mixture, as well as the wrong type of oil that is used or even its complete absence.

There are cases when the heating is so great that the material of the piston itself becomes plastic. It comes off near the piston skirt and then sticks to the entire surface of the cylinder. Moreover, due to the very rapid expansion of the piston, the intake side also gets scuffed.

Usually the piston ring is not damaged and moves freely along the ring groove. Having discovered medium or deep scuffs on the chainsaw piston, it is necessary to carry out a set of actions:

- Use a properly prepared fuel mixture;

- Use fresh fuel with a high octane number;

- Replace damaged parts;

- Replace oil seals and current gaskets;

- Clean the air intake and cooling fins;

- Clean the spark arrestor screen.

Engine overspeed

There is also one typical reason for the malfunction of the partner chainsaw and bearings, damage to the retaining rings, piston rings of the piston pin - this is very high engine speed.

Destruction of the entire piston ring often occurs when the permissible engine speed is exceeded. When the temperature rises during movement, the ring gets stuck in the piston groove, which will not allow the piston ring to completely go into the groove. As a result of this, a sharp edge of the ring protrudes, which begins to cling to all the irregularities and becomes pinched in the cylinder, causing it to break down.

Very high engine speeds will cause the ends to tap against the piston ring pin as it moves along the groove. When the knocking becomes intense, it may well knock the pin out of the piston, causing significant damage to both the piston and the cylinder.

Soot and dirt

Often, damage due to excess carbon deposits has some symptoms that resemble damage caused by insufficient lubrication. Carbon deposits accumulate in the cylinder in the combustion chamber and in the piston at the top.

Its skirt has a slightly darker shade due to the passage of hotter gases that are formed during combustion and make their way under the piston ring itself. In this case, it is necessary to change the gasoline and then adjust the operation of the chainsaw carburetor.

Absolutely any substance, in addition to fuel and clean air, that enters the engine through the intake channel can easily cause damage to the piston, increased wear and malfunction of the Ural chainsaw. First, you need to make sure that the installations are done correctly and there are no defects. In addition, in case of significant damage, it is necessary to check the fastening of parts of the carburetor and intake system.

Problems starting the engine

How to start a cold engine immediately after purchasing it in a store or after storing it for at least two days? When purchasing gasoline equipment from a specialized store, the consultant can tell you in detail all the details about the operation and startup of gasoline tools, and will even demonstrate this in practice.

In order to start a cold engine, you should set the lever (also called a switch) to the position called “throttle closed”. Next, you need to pump the mixture into the carburetor, if there is a fuel priming pump. Then pull out the starting handle until the engine resistance becomes noticeable, and vigorously pull in amplitude, moving your hand to the side.

After two or three such movements, the engine should first start and then stall. This may not happen, then it is necessary to move the lever to the half-throttle position or simply to the working position and continue driving in this mode with the same movements. After all this it usually starts.

If it doesn’t work out again and the saw doesn’t start, you need to calm down, then take a breath for a couple of minutes and try to start it again in the same mode. Some gas-powered tools have a simple key switch for the ignition; you need to make sure it is turned on.

It should be remembered that current preventive maintenance and fairly competent repair of chainsaws will extend the effective operation of the tool for a long time, and then the reasons for the malfunction of the chainsaw will not appear.

Chainsaw design and general classification of faults

The main condition for successful repair is correct. Therefore, in order to determine why the chainsaw failed and, most importantly, how to make it work again, you first need to know the features of its design.

It should be noted that it is not particularly complex, as it includes:

In order to simplify the diagnosis of faults, they are usually divided into two main categories:

- engine malfunction;

- malfunctions of other chainsaw components.

Most often, failures occur in, however, other parts of the tool can fail at any time due to intensive use or improper care. How to determine exactly where the breakdown occurred? Simple logic will help us with this.

If the problem is in the engine, it will:

- won't start;

- stall;

- work unsteadily;

- overheat;

- smoke;

- develop insufficient power.

As for all other faults, as a rule they manifest themselves when the engine is running normally.

Engine

In most cases, the following problems occur in engine operation:

- the engine stopped starting;

- the engine starts, but after a while it stalls;

- the engine is not able to develop the required power;

- The engine is extremely unstable.

How to check crankshaft seals

The presence of oil seal leaks can only be checked by getting to the crankshaft itself and carefully examining it for leaks. You can see how to do this correctly in the video:

How to check compression on a chainsaw

At a compression level below 8 atmospheres, the engine will not have enough power, which means the chainsaw will not be able to fully function.

To measure compression you need:

- Remove the protective cover and unscrew the spark plug.

- Insert the tip of the compression gauge into the hole where the spark plug should be located.

- Using the starting cord, rotate the piston and remember the maximum readings of the measuring device.

How to properly install a piston on a chainsaw

The work of replacing the piston for most models of modern chainsaws is carried out according to the following algorithm:

- The top and side covers are removed.

- The candle is unscrewed.

- The stoppers are removed from the shock absorbers and the handle is disconnected from the body.

- The drive sprocket and starter are removed.

- A piston stopper is installed in the spark plug hole and the nut securing the flywheel and clutch is unscrewed.

- The flywheel, clutch, and worm drive of the oil pump, located immediately behind the clutch mechanism, are removed.

- The screws securing the carburetor and air filter are unscrewed, after which these components are removed along with the engine control lever.

- The ignition coil is removed, as well as the muffler.

- The saw is turned upside down and, by unscrewing the screws securing it to the body, the engine is disconnected.

- The pan is unscrewed and the piston is removed.

- Since the piston is removed only together with the crankshaft, to disconnect it it is necessary to remove the retaining rings.

- The old piston is replaced with a new one, but as carefully as possible. This is caused by the high fragility of compression rings.

- The crankcase is put in place, and sealant is used instead of a gasket.

Starting the engine: checking the spark plugs

If the chainsaw does not start, the first thing to do is check the tank for . By the way, it must be prepared in the proportions specified by the engine manufacturer, otherwise the tool simply will not start.

After making sure that the fuel mixture is correct and available, you should check the ignition system. To do this, you need to inspect the spark plug.

Her condition can say a lot:

- dry candle

indicates that the fuel mixture does not enter the carburetor, which means the problem is not in the ignition;

- fuel-spattered candle

is the result of an excess of the fuel mixture, which lies either in a violation of the engine starting algorithm or in incorrect carburetor adjustment;

- carbonated candle

This is a signal about the presence of low-quality oil in the engine lubrication system, incorrect carburetor settings, or an incorrectly prepared fuel mixture.

If it is splashed with fuel, it must be thoroughly wiped after removal. The fuel supply system should also be cleaned. To do this, it is closed, after which the starter is turned on. A candle covered with soot must be carefully cleaned using an awl and sandpaper.

When checking spark plugs, you should pay attention to the distance between the electrodes (the normal gap is 0.5-0.65 mm), as well as the condition of the gasket and the presence of a spark. A damaged or worn gasket will need to be replaced, and the spark can be checked by putting on the ignition cable, connecting the cylinder and spark plug nut, and turning the starter.

If the discharge does not occur, the spark plug needs to be replaced. If a spark does not appear even with a new spark plug, then the problem is in the connection to the high-voltage wire or in it itself.

The chainsaw does not start or does not start well. Reason and how to fix it.

Why the chainsaw won’t start. Reason. How to fix it.

The most vulnerable element of a carburetor engine is the spark plug. It also allows us to judge the probable causes of malfunction of individual components of a gasoline engine. The following procedure is recommended.

Read:

Carbon deposits on the spark plug

Chainsaw ignition coil

When installing a new electrical module on the engine, the magneto clearance should be adjusted. The optimal distance between the flywheel and the ignition coil is 0.2-0.4 mm for most chainsaws.

Additionally: How to Adjust the Stihl 250 Chainsaw

Gap between magneto and flywheel

To be sure, it is recommended to carefully study the documentation for the purchased model and follow the manufacturer’s requirements.

With such a small gap, it will not be possible to use the available measuring tool for direct measurement. In practice, for the Husqvarna saw, a template is used in the form of a spacer, cut from a thin and flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when installing it, and then pulled out.

To avoid the need to adjust the ignition, operate the tool carefully, avoiding impacts. In particular, this applies to chainsaws with electronic chips in the ignition system, as they are very sensitive to mechanical damage.

Read:

- magneto;

- spark plugs;

- an electrical cable connecting them to each other;

- motor shutdown buttons.

Here are some common cases:

- The chain saw does not start;

- If so, it works intermittently;

- Insufficient power to operate properly.

Here are some common cases:

- The chainsaw does not start;

- If it starts, it works intermittently;

- Insufficient power to operate properly.

The carburetor serves to prepare a combustible mixture of gasoline and air in a proportion determined by the operator.

The proper functioning of the device depends on proper configuration and adjustment.

And for this you need to know the principles of operation of the Husqvarna chainsaw carburetor.

Its design consists of the following elements:

- housing with clamping bolts and a set of gaskets;

- fuel pump - a device that pumps a gasoline-oil mixture into the carburetor;

- diaphragm - designed to limit the flow of combustible mixture into the engine;

- float chamber - fuel is collected in it, the level is adjusted by a float, and as necessary, the mixture is supplied to the main chamber for mixing with air;

- main chamber - air passes through it, and fuel is injected there; the amount of mixture supplied to the engine is regulated by a throttle valve located here;

- diffuser - a narrowing section of the air supply tube at the point of fuel injection;

- needle valve - a device that regulates the fuel supply;

- jet - screws that regulate the flow of mixture at high and low speeds, as well as the idle screw.

Also in the carburetor design, in addition to the throttle, there is a damper located at the inlet of the air filter. It artificially reduces the air supply, making the mixture richer for easier starting of a cold engine.

The injector valve is responsible for injecting fuel into the main chamber, and it also prevents air from entering. When setting up the carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct impact on the operation of the engine. If stored for a long time, the nozzle may stick. This will restrict the flow of fuel and prevent the engine from starting.

Also, due to prolonged use or due to a manufacturing defect, the valve may allow air into the main chamber. In this case, only replacing it will fix the problem.

The carburetor operates as follows: the air flow entering the diffuser is mixed with the injected fuel, and the resulting mixture is supplied to the engine. The amount of mixture is controlled by the throttle valve. The more mixture, the higher the engine speed.

In the event that the chainsaw does not develop speed or, on the contrary, operates at too high speeds, the carburetor can be adjusted without removing it.

But if the chainsaw does not start, the speed hangs at the same level or it works unstably. Adjusting the chainsaw carburetor will not change the situation. It must be removed for cleaning or replacing parts. You must proceed in the following order:

- After unscrewing the retaining fasteners, remove the upper casing of the saw.

- We remove the gasket and part of the air filter by unscrewing the bolts or snapping off the fasteners.

- There is a fuel hose on the right side of the carburetor. We remove it together with the air damper control rod.

- Remove the carburetor from the mounts holding it.

Disassembling the carburetor is carried out in accordance with the instructions supplied with the kit. When disassembling, take special care to place the parts on a previously prepared cloth. Due to its small dimensions, there is a risk of losing components during disassembly and washing.

All parts obtained in this way are washed in a special liquid, dried and wiped with a lint-free cloth.

Additionally: Shtil ignition adjustment 180. Basic faults and repairs of the Shtil 180 chainsaw

Channels, tubes and jets are purged with compressed air, if possible, after having previously washed them in an ultrasonic bath.

After setting up, you need to start the chainsaw. Check stability at idle speed. In this case, the chain should not move. When you press the accelerator, the chainsaw should accelerate steadily and stop without delay.

At minimum and maximum speed levels, the Husqvarna 350 should operate stably, without any extraneous noise. There should be no sudden loss of power or shutdown during operation.

DIY chainsaw repair: fuel supply system

If the fuel mixture does not enter the cylinder, but the spark plug works normally, this may mean that:

- The fuel filter is clogged.

To clean this unit, remove the fuel hose and check the flow. If it is weak, the filter must be removed through the filler hole of the fuel tank and cleaned or replaced if completely worn out.

- The breather is clogged.

This is nothing more than a hole in the fuel tank cap, which is cleaned with an awl.

- The fuel mixture is not supplied or is supplied in insufficient quantities.

There may be several reasons for this:

Chainsaw malfunctions

All chainsaws are similar in structure, regardless of whether they are made in Europe (Makita 5704RK, Hitachi C7SS, Bosch GKT 55 GCE, DeWALT DWS520K, Bosch PKS 40, Husqvarna 445e, Stihl MS 250, Bosch Keo, AEG US 400 XE, Makita 2107FW , JET JWBS-9, DeWALT DWE397, EIBENSTOCK EDB 480, FUBAG PKH 35A 120M) or domestic (Interskol DP-140/800,). Inside the body there are the main elements - the fuel tank and the engine, and outside there is a starter, a handle, a saw part (tire) with a chain. A sharp tug of the cable starts the engine, and it starts the saw blade.

To begin with, we invite you to familiarize yourself with videos that show how a chainsaw works and how it works:

From time to time, malfunctions occur in the operation of the saw, which require disassembly to eliminate. What can happen to such a simple mechanism as a chainsaw?

At least the following:

- Stops starting;

- It starts, but soon stops;

- Stops functioning when cutting;

- Loses its power;

Most problems are associated either with interruptions in engine operation (fuel supply system, exhaust system, ignition, cylinder-piston part), or with malfunctions of other systems and components (clutch, chain brake, tire, lubrication system). Let's look at the most common breakdowns and methods for eliminating them.

| Possible malfunctions of the chainsaw | ||

| The engine does not start or stops spontaneously | Incorrect startup procedure | Refer to the Guide |

| Plug dirty or incorrect air gap | Check spark plug or replace | |

| Air filter clogged | Clean or replace the filter | |

| Empty fuel tank | Fill with fuel | |

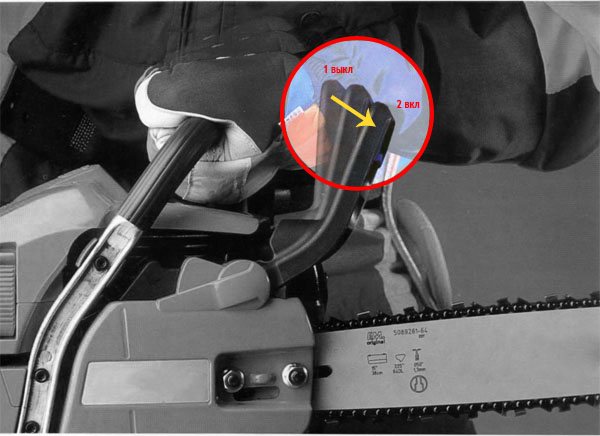

| Perhaps the saw switch is in the “O” position | Turn the switch to position “1” | |

| The air damper is in the extended position; press it against the saw body. | Open the air damper | |

| The engine starts, but there is not enough power | Air filter clogged | Clean or replace the filter |

| Check the spark plug | Clean or replace with a new one if necessary. | |

| Carburetor not adjusted | Adjust the carburetor | |

| Check the air filter, it may be clogged. | Clean or replace with a new one | |

| Incorrect mixture composition | Prepare the mixture according to the Manual | |

| There may be old fuel mixture left in the fuel tank. | replace it with a new one. | |

| Engine does not develop power under load | Plug dirty or incorrect air gap | Check the spark plug |

| Carburetor not adjusted | Adjust the carburetor | |

| The engine smokes a lot | Incorrect mixture composition | Prepare the mixture according to the Manual |

| You may have confused motor oil with chain oil. | Drain the old fuel mixture, flush the fuel tank with gasoline, fill with fresh fuel mixture | |

| Air filter clogged | Clean or replace the filter | |

| No chain lubrication, chain gets very hot | Clogged channel or oil holes | Clean the channels and hole in the bar, remove dirt from the saw body. |

| Grease available | Check the presence of chain oil in the tank | |

| Empty oil tank | Fill with lubricant | |

| When the drive is running, the chain does not move | Brake on | Turn off the brake |

| Chain brake faulty | Repair the brake | |

| Unlock Chain Brake | pulling it towards the front handle. | |

| The chain travel is difficult or the chain comes off the bar | Incorrect chain tension | Adjust tension according to the Manual |

| Low cutting performance | The chain is dull or improperly sharpened | Sharpen or replace the chain |

| Incorrect chain tension | Adjust tension according to the Manual | |

Suitable for models DeWALT D24000, Stihl TS 420, Echo CSG-680, Husqvarna 240, Stihl MS 180-14, Echo CS-353ES-14, Hyundai X360 Makita EA3203S-40, PARTNER P340S, Bosch AKE 30 LI, Makita DCS4610- 40, Husqvarna 436 Li

Troubleshooting muffler problems

If it works fine at low speeds, but starts to stall and smoke at high speeds, the problem may be hidden in the muffler.

To check the quality of its work you should do the following:

Dry cleaning without respiratory protection is not recommended. Carcinogens present in carbon deposits will be released into the surrounding atmosphere in the form of dust, the inhalation of which is extremely dangerous to health.

To prevent clogging of the muffler during operation of the chainsaw, you should carefully monitor the composition of the fuel mixture and the quality of its components.

Chainsaw Doesn't Cut Under Load

Content

Why does a chainsaw stall under load?

The chainsaw starts and stalls, the reason

A chainsaw has long been no longer a luxury, but a necessary tool for anyone who has at least some suburban area. With its help, it is possible to carry out gardening work, collect firewood, process lumber, and not just anything else. There are a lot of models of chainsaws on sale, differing both in power and not in the overall quality of workmanship. You can check it here. e-catalog.ru.

But no matter what type of equipment you find capricious, chainsaws are no exception. Let's look at more relevant obstacles.

The tool stalls immediately after starting

One of the likely circumstances is a lack of fuel. Check the volume of fuel in the gas tank and add more if desired. In all this, you should strictly follow the advice in the instructions, especially regarding the properties of gasoline and oil. In our country, such subtleties are often ignored, filling the saw with whatever is necessary, which causes accelerated wear of the motor and does not lead to failures.

The saw may also stall due to deterioration in the contact of the spark plug with the high-voltage wire. This is caused by a mechanical shift or the formation of carbon deposits. It is recommended to replace the candle with a new one from time to time if the old one did not show any problems during operation.

A chainsaw can work normally when in a straight horizontal position, although annoyingly it stalls when tilted to the side. You, this is also due to a lack of fuel: the fuel pipe rises when tilted, when there is virtually nothing of fuel, then, like oil, it rises above the fuel level.

Chainsaw stops idling

Our client is advised to check the muffler, because its contamination can lead to a deterioration in the exhaust gases, due to which the engine does not stop.

If cleaning the muffler did not help resolve the problem, and your saw has a carburetor engine, then there is an option to try and tune it. Most engine models have adjusting bolts of a rough, unclear option (H not L, respectively). By increasing the engine speed, this will remove the problem. Keep in mind that adjusting the carburetor is a rather complex process that requires the use of a tachometer.

The engine cannot withstand the load

If the chainsaw stops right in the middle of a particularly thick log, then the problem for you is caused by problems in the fuel supply system, or, in other words, problems with the air filter. The engine simply does not get enough of a flammable consistency in a workplace with a heavy load, and does not stop.

The usual solutions to these problems are changing the fuel in strict accordance with the advice in the annotation (we have already talked about this) and not cleaning (replacing) the air filter.

The chainsaw stalls when the speed increases

The prerequisites for this phenomenon are similar to the previous ones: either a problem in the fuel system or in the air filter. Try to disconnect the fuel hose from the carburetor - if gasoline flows poorly (but you definitely understand that there is fuel in the tank), then the reason is the gasoline filter. You can, at the same time, check not the fuel pump - fuel should not penetrate through it. When this happens, it is advisable to change the pump.

Why does the chainsaw stall?

There are several reasons why a chainsaw stalls. No, you, they can be solved without the help of others, without going to a service center.

First, check the filters: fuel not air. If they are clogged, then this is probably not the natural reason for the instrument not working properly. At the same time, dirt is not always visible to the naked eye. If it seems that what remains to be done is in order for our client, it is better to carry out this function.

READ Chainsaw Starts Only With Gas

Another reason for you is in the candle. Do you remember the last time you changed it? When using chainsaws, this should be done once a year.

If this does not help, then it is worth trying to adjust the carburetor. For you, due to vibrations while working with a chainsaw, its factory options were lost.

Opposite the saw stalls after long storage, nettle, in an unheated garage, then it’s worth taking a look at the fuel line. As a rule, this is a rubber tube, which can crack due to dampness or temperature changes, but this is not a reason for the chainsaw to malfunction.

If none of the above helped, then, most likely, the breakdown is more severe; unfortunately, you will have to contact a workshop.

What to do if your chainsaw stalls?

- The car stalls at idle: probable reasons

- Problems with fuel and air filters do not eliminate these defects

- Difficulties with the spark plug, not methods for solving them

- Substandard carburetor operation

- Obstacles associated with incorrect operation of the fuel complex accounting programs

- Difficulty idling due to a faulty muffler

- Malfunctions of the cylinder-piston group

Builders, installers, rescuers are not summer residents #8211 when they carry out their tasks and take up a chainsaw. It’s not how the myth tool works that ultimately depends on the final outcome of their activities.

Chainsaw

used for cutting wood.

It should be noted that a chainsaw is a relatively lightweight device. Moreover, in other words, not only oil, but also other mechanisms sometimes break down. When a chainsaw stalls while idling (this is one of the most common malfunctions), the biggest problem #8211 is to determine the reasons for this behavior of the device. If the source of the “disease” is correctly identified, returning the device to a working position will not be so difficult.

Therefore, you first need to find out what malfunctions a chainsaw has, not what causes the engine to stop idling.

The car stalls at idle: possible reasons

To answer the question what is real, why the saw, sometimes capricious, stalls at idle

, you need to keep in mind that this tool is based on a regular two-stroke gasoline engine.

We conclude that malfunctions are caused by various problems with the main components of any internal combustion engine: fuels and lubricants, the ignition system, the quality of the air-fuel mixture and compression inside the cylinder.

The main engine malfunctions include the following:

- the engine won't start

- it starts, as annoying as it may sound, it works unstable, it quickly stalls at idle

- The chainsaw runs fine at idle, but stalls under load.

The reasons for idle speed problems vary. But there is an option to reduce all of them to several general positions. What is necessary, internal combustion engine malfunctions are caused by such obstacles as:

Internal combustion chainsaw engine.

Possible clogging of the fuel and air filter

- Another disadvantage is problems with the spark plugs

- a violation in the initial carburetor settings caused by strong vibrations during operation of the mechanism

- disadvantages of the gas pipeline

- incorrect ratio of ingredients in the “fuel mixture”

- muffler contamination

- malfunction of the cylinder-piston group.

The saw does not develop speed, does not develop power.

Why does such a problem arise that it seems like a saw

It worked great, but suddenly the power is lost without

spinning

up.

Return to contents

Problems with fuel and air filters and their elimination

The chainsaw will shut down at idle if the fuel air filter is clogged. To find out the condition of the first element of the fuel complex of accounting programs, you should disconnect the gas line from the carburetor. If, during pumping, fuel is supplied in doses that comply with these standards, then the cause of the malfunction should be found wherever you like. When gasoline flows to the carburetor weakly, or in other words, does not flow out of the hose at all, then perhaps the filter is clogged with debris.

To clean it, it is removed from the tank (from the tank before the moment it is drained, our client is left with fuel). Removal occurs through the filler neck of the tank using a wire hook. The filter is disconnected from the absorption hose. If possible, clean the filter. If there is no such ability, or, in other words, doing this is impractical for a number of circumstances, the used filter is replaced with a new one.

READ Day R Survival Where to Find a Chainsaw

The chainsaw may stall if the fuel filter becomes clogged.

The air filter is also clogged with dirt, also called dust, which leads to malfunctions at idle

. It should be remembered that this filter becomes clogged quite often, making it difficult for air to enter the system. The proportion of gasoline in the fuel-air mixture increases, and it becomes excessively enriched. In this case, normal engine operation cannot be expected.

To clean the air filter, remove it with extreme care so as not to shake dust into the carburetor. Next, it is cleaned and washed thoroughly. Detergent is added to the rinsing water. After drying, the air filter returns to its place in the chainsaw.

For normal operation of the cutting tool, it is recommended to change the fuel and air filters every three months.