Working in the fields is hard work. The advent of agricultural machinery ensured high-quality agricultural work with less labor input. Developed on the basis of the grain harvester, the forage harvester allows you to prepare silage.

The harvesting process begins with the mowing of meadow and seeded grasses, as well as grain forage crops, followed by crushing and loading. Modern forage harvesters perform additional functions, enriching forage with mineral and vitamin supplements, and copying the landscape of the area.

Main classification of forage harvesters

Forage harvesters are classified according to two principles. According to the principle of autonomous operation (trailer, mounted, self-propelled), and the principle of arrangement of knives (drum, disk).

The structure of a self-propelled combine includes a chassis - a chassis and an engine. This ensures independent movement on the field. The productivity of such combines is higher, since they cover a larger area of the cultivated area. Self-propelled forage harvesters are used to work with large areas.

Mounted and trailed combine harvesters. They are attached to the driving mechanism (tractor). What makes them distinctive is the principle of fastening. Trailed combine harvesters are typically located at the rear. Mounted ones are located on the side of the driving mechanism. The harvesting area of such combines is smaller than that of self-propelled ones. Performance is lower. They are used in medium and small areas.

Forage harvesters also differ in the design of the chopping apparatus. Drum type involves the presence of a drum with knives and a sharpening device. This allows you to simultaneously chop forage and sharpen knives.

A disk shredding machine consists of a disk working body with knives mounted on it, located at an angle, a rotation drive and a shear plate. The working body consists of two parts with internal and external disks. Fast grinding reduces energy costs.

How we are the first in the world to robotize forage harvesters

Recently, my colleague told how we robotize combine harvesters and what we have learned this season. Harvesting of forage crops begins and we are actively mastering forage harvesting equipment. A forage harvester is a technically more complex and powerful machine. In conjunction with it there are several vehicles for harvesting (tractors with trailers, trucks, silage trucks). Only experienced machine operators with several years of experience behind them are allowed to operate such equipment.

Operating a combine while harvesting feed corn is similar to driving in a car in thick fog, only instead of fog, there is a tall green wall of plants along the entire route from which a boar, a pole or a person can jump out. After grinding a person (the story is in my last article), the combine operators turn gray and can no longer work. In addition, in this “green fog” you must be able to avoid crashing into a silo truck driving nearby, monitor the accuracy of loading the silo with a trunk up to 7 meters long, from which 50-60 kg of silage per second flies out, and fill the van evenly so that it does not drove half empty back and forth.

In fact, one combine operator works for three, monitors the corn harvesting process (one workplace), drives the equipment (second workplace), and loads the silo truck (third workplace). As a result, something suffers. If you drive poorly, you can break expensive equipment (the minimum price of a forage harvester is 16 million rubles, there are models for 50 million), so the quality of harvesting and loading usually deteriorates.

We automate most of the work, now I’ll tell you what difficulties we overcome and what we do.

No visibility

The height of ripe corn is on average 2-2.5 meters, the height of the combine is 2.5 meters, the machine operator is most often at a level slightly higher than a person standing on the ground and sees only plants in front of him, he essentially no longer sees further than his nose, and so on throughout the entire working day, and this is a 12-hour shift, few can withstand such strain on the eyes and maintain the pace of assembly, and pigs or a pole may jump out on the way!

There are combines, for example KRONE, with a telescopic cabin that rises to a height of up to 3 meters, or Acros RSM-142 with a height of 4 meters, but this is rather an exception to the rule.

Therefore, only experienced combine operators who have worked for 3-4 seasons can operate such a combine.

Losses during operation

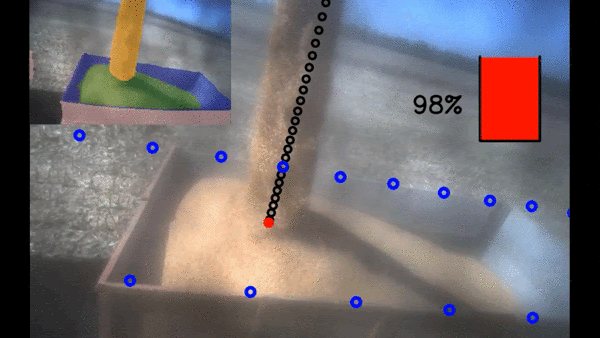

Unlike grain harvesters, a forage harvester cannot store the crop in a bunker, but immediately releases it through an unloading trunk into a vehicle driving nearby. As I said, the silage ejection speed can reach 50 kg per second, depending on the model of the combine, the length of the trunk is 5-7 meters. I drove a little sideways away from the car or slowed down and lost half a ton of silage in 10 seconds. On average, up to 7-10% of the harvest remains on the field. Nobody collects the lost silage anymore; losses on fuel and lubricants will be much greater. The video shows how the silage spills out if you move the trunk a little.

Uniform filling of the van

In a team with one combine there are up to 7 cars, one car is filled in about 20 minutes. In a day they can make over 10 trips to the silo. It all depends on the length of the delivery arm. If the field is near the pit, then the arm is short and more trips can be made for unloading; if further, there are fewer trips and here it becomes very important to properly fill the van (silage truck) so that it does not carry air. I brought half of the trailer, but I think I lost it on fuel; the combine operator must guide the trunk as correctly as possible in order to evenly fill the silo truck.

What can we automate in forage harvesters?

As mentioned above, only experienced combine operators are allowed to operate such combines.

Almost all effective machine operators trained under the USSR, after which the technological secrets of this civilization were lost. Specifically, training has weakened, and the “young” people who come in naturally work worse. This is normal for almost all working professions, but here our robot is in great demand primarily because of this effect. Second, our robot sees the edge, obstacles on the field, and sees other equipment. The work of the combine operator is simplified as much as possible; now he can monitor the technical condition of the combine and the calibration of the corn fraction that is most suitable for this type of livestock.

Also, our robot can completely and evenly, and most importantly accurately, fill the silo tank, this reduces losses on fuel and lubricants and reduces harvesting losses to zero.

The norm is considered to be a loss of 7% of the harvest during harvesting, if they are reduced to zero, then since silage is made mainly not for sale, but for feeding our livestock, we can reduce the sowing of corn by 7% and give it to wheat, which is more profitable. Let's say, if 1000 hectares are allocated for corn, of which 70 hectares are allocated for wheat, then even according to minimal estimates, with a harvest of 30 centners per 1 hectare, we will collect 210 tons, and this is approximately 1.5 million rubles in direct profit. At the same time, due to more complete assembly, fuel consumption is reduced by reducing the number of trips from the silo to the field.

How we train neural networks to analyze corn harvesting scenes

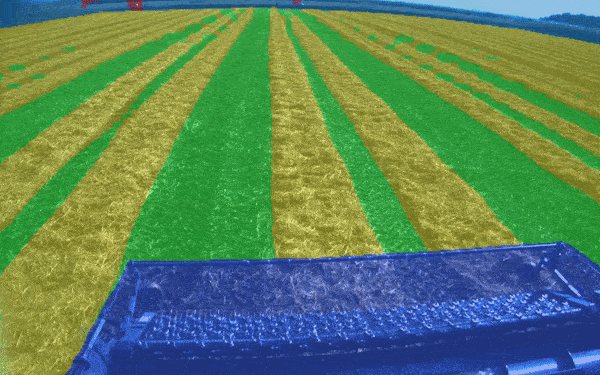

Corn is harvested using special attachments for row crops. For this case, an operating mode is provided in which the combine tries to hold the header in the middle of the row spacing. Having received a frame (scene) segmentation map and knowing the position of the header, you can find the so-called vanishing point and calculate the deviation of the header tooth from the required position.

Unlike wheat, where we monitor the edge of the harvested field and drive the harvester along the edge, here the task of the neural network is to see the row spacing between the plants. The neural network perfectly sees the rows between the corn, unlike a person, the camera is located above the crop, and at the same time it does not get tired.

Images come to us in video stream format, or as separate images. The data is processed and stored in Cognitive Agro Data Factory. In addition to raw data from the camera, there are also target marked frames, which, if necessary, can be added to the training dataset.

To more accurately select possible harvesting scenes, it is necessary to correctly compose the training dataset. In addition to real images obtained from the camera during the harvesting process, an approach is used to generate synthetic images using an augmentation procedure based on natural images.

The network accepts a 3-channel RGB image as input. Further, in the process of training the neural network, brightness/color distortions in HSV space, local distortions of channels in HSL space are applied to the input tensor - the procedure for adding artificial shadows, geometric distortions and adding noise. Selection of augmentation parameters is a non-trivial procedure that requires a detailed analysis of scenes obtained in real conditions.

The trained network is capable of producing segmentation maps that define the row space.

Hay cleaning

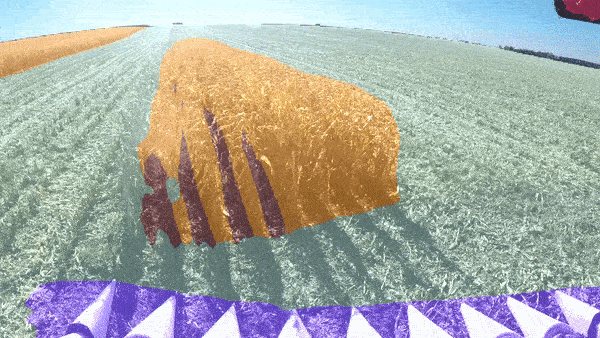

In addition to silage, forage harvesters are also used to collect haylage using a pick-up attachment. The harvesting process is similar to corn, the only difference is that the combine goes along the windrow. The windrow may not differ in color from the total mass and the combine operator may often run idle.

For example, in the video above you can see that the windrow is practically indistinguishable from grass and how precisely the combine operator needs to drive the machine along the windrow and at the same time constantly monitor the process of loading the haylage into the truck. The work is very intense; by the end of a 12-hour shift, combine operators simply collapse; they can only handle a full shift if they have at least 3-4 seasons of experience.

If the combine operator is inexperienced, then idle work is a waste of fuel and lubricants. A forage harvester, unlike a grain harvester, spends only 10% of fuel and lubricants on the movement of the combine itself, the remaining 90% goes to cutting, chopping, pulling, throwing silage or haylage. Therefore, it is very important to work with a fully loaded combine.

The neural network does a great job with windrows, an example of how the network sees windrows.

Here our system can help the combine operator in driving the combine along the windrow, also our robot can completely and evenly, and most importantly accurately fill the silo tank, this reduces losses on fuel and lubricants and reduces harvesting losses to zero, the combine operator becomes the operator of the combine, and takes on all the work yourself on autopilot.

We are now developing feed corn, sunflower, and haylage. At the end of the season, if you are interested, we will tell you how our robots coped with forage harvesters.

PS If your agronomist is not on Habré, but he is interested, then you can find contacts here: promo.cognitivepilot.com and discuss in detail which combine harvester requires which specific set of equipment, approximately how much it costs, and how you can quickly see and test it.

Forage harvester mechanisms

The main mechanisms affecting productivity and energy consumption include: · Headers or supports; · Feeding, transporting and grinding devices; · Breakdown protection system; · Devices for adding mineral additives; · Engines; · Control transfer mechanisms; · Hydraulic equipment; · Electrical equipment; · Chassis for self-propelled forage harvesters.

Modern harvesters are also equipped with stone recognition devices. This prevents them from getting into the cutting mechanisms, dulling the knives and breaking the moving mechanisms.

There are a large number of models of forage harvesters from domestic and foreign manufacturers on the modern market.