Use and purpose of a special device for transporting goods for a mini tractor

If you plan to make a trailer for transporting boats, then you should take into account the fact that in this case it falls into the category of special-purpose vehicles. In this case, its weight and dimensions depend on the dimensions of the craft that will be transported. During the design process and subsequent manufacture of the device, it is necessary to take into account the class of the minitractor.

The trailer allows the motorist to transport large cargo, as in the photo. Despite the fact that today there is a huge selection of different models of finished products on the market, if you already have an idea of how much capacity a device should have in order for it to be convenient to use, then it is more advisable to make it yourself. In the photo you can see a homemade trailer for a mini tractor.

When you have your own farm, such a device is a necessary vehicle for transporting goods. The owner of the site simply cannot do without it. This device may be

The two-axle version is intended for transporting various bulk cargo, such as small special equipment or motor vehicles.

Single-axle can be used to transport any cargo, including bulk, liquid and semi-liquid. This option is ideal for construction and agricultural work.

Look at the photo to see the difference between the two types of devices: single-axis and two-axis.

What is required to make a tipper lifting device for a mini tractor

If you decide to independently undertake the manufacture of the device you need for your household, then you will need to prepare in advance the following building materials, tools and equipment:

- steel (sheets),

- steel channel,

- plywood,

- aluminum tubes,

- chassis,

- wheels,

- electrical equipment,

- metalworking tools,

- fastening parts,

- welding machine.

Installing a dump trailer for a mini tractor will allow you to easily transport and self-unload a variety of materials, such as crushed stone, sand, coal or soil. In addition, you will be able to transport other cargo for construction or household purposes that do not require any special conditions for unloading. The device is equipped with a rectangular body. Its unloading mechanism is fitted at the rear.

In addition, the craftsmen have already proven that it is possible to make a trailer from a variety of available materials, for example, from spare parts from a motor scooter or an old Moskvich. In the first case, the load capacity of the device will be at least 500 kg, and in the second - up to 750 kg. A self-made dump truck device can lift heavier loads – up to 1 ton.

In the video you can watch all the stages of the sequential construction of a trailer for a mini tractor with your own hands

- The frame is made of 57 pipes.

- Body made of profile steel.

- The brake system is taken from a Tavria car.

- A metal plate is welded into the beam from Tavria for reinforcement. The trailer beam is ready.

- The base for the body is made from pipes.

- The body is taken ready-made, the rest is from improvised means and supplies.

Next, a special device is prepared, which is made specifically to ensure good adhesion. It is done according to the pipe-in-pipe principle. To do this, be sure to take pipes with thick walls or hardened ones. In this case, the device will serve you for a long time.

For most agricultural machinery, a variety of equipment is offered, which in one way or another simplifies work and increases the functionality of tractors. For mini tractors, purchasing a special trailer will be very useful and probably even mandatory. The properties of the trailer must fully match the tractor model used, otherwise their interaction and efficiency will be complicated.

Fortunately, today there are many trailers available for certain models of equipment, so choosing the right product will not be difficult. But for certain reasons, some tractor owners are trying to make a tractor trailer with their own hands, which today is more than a simple and affordable task.

Making a four-wheeled cart

When creating it, you will need tools that only a person who has been doing homemade things for a long time will have. To work you will need:

- welding machine;

- grinder with several cutting discs;

- drill;

- hammers, keys;

- devices for assembling and fitting parts.

Necessary materials:

- profile pipes or corner 50×50 mm for the frame;

- sheet metal 1-2 mm thick for the platform;

- furniture bolts for fixing connecting units;

- cast rollers with a cast iron rim and a rubber lining on top, or simple pneumatic wheels with axles.

Operating procedure:

- Profile pipes or corners are divided into lengths: 100 cm - 2 pieces, 60 cm - also 2 pieces. The edges of the corners are cut at an angle of 45 degrees for better joining. Everything is assembled into a 100×60 structure and boiled on both sides.

- The metal sheet is cut out 10 cm larger than the frame size. These edges will be needed for the sides. After manufacturing this metal platform, it can be placed on the frame with its sides up or down if large cargo is being transported. For ease of rearrangement, it is fixed with furniture bolts.

- The axle of the rear wheels is firmly welded to the frame strictly perpendicular to the side walls.

- The front axle is made rotary. This node must be very reliable. To do this, a small frame is welded onto it, as in the photo, and connected to the main body of the cart using a strong bolt. A washer should be inserted where the frames touch to facilitate turning. The bolt must be locked.

- The handle is made from a pipe, welded into a T shape, one end of which is hinged to the front axle frame.

The result will be an excellent maneuverable cart that will be indispensable for household chores.

There are still a whole host of ways to build another swivel unit or another design of a four-wheeled assistant. Only in all cases you need to be slow and able to work with any type of tool.

Owners of garden plots do not have to sit idle. You need to either dig up the ground, then fertilize the garden or remove garbage from it, or plant or replant something. During these works, quite often there is a need to move any heavy or bulky cargo. A DIY garden cart will help solve this problem. Made from materials at hand or purchased in construction stores, it will become an indispensable assistant for a summer resident.

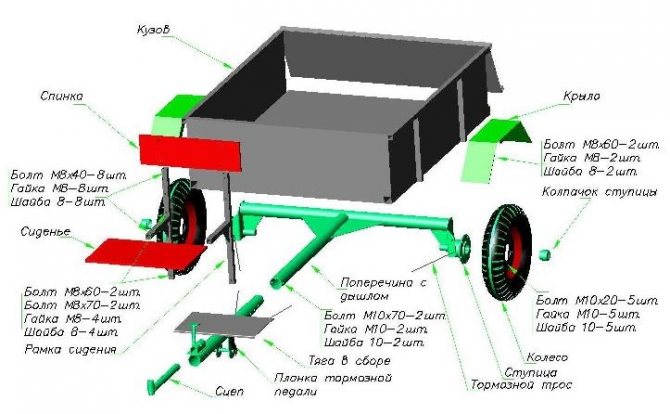

Trailer installation for tractor

Before you start creating your own trailer, it is important to know its structure and design features. Consists of the following parts:

- flatbed body;

- several wheels and chassis;

- base - metal frame;

- mechanism for lifting the body;

- trailed for connection to a tractor.

Also, depending on the scope of use and required characteristics, there are two types of trailers:

- With one axis - the simplest and most popular model, especially relevant for transporting bulk or other materials;

- With two axles - they have a powerful design and therefore allow you to transport heavy loads and materials.

What types of trolleys for mini tractors are there?

Carts for mini tractors are usually installed on the rear three-point hitch and differ in load capacity, design details, functionality and preferred scope of application.

Trailers for mini-agricultural equipment that exist today can be classified according to several criteria:

I. Number of axles - this parameter is directly proportional to the weight that the tractor can lift:

- single-axle - for example, carts of type 1-PTS-2, 1-PTS-4 and 1-PTS-9, compatible with mini tractors with a force of 6-16 kN. Their chassis is completely devoid of springs, and the unloading process can be done either only backwards, or in 3 directions. Can be used for the Photon, Dong Feng or Ural mini tractor;

- biaxial - they are distinguished by better maneuverability, cross-country ability, and therefore move cargo along roads with any type of surface. A popular two-axle trailer is the 2PTS4, which can be unloaded through the rear or 2 side walls. Compatible with wheeled and tracked mini tractors with power up to 30 kN;

- triaxial structures are the best option for frequent use. Their minimal wear and tear completely pays for the expensive cost of the unit. For example, which is used with powerful mini tractors;

II. Body type:

- dump trucks - ideal for transporting bulk materials and scrap metal, the unloading of which does not require additional devices;

- side – equipped with folding sides, which not only simplify the loading of material from the trailer, but also easy access to its contents;

- barrel carts – suitable for cargo packaged in boxes, bags, barrels, containers.

Build process

If you are planning to make a trailer for a mini tractor at home, you will need the following tools and materials:

- steel sheets;

- plywood;

- steel channel;

- aluminum tubes;

- chassis;

- electrical equipment;

- wheels;

- metalworking tools;

- welding machine.

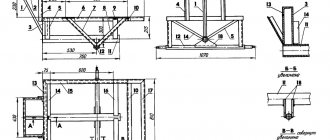

At the very beginning, you need to weld a frame that acts as a supporting frame. It can be made from round pipes with a diameter of more than 40 cm. All fasteners must also be welded.

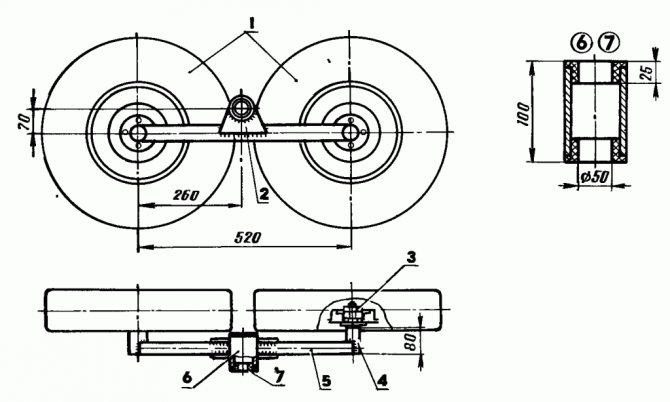

Now you can move on to making the wheelbase, where you should use a steel rod as an axle. It is bolted firmly to the frame, and side rails and corner supports can also be used. A self-made trailer for a walk-behind tractor can serve you for many years for transporting various things.

Correct connection of the trailer to the mini tractor

It is important to note that a trailer for transporting a mini tractor must also have a reliable attachment to the vehicle, and it is best made on the basis of an articulated drawbar, which is inserted into a special tubular body. In the upper part it must be fixed with a special fuse, which will provide additional protection against accidental disconnection. The design of this unit should be approached very carefully, since in this place there is a high load combined with vibrations and strong friction.

Assembling individual catches into a single whole

When all the structural systems are ready, they must be carefully assembled into a single whole, which is best done with an assistant. In this case, you need to carefully monitor the entire progress of the assembly, double-checking the reliability of the joints being connected, the strength of the hinge joints, and the bolt ties. When the mechanism is ready, the resulting trailer should be run in without a load so that all the necessary parts get used to each other well.

conclusions

Summarizing the above, we can say that with due persistence and care, it is quite possible for many domestic craftsmen to construct homemade dump trailers for mini tractors. The only thing is that during installation, it is advisable to make all structural elements from durable, non-rusty materials that can withstand heavy loads. It is also recommended to coat all metal elements with oil paint to reliably protect them from corrosion, which will significantly extend the useful life of the trailer.

Video review of a homemade trailer:

Comparison of homemade and factory trailers

You can buy a factory semi-trailer or a dump trailer. Trailers for mini tractors are sold in all cities of Russia. It's just the price that may disappoint you. The cheapest type costs 10 thousand rubles, not to mention the design with a lifting mechanism.

Why spend money when you can make a reliable and durable trailer for your equipment with your own hands. You just have to have the materials necessary for the business and, most importantly, the desire. By the way, if you have not decided on the choice of the tractor itself, then a reliable assistant for working on agricultural land is the Belarus MTZ tractor. This brand of manufacturer differs from others in its quality and durability. The price may be higher than average, but the characteristics are not inferior to other devices.

In order not to get confused in the choice, it is necessary to take into account the parameters described above. The choice is always yours, but remember that with your own hands you can make a more reliable and high-quality product than what is available on trading platforms.

The miniature tractor has already been appreciated by many farmers. But supplementing it with factory trailers is a very expensive pleasure for many. The solution is to independently manufacture a device for transporting goods.

Is it possible to make a homemade trailer for a mini tractor with your own hands?

As prices for factory carts rise, homemade mechanisms, which can be made at home from scrap materials without much skill or special knowledge, are becoming increasingly relevant.

We will look at several options for designing a homemade trailer - for beginners and for more experienced craftsmen.

Non-tipping trailer for transporting light loads

The most primitive design of homemade carts can be called single-axle with 2 transport wheels and without mechanisms for turning the body over.

Work progress:

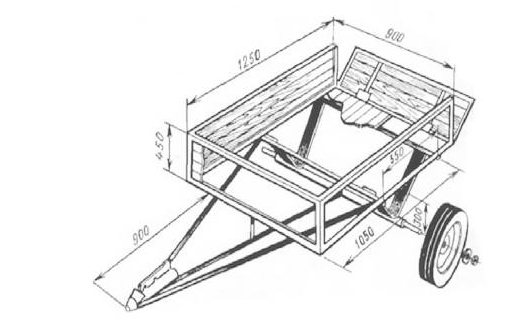

- Making a drawing of a future homemade product - it should reflect the dimensions of the finished device, the size of the parts, the size of the sections, etc. You can use ours presented below as a base one;

- The cycle of preparatory and organizational work - at this stage, the necessary materials (metal angles, channels, stainless steel sheets, wheels, plywood) and tools (electric drill, welding, grinder, screwdriver) are prepared. It is advisable not to use rotten parts to avoid double work in the future;

- Creating a frame - it will be the load-bearing support for the future homemade product. For it, metal pipes with a diameter of 4 cm are taken, cut to size from the drawing and welded into a rectangle. It is important to provide a front traverse in the frame, weld a hitch for the central axle and strengthen the rear beam;

- Equipment of the wheel part - its axis can be a hollow steel rod connected to the frame with bolts. To strengthen the structure, supporting corner blocks and side spars can be used;

- Recreating the body - it can be made in wood or metal. It will be easier to make a wooden one if you have dry, undamaged wooden beams, but it cannot compare with metal ones in terms of durability. For a wooden body, the beams are cut into boards, which are sealed with metal corners, and then primed and coated with powder paint. A metal cart is best made of stainless steel or aluminum, which will not rust and will withstand heavy loads;

- We adapt the towing mechanism, which will maintain a balance between the drawbar fastening and the frame frame;

- We adjust the wheels - they can be taken from an old walk-behind tractor or a passenger car in the amount of 2 pieces. The advantage will be the presence of tires with a rough tread, which will eliminate loading and slipping on country roads and after rain;

Reliable do-it-yourself cars

Realizing that two identical bad one-wheeled cars in one garden was too much, I decided to radically remake one of them and “bomb the other” for spare parts. First of all, I removed the wheel from it and installed it as an additional one on the first wheelbarrow, next to its original wheel (photo 3).

I decided to upgrade the two front flimsy separate supports. To do this, I tied them together with a piece of polymer pipe, into which I had previously inserted a log of the required diameter. And into the gaps between these “components”, from each end, I hammered the support legs of the front struts of the cart, bent in the appropriate directions, with a hammer. The result was a rigid closed structure supported on the ground (photo 4). That's what a pipe paired with a log can do!

But emotions aside. The bottom line is that the wheelbarrow is now very stable when loading, it doesn’t get drilled into the ground, and when I’m driving it loaded (even to the brim) along a slope and I feel like it’s about to tip over, I quickly lower the front part. The support pipe sits on the ground and reliably keeps the wheelbarrow from tipping over. The second version of “figured driving” is when I drive a heavily loaded car (or when the center of gravity of the load is too high) at low level, i.e. with minimal separation of the polymer support pipe from the ground.

Pairing the wheels (and they are installed on a common axle without clearance) made it possible to reduce the depth of the rut left by the wheels in loose soil by two and a half times.

Thanks to this pairing, the lateral stability of the wheelbarrow also increased slightly.

Now let’s talk in more detail about the already mentioned burlat webbing. In fact, this is a flat rubber-fabric rope that I secured to the handle of the wheelbarrow. I harness myself into it and pull the load uphill without much effort, because my strongest muscles are working - my legs and torso. And the rubber-fabric rope itself, thrown over the shoulder, transfers to them the force of gravity from the load located in the front of the wheelbarrow. And now I only need my hands to keep the car from flipping sideways when hitting bumps. In general, living on the site immediately became more fun.