Do-it-yourself grass and branch chopper - functionality, requirements

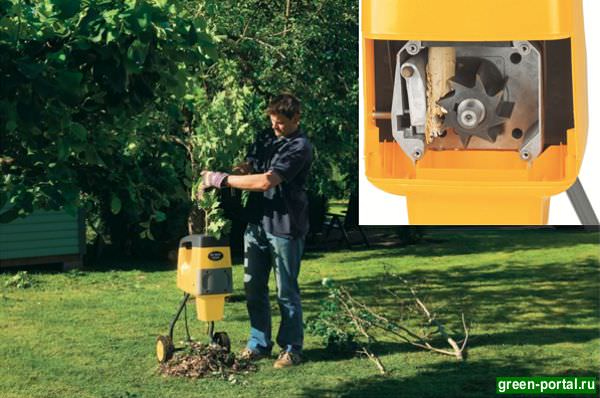

The machine is required to quickly cut cut greens and small branches into small pieces. In order not to carry cut plants far, the chopper can be made on wheels for mobility. Loaded branches or leaves must not be blown back out of the tank. The casing prevents small particles from flying in different directions.

To assemble the device with your own hands, you need to consider the availability of parts and the reliability of materials.

Safety precautions when working with a chopper and during its manufacture

Since the design of the garden shredder includes piercing and cutting elements driven by a powerful engine, in order to avoid injuries you should follow the safety rules when working with it:

- Before starting work, it is necessary to protect your face, eyes and head from wood chips, which can fly in different directions during the grinding process. This point is especially relevant when processing large branches. To do this, it is recommended to wear special safety glasses, a hat and a mask. You also need to select protective gloves that are sized so that they do not fall off your hands while loading raw materials.

- The garden shredder must be installed on a flat surface to avoid it being thrown over during the working process. It is strictly forbidden to operate electric grass cutters in rainy or windy weather.

- You can push and straighten the branches located in the funnel of the device only with a special pusher, but not with your hands.

- Breaking branches should be of the recommended thickness, which will help avoid equipment breakdown.

- Before loading the grass into the grinder, it is recommended to first sort it out, removing foreign objects from it (stones, metal, glass, plastic, etc.).

- It is recommended to use only fresh branches for crushing. To avoid short circuits, do not use units with a damaged wire or socket, or allow moisture to come into contact with the cable. When refueling a petrol shredder, do not use an open fire near it, or smoke.

- Before cleaning the device, you must wait until all units have completely stopped and disconnect the chopper from the power supply.

A garden shredder is an indispensable and useful thing for gardeners and farmers, which can be easily purchased at markets or made with your own hands. The main thing is to follow safety precautions and properly maintain the unit.

The principle of operation of the chopper

A garden waste shredder is somewhat reminiscent of a food processor in operation. It consists of a receiving box, a motor, knives mounted on a shaft, a frame and a box for finished small particles.

Small branches, greens and leaves are lowered into the receiving box. At its bottom there are blades that rotate at high speed due to the operation of the motor. The knives are attached to the operating shaft, which is spun by a motor using a belt (chain) or directly. The ground waste is blown through an outlet pipe or casing into a receiving container.

Types of Garden Shredders

The most popular cutting systems (RS), tested in practice and proven to work well, are:

- Hammer PC - installed on low-power units that are designed for processing small-caliber branches. The advantage of such shredders is their low price;

- RS based on cutting mills - used in powerful units for grinding solid waste, as well as large wood waste;

- Blade PC - used in most popular models of garden shredders. Devices with such a system easily process both grass and leaves, as well as branches of various thicknesses.

Note! The blade cutting system of a garden shredder is the most versatile and is well suited specifically for those jobs that are performed in the garden.

Design and principle of operation of a shredder with a knife RS

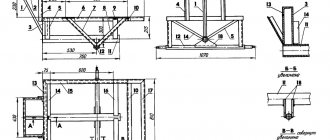

Despite the rather complex drawings that can be viewed on the Internet, the design and operating principle of such a chopper are quite simple.

The body of the garden shredder is usually mounted on a special support in the form of wheels or legs for convenient transportation of the device. Externally, this whole structure looks like a cart with a handle. Inside the housing there is a mechanism (gasoline or electric), as well as a grinding system.

The whole principle of operation of the chopper is very similar to the principle of operation of a conventional meat grinder:

- A cutter with knives is attached to the electric motor shaft, with the help of which garden waste is shredded;

- The drive is carried out using a belt and a transmission mechanism;

- The hopper (a special bag for collecting garbage) receives waste, which is ground by the cutting system described above;

- The shredded wood obtained from the bunker can be used by the gardener as compost.

Here you can learn how to make a compost bin.

And in this article, read about how to scare birds away from your site.

Components of the structure

It’s not difficult to assemble a DIY herb chopper from a washing machine. Many of the parts are available at home; the missing parts can be purchased. Such homemade products are indispensable in the household.

Electric motor

Minimum requirements for the motor: power 180 W and engine speed in the range of 1350-1450 rpm. The greater the power and speed, the greater the volume of waste that can be processed. Motors from a modern washing machine are more difficult to use, since they are controlled electronically. It is better to take an engine from the Oka, Fairy or Malyutka car models. The greater the engine power, the thicker the branches it will be able to cut.

The receiving box must be durable. Stones or wires caught inside may damage the housing. It is better to choose a cylindrical tank shape. The tank can be made from a large metal bucket or barrel, additionally strengthened with a sheet of iron. You can use a washing machine tub. If it is very tall, it can be easily shortened with an angle grinder. When the blades rotate too quickly and the grass flies out of the box, it is equipped with a lid.

At the bottom of the tank, at the level of the blades, there is a hole for pouring out crushed particles. A steel angle can be welded or bolted to the bottom of the tank in front of the hole to drain crushed particles.

There can be one or several blades in a grass cutter. This is usually a rectangular metal plate, sharpened on one side, attached to the motor or shaft. There may be several plates. Disc-shaped knives are also used. The size depends on the desired size of the cut. You can make your own blades from a hacksaw blade or an old saw, or use lawn mower blades.

The size of the knives should be such that they do not touch the walls of the tank. But you don’t need to make a long distance so that the grass doesn’t get wrapped up.

A knife is cut out of a sheet of iron. The simplest option is a rectangular plate with a hole for fastening in the middle. The short edges of the rectangle can be left as is or ground off to give the plate a diamond shape. This shape is suitable for cutting grass. Long edges are sharpened. If the engine is not very powerful, then the knives are made as light as possible.

Protection

The hole through which the crushed waste pours out is covered with a casing on top. It prevents small particles from scattering in different directions and directs them into a container for ground waste. The casing is made of sheet metal and bolted to the tank. You can make protection from a piece of metal or plastic pipe. If the design allows, you can attach the receiving container directly to the tank, without a casing. This design is less safe and more cumbersome.

Grass container

The container for crushed waste can be of any shape and size. You can take an ordinary bucket or basin, placing it under the protective casing. Sometimes there are no holes in the receiving box for an additional container. The grass remains in the tank after grinding. This design is counterproductive because you have to stop the grinder to empty the tank.

How to do it yourself, step by step

A grass cutter is useful in many summer cottages. To save money, you can make such a unit yourself.

- Disconnect and remove the motor from the washing machine. Before starting work, turn off the power to the device and follow the safety rules. The method for removing the motor depends on the model of the washing machine. If it is stuck in the seat, you need to pry it out with a screwdriver. When removing an inverter or activator motor, the rotor must be blocked or held by hand to prevent it from rotating.

- Prepare the tank. Using a grinder, cut a hole at the bottom through which the motor shaft will be inserted.

- Prepare a stand for the chopper. Weld the frame from metal corners and equip it with wheels.

- Attach a bushing to the washing machine motor shaft. The length of the part is from 5 cm with a thread on one end and mounting holes on the other. It is better to order from a turning workshop.

- Attach the motor from the washing machine to the tank from below vertically. If possible, it can be welded or mounted on studs. It is recommended that you first just “attach” the engine to the bolts in order to mark the height of the blades and the place for the hole through which the chopped grass will be removed.

- At a height of 5-7 cm from the bottom of the tank, the knives are attached with a bolt through the hole in the middle to the sleeve through the thread. If the knife vibrates strongly during operation of the chopper, you should try sharpening it on the other side. This will balance the size and weight of the plate and reduce vibration.

- Mark a place for disposal of crushed waste. Using a grinder, cut a hole 7 cm wide and 20 cm long in the side wall of the tank at the level of the knives or a few centimeters below. If the hole is too small, the shredded debris will be difficult to remove from the tank.

- Attach the protective cover to the outside of the tank with bolts.

- Network connection. Test the motor winding using a tester or multimeter. The engine is connected using a start button (PNVS). You will also need a cable with a power plug at one end and a stripped core. The cable must be long enough.

- Connect an electrical cable to the button on one side, and windings on the other (the starting winding should be in the middle). If four wires come from the engine, then one end of the starting winding is twisted from the working winding and connected to the button. The principle of operation of the button is simple: when pressed, all three contacts close, current is supplied to the starting winding and the engine starts. When the button is released, the starting wire circuit opens and only the working wires remain energized. Pressing the button again opens the entire circuit. It is necessary to ensure that all wires are carefully insulated.

- The entire structure is fixed on a stand.

List of assembly tools

To assemble a branch chopper from a washing machine yourself, you will need the following tools:

- Electric drill.

- Bulgarian.

- Multimeter (tester).

- Screwdriver Set.

- Hammer.

- Bolts, studs, washers.

- Pliers.

- Welding machine (if you make the frame yourself).

- Insulating tape.

Safety

It is necessary to observe safety precautions both when assembling the grass cutter and when working with it, making sure that no exposed wires are left during assembly. It is important to wear safety glasses or cover the tank while the shredder is operating.

Gardening work involves the use of various devices and tools. Some you can do yourself. For example, crushed weeds and twigs are added to prepare good compost or fertilizer. Pulling grass by hand is time-consuming and difficult; it’s easier to do it in a shredder.

How to make a grass and twig chopper for your garden with your own hands

About the Bosch garden shredder - operating principle, best models

All about garden shredders - types of shredders for branches and grass

Attachment for chopping branches on a walk-behind tractor - what is it, characteristics

All about the Zubr garden shredder - operating principle, how to use

Makita UD2500 - parameters and description of a branch chopper for the garden

conclusions

Most home craftsmen can make a grass cutter. Use an oil flask, barrel, etc. as a tank. To make a homemade product you will need a set of tools:

- Bulgarian;

- drill;

- welding inverter;

- set of locksmith tools.

The main consumable part is the engine. Users used used drives. Is it profitable to make grass cutters yourself? Compare prices for factory models and calculate how much it will cost you to buy parts for homemade products. Don't forget to add time costs.

Want to know more? to the authors of grass cutters in the topic Homemade Grass Cutter “Monster 2015”.

- Photo instructions for making a profile bender yourself for 2000 rubles from spare parts from old cars and bicycles, bearings, threaded rods and channels.

- 5 options for a sawhorse for sawing logs into firewood - cheap homemade devices for sawing logs into logs and splitting firewood: drawings, design, experience of use.

- A universal homemade stand for an angle grinder with a rotating mechanism, an eccentric clamp and metal cutting in two planes.

DIY herb grinder

How nice it is to stroll through your own garden, along its beautiful paths, admire the well-groomed beds and flower beds, and then eat a rosy apple straight from the branch. But in order for all this splendor to exist, a lot of work has to be done. In order for the soil to be fertile, it is necessary to add a lot of organic matter. Mulching with grass is a great way to keep the soil in good condition. It can be spread out on the beds immediately after mowing or pre-composted. In order for thick stems of greenery to decompose more actively, it is recommended to chop them first. You can make your own herb grinder or just buy one.

Methods for making the unit yourself

The main purpose of this article is to find ways to independently manufacture the equipment that will be needed on the farm. If you have the desire, patience and minimal skills, you can make a homemade herb grinder that will work just as well, and perhaps even better, than a store-bought one. Better, because only you yourself know the needs of your farm and can perfectly adapt the device to your own needs. It will be exactly what you need!

Drill herb chopper

An excellent grass cutter can be very easily built from a regular drill. Exactly how this simple device works is posted below.

So, the grinding process resembles the work of a food processor: in a cylindrical body, the role of which is played by a simple bucket, there is a sharply sharpened knife. When it rotates in a circle at high speed, the grass is cut. To make this grass cutter, a two-mode Temp drill with a power of 850 watts is used. The knife is made of hacksaw blade. The whole secret is hidden in sharpening the knife. If done correctly, the grass will not wrap around the blade. The knife should remain clean and free of greens.

Sharpen the knife with a one-sided sharpening. It should be oriented with the sharpened plane facing down. If you have to chop fresh grass, the best shape of the knife would be a narrow diamond so that the cutting edge disappears at an angle to the edges. As a last resort, you can round the blade towards the tip. Then the grass, which is affected by centrifugal force, slides along the cutting edge of the knife straight to the edges. It cuts easily and never wraps around the knife.

Grass chopper from a vacuum cleaner

The working principle of this device is no different from the previous one. It just looks more civilized and its performance is higher. If in the previous case the grass was already in the container where the cutting tool was placed, now the raw material is supplied through the upper hole, and the finished substrate comes out through the lower one, located in the side of the apparatus. To prevent the finished silage from being scattered when spilled, you need to use a protective cover for the outlet.

Perhaps such a grass cutter does not look as presentable as a purchased one, but it is functional and practically free. Decide what is more important to you. The chopped grass is collected in a bucket, which must be carefully placed under the outlet. It is clear that when choosing the height of the racks for the unit, it should be taken into account that a bucket of normal parameters must pass freely in order to place it in the right place. So what does Typhoon have to do with it? The body from the old Soviet Typhoon vacuum cleaner is ideal for a basic garden grass shredder: it has an upper hole of the most suitable size. I repeat once again: this is an ideal option. But not the only one!

Any cylindrical container, be it an old pan, bucket or piece of pipe, will also work. The 180-watt motor can be borrowed from an old washing machine. An old hacksaw blade will be used for the knives, and it is recommended to use a 15x15 mm rectangular profile as stands. The bushing, 40 mm high, on which the knives will be attached, will have to be turned on a lathe.

The process of making a herb grinder is not as complicated as it seems. In the photo: No. 1 - the body, very convenient, because you can load grass into it from above, No. 2 - the motor from the washing machine, No. 3 - the location and appearance of the knives. The engine with the pulley removed is mounted on studs from below to the container. To tighten the knives, water nuts 32 mm in diameter are useful. When making bushings, be careful to cut threads for these nuts. Don't forget about the hole for the motor shaft. To ensure reliable fixation on the shaft, two holes of 7 mm in diameter are made in the bushing with M8 threads cut into them for locking bolts. Pads are machined on the reverse side of the motor shaft to increase the reliability of the bushing being secured with locking bolts.

At a height of 15 mm in the upper part of the cylinder, the edges were removed with a grinder to form a square with a side of 25 mm. Knives will be put on him. To make knives, you need to cut 4 blanks from a hacksaw blade using a grinder. A square hole with a side of 26 mm is cut out in the central part of each workpiece. The width of each part depends on the degree of rigidity of the original metal. It is clear that the knives should be placed closer to the bottom. Their cutting edges are sharpened using a sharpener. The bolts securing the sleeve are placed above the knives.

If it is not possible to make an outlet for the silo directly under the knives, then it will be equipped on the side. To do this, you can use a grinder to make a 7x7 circle. Tin is used to form the guide body. The housing is attached to the chopper with M3 bolts. The platform of the unit must be as stable as possible. To do this, its base is made larger than the top. It has to be made as functional and convenient as possible.

The purpose of the platform is not only to support the chopper, but also to protect the engine. It is secured to the container with 3 M 6x45 bolts. It is better to cover the side edges of the platform with sheets of tin. The racks are threaded for M3 bolts, with which the sheets are secured to the platform.

Grass cutter from what was on hand

Armed with the knowledge gained from reading the description of the manufacturing process of the previous unit, you can build yourself something equally simple and useful without much difficulty or effort. This grass cutter is literally made from something you found in the shed. All the things have served their purpose a long time ago, but in this design they will certainly be useful to their owner for a long time.

For basic grass cutting you will need:

- Agidel pump or any similar electric motor capable of 3000 rpm and powered from a 220V network;

- old aluminum pan;

- used wood hacksaws, from which you can make wonderful knives;

- to start the engine you need a button, the role of which will be perfectly played by the NVD from the washing machine;

- plug and power cord.

We invite you to carefully examine the photographs, because they do not need any special comments. Everything is very clear. Start creating your herb grinder and you'll do great.

Pay attention to how the blades are placed in this herb chopper. It is possible that you will choose this particular model. The motor is installed under the pan, and the start button is located at the rear of the platform to make it easier to reach. Such grass, chopped using a grass cutter, is perfect for feeding livestock and poultry, as well as for mulching purposes.

Homemade straw cutter

Three previous units successfully turned grass into silage. But if we need a chopper not only for grass, but also for hay, it’s worth taking a closer look at another invention, which is presented in great detail in the video below.

Choosing a grass chopper

A grass grinder can turn growing grass into excellent feed for chickens and other poultry. Grinding grass will be tedious and time-consuming if you do not use a special device. Household devices for grinding dry grass and hay will help you quickly and easily grind any grass, as well as various food waste. It acts like a food processor. Sharp rotating knives are used to chop dry and green herbs, which are also suitable for cutting leaves and medicinal herbs. The cylindrical container contains knives. The grass is placed on top of a special container, and in the lower part on the side it is poured out in crushed form. Shredded waste is collected in a special container so that it does not fly apart; a special box is provided with which the hole is closed.

You can also place a regular bucket under the outlet hole; this is provided for by the height of the racks. For the garden, it is best to use an electric garden shredder for branches and grass. It will not be difficult for such a shredder to process a large amount of dry branches and leaves. The crushed waste can be used to feed chickens. Natural waste of any kind can be shredded. Grass cut by a trimmer can take up space, and to clean the area, you can use this device, this makes it possible to conveniently remove small waste. To chop the grass, you can use the convenient electric chopper Worx WG 430 E or Bosch.

Household grinders can also grind a large number of medicinal herbs, from which you can make various tinctures, teas and much more. Choppers come in different types and brands, and real craftsmen can make a homemade chopper using a special drawing. Such a device will quickly justify itself, because manually this process is very long, and using a root crop and herb chopper, you can cope with this task in a few hours.

Method two. With vacuum cleaner Typhoon

The principle of operation is very similar to the previous one, but the device is more productive. Here, grass and branches should not be fed into a bucket, but into the hole located at the top. Substrates come out from below, or rather from the side of the unit.

A bucket must be pre-installed under the outlet hole. What is the relationship with Typhoon? The fact is that its body, like nothing else, will be better as a grass chopper. But this is far from the only option; millet is the most suitable.

Here you can also use any cylindrical container. Any motor with a power of 180 W can be installed. For knives, you can use a special hacksaw blade. Racks can be made from a profile measuring 15*15 mm. The only thing you need to make yourself, by turning it on a lathe, is a bushing 4 cm high. It is on this that you will need to attach the legs of your homemade electric herb chopper.

What types of grass grinders are there?

Let's look at the main types of grass grinders that are available on the market today:

Kubanets

The Kuban chopper is intended for use both on small farms, subsidiary plots, and for the garden or cottage. It is suitable for chopping hay, dry and green grass, leaves. Such waste is good for feeding chickens and other animals on the farm. This chopper can process up to 300 kg/h of various grass and hay. The electric device can chop a variety of root vegetables if the grass hopper is removed. The crushed grass ranges in size from 2 to 10 mm. The weight of the chopper is small, up to 45 kilograms. Gardeners leave only positive reviews about this device. This grinding apparatus is easy to use and has a fairly simple design; you can try to build such a grinder yourself using a drawing.

Herb Grinder Manufacturers

Worx WG 430 E

Worx WG 430 E is an electric shredder of dry and green grass and leaves. It can be used in urban environments, in the country, in the garden, farmsteads and farms. The Flex-a-Line mulching system, which is equipped with the Worx WG 430 E shredder shown in the video, does not use knives. In one hour it processes up to 12 cubic meters, its electric motor is very powerful. Plants can be fertilized with crushed waste, and it can also be used to feed chickens. The Worx WG 430 E unit is assembled very simply and easily; no additional tools are needed for assembly. To shred waste, he uses a trimmer line, this is his cutting element. Features a universal trash holder. The Worx WG 430 E shredder has a patented dust protection for the engine cooling system. The wg430e is in demand, and the wg430e is very powerful.

A large number of leaves are collected annually by summer residents; using the Worx WG 430 E shredder, you can forever forget about the problem of labor-intensive leaf disposal. The unit grinds them so finely that it is not difficult to dispose of them, or you can even send them to feed poultry. Shredded waste is also excellent as a fertilizer for vegetation. The herb grinder looks very simple and you can make it yourself if you use a suitable drawing. Worx WG 430 E makes chopping dry and green grass and leaves simple and convenient. Up to 53 liters of shredding materials can be shredded per minute. It has a wide opening of 33 cm in diameter for feeding leaves and other natural materials.

The chopper is very easy to use, has a rotation speed of 8500 rpm, thanks to the Flex-a-Line system, the Worx WG 430 E chopper chops without the use of knives, 2.3 mm trimmer line is required for this unit. There are two colors available: black and orange. The weight is quite light - 9 kg. With the Worx shredder, the garden will be cleaned and fertilized in a short time. The device has no negative reviews; every summer resident who uses this unit is satisfied with its performance. You can watch the video of this device in action.

For the garden and dacha, a reliable and powerful device is the Bosch grass and branch chopper. He does his job very well. This device shreds up to 230 kg of waste per hour. The thickness of the chopped branches can be up to 45 mm. Suitable for grinding medicinal herbs, as it has a special herb collector. Bosch shredders also have a quiet operating mode, which makes their use comfortable. You can make a similar herb chopper yourself if you use the right drawing.

Viking

The Viking branch and grass chopper has a 2500 W electric motor and can chop branches up to 35 mm thick. It is capable of shredding fairly thick branches very quickly. After watching the video, you can evaluate its work. Positive reviews clearly demonstrate the great advantages of the unit. The Viking shredder company, in addition to electric units, presents a gasoline shredder for leaves, dry and green grass. This device can handle any type of garden waste. But it has disadvantages: during operation it makes a lot of noise, before use it is necessary to prepare the fuel mixture, the gasoline unit is expensive, which makes it not affordable for everyone. Milling and disk system of knives at the chopper. An electric shredder is perfect for dry and green grass, and a Viking petrol shredder can handle dry branches. In the photo you can see what a grass chopper looks like. In addition to all these commercial grass shredders, you can make a homemade unit for shredding green or dry grass, leaves, branches, shrubs and other garden waste. You can make both an electric and a gasoline-powered device with your own hands. It will be no worse than household shredders such as Worx or Viking. It can be constructed using a special drawing

How to make a homemade shredder

Making a shredder with your own hands is not an easy process, but it will justify the cost of its manufacture in a short time. Do-it-yourself household grinding devices can be indispensable helpers in the countryside. Practicality and ease of use are the main advantages of shredders. With their use, it becomes easy to grind medicinal herbs, leaves, branches, hay, bark, cones, roots and much more. Using the drawing, you can build a grass chopper for your summer house.

What you will need to make a homemade shredder:

- Steel pipes;

- Electric or gasoline motor;

- Set of circular saws;

- Drawing.

A chopper for green grass, hay, and branches is made independently, using a drawing. The photo shows what a homemade device looks like. Maximum power can be achieved by making a grass grinder with your own hands; it can also be small in size and much cheaper than a purchased one. Vegetable waste is ground, rotating in a circle at great speed, it works in the same way as a food processor.

Top 10 rating according to KP

Editor's Choice

An excellent purchase for owners of suburban areas at a reasonable price. This garden shredder is used to quickly work with organic waste. Withered leaves, branches, fallen flowers, plant stems - this and much more can be loaded into it. The resulting mass can be used as fertilizer. Manufacturers claim that the model has reliable and sharp knives and good speed. However, take into account the diameter of the branches that the device can handle - they should be no more than 40 mm.

Characteristics: grinding system - knife; case material - plastic; branch diameter - 40 mm; there is a container; rotation speed - 4500 rpm; weight - 11 kg. Engine - electric; power - 2.4 kW; launch - automatic; voltage - 220 V.

+ Price + Size

Characteristics: grinding system - milling; case material - plastic; throughput - 175 kg/h; branch diameter - 40 mm; container - 53 l; rotation speed - 41 rpm; weight - 31.3 kg. Engine - electric; power - 2.5 kW; launch - automatic; voltage - 220 V.

+ Quiet + Good at breaking thick branches

— Poorly picks up thin and fresh fibrous branches

Expensive, but high-quality garden shredder. It features an impressive loading hopper (46x46 cm). Three ways to load debris - a metal tray for thick branches, small branches can be loaded from above, small debris can be collected with a rake and raked into a hopper lowered to the ground - make the model universal. Among other things, it is possible to install a device for transportation. There is also a high grinding ratio of 10:1.

Characteristics: grinding system - knife; case material - metal; branch diameter - 75 mm; container - 90 l; weight - 75 kg. Engine - petrol; power - 7.5 hp; launch - manual; cycle - 4-stroke; fuel type - gasoline; engine capacity - 250 cm³; fuel tank volume - 3.8 l. + Fast grinding + Excellent quality

Principle of operation

The operating principle of the unit for chopping grass and thin branches is quite simple:

- The power plant, through a shaft or belt drive, drives a knife located in a special container or chamber.

- Through the feed hole, the material that needs to be crushed is fed to the knife.

- The knife breaks incoming branches, grass or plant stems into small particles, and through a specially equipped hole, the crushed mass is poured into a receiving hopper or bag.

The power plant of such machines can be made in the form of an electric motor, or a gasoline or diesel engine.

Fuel installations have high power, and installations designed on their basis are mobile. But their disadvantages are the high price of fuel, the bulkiness of the device and heavy weight.

Electrical units are compact and lightweight. Their disadvantages are relatively low power (it all depends on the type of engine selected) and attachment to a source of electric current.

The simplest, “old-fashioned” herb chopper is a horizontal knife, to which a handle is attached on top, at a right angle. With this “axe” the plant mass is chopped up manually in a wooden trough. But today we are not talking about him. In this article we will talk about a garden shredder with an electric motor.

Garden shredder