Milking machine and its structure

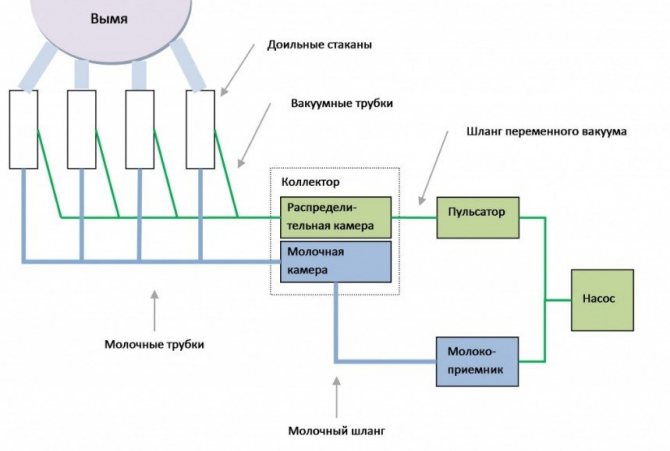

The milking machine is quite simple. It consists of the following components:

- Four teat cups

- Milk and air lines

- Milk collection container

- Pump

- Collector

- Pulsator (available in machines with a pulsator. If a milking machine for cows has a piston pump, then it does not have a pulsator, since the role of a pulsator is played by the pump and valves in the can and pump. They open and close in connection with the direction of movement of the piston).

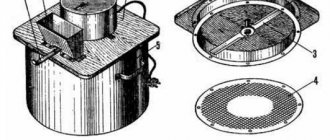

One of the main pieces of equipment is the milking cups. They have a rather complex structure. The glasses are based on hard glasses (made of metal or plastic), with rubber tubes located inside. A sealed inter-wall chamber is formed between the rigid glass and the rubber tubes.

Two tubes are attached to the glass.

One tube connects the glass to the nipple (internal) chamber. This tube is needed to suck out milk. The second tube is connected to the interwall chamber. This tube is needed to create a vacuum pulsation. The milking machine works according to the following principle:

- A vacuum (low pressure) is stably maintained in the nipple chamber.

- The compression of the nipple occurs with the help of vacuum pulsation in the interwall chamber.

- During the period when the same low pressure is created in these two chambers, milk flows from the nipple.

- The milk enters the collector, and then into a can or other prepared container.

- During the period when the pressure in the interwall chamber rises to atmospheric pressure, the rubber tube contracts, compresses the nipple and the milk stops flowing.

Did you know? Modern milking machines allow you to milk up to 100 cows per hour; an experienced milkmaid can milk only five cows manually in the same time.

This operating principle is typical for push-pull units. The pulsation frequency during milking ranges from 45 to 60 beats per minute. The ratio of the duration of the suction stroke to the compression process ranges from 50 to 50 to 85 to 15, and in modern equipment it is 60 to 40.

Which milking machine is best for cows?

When choosing a device, you need to compare its cost with the technical characteristics and number of livestock.

Milking machine for cows at home

If a household has only a few calving cows, a compact, inexpensive unit will do. Below are the most popular milking machines for cows at home.

Melasty TJK 1-AS

The Turkish milking machine for cows from Melasty is used for milking 1 cow. If a household has 8-10 cows, one hour is enough for them all to be served.

The device is equipped with a dry vacuum pump, a 25 liter milking bucket and a 200 ml manifold. The kit includes a rubber nipple liner, but upon request it can be replaced with silicone, extending the warranty period from 6 months. up to 1 year. All devices are equipped with a silencer, so Melasty operates quietly and efficiently. The kit includes cleaning brushes for maintenance, instructions, and after assembly the device can immediately be used for its intended purpose. The manufacturer guarantees that all parts and direct assembly were carried out in Turkey. Warranty - 24 months.

A milking machine for a Melasty TJK 1-AK cow costs about 31 thousand rubles.

AID-1-01

The device is equipped with a motor that rotates the vacuum pump and creates a constant vacuum. A pulsator is used to create an alternating vacuum. The motor power is 750 W. AID-1-01 is equipped with all the means for effective washing. In one hour, using AID-1-01 you can serve up to 10 cows.

The cost of the unit is about 22 thousand rubles.

Burenka-1

The unit is suitable for domestic service of 1-5 cows. “Burenka” is equipped with a dry rotary type vacuum unit and includes a 20-liter aluminum can with a lid. The milking system is synchronous two-contact.

The cost of the unit is about 15 thousand rubles.

There are also more powerful units used on large farms. These are mainly mobile systems. To ensure that the milking process does not drag on for the whole day, high-performance units are used.

Birch

The Berezka machine serves up to 12 cows per hour. It is equipped with a dry rotary type vacuum pump, has a 20 liter can, stainless steel cups and a 140 cm2 manifold. The milking system is push-pull synchronous.

The cost of the unit is about 20 thousand rubles.

Burenka-1 combi 3000 oil

The device is equipped with an oil rotary type vacuum unit. A special feature of the unit is its super-light weight. Unlike its analogues, in Burenka the milking bucket is located separately from the installation. Experienced farmers advise paying attention to the Burenka Tandem model, which allows for double milking. Some modifications of Burenka (Standard, Euro, Maxi) serve up to 20 heads per hour.

The cost of the equipment is about 18 thousand rubles.

Doyushka

Very compact, reliable and easy to use device. The vacuum is created using a piston pump. The milking machine ensures the most careful treatment of the cow's udder; the rhythm of the vacuum is similar to the natural process of milk sucking by a calf.

In gentle mode, Doyushka will help milk 5 cows per hour.

Installation price is about 24 thousand rubles.

Kinds

The classification of milking machines can be made only according to technical characteristics. Most of them are vacuum. Such installations have the same operating principle, the only difference is in the details.

Milking method

Depending on the milking method, the machine can be suction or squeeze .

Vacuum pumps are used in suction-type installations. Such equipment is manufactured on an industrial scale and has a number of advantages:

- Without nipple rubber

- More gentle on the udder and teats

The equipment works on the following principle: using a pump, pressure is created in glasses (placed on the nipples), which sucks milk out of the udder.

When air replaces the vacuum, the pressure increases and the nipples are compressed by the rubber tube, stopping the milk supply. With the help of pressure differences, the process approaches natural milking. In squeeze-type milking machines, excess pressure is added to the vacuum. These types of equipment are produced individually.

Milking discontinuity

Depending on the milking method, there are permanent, two- and three-act installations.

Permanent milking machines operate continuously - the process of milk suction takes place under the constant outflow of milk from the udder. Such equipment does not have a standby mode (rest phase). Such devices are not physiologically convenient for cows.

Push-pull devices operate in two modes - sucking and compression. In three-act plays there is also a third mode - rest.

Modern devices are predominantly two-act. Three-acts are more powerful, but two-acts are lighter. And if the device is not stationary and will need to be worn, then it is better to choose a two-act installation.

Transportation of milk

Also, depending on the type of milking machine, milk can be collected in a can or through pipelines. If it is a compact device, then the milk goes into the can. Such devices are well suited for small farming. Devices that are connected to pipelines are used on farms with large livestock.

Manual devices

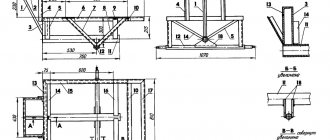

You can make a manual milking machine for obtaining milk from cows with your own hands at home. It is worth considering the fact that all the necessary parts are still purchased in specialized stores. The main thing is to know the assembly plan and strictly follow it.

Equipment and assembly:

- The basis is the engine, which regulates the operation of the entire system. It can be electric, mechanical or foot-operated; oily and dry (this depends on the technical characteristics of the models).

- The most common method is vacuum milking. This process is carried out using a special pump.

- The largest part is occupied by the milking system, which consists of two hoses: milk and vacuum; pulsator; hanging unit, collector, bucket or can.

The water tank is connected to the pump. The hanging unit includes several clear glasses that help you monitor the flow of milk.

You can make a milking machine yourself, but it will take a lot of time and effort to assemble it. It is better to purchase high-quality equipment with a complete set in a special store.

How to choose a milking machine

There are a large number of milking machines, since not a single farm can do without automating the process of obtaining milk. All cars differ from each other in configuration, power, dimensions and are not a new category.

However, all devices operate on the same principle and contain a vacuum pump with pressure. The choice depends on many individual requirements. An important criterion is how the milk is collected and how many cows can be milked at the same time.

Required indicators

It is necessary to take into account the technical characteristics of the machine and, based on this, classify the equipment. Livestock breeders divide milking machines into main types: individual and group.

There are three types of vacuum pumps in milking machines:

- A diaphragm pump is the cheapest option and is not designed for heavy loads. You can milk no more than three cows at a time. Such a vacuum pump would be appropriate in machines on small farms.

- The piston pump is somewhat more powerful than the previous one, but also has disadvantages. Animals may be negatively affected because this type of pump is very noisy and heats up quickly. It should also be noted that the device equipped with such a pump is large.

- The rotary pump is quieter than the previous ones. This option is ideal if your animals are afraid of loud noises and you are concerned that the milking machine may frighten them. The rotary pump is of dry and oil type.

Typically, farms use three- and two-act milking machines.

The types of machines differ in that in three-act compared to two-act machines, in addition to compression and sucking, there is also a resting stroke. According to the type of milk collection, the equipment differs into machines that collect milk through pipes or into a can. The small milking machine is suitable for collecting milk into a can, so it can be used for a small number of cows. Large stationary installations collect milk through pipes; such equipment is used on large farms, where the amount of milk collected is an order of magnitude higher.

Did you know? Because the proteins in cow's milk bind to toxins in the body, it is recommended to chemical workers because it effectively removes toxins. Milk will also help remove harmful substances from the body after drinking alcohol.

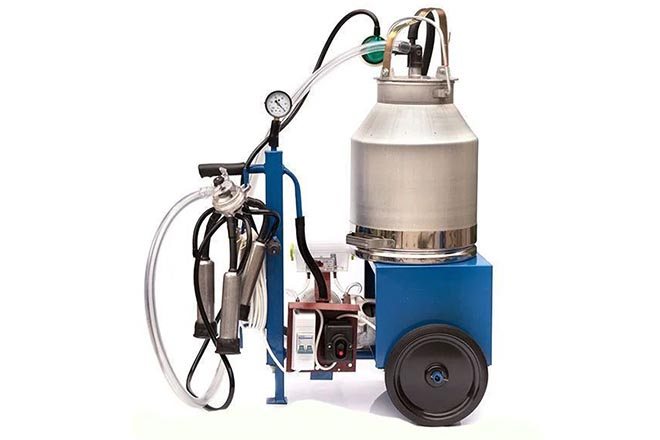

You can choose a device based on the principle of possible movement. Machines can be mobile or stationary. For large farms, mobile ones are suitable, which resemble a cart with wheels, a support, milking buckets and a pump.

The ease of moving the device means it can serve many more cows. Moving such equipment will take a few minutes and does not require much effort.

What you can ignore

Regardless of the type of installation chosen, the speed and quality of milking compared to manual milking will increase by an order of magnitude. Any device will be ideal for your cows.

The main thing in keeping cows is a properly combined diet - it should contain both rough dry feed (hay, straw), juicy feed (silage, apple cake), and root vegetables (potatoes, beets, carrots, Jerusalem artichoke), as well as sunflower additives that improve the quality of milk oil cake, meal, oats, barley, wheat.

Also, do not pay attention to the complexity of mastering different types of installations, since modern milking machines, regardless of type and manufacturer, are quite easy to master even for a non-specialist. You just need to read the operating instructions and follow the necessary hygiene rules.

Also, in modern installations you should not pay attention to the manufacturer, since domestic developers produce cars no worse than foreign ones.

How to milk a cow with a machine

To obtain high milk yields at low physical costs, machine milking is widely used. For the success of such milking, you must strictly follow the instructions on how to properly milk a cow with a milking machine, as well as the rules for handling cows. Make sure milking machines are in good working order.

The milking machine works on the following principle: rarefied air flows through a special hose from the vacuum line into the pulsator, then through the variable vacuum hose directly into the inter-wall space. The result is a sucking stroke, the vacuum acts all the time in the nipple chamber of the teat cup.

Before transferring cows to machine milking, you need to inspect the cow and her udder. It is necessary to check for mastitis in the udder and teats, since cows with the disease are milked by hand. Machine milking begins only after the animal has completely recovered.

The speed and completeness of milking animals depends on the correct operation of the apparatus. Before you begin, check the serviceability of the equipment, the entire installation, pay attention to how the pulsator and collector work. Look at the number of pulsations; in a three-act machine there should be 50 in 1 minute, in a two-act machine - 90. Also check the operation of the vacuum gauge, whether the vacuum installation is working correctly and whether a constant vacuum is maintained.

Important! Before milking, you should manually milk a small portion of milk and make sure that there are no blood clots, lymph inclusions, etc. In addition, milking the first portion of milk manually gives the animal a powerful incentive to give back the entire milk yield.

the udders are washed with clean warm water or a special solution, and the stalls are cleaned.

It is not recommended to wash the udder with cold or too hot water, as this will slow down milk production. At the same time the udder is massaged to prepare it for machine milking. To do this, stroke the udder with your fingers in a circular motion, slightly pushing up individual lobes of the udder, as a calf does when suckling.

The operation of preparing for machine milking must be carried out very carefully, accurately and quickly. During this time, the milk ejection reflex will occur, and you can start milking.

The productivity of cows depends not only on housing and feeding conditions, but also on the breed - Kholmogory, Shorthorn, Brown Latvian, Yaroslavl, Highland, Kazakh Whitehead, Kalmyk, Red Steppe, Black and White, Aberdeen Angus, Jersey, Ayrshire, Holstein, Dutch , Simmental - have completely different characteristics.

Having previously opened the vacuum valve of the milking machine, you need to put on the milking cups immediately after preparing the udder. The milkmaid should take the collector from below with one hand, bring it to the udder, with the other hand she should alternately put the milking cups on the teats, starting with the rear ones.

If necessary, the milkmaid uses her index finger and thumb to guide the teats into the milking cups. If it is necessary to lift the teat cup up, you must first clamp the milk tube.

The glasses should fit tightly to the nipples; there should be no hissing of air when the machine is running. Move to the next cow only after you have put on the teat cups correctly and milking has begun.

Milking control is carried out through a transparent teat cup cone or transparent milk hoses. If for some reason the milking slows down or stops, it is necessary, without removing the equipment, to massage the udder before resuming the process.

If the milking cups fall off the teats, turn off the machine, rinse the cups with clean water, massage the udder and put them on the udder again. To prevent the cow from knocking over the machine, it should be placed closer to the animal's front hooves.

If cows are accustomed to machine milking, they are milked quickly and do not require hand milking. It must be done according to a signal from the device, which is found on some types of machines, and after milking has stopped.

To finish milking a cow, the milkmaid takes the collector with one hand and pulls it along with the milking cups down and forward. The (final) massage of the udder is carried out with the other hand. The energy and duration of the massage depend on the individual characteristics of the cow.

To properly remove the teat cups, grasp the collector or milk tubes with one hand and squeeze them. Another is to close the valve on the manifold or the clamp on the hose. After this, the rubber suction cup of the glass is pressed away from the nipple with your finger to let air in, at the same time you need to smoothly remove all the glasses. Then connect the collector to a vacuum and suck out the remaining milk in the milking cups.

Important! After milking, the cow's nipples must be wiped with a clean, dry towel and lubricated with Vaseline or an emulsion that has an antiseptic effect.

After the process, milking machines are washed with warm water using a vacuum; first water is passed through the machine, and then a disinfectant. Washed milking machines are stored in a specially designated room.