To quickly and effortlessly tidy up a summer cottage or local area, brush cutters are used. Their most intensive use occurs in the warm season. Before work, preparations are made - lubrication of moving parts, checking and replacing the cutting set, refueling with the fuel mixture. Not everything always goes smoothly - the engine may not start or stall almost immediately. To identify and repair faults, look at the attached documentation. The article will discuss the repair of lawn mowers, with photos and illustrations, as well as its most common malfunctions.

Petrol mower device

The main element is an internal combustion engine, usually a two-stroke one. Connected to it through a gearbox is a shaft that transmits force to the cutting headset and is covered by a tubular rod. The cutting part in the form of knives or fishing line rotates at high speed (10-13 thousand rpm). The protective casing has technological holes for lubricant supply. For comfortable use, the brush cutter is equipped with a belt.

There are two types of cutting elements:

- Line with a cross section of 1.6-3 mm for the trimmer head. During operation, the fishing line wears out, and either the bobbin with fishing line is replaced, or the fishing line is rewinded and replaced.

- Double-edged steel knives for cutting small bushes, or thick and dense vegetation. The difference between them is both in shape and sharpening.

The handle attached to the bar is equipped with buttons and levers for controlling the lawn mower. A protective casing is installed on the cutting mechanism.

Refueling is done into an existing tank, mixed in the required proportions with gasoline and oil, and gasoline is used with an octane number of at least 92. Gasoline mowers with a four-stroke internal combustion engine are refueled differently - gasoline is refueled separately, oil is poured into the crankcase separately.

Video: How to Clean a Trimmer Carburetor

Entrance needle wear

The suction needle fails, usually due to the presence of abrasive particles in the fuel liquid.

- The tightness of the inlet needle seat is broken;

- Leakage of fuel mixture;

- There are engine malfunctions associated with over-enrichment of the fuel mixture.

In addition, the input needle may simply get stuck.

Causing the intake needle to stick can be caused by the presence of dirt in the fuel, or a long idle machine without running.

The control cavity is clogged

If dirt accumulates in the control cavity, the inlet needle cannot close the hole tightly and a lot of fuel spills into the chamber.

This causes the fuel to become over-rich and the engine begins to fail. It is necessary to disassemble the carburetor and clean the cavity of the adjusting membrane.

Control membrane deformation

The membrane can become deformed during prolonged operation of the unit and when using aggressive fuel.

The impossibility of normal adjustment due to a defect leads to:

- Piston damage;

- Difficulties in starting;

- Fuel depletion;

- Engine failure.

READ What Line Diameter to Choose for the Champion Trimmer

Enter lever problem

This problem may occur if the control arm is not installed correctly or is bent before installation. As a result, the contact surface takes an incorrect position, which disrupts the supply of additional fuel.

Damper wear

The throttle and choke valves mostly wear out due to the presence of abrasive particles in the air. Defective shock absorbers look as if they have been sandblasted.

Damper wear reduces engine performance, engine malfunctions and wear on the piston rings, piston and cylinder head.

Gas and air wear

The air and throttle shafts can wear out for the following reasons:

- Insufficient and improper maintenance of the air filter;

- The air filter is damaged;

- The air filter is not suitable for this device.

Due to the impact, poorly purified air causes the shaft to wear out and may break. Broken shaft parts can enter the combustion chamber or crankcase and cause serious damage to the entire piston system.

To eliminate problems with air purification, it is necessary to replace the faulty filter or rinse the existing (working) one. The filter must be washed in soapy water and dried.

It is impossible to start the engine - reasons

The first thing to do is check whether there is gasoline in the tank, and if so, what quality it is. The use of low-quality or low-octane gasoline leads to failure of the piston system. Repairing a piston trimmer will cost almost half of its total cost. The correct proportion of gasoline and oil, given in the attached operating instructions for the tool, is also important.

Making a large amount of the mixture is undesirable, since it becomes unusable over time. You should not use an old mixture that has been standing for some time.

The engine may not start if the fuel filter is seriously clogged. If it is severely clogged, it must be replaced. Do not use the trimmer with the fuel filter disconnected. The air filter may be clogged. In this case, it is washed with water and detergent and dried, or in extreme cases, soaked in gasoline. After installation, the dried filter is moistened with the oil used in the mixture.

If after the above measures the internal combustion engine does not start, it is adjusted at idle speed using a screw on the carburetor.

Common carburetor malfunctions

Trimmer carburetor breakdowns occur due to the use of poor quality gasoline, a damaged air filter, and the accumulation of dirt in the chamber of this unit. Most often, it is quite possible to repair a carburetor yourself. Listed below are typical problems with the carburetor of a brush cutter.

Fuel pump problems

A common malfunction that “haunts” the fuel pump is deformation of the pump membrane. For this reason, it does not seal properly and the pump channels do not seal.

The reasons for membrane deformation may be the following:

- long-term trimmer operation;

- use of unsuitable fuel;

- entry of gases into the pulse channel.

As a result, damage to the membrane reduces pump performance, and as a consequence:

- the combustible mixture becomes depleted;

- it is difficult to start the engine;

- there are interruptions in the operation of the motor;

- the piston is damaged.

Quick start of the brush cutter

The procedure is as follows:

- Putting the lawn mower down with the air filter facing up, remove it and pour a little mixture into the carburetor and put the filter back on.

- If after the above procedure it is not possible to start the brush cutter, you need to check the spark plug. The internal combustion chamber is dried and the spark plug is replaced with a working one.

- If the spark plug is working, proceed as follows. Close the air damper on the carburetor and pull the starter handle. Open the damper and pull the handle 3-4 times. The process is repeated several times.

Spring can get in the way

My first attempt at adjusting the carburetor braid failed because the spring on the fuel mixture adjustment screw prevented it. The factory spring was too thick when compressed and did not allow the fuel flow to be reduced to the required level. I had to assemble another spring and continue making adjustments after replacing it.

READ How to Assemble a Starter for a Husqvarna 128 Trimmer

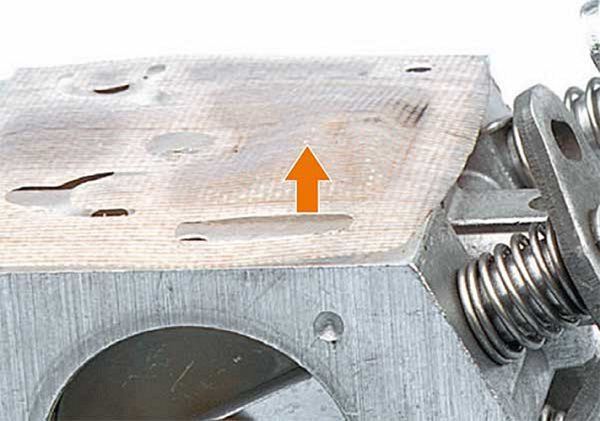

Spring adjusting screw

In the photo above. Factory spring, below the adjusting screw with the selected spring. I am writing about this because I am not sure if this is an isolated case and someone else may face the same situation.

Spark plug malfunction - action algorithm

They act this way:

- let the engine sit to cool down;

- remove the high voltage wire from the spark plug and unscrew it with a special wrench;

- after inspecting the spark plug, it is replaced if it is heavily soiled, there is a crack in the body or any other malfunction;

- check the gap between the electrodes, it is ideally 0.6 mm;

- clamp the new spark plug using a special key;

- connect a high voltage wire to the spark plug.

Operating principle

A carburetor is a power source in which liquid fuel and air are mixed before being introduced into the engine cylinders. Depending on the tool and its operating mode, mixing and feeding are adjusted accordingly.

The carburetor design is the same in almost all cases. Belongs to the category of floating devices. The latter provide stable parameters for the finished mixtures.

The operating principle of the module is as follows.

- Air enters the tube body with an air damper. The latter increases or decreases the air flow depending on its position.

- In the area where a hole for gasoline is formed, the tube has a narrowing - a diffuser. Here the flow speed increases.

- Fuel from the float chamber is supplied to the pipe through the nozzle. The float level determines the amount of fuel supplied. Since the pressure in the chamber is normal and low in the pipe due to the greater vacuum of the air, gasoline is sucked through the nozzle.

- The accelerated air flow collects the fuel and atomizes it, forming an air-fuel mixture of the desired density.

- The mixture is sucked into the cylinder through a pipe.

The more open air valves in the pipe, the higher the air flow density, which means more fuel enters the cylinder. Installing a brush carburetor comes down to establishing a damper ratio at which the density of the fuel mixture becomes optimal.

The lawn mower stalls after starting

The probable cause of the failure is a problem in the lawn mower's carburetor. A sign of this is that the tool vibrates strongly during operation. They do this - they adjust the carburetor according to the diagram specified in the documentation.

Another reason is a clogged fuel valve. They clean it. It may be difficult to supply the mixture to the carburetor, and then the lawn mower will suddenly stall. In such cases, the carburetor valves are loosened.

When too much air enters the system, the lawn mower also stalls. It is necessary to increase the engine speed and squeeze out the air, and also check whether the fuel hose is damaged. If defects are found, it is replaced.

Timely and proper care of your lawn mower is the key to its trouble-free operation for several seasons. It is better to spend a little time on prevention than much more on repairs, not to mention wasting money.

Carbon regulation

Clean the air filter before adjusting the carburetor. It is recommended to rinse every 10 hours. After this you can start setting up. The example photo shows the carburetor of the petrol trimmer PRORAB-8406. The numbers indicate the adjustment screws we will use.

READ How to Change Line in Champion Trimmer Video

Screws for adjusting the carburetor of the PRORAB-8406 carburetor

Purpose of adjusting screws:

- Screw for adjusting the fuel mixture.

- Idle speed adjustment screw.

- The propeller limits the maximum speed.

Start the brush and wait for it to warm up.

Fuel adjustment

Start slowly tightening the propeller, which regulates the fuel mixture, until the engine stalls or freezes if you haven't caught the timing. Then back the screw a quarter turn if the engine is not running, or a half turn if it is not running. Start the stopped engine. Check by opening the throttle how the engine accelerates. Continue unscrewing the No. 1 screw a quarter turn until the engine begins to confidently gain increased speed when gas is applied. This will be the moment of the most economical stable operation of the engine. On the PRORAB-8406 gas trimmer, turn the adjusting screws clockwise and unscrew. Counterclockwise, some other brands of hedge trimmers may be the other way around.

Idle speed adjustment

Let's move on to the low speed setting. Screw #2 limits the reverse movement of the throttle lever. By turning it around, we increase the idle speed, unscrew it, and reduce it. Adjust so that the engine runs strong at low speeds and even a little faster (for better starting), but so that the line spool or blade does not spin, and there is enough headroom before you start spinning. If the engine starts hard, still increase the idle speed.

Maximum speed limit

After adjusting the fuel mixture and low speed, check how the hedge trimmer engine operates at maximum speed. If necessary, limit the maximum speed to the required level using the #3 hollow screw. Unscrew the locknut and tighten it to reduce the maximum speed, or unscrew it to increase it. After adjustment, tighten the nut. Setting the maximum speed is necessary to protect the trimmer motor from overheating and to be able to use the key lock to reduce right hand fatigue.

You may need to adjust the carburetor trim later. For example, if the engine starts to rev poorly when running at full load, turn screw #1 back another quarter turn. If starting is difficult, increase idle speed. Weather conditions and the quality of the fuel mixture can affect the performance of brush cutters. Vibrating propellers themselves can also tip over due to vibration.