What are hedgehogs for weeding potatoes and why are they needed?

Hedgehogs are an important agricultural tool, the main purpose of which is to save the gardener’s time and effort through high-quality and careful weeding of potato beds.

Along with their main function, they successfully loosen the soil and hill up emerging seedlings, while at the same time scaring off moles and other rodents in the cultivated soil.

What is their advantage

The advantage of hedgehogs for weeding potatoes, in addition to functionality, is that they can be used with all types of cultivators (manual, electric or gasoline).

This makes the tool suitable for use both in small individual areas and on an industrial scale.

What are they?

Despite the fact that the main function of all hedgehogs is the same, there are several types of such tools, with slightly different designs.

Differences affect the effectiveness of a hedgehog in an area of one size or another.

For processing potatoes in one furrow

Single-furrow potato hedgehogs are designed for weeding small areas. The simplified design of this type of hedgehog makes the work of the gardener easier, representing a pipe 250 mm long, on which several disks with metal spikes 150-200 mm long are fixed.

Fastening is carried out by 2 bearings and a shaft. This design is usually attached to a walk-behind tractor to simplify the work and save time when weeding potatoes.

For weeding potatoes on bearings

Hedgehogs on bearings are designed for weeding beds ranging in size from 60 to 90 cm. They are used immediately after emergence and after ground tillage.

The advantage of this type of hedgehogs is that they have a bearing unit, which provides additional fixation, as well as 3-position adjustment of the weeding angle, which ensures high-quality loosening of the earth.

Rotary weeding

The purpose of rotary hedgehogs is pre- and post-emergence soil treatment. These hedgehogs simultaneously fluff up and hill up the soil, while removing weeds. In this case, the row spacing varies between 50-75 cm.

Processing potatoes with rotary hedgehogs is not a labor-intensive process, since the rippers can be attached to any walk-behind tractor, cultivator, and even mini-tractor.

Design and features of hedgehogs

Unlike flat cutters, such devices remove weeds with roots, loosen the soil, allowing it to pass moisture and oxygen to the potatoes, and repel pests. This allows you to get a rich harvest, hilling without damaging potato roots or repelling pests. The equipment is a special metal device of a conical or other shape, which consists of three rings of different sizes. They are connected with special jumpers, and metal spikes are also welded to them.

This design of hedgehogs provides:

- effective removal of all weeds;

- quick and easy fluffing of the soil;

- simple garden or field care.

Based on their functionality, models can be divided into two types:

- Rotary - using this technique you can weed, fluff up the soil, and hill up rows.

- Conical - used to remove weeds even before the first potato shoots appear.

The ripper is suitable for hand cultivators or equipment running on diesel, gasoline, or electric power. Its dimensions can be very different, depending on the area of the treated area and the space between the rows. The hedgehogs are attached to the walk-behind tractor using special bolts; they are very convenient and do not make working with the unit more difficult.

How to make hedgehogs with your own hands

Making hedgehogs for a potato cultivator with your own hands is a painstaking, but obligatory step to ensure the most comfortable use of the future tool.

The metal structure consists of 3 rows of disks of different diameters with metal spikes welded to them. The disks are connected to each other by special jumpers. The device is assembled on an inch pipe, inside of which there is a 20 mm fixed axis attached to a bracket on the handle.

Necessary materials

You will need:

- steel sheets with a thickness of at least 4 mm for future disks;

- strip of carbon steel with a width of 20 mm and a thickness of 4 mm for jumpers;

- metal rods with a diameter of at least 8 mm and a length of 100-140 mm for spikes;

- pipe with a diameter of 250 mm for the frame;

- steel U-shaped bracket with a thickness of at least 4 mm and a width of 70 mm;

- a metal rod with a diameter of 20 mm, which is placed inside a pipe filled with thick lubricant, and the ends are inserted into the holes of the bracket.

Preparatory stage

At the preparatory stage of creation, you need to collect all the tools that will be needed in the process of making hedgehogs: a welding machine, an angle grinder, a metal cutter, and a set of plumbing tools. You should also prepare drawings of future hedgehogs (see examples below).

Step by step creation

Instructions:

- It is necessary to cut a piece from the steel pipe in accordance with the size of the row spacing on the site.

- Cut tenons 120 mm long from the rod and sharpen their edges at 45°. On average, 75-90 spines are required for 2 hedgehogs.

- Cut discs from a metal sheet. The optimal diameter is 300, 200 and 100 mm. Cut holes in these blanks for the pipe. The diameter of the holes must be 1 mm larger so that the discs can be inserted and welded to the pipe.

- Finish the parts with a grinder to eliminate burrs and irregularities.

- Distribute the spikes evenly across the discs. On average, each requires 7-15 pieces.

- Bend the bracket on which the axle will be attached. The bracket can either be welded or have holes made in it for bolted connections.

- Put the pieces together. There should be a distance of 150-160 mm between the discs. Insert the ends of the axles into the holes of the brackets. Secure them with nuts or welding.

- Use a grinder to clean all sharp corners and irregularities.

Construction stages

Consider a plan for creating a simple hedgehog:

- Cut a piece of pipe that will act as an axis. The length should be chosen according to the size of the lines in your area.

- Cut the tenons from the rods 6-7 cm long. They can be additionally sharpened at an angle of 45 ° on one side.

- Weld the spikes to the pipe so that they form several circles at a distance of 4 cm from each other. Each circle should have about 5 peaks.

- Make a U-shaped spacer frame from the tubing. The length of the legs should be 34-36 cm, so that the spike tube can rotate without interference. Make holes along the edges of the legs.

- You can place a rod and bearings in the pipe, or simply weld the ends of the plugs using 1.6cm pins.

- Assemble the structure by inserting pins or the ends of the rod into the holes in the frame. Weld the corners to the frame and fasten a wooden handle between them.

- When using such a device, it is forced forward. In this case, the spikes must penetrate the ground.

It is much more difficult to create a suspended structure with your own hands. In addition, this is associated with risk - there is a danger of damaging the equipment.

If you are confident in your abilities and want to try, carefully consider the drawing of the future design and its dimensions. For a large hedgehog you can use wheels of sizes 30, 20 and 10 cm, for small ones 24, 17 and 10 cm.

For example, consider the option:

- Cut two rings from the metal sheet with an outer diameter of 30 cm and an inner diameter of 20 cm. The circles cut from the center become medium-sized rings - small circles with a diameter of 10 cm are cut from their center. Finally, in small circles, make a hole for the pipe 1mm larger in diameter.

- Prepare two pieces of pipe. Place a small weld on each of the three rings, and connect the middle and large ones with knitting needles. The distance between the large and small disks should be 17-18 cm.

- Cut 24 jumpers from steel strip. Connect them with large and medium rings - 8 pieces each. for each pair. Then connect the middle and small rings - 4 pcs. for a couple.

- Cut 80-90 spikes 12 cm long. Weld them on disks - at least 15 for large ones, 10 for medium ones and 5 for small ones. There can be more if desired. You can also add tenons to the jumpers.

- Bend the paperclip blank into a P shape. Make holes for it in the axles.

- Insert the rods with bearings into the pipes. The ends of the rods on the large ring side are placed in the holes on the bracket and bolted or welded. Between themselves, the hedgehog should be at an angle of 45°.

To reduce the load on the structure, two guide wheels can be added to the bracket. It is recommended to test the completed structure in an empty area first.

Drawings with dimensions and explanation

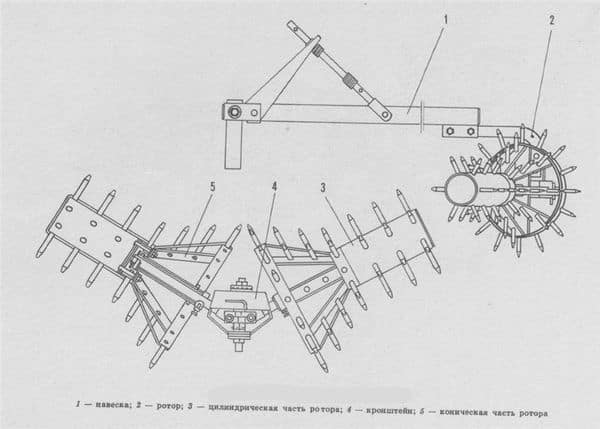

Drawing No. 1 shows a cross-section of a hedgehog and its main parts:

- 1 – hitch;

- 2 – rotor (rotating shaft);

- 3 – cylindrical part of the rotor;

- 4 – bracket that connects the hedgehogs;

- 5 – conical part of the rotor on which the disks are fixed.

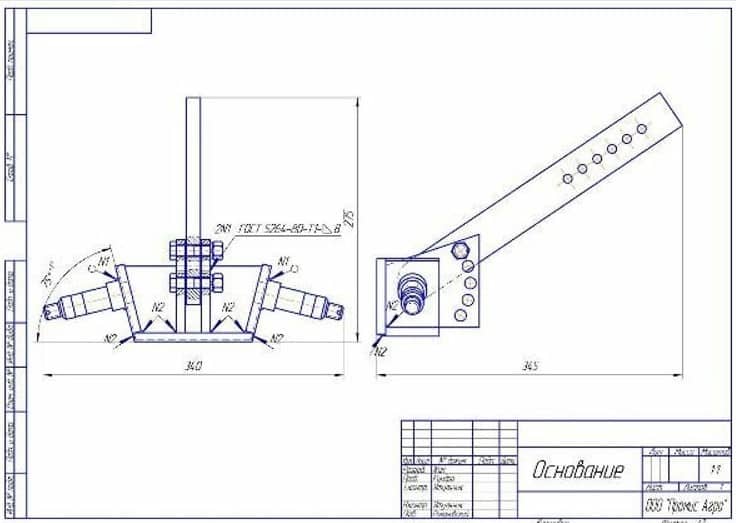

Drawing No. 2 shows the base of the hedgehog along with the bracket, as well as their optimal dimensions. The height of the device is 275 mm, width – 340 mm, and length – 345 mm. The rotor angle is 75°.

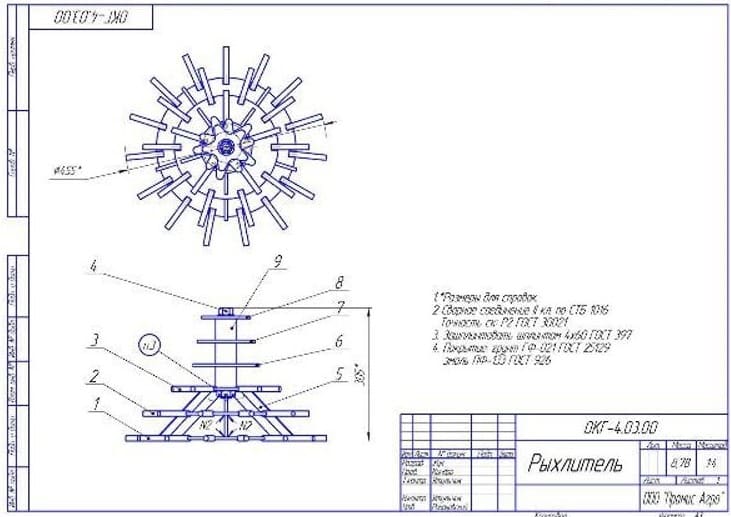

Drawing No. 3 shows a cross-section of a conical ripper:

- 1, 2, 3, 6, 7, 8 – discs with spikes;

- 4 – fixing bolt;

- 5 – bar that connects the disks to each other;

- 9 – rotor.

How to use hedgehogs on a walk-behind tractor

Operating rules:

- Do not attach hedgehogs to the back of the walk-behind tractor, because in the event of an unexpected impact, not only the base of the device, but also the walk-behind tractor itself may be damaged.

- Regularly clean the hedgehogs' spines of weeds and soil.

- Use hedgehogs only in dry weather. Frequent contact with wet soil can cause rust. Treat hedgehogs with anti-corrosion agents at the end and before the beginning of each season.

- Sharpen only the lowermost part of the tenons. Otherwise, hedgehogs will cut off the weeds, leaving roots in the ground. For sharpening, use a grinder with the finest abrasive wheels.

How to attach

The hedgehogs are attached to the walk-behind tractor using bushings and jumpers at an angle of 45°.

To reduce the load on the attached structure, 2 guide wheels are installed. They can be strengthened with a bracket, which is made from a metal strip at least 70 mm wide and 4 mm thick.

DIY hedgehogs for processing potatoes: drawing

If you grow potatoes on your plot, then you know how difficult it can be to cultivate a vegetable garden. To make your work easier, use special hedgehogs for weeding potatoes. What are they, and how do experienced gardeners use them? Is it possible to make such equipment with your own hands?

Hedgehogs for weeding potatoes can be purchased at the store or made with your own hands

To provide your family with potatoes for the whole year, and maybe even earn money, it is important to care for them properly. Weed control is important. If they grow in the area, they will draw all the minerals and water from the soil.

Potatoes are hilled and weeded to saturate the soil with oxygen. You need to take care of the area at least once every 3 weeks. This is also done manually, using a hoe.

But then weeding and hilling takes a lot of effort and time. And it’s time to forget about manual labor in our age of advanced technology. An affordable and economical way is to use hedgehogs.

They are used in agriculture for the following purposes:

- Clearing weeds. The advantage of hedgehogs is that they do not cut weeds, but also remove their roots. Therefore, weed thickets are destroyed.

- Loosening the soil. Thanks to this, the tubers receive the water and oxygen they need.

- Rows are formed. This is necessary to make harvesting easier.

- Hilling. Not only weeding is carried out, but also hilling. The hedgehog does not damage potato tops;

- Pest control. In vegetable gardens, crops are damaged by moles, rodents and other pests. Hedgehogs scare them away, and some insects are brought to the surface. Birds peck them there.

Weeding hedgehogs rid beds of weeds, insects and moles

You can buy hedgehogs. They are often sold together with a walk-behind tractor and are included in the set of necessary accessories. If they are not available, talk to the seller and place an additional order. Or find someone who will make a design especially for you. But the easiest way is to make such equipment for processing potatoes yourself.

If you carefully examine the design, you will see that making it with your own hands is not so difficult.

A hedgehog for processing potatoes is 2-3 connected rings of different diameters, located at a short distance from each other. From the outside they resemble a cone.

There are spikes attached to the rings. They are needed to get the job done. Two cones are attached to one handle. They need to be connected not parallel to each other, but at a slight angle so that elevations are formed in the garden bed.

The device is mounted on a special frame and then screwed to a wooden handle. The hedgehog is ready for tillage. It is rolled back and forth across the garden bed. This requires physical strength. Before you make this device yourself, ask your friends to borrow it.

It may be difficult for you to do the work, test yourself first.

Handmade hedgehogs have a fairly simple design

Hedgehog for walk-behind tractor

If you need a hedgehog for a walk-behind tractor, then you should think about buying it in a special store. But if you want to use homemade ones, carefully consider the design drawing.

Making a hedgehog:

- Find 3 metal disks of different sizes. Proportions: 240, 170, 100 mm or 300, 200, 100 mm. It's better if you use rings instead of discs. Then the whole structure will be much lighter. Another advantage of this lightweight option is that it is much gentler on the soil and plants.

- Take a pipe (25 mm in diameter). Collect disks on it. Start with the largest, end with the smallest. The distance between them is no more than 18 cm.

- Weld the spikes. A metal rod is suitable for them. One hedgehog will need about 40 spikes. The length of each is 10-14 cm. 5 spikes are attached to the small disk, 10 to the larger one, and 15 to the third. The part is attached to the axle itself.

- Inside is the largest disk, then the middle one and the smallest one. They are attached using bushings and jumpers to the frame at an angle of 45 degrees.

- You also need to add guide wheels. They are needed to reduce the load on the towbar. There should be two of them. First, a bracket is made from a metal strip 7 cm wide and 4 mm thick. Drill holes there and strengthen the wheels.

Agricultural work takes a lot of time and effort. This can be made easier by special devices for weeding or hilling, for example, hedgehogs for processing potatoes.

Hedgehogs for processing potatoes

Weeding potato beds with your own hands is time-consuming and energy-consuming, especially with large areas of planted territory. Therefore, the demand for specialized equipment that facilitates agricultural work is always high. Hedgehog is especially popular for potatoes.

The hedgehog is a manual or mechanical device that allows hilling and weeding of plants. That is, this tool removes all weeds from the inter-row area, loosening the soil and raking it to the beds. The plantings acquire a pleasant appearance, and the root system of the planted crop is enriched with oxygen.

Manual and mechanical devices differ little in design from each other. Only the dimensions of the mechanisms and the presence of special fasteners for the mechanical apparatus for attaching to a mini-tractor or walk-behind tractor are highlighted.

Hedgehogs are devices consisting of 3 metal rings of different sizes, welded together. Metal rods 5-10 cm long are welded to the surface of such rings. There can be 2 or more such cones made of rings.

The paired structure is fastened with a special bracket, which forms an angle of 45° between the working parts of the tool. The metal frame to which such cones are attached may have a handle or a special attachment to agricultural machinery.

Another option is simplified. Instead of welded cone-shaped disks, a piece of metal pipe is installed, to which rods are welded. The resulting working part of the tool is mounted on a shaft attached to a frame with a handle.

In addition to speeding up and facilitating agricultural activities, such a device effectively copes with the assigned tasks. Its advantages are:

- high-quality removal of weeds even before their emergence.

- loosening the soil, necessary to saturate the roots of plants with oxygen.

- possibility of additional hilling.

- correct formation of rows of seedlings.

- the ability to use the device in pest control - mice, moles, etc.

This is a rectangle and a hiller, created in one body. It has almost no flaws. The only negative is the high cost. But waste can also be avoided if you make such a machine for processing potatoes with your own hands.

The size of the hedgehog will depend on the size of the walk-behind tractor

We suggest you find out what kind of wood is best to cut figures from

Features of making a mechanical hedgehog with your own hands depend on the size of the equipment, the number of cone-shaped tools and the presence of mounts for agricultural machinery. In order to make such a device, it is important to develop or purchase drawings and strictly adhere to them during the work process.

The process of constructing a cultivator itself is impossible both without a welding machine, a gas cutter for metal and other tools, and without certain skills in using them.

Materials

To make a weeder for processing potatoes, you need to prepare the required amount of materials. To make such a device you will need:

- steel sheet, 4-6 mm thick (for making working tools);

- steel strip 20-30 mm long and 4 mm thick (for jumpers);

- steel rods 8 mm thick (for spikes);

- pipe with a diameter of 25 mm (for the frame);

- steel rod, 2 cm in diameter (for the axis of the device on which the working tool will be attached);

- steel bracket, 4 mm thick, at least 7 cm wide and 20 cm long.

The rod is placed in a metal pipe with a diameter of more than 20 mm, pre-lubricated with grease. And its ends will be fastened with a metal bracket. Once all the necessary materials have been prepared, you can proceed to assembling the apparatus for processing potatoes.

The manufacturing process of the device is carried out strictly according to the drawings. If it specifies the use of steel discs, they can be replaced with rings. Their diameter is 300, 200 and 100 mm. The process of making the tool itself goes like this:

- Using a cutter, 2 rings with an internal diameter of 20 cm and an external diameter of 30 cm are cut out (they will serve as blanks for rings with an external diameter of 20 cm).

- It is necessary to cut holes in the blanks with a diameter of 10 cm. The result of the work is 2 rings with an outer diameter of 20 cm and an inner diameter of 10 cm.

- Small disks with a diameter of 10 cm should be cut out of the remaining material (steel sheet). Holes are drilled in them for the prepared pipe with a margin, that is, 26 mm.

- Jumpers should be cut from a metal strip in the amount of 24 pieces, each 9 cm in size.

- Marks should be made on the cones where the jumpers should be welded. Large disks have 8 jumpers, and small disks have 4.

- The spikes should be cut into 12 cm pieces, and their ends should be cut off at an angle of 45° (there should be at least 80 spikes in total).

- It is necessary to weld the spikes to the disks at the required distance. There are a total of 40 spikes per cone.

- The bracket should be bent to the dimensions of the axle and welded to it.

- A frame is welded from a metal pipe and welded to the bracket.

The resulting apparatus will have two cone-shaped hedgehogs, which are located at an angle of 45° relative to each other. A properly made device should have a distance between the cones of 40-50 cm.

walk-behind tractors How I made hedgehogs. DIY hedgehogs. Active rotor for weeding potatoes. Cultivator with “hedgehogs”. Pre-emergence processing of potatoes.

The simplest tool that you can make with your own hands consists of a working tool, a metal frame and a holder. The working tool can take the form of a pipe or a truncated cone with welded spikes located at a distance of 4-5 cm from each other.

Hedgehogs perform the following functions:

- Clear the beds of weeds, removing them along with the roots.

- During operation, moles and rodents are repelled. A number of harmful insects are brought to the surface, after which birds eat them.

- They loosen the soil, providing better air and water flow to the roots.

- Bushes are being spudded.

Reviews from experienced gardeners

Gardeners who used hedgehogs to weed potatoes share their impressions.

Vitaly Panasenkov, Krasnodar: “I recommend buying hedgehogs for a walk-behind tractor in a special store. Otherwise, you will have to draw up a really competent drawing of a hedgehog, otherwise the effectiveness of weeding will be minimal.”

Anton Krasnov, Izhevsk: “Don’t forget to paint the hedgehogs. This will save the wheels from rust much better than any anti-corrosion agent.”

This is interesting:

What does the trimmer attachment for weeding potatoes look like and how to use it correctly

Detailed descriptions and effective methods for treating potato diseases

Reasons for tops drying out and whether potatoes grow after this