ENGINE

At the request of the customer, this model can be supplied with different engine models.

YaMZ-236ND-2 136 kW (185 hp),

QSB 6.7-C204 137 kW (187 hp)

TRANSMISSION

Planetary power shift transmission with 345 mm diameter oil-fed clutches with high torque transmission capability, providing three forward and three reverse gears. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. A three-element, single-stage torque converter with an active diameter of 390 mm, a maximum transformation ratio Ko = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan transmission and an elastic coupling mounted on the engine

| Broadcast | Forward travel | Reverse |

| 1 | 3,7 | 5,0 |

| 2 | 6,8 | 9,0 |

| 3 | 11,10 | 14,4 |

The traction force depends on the weight of the tractor and the traction force.

CHASSIS

Suspension: three-point semi-rigid with a remote swing axis of the bogies provides high traction properties, reduced shock loads on the chassis system, and improved working conditions. Support, support rollers and idler wheels with one-time lubrication for the entire service life with self-clamping “double cone” seals.

Number of support rollers (on each side) - 6 Number of support rollers (on each side) - 2

Caterpillars:

prefabricated with one lug and a seal to hold liquid lubricant in the hinge. Track tension is easily adjusted with a grease gun.

Link pitch - 203 mm Number of shoes (on each side) - 39 Height of lugs - 65 mm Shoe width - 510 mm Base - 2616 mm Support surface area - 2.668 m2 Ground pressure - 0.76 / 0.75 kgf/cm2

Hydraulics and attachments for the Chetra T-11 bulldozer

The separate-module system of the T-11 bulldozer includes:

- The S1A6097 gear pump produces a capacity of 163 l/min at an engine speed of 1800 rpm. ;

- Four-section distributor from , three working sections, one valve;

- The safety valve operates at pressures above 200 MPa;

- Welded hydraulic tank, capacity 85 l;

- Hydraulic cylinders 5 pcs. 2 for raising and lowering the blade, 1 for turning the blade left and right, 2 for raising and lowering the ripper.

Bulldozer equipment.

A large-capacity hemispherical blade provides the T-11 bulldozer with high performance. The use of diagonal traction when transferring lateral loads from the blade to the left spar of the bulldozer provides the greatest proximity of the blade to the hood and the greatest support force on the blade blade.

We recommend reading: MTZ-311: owner reviews

Ripper.

Depending on the required productivity, CHETRA bulldozers are equipped with rippers with one tooth, as well as with three or two teeth.

- Type of ripper – multi-shank/non-adjustable;

- Number of teeth – 3/1;

- Depth – 640/530 mm;

- Penetration force – 6.14/5.7 t;

- Pull-out force – 17.15/16 t.

WORKPLACE

The CHETRA T11 tractor has a single-seat, double-glazed cabin that provides maximum visibility of equipment and work areas, regardless of the ambient temperature, equipped with a ventilation system and a dependent-action heater, as well as a vibration-proof seat and noise-absorbing upholstery. Additional heating and air conditioning are available upon request. The controls satisfy ergonomic requirements and are easy to operate and reach. The diesel engine is controlled by a pedal fixed at the selected crankshaft speed. Shifting gears and changing the direction of movement is carried out by one lever, the onboard clutches are controlled by two levers, and an emergency stop is provided by pressing the brake pedal. The bulldozer and ripper are controlled by separate levers. All control is carried out from the driver's seat, which allows him to work without fatigue during the work shift.

The history of the creation of the Chetra T-11 bulldozer

The decision to build a new, large tractor plant was made in 1971, and in January 1972 its construction began. Simultaneously with the construction, recruitment was underway for the team of tractor builders of the new enterprise, the Cheboksary Industrial Tractor Plant or ChZTP.

Experienced specialists from such enterprises as ChTZ, PTZ, VgTZ, etc. were invited to lead positions. In the same 1972, recruitment began for ordinary positions, and young people from different parts of the country flocked to the new enterprise.

In December 1974, the first workshop of the plant began operating; components for the first tractor were manufactured on its premises. In 1975, on October 25, the technical control department accepted the first bulldozer of the ChZPT brand, a heavy T-330 with a power of 330 hp. This day is considered to be the birthday of the enterprise. In September 1982, the anniversary, 1000th tractor T-330 was manufactured.

At the end of 1993, ChZPT was privatized and transformed into Promtractor OJSC.

In 1995, the T-35 and T-25 tractors went into production; these machines were equipped with YaMZ diesel engines. Work on bulldozers with a power of 240 and 280 hp, called T-15 and T-20, began in 1996.

We recommend reading: At Golden Autumn an agreement was signed with the CLAAS dealer to implement a project worth 350 million rubles

The T-20 was assembled first in the winter of 1997, and in October 1999 the first production T-15 was assembled. In the same 1999, the design of the T-11 began, it weighed 19 tons and the power reached 180 hp. The first T-11 bulldozer was manufactured in 2001, Sberbank took part in this project as an investor, and its mass production was launched in the same year.

In 2002, at the Tractor Show, where new tractor models were demonstrated, Promtractor OJSC for the first time presented to the public its products under the CHETRA brand. In June 2005, the company became part of the Tractor Plants LLC concern.

Catalog of spare parts for bulldozer Chetra T-11

The modular use of components allows for complete repairs at minimal cost. Each element is easily transported, leaving a multi-ton vehicle on site, it will be possible to transport spare parts and make replacements there.

The catalog allows you to replace any element: transmission, electrical equipment, chassis, attachments, controls. An expanded catalog allows you to select suitable parts and also become familiar with the design, which simplifies the replacement process.

Chetra T-11 outperforms many competitors; even foreign analogues cannot compare in technical components. Domestic manufacturers have finally paid special attention to operator comfort. When creating equipment, modern developments and design solutions are used. There are also minor shortages. The first problems with hydraulics arise after 2-3 thousand hours or with the transmission. Experts are already working to eliminate the shortcomings. Otherwise, you will be pleased with the technical characteristics and performance of the equipment. The cost of such a unit is 4-7 million rubles, depending on the model and year of manufacture; it will be cheaper on the secondary market. The Chetra T-11 is designed for work in difficult conditions, the investment will be worth it.

BULLDOZER CHETRA T-11

To order

The CHETRA T11 bulldozer-loosening unit is manufactured according to technical documentation T-11.01Ya/K, has greater productivity thanks to the use of advanced design and technological solutions and can be used in industrial, oil and gas, hydraulic engineering, road construction and mining industries for earth-moving work, including including when developing frozen soils.

Specifications:

ENGINE

At the request of the customer, this model can be supplied with different engine models.

| Engine model | Power |

| YaMZ-236ND-2 | 136 kW (185 hp) |

| QSB 6.7-C204 | 137 kW (187 hp) |

TRANSMISSION

Planetary power shift transmission with 345 mm diameter oil-fed clutches with high torque transmission capability, providing three forward and three reverse gears. Structurally, it is combined with a matching gearbox and main gear into a single power unit installed in the bore of the rear axle. A three-element, single-stage torque converter with an active diameter of 390 mm, a maximum transformation ratio Ko = 2.539 with a pump drive gearbox, connected to the gearbox with a splined clutch, installed on the front wall of the rear axle. The torque converter is connected to the engine through a cardan transmission and an elastic coupling mounted on the engine

| Broadcast | Forward travel | Reverse |

| 1 | 3,7 | 5,0 |

| 2 | 6,8 | 9,0 |

| 3 | 11,0 | 14,4 |

The traction force depends on the weight of the tractor and the traction force.

STEERING AND BRAKING CONTROL

Side clutches are multi-plate clutches that are hydraulically actuated. Stopping brakes are multi-disc clutches that are permanently closed by spring force. Onboard clutches and brakes are cooled by oil under pressure and do not require adjustment during their entire service life.

FINAL TRANSMISSION

The final drive is two-stage, the 1st stage is external gears, the 2nd stage is planetary according to the “k+1” scheme (with a stopped ring gear). To facilitate easy replacement in the field, the drive sprocket is made of five sectors, which are secured with bolts.

CHASSIS

Suspension: three-point semi-rigid with a remote swing axis of the bogies provides high traction properties, reduced shock loads on the chassis system, and improved working conditions. Support, support rollers and idler wheels with one-time lubrication for the entire service life with self-clamping “double cone” seals.

| Index | Meaning |

| Number of road wheels (each side) | 6 |

| Number of support rollers (each side) | 2 |

Tracks: Prefabricated with a single grouser and seal to retain liquid lubricant in the joint. Track tension is easily adjusted with a grease gun.

| Index | Meaning |

| Link pitch | 203 mm |

| Number of shoes (each side) | 39 |

| Height of lugs | 65 mm |

| Shoe width | 510 mm |

| Base | 2616 mm |

| Supporting surface area | 2,668 m2 |

| Ground pressure | 0.76/075 kgf/cm2 |

REFILLING CAPACITIES

- Fuel tank - 285 l.

- Cooling system - 75 l.

- Engine - 23 / 17.5 l.

- Torque converter, gearbox, bevel gear - 130 hp.

- Final drive (each side) - 15 x 2 l.

- Hydraulic system of attachments - 135 l.

TRACTOR WEIGHT

Tractor weight 20300-23070 kg

WORKPLACE

The CHETRA T11 tractor has a single-seat, double-glazed cabin that provides maximum visibility of equipment and work areas, regardless of the ambient temperature, equipped with a ventilation system and a dependent-action heater, as well as a vibration-proof seat and noise-absorbing upholstery. Additional heating and air conditioning are available upon request. The controls satisfy ergonomic requirements and are easy to operate and reach. The diesel engine is controlled by a pedal fixed at the selected crankshaft speed. Shifting gears and changing the direction of movement is carried out by one lever, the onboard clutches are controlled by two levers, and an emergency stop is provided by pressing the brake pedal. The bulldozer and ripper are controlled by separate levers. All control is carried out from the driver's seat, which allows him to work without fatigue during the work shift.

RIPPERING EQUIPMENT

Ripper: one-, three-, seven-teeth.

BULLDOZER EQUIPMENT

Blade type:

- hemispherical,

- rotary (mechanical),

- straight,

- rotary (hydraulic).

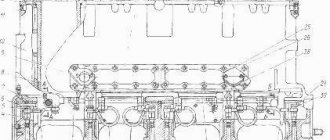

Engine of the bulldozer Chetra T-11

At the request of the customer, this model can be supplied with different engine models.

Six-cylinder V-shaped (camber angle 90°) four-stroke diesel engine without turbocharging, liquid cooling YaMZ-236 DK-7 of the Yaroslavl Motor Plant.

- The cylinder diameter and piston stroke are 130 mm. x 140 mm;

- Maximum torque - no less than 716 Nm. at 1300-1500 rpm;

- Engine displacement - 11.14 liters;

- Operating power - 127 kW. at 2000 rpm..

Fuel pump with injection timing control with all-mode speed controller. Oil purification system with full-flow centrifugal speed controller. Liquid-oil heat exchanger for cooling engine oil. A heat exchanger for cooling transmission oil is installed as part of the radiator block. Thermal control is provided by a thermostat and a fan driven by a disc clutch with automatic activation control depending on the coolant temperature. 24-volt electric starting system.

Four-stroke liquid-cooled diesel engine with turbocharging QSB6.7-C197. Six cylinders, in-line cylinder arrangement.

- The cylinder diameter and piston stroke are 114 mm. x 135 mm;

- Engine displacement - 8.3 liters;

- Operating power - 132 kW. at 2000 rpm..

Full-flow oil purification system with one replaceable paper filter element. Liquid-oil heat exchanger for cooling engine oil. Push type fan. Fan drive via belt drive. Thermal control is provided by a thermostat. Transmission oil is cooled by engine coolant in a heat exchanger installed separately from the engine. Anti-corrosion filter for the cooling system.