Fireman's car lift is a special fire truck equipped with special stationary superstructures in the form of rotary cranked, telescopic boom devices with a cradle on top.

Fireman's articulated car lift

Saving people and property during fires is the most important type of firefighting action. Their main methods are the movement of people and property, including ascent or descent using special technical means to a safe place and protecting them from fire hazards.

When carrying out these actions, non-mechanized and mechanized means are used. The first include stationary and manual (portable) fire escapes, various rescue devices (rescue hoses, ropes, etc.), inflatable and shock-absorbing devices, etc. The second category includes fire-fighting ladders (AL) and fire-fighting aerial lifts.

Fire trucks are mobile rescue equipment: they are used by fire and rescue units of fire and rescue garrisons.

Fire trucks have greater maneuverability than ladders, but lack such an important advantage of the ladder as the ability to continuously evacuate people without changing the position of the boom. At the same time, they have broader capabilities compared to ladder trucks for supplying water to heights, as well as for carrying out evacuation simultaneously from several positions (windows, balconies, different floors).

The load capacity of the chassis and the dimensions of the fire trucks must be such that their maneuverability in urban areas is not limited, and it is possible to install and maneuver fire trucks and fire trucks near objects near which there are no asphalt concrete surfaces. Therefore, they are built on highly cross-country chassis with a 6×6 or 6×4 wheel arrangement (depending on weight) with engines that ensure their operation in transport and stationary modes.

Fire trucks are designed for installation on sites with a slope of no more than 3° and can be safely used at wind speeds in any direction of no more than 10 m/s.

On this topic ▼

Firefighting foam lifters

Types, device and performance characteristics

Control panels for firefighting vehicle lifts are located on the platform and in the cradle, if it is provided for in the design. Firefighting ladders and vehicle lifts are equipped with automation and alarm systems that allow monitoring and adjusting parameters that affect the safety of their operation.

Among the foreign models of firefighting aerial lifts in our country, 30-meter articulated aerial aerial lifts Bronto Skylift 303 on a KamAZ-53213 or Isuzu LV136 chassis, as well as aerial lifts with an articulated-telescopic boom type Bronto Skylift F52HDT and F54HDT on a Scania chassis with a maximum lifting height of 52, respectively, are widespread in our country. and 54 meters.

The carrying capacity of the cradles of 50-meter car lifts reaches 400 kg with a maximum boom reach of 21 meters. On the right side of the boom along its entire length there is a telescopic ladder, consisting of 5 main and one end bends. The maximum load of the lift boom is 8 people (7 people on the ladder and 1 person in the cradle).

Purpose

Firefighting lifts are designed for:

- delivery of personnel and fire-technical equipment (FTE) to the fire site;

- lifting personnel, anti-tank equipment and equipment to heights;

- ensuring the implementation of rescue and rescue operations (ASR) at height;

- supply of fire extinguishing agents to extinguish fires at height.

Convenient equipment for working at heights

Telescopic units are compact equipment used in high-rise work. The devices are used in different conditions - in open areas and indoors.

The main tasks facing the equipment are the delivery of cargo and lifting of working personnel to the required height. The devices operate successfully on construction sites, supermarkets and warehouses, industrial facilities and train stations, exhibition halls, airports, etc.

Electrical and hydraulic high-altitude equipment is capable of handling loads weighing up to 250 kg or more. A modern telescopic lift has compact dimensions, therefore, if necessary, it is used in narrow passages and corridors (where it is not possible to use large installations). In St. Petersburg, the installation can be purchased from a specialized company.

Main characteristics of lifts taken into account when choosing

- maximum load capacity and height;

- dimensions of the platform and the entire installation;

- engine power and platform ascent/descent speed;

- weight, ground clearance and battery parameters.

The equipment is equipped with retractable supports. The tower is controlled using a remote control (the exact characteristics depend on the specific model). The remote control allows you to set different commands.

The average lift weighs about 300 kg. The working platform rises to a height of 10-12 meters. There are different types of installations on sale - single and double mast. The devices successfully replace other tools and structures used when performing work at height, including scaffolding (requiring complex and time-consuming installation), as well as stepladders and high ladders.

Kinds

Fire trucks are:

- cranked (APK) - with articulated joints of the knees;

- telescopic (TPL) – with a telescopic connection of the knees;

- articulated-telescopic - with an articulated-telescopic connection of the knees.

A fire-fighting articulated auto-lift (APK) is a special fire-fighting vehicle equipped with a stationary mechanized rotary articulated and (or) telescopic lifting boom, the last link of which ends with a platform or cradle, designed for carrying out rescue operations at heights, supplying fire extinguishing agents at heights and possible use as a load-lifting crane with a folded set of elbows.

Firefighter telescopic ladder lift (TPL) is a special firefighting vehicle equipped with a stationary mechanized rotary cranked-telescopic boom (pack of knees), the last link of which ends with a cradle, and has a flight of stairs located on the side of the boom, designed for rescue operations and fire extinguishing in multi-storey buildings, as well as for other auxiliary operations.

Homemade device

At home, telescopic lifts for drywall are most often made. This design consists of several mechanisms and additional parts. Moreover, if the latter can vary depending on the available materials, then the basic mechanisms are irreplaceable. They need to be made independently, and then combined into a single structure.

When creating a homemade device, it is necessary to provide all the components and form them in such a way that it becomes possible for quick and easy transportation. As a rule, it is made of folding or removable parts.

Device

All types of firefighting vehicle lifts (see above) have the same design:

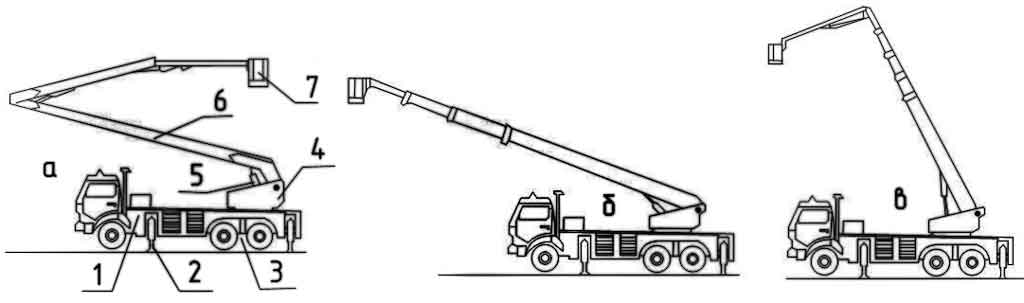

Types of firefighting vehicle lifts

1 – chassis; 2 – supports; 3 – spring locking mechanism; 4 – rotating frame; 5 – knee lift mechanism; 6 – set of knees; 7 – cradle

a – with articulated knees; b – with telescopic knee connection; c – with articulated-telescopic knee joint

In the future, the option with a telescopic connection of the knees will be considered.

The booms and cradle are controlled by hydraulic cylinders.

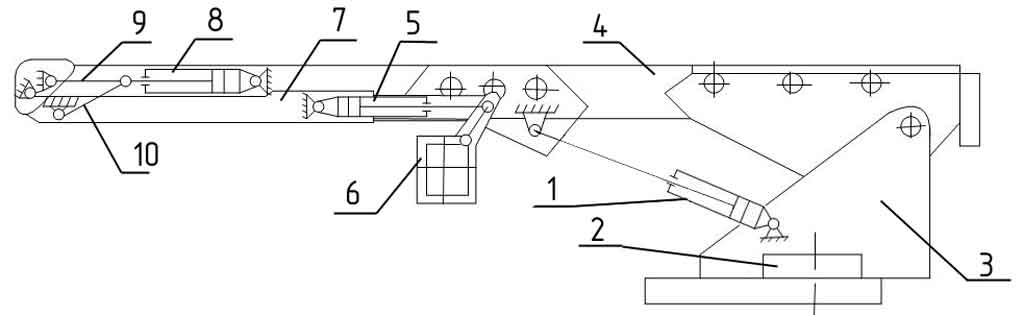

Basic kinematic diagram of lifting and extending the cradle

1 – hydraulic cylinder for lifting the boom kit; 2 – rotation mechanism; 3 – rotating frame; 4 – telescopic boom; 5 – hydraulic cylinder for leveling the cradle; 6 – cradle; 7 – articulated boom; 8 – hydraulic cylinder for lifting the articulated boom; 9, 10 – levers

Hydraulic cylinder 1 (there are two of them on the agro-industrial complex) with dimensions 160×110×1200 mm (piston diameter, rod, piston stroke) provides lifting of a set of booms: telescopic 4 and articulated 7. Hydraulic cylinder 8 (160×110×1440 mm) for lifting the articulated boom 7 provides levers 9 and 10 for lifting it by 180°. On each boom 7 there is a hydraulic cylinder 5 for leveling the cradle 6. This is carried out by a special leveling control unit (BUG).

The cradle with a load capacity of 300 kg accommodates 4 people. It is rotated by a special hydraulic cylinder to turn right and left by 45°.

Fire monitors are usually installed in the cradles, or places for their attachment are equipped. The barrel can be rotated left and right by 50°, and up and down by 65° and 40°, respectively.

Water is supplied to the fire monitor through special water conduits of a telescopic device located inside the booms, which have a box-shaped rectangular cross-section.

The cradle is equipped with a device that limits the load capacity.

The cradle has a control panel.

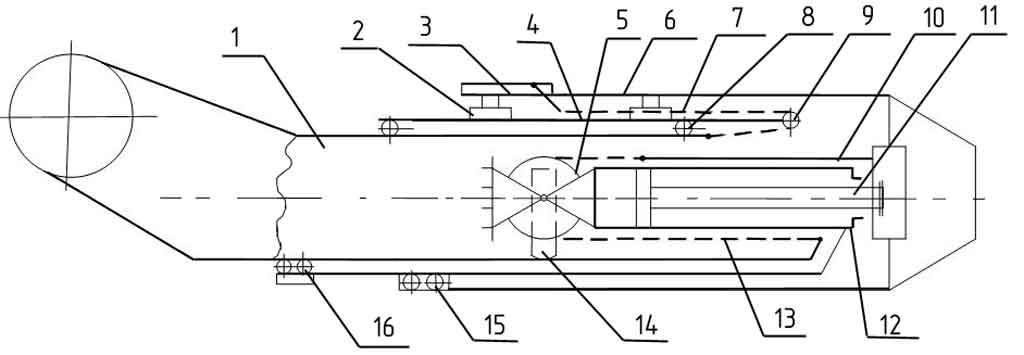

Scheme for extending telescopic sections

1 – first section; 2, 14 – slider; 3 – tensioner; 4 – second section; 5, 8, 9, 15, 16 – rollers; 6 – telescope base; 7 – shift chain; 10 – traction; 11 – rod; 12 – hydraulic cylinder; 13 – extension chain

Telescopic boom 4 consists of three sections placed one inside the other.

All sections of the telescopic boom move relative to each other on rollers and slides. The rod 11 of the hydraulic cylinder 12 is fixed to the end of the base of the telescope 6, and the hydraulic cylinder 12 moves freely, resting with the slider 14 on the surface of the first section 1. When extended, the hydraulic cylinder 12 moves to the left and pulls out the second section, rigidly connected to the hydraulic cylinder. At the same time, the first section is pulled out by chain 13. The first section 1 is pulled out through the roller 5 using a chain 13. One end of the chain is attached to the first section, and the second is secured to the end of the base of the telescope 6 by means of a rod 10.

When the sections are shifted, the hydraulic cylinder 2 moves to the right, retracts the second section 4. At the same time, through the roller 9 with a chain 7 connected to the first section, the entire system will be pulled into the base of the telescope 6. The tension of the chain 7 is carried out by the tensioner 3.

Construction mast lift PMG 500

by dakar, 10/23/2014

The single-mast cargo lift PMG 500 (PMG-1) is used for vertical lifting and moving various cargoes with a total weight of up to 500 kg.

The minimum possible height of the lift structure is 3 meters, the maximum is 100 meters.

A distinctive feature of the PMG single-mast lift is its compactness; its small dimensions allow the structure to be installed both outside and indoors.

Technical characteristics: single-mast sectional lift PMG 500 (1-B-76103-03)

The PMG mast facade lift with a lifting capacity of 500 kg allows you to transport and supply cargo, direct cargo through openings, gates and doors, deliver materials, etc. on the roof of buildings.

Prices for rent and purchase of mast sectional lift PMG 500

The cost of renting a mast construction hoist model MPG 500 starts from 1000 rubles per day. The rental period depends on the conditions of the lessor company. Most companies offer their equipment with a minimum rental period of 1 month, less often from 3 months. However, some companies offer the rental period required by the customer.

It is important to remember that transportation, installation and dismantling of the mast lift are not included in the daily rental price. The cost of installation/dismantling is about 1000-1500 rubles per linear meter, depending on the size and complexity of the structure.

You can read more about the conditions, cost and important details of renting construction equipment in our material.

The cost of a new single-mast sectional lift PMG 500 is from 200,000 rubles, depending on the supplier, conditions and equipment.

You can contact the editors of the portal allfacades.com to get the best prices for the purchase of facade mast lifts, since we constantly monitor current offers on the market.

Video clip demonstrating the operation of the PMG 500 lift platform:

The design of the PMG 500 mast cargo lift includes:

- Support frame (standard dimensions 2.5 meters x 1 meter);

- Load carriage;

- Masts with a section of 0.32 x 0.426 m, a height of 2 meters;

- Header.

A short video clip illustrating the production process of PMG mast lifts to order:

When installing the lift, the masts are installed on top of each other and fixed to the support frame. The carriage is equipped with a roll-out working platform (standard dimensions - 2.7 meters x 0.5 meters) and moves vertically along the masts.

When the carriage reaches the desired height, the load is directed into the building opening using a retractable platform.

The masts are fixed to the supporting structure or walls of the building using wall supports, in increments of 4 meters.

The lift's supporting frame is equipped with a winch, which consists of a gearbox and an electric motor with a power of 4.5 kW, with a built-in braking system.

Before starting work, you need to make sure that the gearbox has the required amount of oil.

According to the requirements of State Standard No. 23652-79, 4.5 liters of oil with a TSP-10 marker are poured.

Safety systems for mast facade lifts PMG 500

The construction hoist safety kit includes:

- Electric blocker for retractable platform;

- Platform catcher and limit switches;

- Load limiting system;

- Automatic brake.

In the event of an emergency, as well as in the event of a cable break or damage, the eccentric catcher stops the platform.

Standard dimensions of the PMG lift diagram

When the platform reaches the lowest and highest positions on the mast, the limit switches automatically stop the platform.

For different weights of lifted loads, different parameters of electric hoists are used.

Regulatory documents for the construction mast lift PMG 500:

- Technical characteristics of PMG-1-B-76103-03;

- Gosstandart number 29168-91;

- PB 10-518-02;

- TU 4835-033-03215451-00;

Categories: Mast lifts

Design features

Firefighting aerial lifts, like aerial ladders, have a fixed and rotating part. The non-rotating parts and rotation mechanisms of AL and APK are identical. Their main difference lies in the design of the cradle extension mechanisms.

The main mechanisms and units of car lifts are:

- base chassis;

- platform with supporting structures for the transport position of the boom;

- power group;

- hydraulic system;

- a support device including a frame, hydraulic outriggers;

- lifting and rotating part, consisting of a rotating tower, lifting booms and a cradle;

- built-in water and foam communications;

- mechanism for deploying booms, turning the turret and turning the cradle around a vertical axis;

- electrical equipment with locking and alarm system;

- controls.

Devices with scissor design

The so-called scissor lift (hydraulic table) today is sought to be purchased by many organizations that carry out various types of construction work or equip warehouses. The price of such equipment varies depending on its basic parameters and manufacturer.

A standard scissor lift is a device that consists of a scissor mechanism and a loading platform. Such a hydraulic unit has many advantages and is therefore often used in practice. Let us list the main strengths of this technique:

- The scissor lift is compact (has a relatively small size) and rational design. It is quite easy to use and store, so this hydraulic unit is perfect for almost any warehouse.

- Almost any scissor lift, regardless of its features, is easy to use and functional. Using the hydraulic mechanism is extremely comfortable.

- Another advantage that such a common device as a scissor lift has today is low noise and the absence of any problems for users. This makes the hydraulic mechanism an ideal option both for warehouses and for construction work.

Lifts of the type in question have many other significant advantages, which can only be verified during direct operation. In addition, their price, regardless of the manufacturer, is usually relatively low, which also attracts many companies.

Standard sizes

Firefighting car lifts, depending on the maximum working height of a fully unfolded car lift, should be manufactured in the following standard sizes:

| Standard size | Lifting height of the cradle, m |

| APK 10-15 | 10-15 |

| APK 16-21 | 16-21 |

| APK 22-28 | 22-28 |

| APK 29-36 | 29-36 |

| APK 37-48 | 37-48 |

| APK 49-56 | 49-56 |

| APK 56-64 | 56-64 |

At the customer's request, it is allowed to manufacture a firefighting aerial lift with a working height of more than 64 m with parameters according to the technical conditions for a firefighting aerial lift of a specific standard size.

Buying or renting lifts

If your organization constantly uses the mentioned special equipment, then it makes sense to purchase it. Buy the required telescopic lift at a favorable price from the official representative office of the manufacturer. In this case, it is possible to obtain equipment on credit or lease.

For temporary or one-time use of a telescopic lift, the price of which is quite high, rental is recommended. One day of operation of the device and personnel will cost from 5,500 to 20,000 rubles, depending on the model and manufacturer. In this case, the tenant saves on routine maintenance of special machines and personnel training.

The highest fire truck lift

On this topic ▼

Car lift Bronto Skylift F 112 HLA

Description and performance characteristics

The Finnish company Bronto holds the height record for telescopic car lifts. Their telescopic car lift, Bronto Skylift F 112 HLA, is capable of lifting firefighters to a height of 112 meters. The record is that the platform can be at a height of 90 meters with the boom extending 25 meters outwards.

The mechanism is mounted on a standard Mercedes-Benz Actros 7660 chassis, modified into a seven-axle vehicle by Paul Nutzfahrzeuge. Five axles of the unusual chassis are steerable, and four are driven. In the transport position, the car lift has a height of 4 m and a length of 19 m, which allows movement on public roads. The curb weight of the “champion” reaches 77,000 kg.

Facade lift

The facade lift is installed only outside and is intended for construction, repair, and finishing work of residential and non-residential buildings, as well as industrial facilities. But it is still possible to use this type for washing windows, cleaning facades and billboards. It allows you to carry out repair and construction work in hard-to-reach places.

The design of a facade lift is quite simple: a cradle, a lifting mechanism, catchers, limit switches and electrical equipment. The cradle is secured to four ropes, their upper ends are fixed with consoles installed on the roof, the lower ends are loaded using special weights. If for one reason or another the electricity supply stops, you can lower the cradle manually.

The load capacity of a façade lift, depending on the type, varies between 200-800 kilograms. The maximum height to which it can rise is 160 meters, the lifting speed is 9.6 m/min.

Designation and marking

The designation of a firefighting vehicle lift has the following structure:

AKP-32 (43118) mod. XHA-XX XX X,

Where:

- AKP / TPL – fireman's articulated car lift or fireman's telescopic car lift with a ladder, respectively;

- 32 – lifting height 32 meters;

- (43118) – index of the base chassis model according to the automotive industry classification (in this case, KamAZ-43118);

- Maud. ХХА – designation of the fire ladder model according to the developer’s system, indicating the modernization (A – first, B – second, etc.);

- XX – two-digit (three-digit) digital index to designate the model (01, 02, etc.);

- XX – conventional letter designation of the manufacturer;

- X – designation of a regulatory document (GOST, TU).

| Symbol of agro-industrial complex on fire extinguishing diagrams | Symbol of TPL on fire extinguishing diagrams |

Operation of aerial platforms

So, where do aerial platforms find their use these days? Well, of course, this is construction, where the aerial hydraulic lift is used for high-rise installation work, repair and restoration of building facades, etc. It is noteworthy that telescopic aerial platforms can be used both for street work and inside large workshops and production facilities, and all thanks to their mobility and compact dimensions.

If we look at all types of aerial platforms (and there are five main types), we can conclude that telescopic ones are significantly superior to similar equipment in some respects. In some types of special equipment, for example, combined or lever-telescopic, a telescopic mechanism is used in combination with other devices.

Telescopic lifts also play a good role in beautifying urban areas and advertising information. So, the Socage aerial platform is perfect for decorating trees and streets in connection with large-scale holidays. You should also add the ability to repair and install lighting devices (lanterns, hanging lamps, garlands, etc.).

Maintenance and inspection

On this topic ▼

Maintenance and repair of fire trucks

Types, procedure, timing

Ensuring the readiness and reliability of firefighting aerial lifts. For the effective use of automatic transmission or AL, maintenance and technical examination .

Maintenance includes all types of ongoing maintenance, as for fire ladders. The list of works is regulated by factory instructions.

Technical examination. Technical examination is carried out in order to ensure reliable operation of all automatic transmission mechanisms. The operation of all automation, blocking and alarm devices is checked along the entire border of the cradle's movement field, called the reach zone. Technical inspection is carried out by the owner. There are two types of technical examination:

- Partial – at least once a year.

- Complete – at least once every three years.

In addition, the load limiter is tested at least once every 6 months.

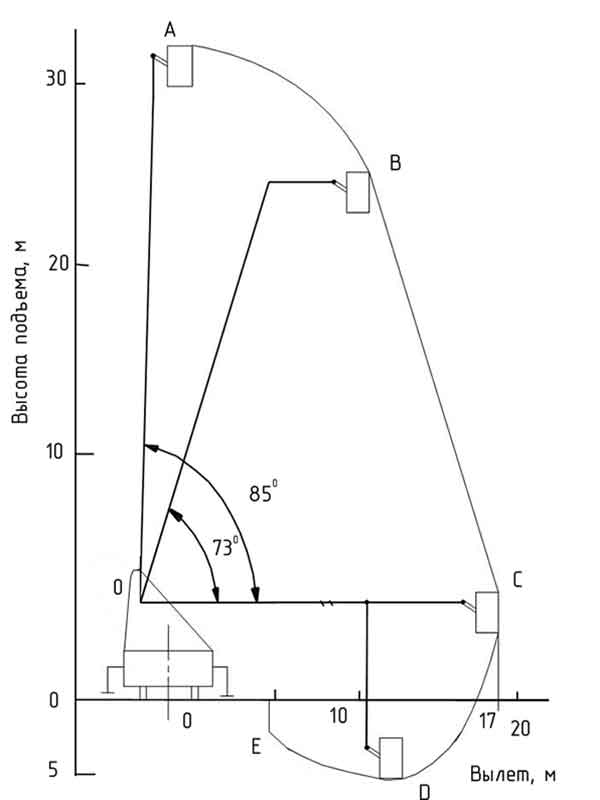

The working field (reach zone) is the area outlined by the top of the boom (the outer edge of the cradle) when maneuvering it with the maximum permissible reach and height for the corresponding lifting capacity. Thus, it includes the safe operating area of a fully loaded cradle, covering the lift height and boom reach. The zone is set by the manufacturer.

Working field of a firefighting vehicle lift using the example of AKP-32(4310)

During a partial technical examination, the following is carried out:

- external inspection (during an external inspection, the condition of the automatic transmission as a whole, its mechanisms, structural elements, and electrical wiring is checked;

- checking the operation of automation, blocking and alarm devices;

- dynamic tests.

A complete extraordinary technical examination is carried out in case of replacement of design elements and assembly units, as well as after a major overhaul of the automatic transmission.

Full technical examination includes:

- visual inspection;

- no-load test;

- checking the operation of automation, blocking and alarm devices;

- static and dynamic tests.

Organization of safe operation of a cargo lift.

Operating organizations are obliged to ensure that freight lifts are kept in working order and their operating conditions are safe by organizing proper supervision and maintenance, technical inspection and repair.

For these purposes there should be:

a) a procedure has been established for periodic inspections, maintenance and repairs to ensure that freight elevators are kept in working order;

b) the established procedure for training (specialists) and access to independent work (staff) is ensured

c) job descriptions for specialists and production instructions for personnel, magazines, programs for performing scheduled preventive maintenance of cargo transportation and warehousing schemes have been developed;

d) ensure that specialists have job descriptions and guidelines for the safe operation of cargo lifts, and personnel have production instructions;

e) conditions have been created for specialists to strictly follow job descriptions, and for staff to strictly follow production instructions.

The number of specialists of the operating organization should be determined by the administrative act of the operating organization, taking into account the number and actual operating conditions of cargo lifts.

During vacation, business trip, illness or in other cases of absence of responsible specialists, the performance of their duties is assigned by administrative act of the operating organization to the employees replacing them by position, who have the appropriate qualifications and have undergone training.

Periodic testing of knowledge of job descriptions among specialists responsible for carrying out production control during the operation of freight elevators, specialists responsible for maintaining freight elevators in working condition, and specialists responsible for the safe performance of work must be carried out in accordance with the administrative act of the operating organization and carried out by commission.

In order to ensure safety requirements, the operating organization is obliged to provide personnel with production instructions defining their duties, the procedure for safe work performance and responsibility. Production instructions must be issued to personnel against receipt before they are allowed to work.

Maintenance and repair of freight elevators is carried out taking into account the requirements of the manual (instructions) for the operation of freight elevators. The operating organization is obliged to ensure timely elimination of identified faults (defects and damage).