How to make a creeper for a cultivator yourself?

Why do you need a creeper for a motor cultivator? Often when operating a cultivator there are times when it is necessary to reduce its stroke. Such situations arise when the operating speed indicators are much lower than the transport speed indicators of the unit. Then a creeper comes to the rescue, which increases the traction force and torque of the equipment.

We create a stroke reducer for a motor cultivator with our own hands

- We carry out all design calculations (rated power, number of revolutions per minute, torque).

- We decide on the body.

- We take 2 gear shaft bearings and cut out the shell.

- We install a high-quality steel flange on the reverse side of the gearbox.

- We attach a steel washer and a bearing (flange) inside the flange.

- Now you need to rotate the flange to the generator housing.

- We connect all the components (gear shaft, key, drive gear) with the shaft and transmission mechanism.

- We secure the V-belt drive pulley.

Creeper device

The design of the mechanism is quite simple from a technical point of view and includes:

- frame;

- rotor shaft;

- flange bearing;

- bevel gear;

- pulley;

- steel parts and screws.

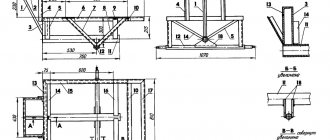

You can select a creeper for a walk-behind tractor at any specialized point of sale of agricultural machinery. If you make it yourself, you can save money and leave a considerable amount of money for anything else needed in the garden. Before manufacturing the structure, it is better to prepare drawings of all components with dimensions.

In this video we will look at installing a creeper:

DIY wheels for a motor cultivator

Many cultivators are equipped with factory pneumatic wheels, which, despite their number of advantages, sometimes do not provide good enough traction to the ground. In this case, many owners of cultivators undertake to equip them with homemade lugs. These are wheels for a cultivator that, due to their weight and design, allow you to cultivate the area with perfect traction with the ground. How to make these wheels yourself.

The popularity of using small-scale mechanization in agriculture is increasing every year. At the same time, walk-behind tractors are the most versatile weapon in the fight for the harvest. Having a large range of mounted and trailed tools, they are able to cope with almost any task that arises when working on a personal plot. If high traction power is required, a speed reducer or reduction gearbox for the walk-behind tractor is used.

The use of a creeper is advisable when cultivating “fat” or virgin soils, deep loosening, transporting heavy loads or using heavy attachments. When working in such conditions, it is necessary to especially precisely control the work process.

https://www.youtube.com/watch?v=HLKhiuZEy2E Video can't be loaded: DSCF2677 Do-it-yourself reverse from an ant gearbox to a walk-behind tractor. Valery Bryzgalov. (https://www.youtube.com/watch?v=HLKhiuZEy2E)

It would be logical to reduce engine speed and operate at a lower speed. But in this case, power is also lost, which is unacceptable. This is where walk-behind creepers come to the rescue, acting as a reduction gear. They allow you to gain acceptable control over the processing process, and even increase power, without slowing down the engine speed and, accordingly, without losing power.

If you have some experience and knowledge, you can make a gearbox yourself using available materials and equipment, or buy a ready-made product, the range of which on the modern market is high and available to buyers with different capabilities.

Assembly technology

After completing the design work and preparing the material, you can confidently begin installing the stroke reduction mechanism.

Assembly work is as follows:

- All necessary calculations are carried out to achieve maximum power and stable torque.

- Two drive bearings are prepared, which will determine the movement of the gear.

- Flange bearings should be located on the opposite side of the gearbox, inside which the washer is installed.

- Install the drive shaft with the fixed gear.

- Connect the shaft to the generator rotor and secure it with a spring nut.

The assembled structure is subject to testing. When putting it into operation, provided it is assembled correctly, the wheelset of the mini tractor should not spin so quickly, and the structure of the walk-behind tractor itself will be pressed to the ground.

Advice. Wheels with a diameter that is too large will negatively affect the operation of the cultivator. Therefore, it is better to choose a wheelset with a small diameter, approximately 25-30 centimeters.

If you plan to load the walk-behind tractor with a plow to plow hard soil, then the stroke reducers should be made as powerful as possible.

Basic rules, adhering to which ensure reliable and long-term operation of the motorized installation:

- after the first successful testing of the speed reducer, it is necessary to carry out a technical inspection of the mechanism once every 6 months with mandatory activation, replacement of bearing engine oil, and lubrication of moving parts;

- before working on a personal plot, you need to check the reliability of the fastening of the elements and the integrity of the mechanism body;

- manipulations of wiping and lubricating the stroke reducer are performed with the equipment cooled down and turned off;

- Children and minors are not allowed to operate the device to avoid accidental injury.

In fact, creating a walk-behind tractor travel reducer with your own hands using ready-made drawings is not particularly difficult. Most parts can be taken from other well-known manufacturers of agricultural machinery. Of course, without the proper experience, it will take more than one day before the desired mechanical unit is born. You need to be patient and concentrate as much as possible, and the result will be a powerful mini tractor that will not hesitate to work in heavy soil and will complete it at a high level and in a short time.

Mechanism elements

Regardless of whether a purchased or homemade reduction gearbox will be used in a walk-behind tractor, you need to understand how the elements of the mechanism are located, how to maintain and repair them. Reduction gearboxes for walk-behind tractors can be of several types, each of which has its own advantages and disadvantages.

Scheme for connecting the speed reducer to the gearbox

Gear reducer

As a rule, it consists of one or two stages; The main elements are gears. This type is one of the most reliable mechanisms used in creepers. Used in the most powerful walk-behind tractors. Its advantages may include:

- durability;

- reliability;

- small dimensions;

- possibility of reverse.

Such creepers are not without their drawbacks, the main ones being maintainability and price. In case of breakdown, as a rule, they are replaced entirely, which requires significant financial costs. In addition, it is necessary to monitor the presence of lubricant, the absence of which can lead to rapid wear.

Worm gear

The main element is the worm gear. Allows you to reduce the dimensions of the walk-behind tractor and improve weight distribution due to the perpendicular arrangement of the drive shafts and wheels. Most often they are installed on light and low-power walk-behind tractors.

Main advantages:

- large gear ratio;

- small dimensions;

- light weight.

The main disadvantage of a worm gearbox is the lack of reverse. In addition, in the event of a breakdown, the stroke reducer is completely replaced.

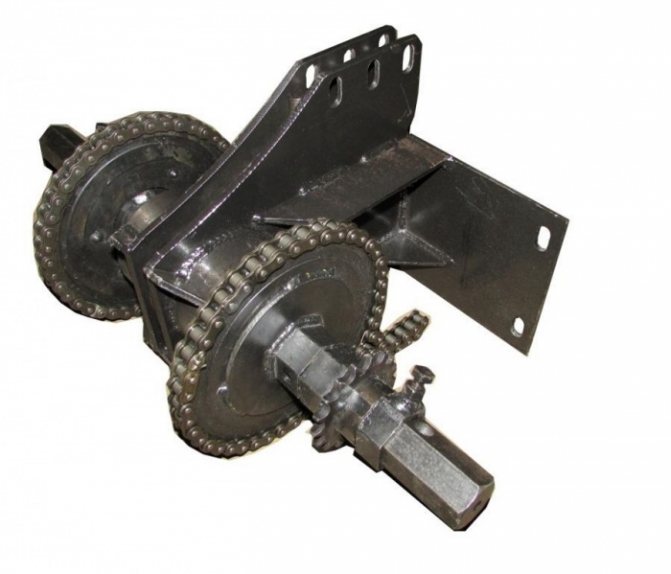

Chain reducer

One of the most popular types of gearboxes among users. Most often they are made dismountable, which simplifies maintenance and diagnostics. The most common failure is a broken or stretched chain, shearing of sprocket teeth or drive shaft keys. All these breakdowns, as a rule, are quite easy to fix yourself by replacing the failed part.

The advantages of stroke reducers of this type include:

- simplicity;

- reliability;

- possibility of reverse;

- maintainability.

Combined gearbox

Gearboxes of this type are characterized by the presence of different types of gears in one mechanism: gear-chain or worm-chain. The need for such stroke reducers is dictated by the fact that in gear and worm gearboxes the center distance between the drive and driven shafts is regulated by the size of the gear and directly depends on the engagement module and the number of teeth. In a chain drive, the distance between the shafts can be adjusted by removing or adding links.

When assembling the design of a walk-behind tractor, it is not always possible to place all the units in an ideal position, and the need for an intermediate transmission link arises. This function is successfully performed by a chain drive, which compensates for the distance from the gear or worm gear to the wheel or drive shaft.

What does the speed reducer consist of?

Depending on the type of reduction gearbox, a homemade creeper consists of the following main parts: input (high-speed) shaft, output (low-speed) shaft, worm and worm wheel, drive and driven gears or sprockets.

In this case, the driving sprockets and gears always have a larger number of teeth than the driven ones. Auxiliary elements can be various couplings, bearings, and keys. In gear and worm gearboxes there is always a housing, which cannot be said about chain gearboxes. They may either completely lack a case or cover only part of the mechanism.

How to reduce the speed of a walk-behind tractor cascade

Nowadays, a wide variety of units are used for soil treatment. Equipment from a domestic manufacturer, called the “Cascade” walk-behind tractor, performs many tasks quite well. Adjusting the carburetor of this equipment will ensure the stability of its engine speed and help prepare the unit for the new season. How to work correctly with the Cascade walk-behind tractor should be considered in more detail.

We suggest you read How to make syrup for candied fruits

According to the instructions, it is a multifunctional device. With its help, they perform various tasks in the process of cultivating soil in areas of various sizes.

The "Cascade" walk-behind tractor has been produced since 2006. The manufacturer is constantly improving the design.

The Cascade walk-behind tractor, the technical characteristics of which meet all modern requirements, is used for plots of 6-40 acres.

The weight of manufactured models ranges from 50 to 100 kg, depending on the type of work performed by the unit.

“Cascade” is a walk-behind tractor, the instructions of which regulate the design and use of this equipment, and provide for the operation of the equipment when equipped with an engine with a capacity of 5 to 8 liters. With.

According to consumer reviews, walk-behind tractors, including Cascade, work longer with higher engine power.

According to the technical characteristics of the Cascade walk-behind tractor, they use domestically produced DM68 engines with a power of 6 hp. With.

The Cascade walk-behind tractor, whose carburetor adjustment depends on the engine type, has the manufacturer’s corresponding recommendations for its maintenance.

Japanese motors are durable and can work without stopping for a long time. American equipment is environmentally friendly and starts easily even at low temperatures. It is used in models that allow, in addition to basic functions, to remove snow in winter.

Engines with a carburetor in the presented technology use gasoline as fuel and are four-stroke.

The carburetor can be either domestic or imported.

Unit design

This technique has a mechanical clutch, according to the design of the Cascade walk-behind tractor, which occurs when the V-belt is tensioned.

After this, the torque is transferred to a two-stage chain gearbox. It provides 4 speeds of such a unit as the “Cascade” walk-behind tractor. The technical specifications indicate that there are two speeds when moving forward and two when moving backward.

In a reinforced gearbox, the output shaft is supported, which allows the reinforcement to be expressed.

With the medium dimensions of the Cascade walk-behind tractor, the gearbox ensures its stability even when using additional attachments.

The steering columns allow you to adjust the height. All control systems are located on the steering wheel, except for the gear lever.

If the equipment uses an imported engine, the marking contains the number “61”. The domestically produced engine in the diagram of the Cascade walk-behind tractor is designated by the number “6”.

The power unit is also marked. The combination “DM66” indicates that the oil is supplied by spraying. The marking “DM68” corresponds to the supply of lubricant using a gear pump.

Designation 06 indicates the presence of wheel locking, and 07 indicates a simpler reinforced gearbox.

Features of work

A distinctive characteristic of the presented unit is the location of all control systems on the steering wheel (except for the gear lever). This simplifies the process - without interrupting work, the user can control the functions of the equipment.

The steering column itself is adjustable to the height of the owner.

The center of gravity of the device is low enough to operate without effort.

Additional parts and devices are provided to ensure the versatility of the “Cascade” unit (walk-behind tractor). The instructions speak of the possibility of processing even virgin soil.

Modern requirements for the operation of the presented equipment are fully met. They are confirmed by the ISO 9002 quality certificate.

Regular maintenance of equipment will ensure efficient and safe operation.

Such work involves, if necessary, changing the oil, checking the engine, adjusting the controls, updating the gearbox seal of the Cascade walk-behind tractor, etc.

If the unit is new, it must be run in gently to allow all components to get used to each other. This will avoid rapid wear of engine components, other moving parts, as well as elements of the gearbox of the Cascade walk-behind tractor, its oil seal and other elements.

The lubricant must be intended for four-stroke gasoline engines. The SunGarden company answers which oil should be used in the Cascade walk-behind tractor and recommends brands ST, SG, SH, SJ, SL, SM.

The first replacement should be made after 2-5 hours of operation of the unit.

According to the manufacturer's instructions, after the end of the first season of operation, the equipment should be adjusted.

This action is performed in the area of the fuel system, valves and carburetor of the Cascade walk-behind tractor.

This is a rather complex process, so you should study the adjustment technology quite carefully.

However, if there are malfunctions or instability of the engine speed of the Cascade walk-behind tractor, the carburetor will need to be adjusted already in the 2nd year of operation.

This procedure will be needed after prolonged exercise or, conversely, inactivity.

Warm up the engine before starting. The carburetor on the Cascade walk-behind tractor is adjusted step by step. The 2 minimum and maximum throttle screws are screwed in all the way and then unscrewed one and a half turns.

The gear lever is set to minimum travel, but the engine must continue to run.

Use the throttle screw to adjust the minimum idle speed of the engine.

Using screws, adjusting the level of fuel entering the carburetor of the Cascade walk-behind tractor is not difficult. Tightening the screw will enrich the fuel, while loosening it will increase the air in the mixture.

Adjusting the fuel level of the carburetor of the Cascade walk-behind tractor should be carried out regularly (at the end or beginning of the operating season).

The essence of the adjustment

The engine speed is regulated by the idle throttle screw. This will allow you to adjust the maximum speed. The same principle applies when setting their minimum value. This is done by changing the closing angle of the valve of the Cascade walk-behind tractor.

The gear lever, switched to the “gas” mode, allows you to adjust the ideal engine speed. The maximum permissible number of screw revolutions does not exceed 2.5.

However, such undesirable phenomena depend not only on the carburetor mixture setting. A malfunction of the ignition or cooling system can cause similar symptoms on the spark plugs.

Carburetor cleaning

When fuel does not reach the carburetor in sufficient quantities, it is necessary to carry out cleaning during the tuning process.

The design of the Cascade walk-behind tractor involves removing the hose from the inlet fitting. For the K45 carburetor, it is enough to press on the seal so that gasoline begins to flow through the hole.

If fuel from the carburetor does not enter the cylinders, you will have to inspect the fuel valve. The cause of this phenomenon may also be the presence of contamination on the jets.

To adjust the KMB-5 carburetor of the Cascade walk-behind tractor, there is a certain adjustment technology.

Initially, remove gasoline from the float cavity. An air mixture is supplied through the fuel supply fitting.

In the case when such actions occur without deviations, the carburetor operation is considered adjusted.

Carburetor K-60

The carburetor should be adjusted strictly according to the manufacturer's instructions for a specific model. Otherwise, you can simply break the equipment.

The K-60 carburetor is used in the M-3 model. He will require that the throttle valve be installed so that the gap between its base and the air duct is 2-2.5 mm wide. It can be seen through the pipe of such a unit as the Cascade walk-behind tractor. Adjusting the carburetor will require tightening the adjustment screw and turning it out 0.5-1 turn.

Do-it-yourself reduction gear for a walk-behind tractor

You can make a reduction gear yourself. To do this, at the initial stage it is necessary to determine the type of transmission, gear ratio, and also determine the center distance between the drive shaft and the wheel shaft.

Let's look at an example of creating a homemade creeper for a walk-behind tractor with a chain drive. A similar design can be repeated for almost any type of walk-behind tractor with minimal changes.

Required materials and parts

To build a reduction gearbox yourself, you will need the following tools and materials.

- Bulgarian;

- welding machine;

- drill;

- files and drills;

- caliper, ruler;

- clamps and vices;

- hammer;

- metal sheet 5 mm thick;

- cuttings of pipe with an internal diameter for mounting bearings.

Gearbox assembly

The main part of the designed stroke reducer for a walk-behind tractor is the housing. The quality of the entire mechanism, the relative position of the axes and shafts, and the alignment of the bearing seats depends on it. The body will be made from sheet metal by welding. To facilitate maintenance, one of the walls is made removable.

Instead of bearing housings and precision boring, pipe cuttings are used, the inner diameter of which is equal to the outer diameter of the bearing. They are placed in the required position and finally secured by welding.

For the manufacture of shafts, round rolled products from high-quality steel are used. I grind it to the required size, make collars and grooves, and mill keyways. During operation, the shafts rotate together with the sprockets, transmitting torque through the chain and keys.

Bearings serve as supports for the shafts. They take significant loads during the work process. The durability and normal performance of the gearbox will largely depend on their correct choice. It is optimal to use sealed radial bearings, which require minimal maintenance.

Sprockets and chain will most likely have to be either purchased or used from decommissioned equipment. Making such parts yourself is labor-intensive and low-tech.

The assembly sequence of a reduction gearbox for a walk-behind tractor follows the following algorithm:

- Cut the steel sheet into body and lid parts.

- Pipe cutting.

Video can't be loaded: do-it-yourself creeper gearbox for a walk-behind tractor (https://www.youtube.com/watch?v=QQfR54zbPrs)

https://www.youtube.com/watch?v=1RdECkdic7Q Video can't be loaded: Manufacturing of the ViterOK-2 creeper (https://www.youtube.com/watch?v=1RdECkdic7Q)

https://www.youtube.com/watch?v=cagUBrEN1Io Video can't be loaded: Speed reducer for Rostselmashevsky walk-behind tractor (https://www.youtube.com/watch?v=cagUBrEN1Io)

A creeper for a motor-cultivator is used at high speeds of the motor-cultivator, when it is necessary to reduce it to a speed effective for cultivating the land. Creepers are best used when working with additional trailed equipment, trailers, hilling soil and removing snow.

Self-assembly of the stroke reducer

Having all the necessary spare parts, you can begin assembling the speed reducer with your own hands. In order for the finished structure to cope well with its functions, you should act strictly according to the algorithm described below:

- First, make all the necessary calculations so that the result of the work is a well-balanced design. As a generator, you can take an element from the domestic Ural motorcycle;

- The main thing that is required from the device is high power and stable torque;

- Next, start cutting out the shell of the two bearings that will be needed for the drive shaft. It will start the gear. When working, take into account the diameter of the gearbox;

- Then you need to decide on the bearings. The flange must be located on the opposite side of the gearbox. There should be a metal washer inside it;

- Next, install the driven shaft on which the gear will sit. The product must be connected to the rotary generator shaft and transmission mechanism;

- Finally, you will need to secure the pulley to the driven shaft using a spring nut and washer.

Having made the creeper, it will need to be tested. To check the device, it should be connected to the hitch of the unit, and the wheels for the cultivator should be installed. If you did everything correctly, the wheels will spin slowly, while the cultivator itself will be pressed to the ground.

When choosing wheels for a motor cultivator that will work in tandem with a speed reducer, you need to pay great attention to their diameter. There is no need to choose too large parts so as not to load the unit’s motor. Wheels with a diameter of 25 to 30 cm will be optimal.

READ MORE: Caring for Sansevieria Hanni at home

If homemade devices are planned to be used in conjunction with other attachments, for example, for a plow, then the creepers must have sufficient power to press the equipment to the soil. Be sure to take this into account when preparing spare parts for the manufacture of the device.

A creeper for a motor-cultivator is used at high speeds of the motor-cultivator, when it is necessary to reduce it to a speed effective for cultivating the land. Creepers are best used when working with additional trailed equipment, trailers, hilling soil and removing snow.

Using a factory-assembled creeper

To reduce the speed of movement of the motor-cultivator, a shaft with a reduction gear is used, which, through a belt drive, reduces the number of revolutions of the drive wheels. Also, there are creepers that are built into the cultivator engine itself and, with the help of the required equipment, reduce the speed of the internal combustion engine and, as a result, reduce the speed of passage of the land plot by this device. The operating principle of such a device is quite simple. Small sprockets are installed on the axle shafts of the motor-cultivator, and sprockets of larger diameter are provided on the creeper, thus, the revolutions from the motor-cultivator are transmitted much less than at the beginning.

Speed reducers are best used on air-cooled gasoline and diesel engines, since the traction properties in relation to the engine are quite low. On heavy soil, it is better to use diesel motor cultivators, since their traction properties are much higher than those of gasoline engines.

DIY creeper

It’s quite easy to make a creeper for a motor cultivator yourself.

. To reduce the number of wheel revolutions, larger diameter wheels can be used, depending on the required speed. We all know that rotation from the engine shaft is transmitted to the drive wheels and the speed of the shaft does not change. With larger wheels, fewer wheel revolutions can be achieved, since the shaft has rotated and will rotate at the same speed, and the wheels are now at a lower speed.

Also, there is another method of reducing the speed of a motor cultivator using a creeper. To do this, you can take several steel sheets and make a box. Drill the necessary holes in it and secure it as an attachment under the body of the motor cultivator. Then, weld a metal tube of any diameter inside and place a larger gear on it than on the drive shaft of the cultivator. Pass the chain to transmit rotation of the drive and driven gears. So our creeper for the motor cultivator is ready.

To facilitate agricultural work, a walk-behind tractor has been used for a long time. This most useful machine simply performs a wide range of tasks, and as we have said more than once, it is an indispensable thing when working with land, transporting goods, preparing animal feed and firewood, removing snow, etc. Of those who have used a walk-behind tractor at least once, those who want to return to a plow or shovel can be counted on the fingers of one hand.

In order to make the walk-behind tractor more efficient, various accessories are used. Grousers, for example, allow for more thorough adhesion to the soil, which is necessary during plowing or harvesting potatoes. These are peculiar metal wheels with spikes, which are not at all difficult to make yourself. You can read about how to do it in the previous article. In addition to the lugs, you should pay attention to the adapter, which consists of 2 wheels, a drawbar, steering and a seat. By purchasing an adapter, you will turn your walk-behind tractor into an incredibly convenient device that you don’t need to walk to get.

Another attachment for the walk-behind tractor is the creeper. There are situations in which it becomes necessary to reduce the stroke of the walk-behind tractor. This occurs when the machine's operating speed is lower than its transport speed. The creeper allows you to increase the torque and, accordingly, increase the traction force. Essentially, a creeper is the same as a reduction gearbox. With the help of the necessary chain, it allows you to transform the driving force of the unit into the operation of attachments. You can or you can make it yourself.

In order to assemble a creeper for a walk-behind tractor

with your own hands,

you will need: a generator housing, a flange bearing, a rotor shaft, a washer and a flange made of high-quality steel, a drive bevel gear, a gear housing, a key, two pinion shaft bearings, a driven gear shaft, steel for the manufacture of gear shaft bearing shells, screws for fastening the pulley and flange, V-belt pulley.

There is nothing difficult about assembling a creeper with your own hands. However, if you have not made your own attachments for a walk-behind tractor before, then you may experience some difficulties, which you should not be upset about at all. You will definitely be able to assemble the creeper with your own hands. Just be patient.

Initially, you should perform some calculations and decide on the body of a homemade creeper. This role can be perfectly fulfilled by a factory part, borrowed from well-known motorcycles such as the Irbit Ural or the Kyiv Dnepr. Regarding the calculations, it is necessary to calculate the rated power, torque and the number of revolutions made per minute.

Having finished with the calculations and decided on the choice of housing, proceed to cutting out the shell of the gear shaft bearings. To cut through steel, you will need a drill of the appropriate size and a caliper. Focus on the diameter of the gearbox. Immediately after cutting, we determine the dimensions of the gear shaft bearings and select the appropriate ones. We install the steel flange on the opposite side of the gearbox. Inside it we place a steel alloy washer and a flange bearing. Using screws, screw the flange to the generator housing. We are looking for the most suitable driven gear shaft, steel key and drive gear. All components, without exception, must be connected to the shaft of the rotary generator and the transmission mechanism. Using a nut and a spring washer, we fix the V-belt pulley to the driven shaft.

Voila! A homemade creeper is ready for installation on modern ones running on gasoline or diesel using an air cooling system. As you can see, it’s quite easy to assemble a creeper for a walk-behind tractor with your own hands. Just a few hours, and your powerful unit is ready to work in the most severe conditions; He doesn’t mind even the heaviest soil. All the power of the walk-behind tractor will be directed into useful channels. Do not forget that such an invention requires careful care, regular diagnostics and lubrication. Overhaul your custom speed reducer from time to time and take care to properly lubricate the moving parts. With normal operation and due attention, a homemade creeper will serve you for many years, becoming a worthy alternative to products from leading domestic and foreign manufacturers.

The drive and reduction gear are the main components of the walk-behind tractor. The gearbox is necessary to change the speed characteristics of rotation of the output shaft, which, in turn, is necessary to increase torque.

A reduction gearbox for a walk-behind tractor can be:

- Geared.

- Worm-like.

- Chained.

- Combined.

This unit can have 1, 5 or more stages.

Increasing the power of the walk-behind tractor will allow you to use the unit as efficiently as possible

A walk-behind tractor is an indispensable thing for farmers. Increasing the power of the walk-behind tractor allows you to increase the productivity of equipment and speed up agricultural work. You can improve your equipment either with your own hands or by purchasing the necessary equipment.

You can increase the speed of the walk-behind tractor in the following ways:

- replacing a gear pair;

- installation of wheels with a large diameter.

Increasing speed in the first way is a rather complicated process. Therefore, without knowledge and skills in this area, it is better not to do this yourself and contact a special service center. If you have the necessary skills, you can make the replacement yourself.

Just like any other equipment, the walk-behind tractor has several speed modes controlled using gears. The walk-behind tractor moves at a speed of 2 to 15 km/h. The larger gear usually has 61 teeth, and the small one – 12. To increase the power of the walk-behind tractor, the gear pairs of the gearbox are replaced.

Maximum speed can be achieved by increasing the number of teeth on the gear.

When replacing a gear, be sure to select the correct pulley. If the pulley is selected incorrectly, the walk-behind tractor may stop working.

To increase the speed, you can install tires with a diameter of 70.4 cm; such a replacement will help speed up the walk-behind tractor several times. If the arches in which the tires are placed allow the installation of wheels with a larger diameter, you can try to increase them by a few centimeters.

So, how to improve a motor cultivator with the help of weights. You can buy them or make and install them yourself. Weights are installed on the frame and wheels. Wheel weights are made of solid profiles and steel wheels. The body is weighted using special removable frames and a corner. Loads with different weights and configurations are attached to the frame.

So, sometimes you need to make a motor cultivator quite heavy, you can use reinforced concrete products.

Such loads can load the walk-behind tractor quite well. With the help of such simple devices, the range of application of technology is significantly expanded.

A homemade snowmobile can be equipped with a sled to transport property or feed for animals, or go fishing or hunting.

We suggest you familiarize yourself with How to plant walnut chestnuts at home

Setting the reverse speed on a walk-behind tractor is another way to improve the walk-behind tractor. The presence of reverse depends on the sizes and models. It can work on any type of equipment, it all depends on the tasks assigned to the equipment, be it a light or heavy walk-behind tractor, or a motor-cultivator. For equipment weighing up to 30 kg, there is no need for reverse speed, but on a heavier unit it is more difficult to weed without it.

Gearboxes are:

- gear;

- reverse gear;

- angular;

- downward

A gear reducer is a transmitter that operates between the wheels and the motor. The reverse gearbox consists of a clutch located between the gears and located on the main shaft. The corner is responsible for the operation of the transmission with the engine, which affects power.

The reduction gearbox is responsible for reducing the speed, which helps increase power. The main task of this system is to provide reverse gear. To make this mechanism at home, you first need to make a body. Then select the necessary parts.

But it’s better to buy a ready-made gearbox.

Walk-behind tractors are sold with a minimum number of components. However, a milling cutter and a standard plow are not enough to perform all agricultural work. How to improve a motor cultivator using scrap materials? With the help of tools that are in every home, you can expand the capabilities of the walk-behind tractor. Equipment that you can make yourself:

- Installation of a rake on a walk-behind tractor for collecting debris, leaves, and hay. Such a simple device will speed up autumn field work and allow you to clear large areas of debris in a matter of minutes. To make a rake you will need: several meters of reinforcement with a cross section of 8-12 mm and a strip of sheet metal. The reinforcement is cut into pieces 10 cm long and welded to the plate in several rows with an interval of 3-5 cm. To increase maneuverability, the rake can be equipped with roller wheels.

- A trailer and cart will help transport large loads. The cart can be made from scrap materials - channel and old car wheels, metal profiles and boards. The clutch is made standard for both tractors and cars.

- If desired, you can make a potato digger, hiller and harrows, which will not be inferior in quality to purchased ones.

Another device for cultivating soil using a walk-behind tractor is a plow.

The following types of plows are distinguished:

- The easiest to use is the single-hull one, also known as the Zykov plow.

- Reversible plow for walk-behind tractor: rotary or reversible. The upper part has a curved feather, which turns the soil over during plowing. A universal device that easily copes with plowing heavy soils. Quickly copes with the treatment of areas with clay and marshy soil.

- The rotary plow for a walk-behind tractor has a complex design. Depending on the number of ploughshares, there are two-body and three-body models. Active plowshares dump soil in one direction only, while passive plowshares level the beds and lift them. Tilling the soil with such a plow has a number of advantages: the soil is maximally saturated with oxygen; tire wear and fuel consumption are reduced; after processing there are no large clods of earth left.

- A rotary plow for a walk-behind tractor provides unlimited possibilities. During operation, the axis rotates, and with it the soil layers. It easily plows even very hard soil at a depth of about 30 centimeters. There are paddle, drum, shovel and auger plows. Devices of the first type are equipped with a rigid pusher and can consist of a spring plate or be combined. Units of the second type are equipped with a disk with blades that rotate during operation. A plow with a disc blade for a walk-behind tractor is suitable for work in early spring; it copes well with wet soil.

Any of the above plows can be made independently, taking into account the design features and following the instructions and diagrams. You can also improve an already purchased plow.

A rotary reversible plow for a walk-behind tractor copes with the processing of plots most efficiently, thanks to the optimization of the plowing process. And it is most in demand among agricultural workers.

Thanks to the expansion of capabilities, the walk-behind tractor becomes universal. It can be used to solve a variety of tasks from field work to snow removal in winter.

Basic elements of a mechanical system

To support the main elements, the gearbox (speed reducer) is provided with a system of shafts and axles. Single-stage designs use shafts with rigidly seated driven and driving gears. Rigidity of fit is achieved through the use of keys or splines. Lateral displacements are adjusted with special nuts that press gears or sprockets against thrust collars. The material used is structural steel. It is perfect for making a creeper for a walk-behind tractor or cultivator.

Bearing units are supports for steel axles and creeper shafts on a walk-behind tractor. Bearings bear the main load during operation of the power unit.

Whether the speed reducer for a motor cultivator will work normally depends on the correctness and quality of the bearings. For homemade designs, bearings with closed cages (closed type) are better suited. This will save you from having to regularly change the lubricant. The type of gearbox bearings depends on the type of loads taken. Support bearings are installed on a creeper for a walk-behind tractor with straight gears, and thrust bearings are installed on gears with an oblique tooth profile and worm shafts. They are usually subject to longitudinal axial forces from an electric motor or internal combustion engine.

The gears and sprockets in the gearbox determine the speed and nominal rotation speed of the output shaft. For their production, special equipment and equipment are used. It is better not to make the creeper gears for a walk-behind tractor with your own hands. Buy ready-made gearing in specialized stores.

Whether the speed reducer for a walk-behind tractor will normally accept dynamic loads from the power unit depends on the correct selection of geometric dimensions and gear ratio. When installing gears, all necessary clearances must be maintained. To do this, carefully study the drawings. Clearances directly affect the ability to absorb significant loads from an internal combustion engine or electric motor.

The step-up and step-down gearbox for a minitractor is lubricated with I-20 industrial oil. The oil level is determined taking into account the operating conditions of the unit. Oil seals are used to prevent leaks.

The process of creating a creeper for a walk-behind tractor

- To begin with, you should understand all the components schematically, indicate the torque indicator, power and determine the revolutions per minute;

- Then you need to choose a body for the future instrument. Often an element from a motorcycle is used in this role;

- The next step consists of cutting out some bearing shells for the drive shaft that drives the gear. It is important to immediately pay attention to the diameter of the gearbox;

- When selecting bearings, it is important to place the flannel on the other side of the gearbox;

- Now you need to find the driven shaft, which acts as a basis for fixing the gear;

- The homemade creation must be connected to the transmission mechanism and shaft of the rotary generator;

- The final step is to secure the pulley to the driven shaft using spring washers and nuts.

After carrying out all the specified procedures, you can safely operate the creeper and evaluate all its practical advantages. But we must not forget that homemade devices are especially demanding in terms of care and diagnostics, because if you don’t care about them, they will quickly stop working.