In what cases does the carburetor of a Husqvarna chainsaw require adjustment?

There are a lot of problems that can be solved by adjusting the carburetor. Adjusting the carburetor of the Husqvarna chainsaw is necessary when malfunctions such as:

- increased idle speed;

- strong smoke when operating the tool;

- difficulty starting a cold or hot engine;

- lack of traction and reduced maximum speed.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In some cases, adjusting the quality and quantity of the fuel mixture is carried out after a major overhaul of the engine or during scheduled maintenance of the chainsaw.

The design and principle of operation of the Husqvarna carburetor

To successfully configure the Husqvarna chainsaw carburetor, you need to know its structure and understand how it works. In fact, everything is not as complicated as it seems at first glance.

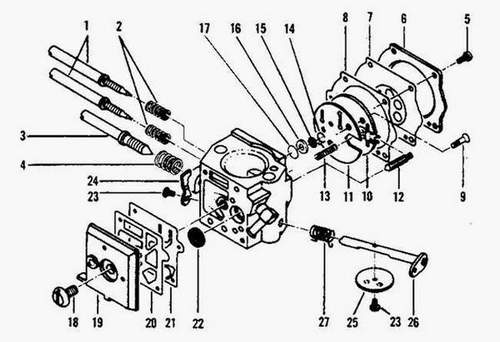

The saw carburetor has a built-in fuel pump, which is responsible for transporting the mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work makes it possible to dose the fuel supply to the main chamber and two dampers.

One of the dampers is designed to regulate the flow of fuel into the cylinder when you press the gas, it is called the throttle, the second is responsible for limiting the flow of air from the air filter to facilitate starting a cold Husqvarna chainsaw. At the moment when the operator shuts off the air supply to the carburetor using the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than when a cold start is carried out in normal mode.

The operation of the Husqvarna carburetor involves a valve-nozzle, which atomizes fuel and prevents air from entering the main chamber. Often problems with saw operation can be caused by defects in this particular element. For example, if the chainsaw is stored improperly, the valve may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, malfunctions in the operation of the nozzle can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation; repair or replacement of the unit will be required.

Three adjusting screws installed in the carburetor body are responsible for adjusting the quality and quantity of the mixture, as well as the number of crankshaft revolutions in idle mode:

- screw (L) – regulates the amount of fuel in low and medium speed modes;

- (H) – responsible for traction at high speeds and their number;

- (T) - changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the tool engine in idle mode.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Incorrect adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or operate incorrectly, causing it to wear out quickly or even seize.

Husqvarna 142 chainsaw device

The Husqvarna 142 chainsaw is equipped with a motor that uses patented X-Torq technology. As a result, the engine consumes less fuel without loss of efficiency and economy during operation.

Husqvarna uses an air injection system to cool the engine, which increases air filter change intervals and reduces wear on critical engine parts. To reduce vibration, the saw is equipped with another proprietary technology. LowVib. It consists of several shock absorbers that act as shock absorbers.

The Husqvarna 142 saw comes with a Japanese Walbro carburetor. It is characterized by durability and increased volume, which allows you to prepare a large amount of fuel mixture in one cycle.

The engine is started using a manual starter. Thanks to the SmartStart function, its resistance is reduced by 40%. The starter cable is located behind the tool. Next to it are other controls. Throttle position switch, throttle lever, and ignition on/off button.

Tires and chains of the brand are responsible for cutting wood. There is a separate sprocket on the side of the chain saw for tensioning the chain. This allows you to adjust the saw element without the use of tools. The chain is lubricated automatically while the saw is running.

All internal mechanisms and spare parts of the Husqvarna 142 are housed under a durable housing made of multi-layer plastic. It can withstand low-height drops and accidental impacts against hard objects. For ease of use of the tool, its configuration includes 2 rubber handles.

Roll protection is provided by a guard for the operator's right hand, as well as an effective chain brake. It is triggered immediately when the chain hits nails and other hard objects.

Model specifications

The Husqvarna 142 chainsaw has solid technical parameters. These include:

- Power. 2.7 l. From.;

- Maximum rotation speed. 13000 rpm;

- Fuel tank capacity. 410 ml;

- Container capacity. 200 ml;

- Recommended tire length. 35-40 cm;

- Chain pitch. 0.325";

- Collected weight. 5 kg.

Thanks to its good characteristics, the Husqvarna 142 can be used not only for gardening, but also for felling. The tool successfully copes with trimming branches and branches, clearing bushes, as well as cutting down trees whose trunk diameter does not exceed 45 cm. The light weight of the saw allows it to be used at high altitudes.

Tools required for work

Before you start setting up the Husqvarna carburetor, you need to make sure you have all the tools that may be useful. To carry out this type of work yourself, you will need:

A regular slotted screwdriver will not work for adjustment, since the adjusting screws on Husqvarna chainsaws can have different cross-sections. You will have to purchase a special one, this is a feature of repairing Husqvarna chainsaws; they did everything so that the saw could be repaired only in a specialized Husqvarna service center.

Why is the Husqvarna chainsaw considered the best model?

There are no perfect tools, and every manufacturer strives for perfection. In the chainsaw market, Husqvarna, Shtil, Partner and Makita compete in the same class. This is high quality equipment. The choice is large, you should know the features of the brand so as not to make a mistake.

The entire range of Husqvarna chainsaws are characterized by improvements that make work easier and more comfortable. First, these new products are installed on professional equipment, then they are added to the layout of amateur models. These options include:

- X-Torq engine, which reduces emissions and saves fuel, increasing torque;

- automatic adjustment of the carburetor to workloads by the Auto Tune system;

- centrifugal cleaning before air intake Air Injection ensures less frequent filter replacement;

- the vibration damping system for the handle is represented by dampers, Low Vib absorbers;

- use of a primer - an easy starting system;

- the chain tensioner is located on the side;

- use of a single key for frequently performed operations;

- In addition to automatic lubricant supply, the driven saw sprocket has a hole for additional injection.

This is not a complete list of improvements; there are additional changes in some models of Husqvarna chainsaws.

In order to exclude counterfeiting of a well-known brand, a list of countries in which the named models are produced has been published. If there is another country on the label, then it is a copy. Production facilities are located:

On this topic:

Choosing the best chain for a chainsaw

Aug 8, 2016

What are Partner and Huter brand chainsaws?

Aug 5, 2016

BACK FORWARD 1 of 6

- in the USA - 132E, 142E;

- Russian brands, Khimki - 254ХР, 257, 262ХР, 262ХРН;

- in Brazil – 55, 61, 288ХР, 268, 272ХР:

- the remaining brands are produced at the main plant in Sweden.

Therefore, a Chinese-made saw is no longer a branded product, it is inexpensive, and repairs are specific.

Any operating instructions discuss the sawing process from a safety point of view. In the household, you need to approach tools with reasonable care. Keep children away from contact with the saw. A saw that is not working or left unattended must be covered with a protective cover.

The advantage of chainsaws is the presence of a sufficient number of service centers where you can purchase spare parts for Husqvarna chainsaws. At first glance, a complex device can be repaired at home. It is important to understand the mechanism and interaction of all nodes. After the warranty period, some operations can be carried out independently. It is necessary to adequately evaluate your skills and it is better to entrust the repair of a carburetor or piston system to specialists. Spare parts for the Husqvarna chainsaw can be ordered through the online store with delivery by courier or mail. Spare parts for each brand are supplied separately.

Algorithm and description of Husqvarna carburetor settings

The Husqvarna carburetor is adjusted in the same way as carburetors on chainsaws from other manufacturers are adjusted.

Immediately before adjustment, it is necessary to conduct a complete diagnosis of the saw and make sure that there is no difficulty in supplying fuel or air leaks into the crankcase of the chainsaw. You also need to make sure that the air filter is clean and, if necessary, replace it with a new one.

The work order is as follows:

- On the muffled saw, the factory settings of the Husqvarna carburetor are installed.

- The engine starts and the saw warms up for several minutes.

- By turning the screw (L) clockwise, the position at which the engine develops maximum speed is found, after which the screw must be turned back 1⁄4. If the chainsaw chain rotates, then it is necessary to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is adjusting Husqvarna's power at maximum speed and adjusting its quantity. To do this, the tachometer is connected to a running chainsaw, the throttle is squeezed to full, after which the tachometer readings are checked. If the maximum speed value differs from the maximum number recommended by the manufacturer, then by changing the position of the screw (H), the tachometer readings are returned to normal.

How to understand that everything is done correctly

For this purpose, the design of the device provides 3 adjusting jets. The idle air adjustment screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) speeds, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- By turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter turn.

- Hold the gas button with one hand for 15 seconds. At this time, turn the jet H to the right until it stops and reaches maximum speed. Then we turn it back one and a half turns or until the “squealing” of the engine disappears.

- After releasing the gas, turn the idle speed screw (T) clockwise until the chain begins to move. After this, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This could be due to the jets being too tight or the mixture being too rich or too lean.

If this happens, you need to tighten the minimum and maximum speed jets all the way. Then turn them back one and a half turns and try to start the saw.

If cleaning and adjusting the carburetor does not correct the existing problem, you need to check the spark plug and adjust the engine. You should act in the following order:

- The spark plug is unscrewed and a visual inspection is carried out. If it is dry with a slight brown soot, it can be considered in good condition.

- If traces of gasoline are found on the spark plug, the carburetor should be re-adjusted. This happens because it supplies excess fuel to the internal combustion engine, flooding it.

- If the spark plug looks normal, check the operation of the electrical equipment. First of all, the cable that supplies current to the spark plug. Its end is brought a short distance to the radiator grille of the cylinder and the starter is turned with a cord. There should be a spark. If it is not there, the cable is checked with a tester and replaced if necessary.

- If the cable is in good condition, test the ignition coil. If the inspection does not reveal singed or broken wires, the coil is run through a tester, comparing the data with the accompanying documentation. If deviations are detected, the block must be replaced with a similar one.

After replacing the coil unit, the gap in the magneto should be adjusted. The gap between the ignition coil and the flywheel should be from 0.2 to 0.4 mm. To set the gap, you need a set of feeler gauges or you can use foil of a suitable thickness. The probe is clamped between the coil and the flywheel at the time of installation, and then pulled out.

Nuances of adjustment

After the adjustment, the chainsaw should easily pick up and drop speed, and operate stably at low and high speeds. If the saw chain rotates at idle speed after adjusting the carburetor control screws, this is a sign that the adjustment was made incorrectly and the position of the screw (T) needs to be adjusted.

Also, when adjusting the Husqvarna carburetor, it is worth taking into account the response time of the chainsaw to the rotation of the screws. The settings do not change immediately, but within five or ten seconds.

One of the indicators of incorrect adjustment is heavy smoking when the saw is operating, which indicates a large amount of fuel entering the combustion chamber. If such a situation occurs, the position of the screw (L) must be adjusted.

DIY carburetor repair

If, during a full diagnosis of the Husqvarna chainsaw, carburetor defects were discovered, some of them can be eliminated without contacting the Husqvarna AB service center. For example, you can do this yourself:

- change the gaskets under the covers of the main chamber and fuel pump;

- clean or replace the strainer;

- replace the diaphragm or needle valve of the main chamber;

- troubleshoot the fuel pump diaphragm.

Gaskets, diaphragms and a needle valve with a rocker arm can be found in the repair kit, which is available for each model of Husqvarna chainsaw carburetors.

Also, if you have some experience, you can try to restore a faulty injector valve, but you cannot guarantee a positive result when trying to restore an injector; if it malfunctions, manufacturers recommend replacing the carburetor completely.

The first thing you need to do before removing the carburetor from the Husqvarna is to clean the saw with a compressor, since dirt can interfere with quality repairs. Next, you need to open the top cover of the chainsaw, remove the air filter, and disconnect the rods from the air and throttle valve control levers. After this, unscrew the carburetor mounting screws.

Disassembling the carburetor body for repairs is quite simple. The main chamber cover is held in place by four screws, which can be removed using a regular screwdriver; the fuel pump cover is secured with one wide screw.

Below is a video, after watching which you will understand exactly how you can repair the carburetor without contacting a Husqvarna service center.

Chainsaw Husqvarna 142 Carburetor Adjustment Video

Adjusting the Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main components, which at times require maintenance and adjustment. In this article we will talk about how to adjust the carburetor on a Husqvarna chainsaw.

IMPORTANT. An experienced electrician leaked to the network the secret of how to pay half for electricity, a legal way. Read more

In what cases does the carburetor of a Husqvarna chainsaw require adjustment?

There are quite a few problems that can be solved by adjusting the carburetor. Adjusting the carburetor of the Husqvarna chainsaw is necessary when defects such as:

- high idle speed;

- strong smoke when operating the tool;

- Difficulty starting a cool or hot engine;

- lack of traction and low maximum speed.

This is by no means a complete list of problems that can be solved by tuning the Husqvarna carburetor. In a number of different cases, adjusting the properties and amount of fuel consistency is carried out after a half-year engine repair or during scheduled maintenance of the chainsaw.

The manufacturer Husqvarna AB recommends adjusting the carburetor before and after break-in.

The design and principle of operation of the Husqvarna carburetor

To successfully install the Husqvarna chainsaw carburetor option, you should know its structure and understand how it works. In fact, everything is not as difficult as it seems at first glance.

The saw carburetor has an integrated fuel pump, which is responsible for transporting the mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows the fuel supply to be dosed into the main chamber and two dampers.

One of the dampers is designed to regulate the flow of fuel into the cylinder when you press the gas, it is called the throttle, the second is responsible for limiting the flow of air from the air filter to facilitate starting a cool Husqvarna chainsaw. At the moment when the operator shuts off the air supply to the carburetor using the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than in this case, when a cool start is carried out in normal mode.

The operation of the Husqvarna carburetor involves a valve-nozzle, which sprays fuel and ensures the flow of air into the main chamber. Often, problems with the operation of the saw can be caused by shortcomings of this particular element. Husqvarna chainsaw For example, if the chainsaw is stored incorrectly, the valve may stick, the fuel supply will end, which will make the engine impossible to operate. Also, malfunctions in the operation of the nozzle can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation; it will be necessary to carry out repairs or replace the unit.

READ How to Adjust a Husqvarna 142 Carburetor

Three adjusting screws installed in the carburetor body are responsible for setting the properties and amount of consistency, as well as the number of crankshaft revolutions in idle mode:

- screw (L) – regulates the amount of fuel in low and medium speed modes;

- (H) – responsible for traction at high speeds and their number;

- (T) – changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the tool’s motor in idle mode.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Incorrect adjustment of the properties and amount of fuel consistency can lead to the engine stopping working or working incorrectly, which will lead to rapid wear or even jamming.

Tools required for work

Before you start setting up the Husqvarna carburetor, you need to make sure you have all the tools you might need. To carry out this type of work without the help of others, it will be useful:

- a screwdriver for adjusting screws (H) and (L), it can be purchased at specialized stores;

- an electric tachometer for determining crankshaft speed readings (with some experience, you can make adjustments by ear);

- Phillips screwdriver for adjusting screw (T);

- compressor with a blow gun for cleaning the saw before work.

How to properly adjust the carburetor on a Husqvarna chainsaw

How to tune the carburetor on a chainsaw Husqvarna Carburetor adjustment

on a chainsaw using 3 THL screws.

Carburetor adjustment!!!Husqvarna 137-142 AntiReg!

Hare to feed the Chinese and rednecks!!! Disassemble and clean the carburetor

, change dry diaphragms, twist and...

A regular slotted screwdriver will not work for adjustment, since the adjusting screws on Husqvarna chainsaws can have a different cross-section. You will have to purchase a special one, this is a feature of repairing Husqvarna chainsaws; they have created everything so that the saw can be repaired exclusively in a special Husqvarna service center.

READ Carburetor Adjustment Stihl MS 250

Algorithm and description of Husqvarna carburetor settings

The Husqvarna carburetor is adjusted in the same way as carburetors on chainsaws from other manufacturers are adjusted.

Specifically, before making adjustments, you need to conduct a full diagnosis of the saw and make sure that there is no difficulty in supplying fuel or air leaks into the crankcase of the chainsaw. Carburetor adjustment on Saw Husqvarna 142, Chainsaw Husqvarna 365 is simply not possible. You also need to make sure that the air filter is clean and, if necessary, replace it with a new one.

The order of work is as follows:

- The factory options for the Husqvarna carburetor are installed on the muffled saw.

- The engine is started and the saw is warmed up for several minutes.

- By rotating the screw (L) clockwise, you find the position at which the engine develops the highest speed, after which the screw must be turned back 1⁄4. If at the same time the chainsaw chain is spinning, then you need to reduce the idle speed by adjusting the position of the screw (T).

- The next stage is adjusting Husqvarna's power at the highest speeds and adjusting their number. To do this, the tachometer is connected to a running chainsaw, the throttle is squeezed to full, after which the tachometer readings are checked. If the maximum speed value differs from the maximum number recommended by the manufacturer, then by adjusting the position of the screw (H) the tachometer readings are returned to normal.

Nuances of adjustment

After the adjustment, the chainsaw should simply pick up and drop speed, work steadily at low and high speeds. If the saw chain spins at idle after adjusting the carburetor control screws, this is a sign that the adjustment was carried out incorrectly and the position of the screw (T) needs to be adjusted.

Also, when adjusting the Husqvarna carburetor, it is worth taking into account the response time of the chainsaw to the rotation of the screws. Options do not change immediately, but within 5, 10 seconds.

One of the characteristics of an incorrectly carried out adjustment is strong smoking when the saw is operating, which indicates a large amount of fuel entering the combustion chamber. If such a situation occurs, it is necessary to adjust the position of the screw (L).

Factory settings

The standard factory settings for the Husqvarna carburetor are the positions of the screws (H) and (L), in which a working chainsaw should be guaranteed to start. For Husqvarna instruments, this is one and a half turns from fully tightened screws (H) and (L). During the adjustment process, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to the power, the number of maximum revolutions and idle speed.

READ Stihl Chainsaw Doesn't Speed Under Load

DIY carburetor repair

If, during a full diagnosis of the Husqvarna , carburetor defects were discovered, then some of them can be removed without calling the Husqvarna AB service center. For example, without the help of others you can:

- change the gaskets under the covers of the main chamber and fuel pump;

- clean or change the mesh filter;

- change the diaphragm or needle valve of the main chamber;

- remove faults in the fuel pump diaphragm.

Gaskets, diaphragms and a needle valve with a rocker arm can be found in the repair kit, which is available for each model of Husqvarna chainsaw carburetors.

Also, if you have some experience, you can try to return the faulty injector valve, but you cannot guarantee a good result when trying to restore the injector; if it malfunctions, manufacturers advise replacing the carburetor one hundred percent.

The first thing you need to do before removing the carburetor from the Husqvarna is to clean the saw with a compressor, since dirt can interfere with high-quality repairs. Next, you need to open the top cover of the chainsaw, remove the air filter, disconnect the rods from the air and throttle valve control levers. Then unscrew the carburetor mounting screws.

Disassembling the carburetor body for repairs is quite easy. Adjusting the carburetor of the chainsaw should I have a Chinese Husqvarna I give on. The main chamber cover is held in place by 4 screws, which can be removed using an ordinary screwdriver; the fuel pump cover is secured with 1 wide screw.

Below is a video , after watching which it will become clear how exactly you can repair a carburetor without calling a Husqvarna service center.

Conclusion

The work of adjusting or repairing the carburetor on Husqvarna chainsaws can be done without any specific experience. In order to do everything right, you need to follow the method and have a small set of tools. It is also worth assessing your strengths in advance and not taking risks if you are completely unaware of the technique. Believe me, from time to time it is better to pay a small amount to the master than to damage the instrument by adjusting it yourself.

Source

Conclusion

The work of adjusting or repairing the carburetor on Husqvarna chainsaws can be done without any specific experience. In order to do everything correctly, you must follow the algorithm and have a minimum set of tools. It’s also worth assessing your strengths in advance and not taking risks if you don’t understand anything at all about technology. Believe me, sometimes it is better to pay a small amount to the master than to ruin the instrument by adjusting it yourself.

Before you go shopping for a chainsaw, you need to decide what kind of work it will be intended for. This could be daily work at a sawmill (see) or using a saw for work in the country.

In both cases, a chainsaw from .

The company called Husqvarna was founded in 1687. Husqvarna is a market leader in industrial and gardening equipment. Part of a Swedish concern that unites several companies. Producing various types of equipment, ranging from compact sewing machines to impressive ATVs.

Husqvarna offers its customers the most expanded range of specialized machinery and equipment. In recent years, the company has increased the number of patented innovations. Husqvarna is firmly committed to progress.

The products manufactured by this brand transform hard work into a simple activity that does not harm either humans or the environment.

The Husqvarna 137 chainsaw belongs to the equipment produced under the Forestry Professionals category. Along with this model, the manufacturer also produces universal professional chainsaws, blowers and pole saws. All manufactured equipment is compact in size and easy to operate. All Husqvarna chainsaws are distinguished by three features - the ability to absorb excessive vibrations

, improved air filtration system, high power.

Chainsaws Husqvarna - model range of the Swedish company

The Husqvarna company is known for the huge range of branded chainsaws on the market. We bring to your attention a review of Husqvarna chainsaws with a detailed description of the most popular models.

Husqvarna 61

This Husqvarna chainsaw cuts through old thick branches efficiently and quickly and helps you prepare large quantities of firewood. Technical parameters of this popular model include:

- Power – 3.9 l. s./2900 Watt;

- Standard tire size – 45 cm;

- Reservoir for replenishing fuel – 750 ml;

- Oil tank – 400 ml;

- Ready-to-use weight: 6.6 kg.

This Husqvarna chainsaw is small in size, so even a small bag is suitable for transportation.

Husqvarna 136

This semi-professional Husqvarna chainsaw is primarily used for maintaining large garden areas. Technical characteristics of this Husqvarna chainsaw include:

- Power – 2.2 l. s./1600 Watt;

- Tire length per set – 45 cm;

- Fuel refill tank – 410 ml;

- Oil tank – 175 ml;

- Operating weight – 4 kg.

The design of this Husqvarna chainsaw is based on a forged piston group, which significantly increases wear resistance and increases the endurance of the model.

Husqvarna 235

This professional Husqvarna chainsaw has received the highest demand due to its well-thought-out design and balance. Technical parameters of this Husqvarna model include:

- Power – 1.7 l. s./1300 Watt;

- Factory tire size – 30 cm;

- Reservoir for replenishing fuel – 300 ml;

- Reservoir for lubricant – 200 ml;

- Operating weight – 3.5 kg.

The modest size of the chainsaw allows it to be easily placed in a carrying case.

Chainsaws Husqvarna 257 XP and Husqvarna 455 Rancher

These Husqvarna chainsaws do an excellent job of sawing small logs and cutting down old branches. The operating parameters of chainsaws are described in the table below.

| Chainsaw model | Husqvarna 257 XP | Husqvarna 455 Rancher |

| Power | 3.7 l. s./2700 Watt | 3.5 l. s./2600 Watt |

| OEM tire size | 45 cm | 45 cm |

| Reservoir for replenishing the fuel mixture | 600 ml | 440 ml |

| Lubricant reservoir | 350 ml | 320 ml |

| Ready-to-use mass | 5.5 kg | 6.1 kg |

The power of these models is quite enough to make an ice auger from a chainsaw or other useful household units with your own hands.

Chainsaws Husqvarna 262 XP and Husqvarna 576 XP

These Husqvarna chainsaws are originally designed for use in the most difficult conditions and can easily cope with sawing fairly thick beams and long-term felling of large trees. The design parameters of these units are described in the table below.

Read also: Snowman stencil for felt

| Chainsaw model | Husqvarna 262 XP | Husqvarna 576 XP |

| Power | 4.7 l. s./3400 Watt | 5.6 l. s./4200 watts |

| OEM tire size | 50 cm | 50 cm |

| Fuel refill tank | 600 ml | 700 ml |

| Oil tank | 300 ml | 400 ml |

| Ready-to-use mass | 5.8 kg | 7.2 kg |

Each of these Husqvarna chainsaws is equipped with a durable 2-stroke motor, chain brake and adjustable oil pump.

Chainsaws Husqvarna 268 and Husqvarna 562 XP

The main area of application for these chainsaws is intensive forest felling and construction. The model parameters are described in the table.

| Chainsaw model | Husqvarna 268 | Husqvarna 562 XP |

| Power | 4.4 l. s./3200 Watt | 4.7 l. s./3500 Watt |

| Factory tire size | 45 cm | 45 cm |

| Reservoir for filling fuel | 600 ml | 650 ml |

| Oil reservoir | 270 ml | 290 ml |

| Ready-to-use weight | 5.7 kg | 6.3 kg |

These Husqvarna chainsaws are equipped with a reliable chain brake and an adjustable oil pump.

Chainsaws Husqvarna 272 XP and Husqvarna 372 XP

These Husqvarna chainsaws are used for felling forest trees and cutting thick logs for construction. The model parameters are described in detail in the table.

| Chainsaw model | Husqvarna 272 XP | Husqvarna 372XP |

| Power | 4.9 l. s./3600 W | 5.5 l. s./3900 Watt |

| OEM tire size | 45 cm | 50 cm |

| Reservoir for fuel mixture | 750 ml | 770 ml |

| Oil tank | 500 ml | 400 ml |

| Operating weight | 6.7 kg | 7 kg |

The technical characteristics of these models allow you to use branded attachments for Husqvarna chainsaws to work with them.

Chainsaws Husqvarna 339 XP and Husqvarna 353

Both of these models are practically the same in design. The main difference is that the Husqvarna 339XP model has more modest technical parameters. The performance of chainsaws is described in detail in the table.

| Chainsaw model | Husqvarna 339 XP | Husqvarna 353 |

| Power | 2.45 l. s./1800 Watt | 3.26 l. s./2400 Watt |

| OEM tire size | 35 cm | 40 cm |

| Reservoir for filling fuel | 360 ml | 500 ml |

| Oil tank | 200 ml | 300 ml |

| Operating weight | 5 kg | 5.6 kg |

Both models are great for sawing logs and cutting down small to medium sized branches.

Husqvarna 345E

This model was included in our review due to the presence of a number of useful proprietary options and high endurance. Among the parameters of the Husqvarna 345 chainsaw, the following should be highlighted:

- Power – 2.7 l. s./2000 Watt;

- The size of the tire included in the kit is 35 cm;

- Reservoir for filling fuel – 500 ml;

- Oil reservoir – 270 ml;

- Ready-to-use weight: 5.1 kg.

This Husqvarna chainsaw is widely used for removing thick branches and cutting down small garden trees.

Chainsaws Husqvarna 440E II and Husqvarna 445E II

Both Husqvarna chainsaws have almost the same design and performance indicators. The model parameters are described in detail in the table below.

| Chainsaw model | Husqvarna 440E II | Husqvarna 445E II |

| Power | 2.2 l. s./1600 Watt | 2.2 l. s./1600 Watt |

| OEM tire size | 40 cm | 40 cm |

| Reservoir for filling fuel | 370 ml | 370 ml |

| Oil tank | 250 ml | 250 ml |

| Operating weight | 4.8 kg | 5 kg |

The Husqvarna 440 and Husqvarna 445 models performed well when cutting down medium and small trees, as well as processing logs for heating.

Chainsaws Husqvarna 357 XP and Husqvarna 365H

These Husqvarna chainsaws have found application in utility companies. Due to their efficiency and long service life, they are also in demand among owners of large garden plots. The parameters of the Husqvarna 357 and Husqvarna 365H models are described in detail in the table below.

| Chainsaw model | Husqvarna 357 | Husqvarna 365H |

| Power | 4.3 l. s./3200 Watt | 4.6 l. s./3900 Watt |

| OEM tire size | 45 cm | 45 cm |

| Reservoir for replenishing the fuel mixture | 680 ml | 770 ml |

| Oil reservoir | 380 ml | 420 ml |

| Operating weight | 6 kg | 6.5 kg |

These Husqvarna chainsaws have enviable reliability and good build quality.

Chainsaws Husqvarna 359 and Husqvarna 395XP

This Husqvarna chainsaw is designed for maintaining large garden areas and intensive deforestation. The technical parameters of the models are described in the table.

| Chainsaw model | Husqvarna 359 | Husqvarna 395XP |

| Power | 3.9 l. s./2900 Watt | 6.66 l. s./5200 Watt |

| Factory tire size | 40 cm | 60 cm |

| Reservoir for filling fuel | 680 ml | 900 ml |

| Lubricant reservoir | 380 ml | 500 ml |

| Operating weight | 5.8 kg | 8.1 kg |

These models are equipped with reliable engines, significantly expanded carburetors and improved ignition systems.

Chainsaws Husqvarna 545 and Husqvarna 555

These chainsaws cope well and quickly with sawing fairly thick beams and quickly cutting down small and medium-sized trees. The characteristics of the models are described in the table below.

| Chainsaw model | Husqvarna 545 | Husqvarna 555 |

| Power | 3.4 l. s./2500 Watt | 4.3 l. s./3200 Watt |

| Recommended tire size | 45 cm | 50 cm |

| Reservoir for filling fuel | 520 ml | 650 ml |

| Lubricant reservoir | 270 ml | 330 ml |

| Ready-to-use mass | 5.4 kg | 6 eg |

The design of this tool includes a high-quality vibration damping system and an instantaneous inertial brake.

Description and technical specifications

The Husqvarna 137 chainsaw model first appeared on sale in 2005. It was released at the same time as the Husqvarna 142 chainsaw. “Amateurs” appreciated it. This amateur saw model is an excellent option for working in the country. Most similar models start poorly due to infrequent use.

In the countryside and countryside, the need to use a chainsaw does not often arise. Husqvarna specialists have developed a new technology that will come to the rescue when turning on the saw is problematic; thanks to this, Husqvarna 137 starts, as they say, with half a turn.

The chainsaw has a special spring built into it

, which turns the crankshaft at the required moment. This allows for stress-free operation of the starter cable.

In addition, the Husqvarna 137 model has an improved ignition mechanism that produces a spark. The manufacturer made sure that the “amateur” chainsaw was equipped with a device that is equipped with professional models of saws.

The design of the Husqvarna 137 chainsaw is as close as possible to the design of professional equipment. However, the ergonomic design is also appreciated by amateurs. The model is equipped with an air injection system called “Air Injection”.

Specifications:

- The volume of the fuel tank is 0.41 l.

- Weight without fuel and without tires – 4600 g.

- Tire length – 220-380 mm.

- Vibration on the front handle – 4.9 m/s.sq.

- Vibration on the rear handle – 7.7 m/s.sq.

- Chainsaw power – 2.2 hp.

- Engine volume – 36.3 cubic meters. cm.

Chainsaw Husqvarna 137 price - from 1200 to 2200 rubles.

Technical characteristics of Husqvarna 137

| engine's type | petrol |

| Fuel tank volume, l. | 0,41 |

| Oil tank volume, l. | 0,20 |

| Engine volume, cm3 | 36,3 |

| Engine power | 1.64 (2.2)/kW (hp) |

| Tire length, cm. | 33-38 |

| Weight, kg | 4,6 |

| Chain pitch, inches (mm) | 0,325 (8,25) |

Setup instructions

Before moving on to setting up the Husqvarna 137 chainsaw, it is necessary to install it. Before starting work, you need to study the structure of the Husqvarna 137 chainsaw.

- Be sure to wear gloves for protection. They are not included in the package, so you need to take care of purchasing them in advance. First you need to install the saw comb and secure it with two screws.

- If chains and bars are not installed, they should also be put in their place. To do this, you need to remove the cover and the nuts securing it. If there is a shipping pad on the chain, it must be removed.

- Adjust the chain tension using the adjusting screw.

It is important that the gripper can fit into the hole in the tire. To advance the grip, you need to turn the adjusting screw counterclockwise. This way you can achieve the correct grip position. - Next you need to prepare the circuit for installation. To do this, its correct position is selected. A sprocket is placed on the chain, which is located behind the clutch drum. The chain is passed between the teeth of the sprocket.

- The upper part of the guide bar must be moved into the groove of the guide bar that surrounds it.

Hold the guide bar relative to the chainsaw body to install the clutch cover.

- then inserted and tightened by hand.

Once the chains have been fully adjusted, they can be fully tightened. - You can find out how in the instructions attached to this saw model. Tuning a Husqvarna 137 carburetor usually does not cause any problems.

When the installation is completed, you can proceed to setting up the Husqvarna 137 chainsaw.

- First you need to set the saw switch to the “On” position.

- Then pull the idle air damper lever all the way.

- Pull the starter cord with a sharp movement of your hand (but no more than ten times).

If the sound of the engine is heard before you have completed the 10th dash, you can move on to the next step.

- Next, you need to move the lever to switch modes to the “HalfChoke” position. This will mean that the air damper will be half closed.

- Next, you need to jerk the starter cord until the engine starts.

- After starting the engine, you need to let it run for about five seconds. The engine starter must then be pressed and released to return the engine to idle speed.

To start and configure an already warmed-up engine, you need to:

- Set the saw switch to the “On” position.

- Direct the mode change knob towards o.

- With your right hand you need to pull the cord until the engine starts running.

- Press the engine starter until it returns to idle speed.

Watch the video for the disassembly and assembly process:

Do-it-yourself troubleshooting and repairs

Malfunctions are simple if they do not require disassembling the chainsaw to eliminate them. For Husqvarna 142, the methods for finding them, as well as eliminating them, are no different: it all comes down to checking the condition of the spark plug, the fuel level in the tank, etc.

If easily correctable malfunctions occur, it is necessary to remove individual components, replace or repair them, and then reassemble the Husqvarna 142 chainsaw. This is how the shock absorbers or carburetor are replaced and the starter is repaired. To repair the starter, it is better to first familiarize yourself with its structure, for example, from a video.

If the chain is not lubricated, we recommend watching a video that discusses in detail the lubrication system, its disassembly and reassembly.

If complex faults occur, complete disassembly is necessary. The design of the Husqvarna 142 chainsaw is not complicated, but you must be absolutely sure that for high-quality repairs you can:

- receive drawings of the device with a description and you can do the detailing;

- perform troubleshooting and reassembly.

Is it worth it to repair the Husqvarna 142 piston group yourself? For high-quality overhauls, you must have at least precise tools - a micrometer and a bore gauge - which can cost you more than spare parts. If you decide to do a major overhaul, we recommend watching a video that sequentially shows how to disassemble the Husqvarna 142, and our article on repairing Husqvarna chainsaws.

User manual

The Husqvarna 137 chainsaw, like other models of this brand, is equipped with an inertial automatic chain brake. This part was invented by engineers working at Husqvarna. Nowadays, most manufacturers still produce chainsaws with contact brakes. That is, the brake is activated when interacting with the hand during a reverse impact. In practice, such a contact brake may not work at all.

The autovibration system of this model operates on the principle of “two masses”.

The manufacturer does not produce other systems.

Husqvarna 137 is equipped with a high-profile professional chain. This is another difference from chainsaws with low profile chains. Chainsaws with high-profile chains have a forty percent higher chain. This is especially noticeable with large volumes of work. In addition, such chainsaws maintain high performance even when working with contaminated wood.

One of the most common mistakes when starting a Husqvarna 137 is closing the air damper without turning on the ignition.

It turns out that the fuel mixture enters the cylinder

(see proportions). But there is no spark, no ignition occurs. After this, you will have to unscrew the spark plug, wipe it and screw it back in. Therefore, it is worth remembering that all Husqvarna chainsaws have a combined damper, and the ignition in them will be turned on automatically at the moment when the damper lever is pulled out. There shouldn't be any errors.

Safety precautions

Due to the fact that the Husqvarna 137 is a high-speed cutting tool, it is necessary to adhere to certain safety rules.

To avoid an accident, please read these instructions carefully.

- The spark plug wire must be disconnected during transportation and cleaning. It is important to ensure that it does not come into contact with the spark plug to avoid the circuit suddenly turning on.

Protective clothing for working with chainsaws

- When working with a saw, you must wear protective clothing: shoes with non-slip soles with steel inserts, special gloves (not included in the delivery package), a mask or safety glasses (anti-fog). Hair should be pulled back above the shoulders.

- If you regularly use a chainsaw, you should periodically have your hearing checked by a specialist.

- Chainsaws should only be used by adults.

- Do not place body parts under the saw while the motor is running.

- While the saw is operating, the presence of children and animals must be limited to at least ten meters.

- Do not use a chain saw while under the influence of alcohol, or when you are upset, depressed or tired.

- Do not start work until you are wearing protective clothing and your work area has been equipped.

- You should only work with the saw in a well-ventilated place.

- When you cut down a branch, be prepared to jump back the moment you finish the job so that you do not get hit by the felled tree limb.

- The saw can only be laid on the surface after it has been turned off.

- Before turning on the saw, make sure that the chain cannot come into contact with anything during operation.

- Maintenance of your chainsaw should only be carried out by a specialist.

- The saw handle should be clean and not stained with machine oil.

- The oil and fuel reservoir caps must always be tightly closed.

- Only accessories from .

- Do not smoke while refueling.

- You need to refuel the saw on bare ground in the open air. This is not allowed indoors.

- Before starting the chainsaw engine, you must move ten meters away from the place where the refueling took place.

- Be sure to let the saw cool before refueling.

- If the moving chain touches any object, a kickback may occur - rapid movement of the device down and up. This may result in complete loss of control of the chainsaw and further serious injury.

Therefore, never try to rotate the saw when removing it from the lower cut, and also do not try to cut several logs at the same time.

- Never cut with just the tip of the chainsaw.

- Use guide bars to help mitigate kickback.

“A carburetor is a device responsible for the mixture and supply of fuel to the combustion chamber of an internal combustion engine.”

I am glad to welcome all lovers of “interesting and necessary men's toys”.

Correct carburetor adjustment ensures reliable operation of the chainsaw in all modes and with economical fuel consumption. However, if we remove the word “chainsaws”, then this applies to all internal combustion engines.

Today we’ll talk about how to adjust the carburetor on a chainsaw. In general, such a procedure is performed occasionally. Factory setting is the best and highest quality option. However, if necessary, it is performed by adjusting special screws. Let's figure out how to rebuild it yourself:

This device prepares an air-gasoline mixture in a certain ratio. If this balance is not maintained, then malfunctions occur in the operation of the internal combustion engine (ICE). A mixture that does not meet the standard can be either oversaturated (when the amount of fuel relative to air increases) or lean (when there is more air than required and less fuel).

- The air flow moves through a special channel, and the damper regulates its speed;

- Opening the damper regulates the amount of fuel and air supplied;

- Gasoline and air, flying through the diffuser, are mixed and atomized;

- The resulting mixture flows through the intake manifold into the combustion chamber (cylinder).

Signs and causes of poor unstable performance

Signs of malfunctioning chainsaw carburetor:

- The engine starts hard and stalls quickly. Possible cause: lean mixture.

- Excessive (more than normal) fuel consumption. In addition, intense (more than usual) exhaust emissions. Possible cause: oversaturated mixture.

- The engine doesn't want to run at all. There are two reasons for this: no gasoline (fuel nozzle clogged) or no spark (faulty spark plug, broken high-voltage wire or failure of the electronic unit).

Settings failure itself is rare and the reasons are usually the following:

- Damage to the fastenings of the control screws due to a faulty (damaged) coating of the protective casing. Possible cause: careless touch, rough adjustment attempt, or strong external vibrations.

- Wear of the piston group. Here, of course, adjusting the carburetor will not help much. Consider repairing your engine or replacing your saw.

- Carburetor contamination*. Probable cause: breakdown or unsatisfactory condition of the air filter, use of low-quality fuel, ingress of scale, tiny sawdust, etc. into the fuel channels. *In such cases, the entire fuel system is first flushed, and only then adjustment is made.

Video: Husqvarna 142 Chainsaw Malfunctions

The chainsaw starts and stops. Repair methods

If the Husqvarna 142 starts and stops immediately, the main reason for this is wear on the rings, which causes loss of compression. If the engine starts and stops during a cold start, check the muffler as well as the contact between the high voltage wire and the spark plugs.

To fix the problem, you will need to disassemble the saw and inspect the piston rings. If necessary, they must be replaced. It would be a good idea to clean the cylinder walls of residual fuel.

If the rings work, check the contact between the spark plugs and the chainsaw wire. You also need to clean to remove the muffler and inspect its walls. Due to prolonged use of the tool, a thick layer of soot accumulates on the walls of the muffler. In this case, you will need to blow out the element with compressed air from the cylinder.

READ Is It Possible to Saw Dead Wood

After completing all the above procedures, you need to assemble the tool and run it. Before using the saw, allow a few minutes to warm up the engine. You can then continue to use the tool as normal.

Chainsaw Husqvarna 142. This is a budget modification that unites the famous Swedish company Husqvarna, which firmly occupies a leading position in the world market. The history of the company began in 1689, chainsaws began to be produced in 1970, at the same time the company began producing gardening tools and equipment. Until 1970, the main specialization of the Husqvarna brand was weapons for the army.

Do-it-yourself carburetor adjustment

In other cases, it is unlikely to guarantee a positive result. The chainsaw carburetor is adjusted with one, two or three screws. It all depends on the brand of saw.

Consider the adjustment option on the popular Husqvarna chainsaw. This carburetor has three adjustment screws labeled:

- T – idle speed control;

- L – regulation of minimum speed;

- H – regulation of maximum speed;

In the first case, there is one “visible” idle screw (T), and the other two (L and H), usually hidden behind the casing. This is no accident. the consumer should make adjustments only with the idle speed screw, since otherwise the optimal factory settings are set. However, for some extreme modes there is still the possibility of adjustment.

The idle speed adjustment screw may be designated by different letters from different manufacturers.

For example, Husqvarna and Partner are designated by the Latin letter “T”, and another well-known manufacturer, Stihl, uses the letters “ LA ”.

Here is a clear picture of the carburetor of the Husqvarna 137 chainsaw:

Hidden lower screws (L and H) serve to adjust the operation of the carburetor in cases where gasoline different from that recommended by the manufacturer is used.

If the octane number is low

– then to increase it, turn the screw from right to left (unscrew it).

This way you can increase power and speed

.

If the octane number is increased

– then to lower it, turn the screw in the opposite direction (tighten it).

This will reduce engine speed

.

The screws are adjusted in this order: L – H – T.

Follow the instructions for your specific chainsaw! It indicates the exact angles of rotation of the screws. This is a mandatory requirement to maintain the best operating parameters of the internal combustion engine.

How to make the adjustment correctly? There is no universal way. This procedure is somewhat different for everyone. However, the process of adjusting any chainsaw can be divided into 2 stages.

- Basic (carried out with the engine turned off);

- Final (carried out with the working engine warmed up for at least 10 minutes).

Wrench (screwdriver) for adjusting carburetor screws

Many manufacturers use branded keys. Use them, don't lose them. Finding such a special tool on sale is quite difficult. For example, like the one in the photo on the right...

Be sure to follow the safety rules specified in the chainsaw instructions

.

Candles

Use original ones and change them promptly. This should be done at least once a year. Although, if you look at it more broadly, it all depends on the volume of work performed. Some work almost every day, while others work once during the summer season.

Air filter condition

His condition must be checked, since he experiences a lot of stress during intensive work. Fine wood dust is everywhere. Upon completion of the working cycle, it is recommended to remove it and clean it (rinse).

If it is a polymer (nylon) mesh, then a neutral soap (not foamed) solution is used. Washing is done under running water and dried in the open air (only at “plus” temperatures).

If the “air vent” is made of foam rubber, you can actually rinse it with kerosene, squeeze it out very well and dry it (although the kerosene will not completely evaporate). There are filters made of material similar to velvet mesh. This filter is rinsed in regular warm water without using detergents. Then they dry it.

The new absorbent element (aka filter) must be the same as the used one.